- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

70 Solar Installation courses

CE516: 2014 National Electrical Code® and PV Systems

By Solar Energy International (SEI)

Rapid shutdown for PV systems on buildings Expansion of ground-fault and arc-fault requirements Changes that further enable 1,000 Vdc PV systems Updates to disconnect and fuse servicing requirements New standards for field-applied hazard markings Major changes for interconnecting PV systems to the grid New requirements for battery-based PV systems, both stand-alone and interactive Additional changes in Articles 690 and 705, as well as other relevant Articles Join SEI instructors and Code experts Rebekah Hren and Brian Mehalic for a fast-paced and fun three-hour long look at how PV design and installation requirements changed with the adoption of the 2014 Code.

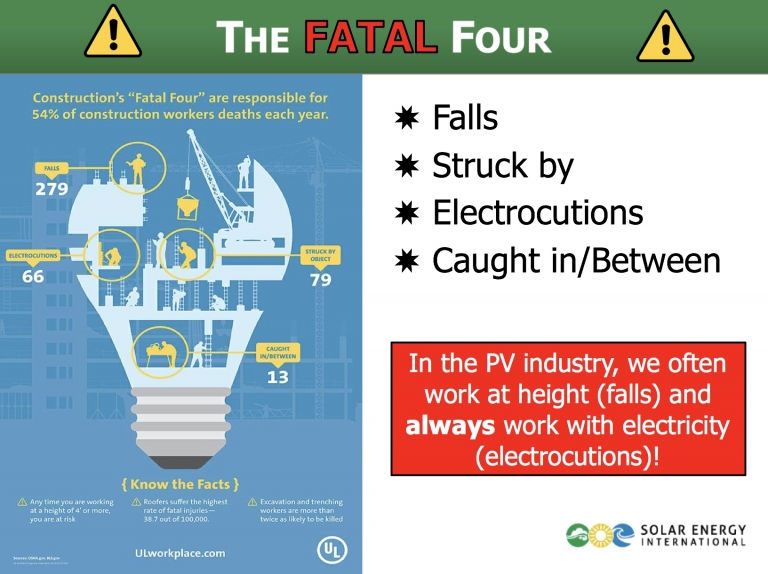

CE523: Residential/Commercial Roof-Mounted PV Installation Safety

By Solar Energy International (SEI)

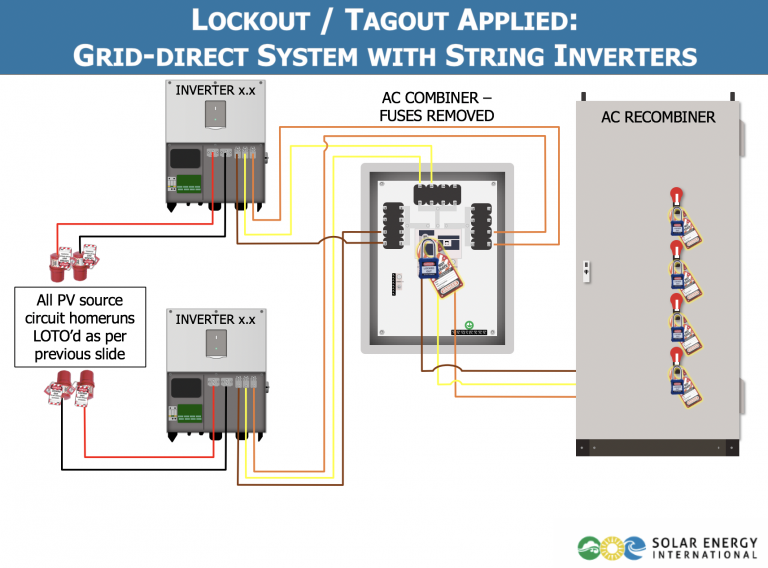

This training includes four (4) three-hour lessons, for a total of 12 contact training hours. Each lesson will include presentations, videos, interactive exercises, and a quiz. 1- Ladder and Lift Safety: In this lesson, we learn about different ladder options and how to choose the appropriate ladder(s) for a PV installation, based on the specific job site and task (accessing different roof surfaces, running conduit, etc.). We discuss how to properly inspect, set up and use ladders, and through interactive exercises we evaluate different installation sites to determine the best location to set up an extension ladder to access the PV array. In the second part of this lesson, we identify equipment and methods for safely lifting PV modules (and other materials) to the roof, including ladder lifts, boom lifts, reach forklifts, scaffolding, and cranes. 2- Fall Protection: Here, we review OSHA fall protection requirements and present different equipment options for working safely AND efficiently on a PV job site. We discuss the differences between fall restraint, positioning, and fall arrest systems; look at different anchor options for roof surfaces commonly seen on PV installations; and via interactive exercises determine where to place those anchors on the roof. 3- PV Mounting Safety: In this lesson, we identify job site hazards specific to PV mounting work, from array layout through securing modules to the racking system. We go step-by-step through a roof-mounted PV installation and call out ways to eliminate and/or control hazards through safe work practices, engineering controls, and personal protective equipment (PPE). Through interactive exercises and videos, we show best practice methods to safely handle PV equipment and manage small parts on a sloped roof. 4- Solar Electric Safety: In the final lesson of this series, we take an in-depth look at electrical hazards specific to PV installation and maintenance work, and discuss the requirements of OSHA, the NEC, and NFPA 70E to assure safe working conditions. We discuss shock and arc flash hazards and identify protective measures (including PPE and lockout / tagout). We dive even further into lockout / tagout and safe electrical testing methods in our interactive exercises and videos.

CE517: Performance Modeling of PV Systems

By Solar Energy International (SEI)

Modeling is a complicated topic - and performance calculation tools offer nearly endless âknobsâ to turn, any of which can impact the projected production. A fundamental understanding of what goes on âbehind the scenesâ is important to be able to make the right decisions when selecting data, adjusting system assumptions and de-rates, and comparing results so you can be confident when you make a production prediction or design choice. Don't worry, the heavy math is left to the modeling tool! Topics include: Examining and applying the core calculations used to predict production of PV arrays Comparing the various modeling programs on the market, and their different approaches Interpreting simulation results from performance models Relating how system design choices impact the production of the array Join Paul Grana, co-founder of Folsom Labs and the HelioScope modeling and design tool, for an in-depth look at PV system performance modeling in four Parts: Introduction and System Design Environment Assumptions and Irradiance Calculations Module Modeling and System Behavior Simulation Results and Model Comparison

CE506: Code-compliant Conductor Sizing for Grid-direct PV Systems

By Solar Energy International (SEI)

The step-by-step process walks through all the requirements to design 2011 NEC compliant systems. This process applies to all circuits in grid-direct PV systems, regardless of size. Developed in conjunction with industry experts and extensively peer reviewed, SEI's wire sizing methodology takes the mystery out! Full coverage of all NEC Article 310 and 690 conductor and overcurrent device sizing. Join SEI instructors Brian Mehalic and Rebekah Hren for a three-hour on-demand training training session.

CE501: 2011 National Electric Code Updates for the Solar Professional

By Solar Energy International (SEI)

Solar Energy International discusses the following topics: Are you are using the best temperature data to calculate maximum system voltage? Have you reviewed new requirements for labeling, marking and routing conductors? 2011 grounding and bonding requirements have been greatly simplified! Wondering about the DC arc-fault protection devices now required? Don't forget that PV source and output fuses now require disconnects within sight! SEI instructors Brian Mehalic and Rebekah Hren also discuss the following topics: The code-making process, looking to 2014, Articles 90.1(B) and 110.3, 690.4(B) Qualified persons 690.8(B)(1) and (2) Overcurrent devices and conductor ampacity 690.13 Exception 2 - Disconnecting means - all conductors 690.31(E) DC circuits inside a building - Type MC, distance from decking, marking 705.12(A) Size limits of parallel production sources

CE525: Large-Scale Ground-Mounted PV Installation Safety

By Solar Energy International (SEI)

This training includes two lessons for a total of 8 contact training hours. Each lesson includes presentations, field videos, interactive exercises, and a quiz. Lesson 1: Site and Mechanical Hazards- Identify common site and mechanical hazards that workers are exposed to when installing ground-mounted PV arrays, describe ways to mitigate hazards, determine safe working practices and PPE requirements. Lesson 2: Electrical Hazards- Determine electrical hazards on large-scale PV job sites, identify shock and arc flash hazards and implement protective measures, define lockout/tagout methods and principles, examine installation, maintenance, and PV testing hazards.

CE519: Off-grid System Considerations

By Solar Energy International (SEI)

Join SEI's Will White - who's been living off-grid since 2007 - for an in-depth look at off-grid system considerations in three parts: Components used in an off-grid system. Design parameters of an off-grid system. How to size individual components for an off-grid system and the maintenance required.

CE513: Rooftop PV: What You Need to Know About Roof Systems

By Solar Energy International (SEI)

Rooftops represent the most available, sustainable and secure real estate, which is why low-slope and steep-slope roofs are increasingly being used as platforms for photovoltaic systems. Low-slope roofs (commonly used for commercial buildings) and steep-slope roofs (commonly used for single-family residences) have separate challenges when integrating PV systems. Information from the roofing industry and roofing manufacturer requirements will be provided as well as numerous photographs. INSTRUCTOR BIO: James R. Kirby, AIA, is Vice President of Sustainability for the Center for Environmental Innovation in Roofing, Washington, DC. Kirby has expertise in roof system design and construction, weatherproofing and energy-efficiency of the building envelope, and rooftop PV systems. His responsibilities include serving as liaison for the Center's PV taskforce, representing the roofing industry at sustainability-focused events, and presenting sustainability-based technical information to roofing and other construction trades within the US and internationally. Kirby holds a bachelor's degree in architectural studies and a master's degree in architecture (structures option) from University of Illinois at Urbana-Champaign. He recently received his Graduate Certificate in Sustainable Design and Construction from Boston Architectural College, and he also is an accredited Green Roofing Professional. Before joining The Center in 2012, he worked for National Roofing Contractors Association, most recently as Associate Executive Director of Technical Communications. Prior to his 16 years at NRCA, he worked for Wiss, Janney, Elstner Associates Inc., Northbrook, Ill., an architectural and engineering consulting firm. He is a licensed architect in Illinois and a professional member of several industry organizations, including ASTM International, American Institute of Architects, Green Roofs for Healthy Cities, International Code Council and U.S. Green Building Council Chicago Chapter. Kirby is a frequent presenter and contributing author to the roofing, energy-efficiency and solar industries. He has given numerous presentations, educational seminars and webinars to industry-related associations and construction-affiliated groups. Kirby also is an annual guest lecturer at the Illinois Institute of Technology in Chicago.

CE509: Advanced Solar Thermal Troubleshooting and Repair

By Solar Energy International (SEI)

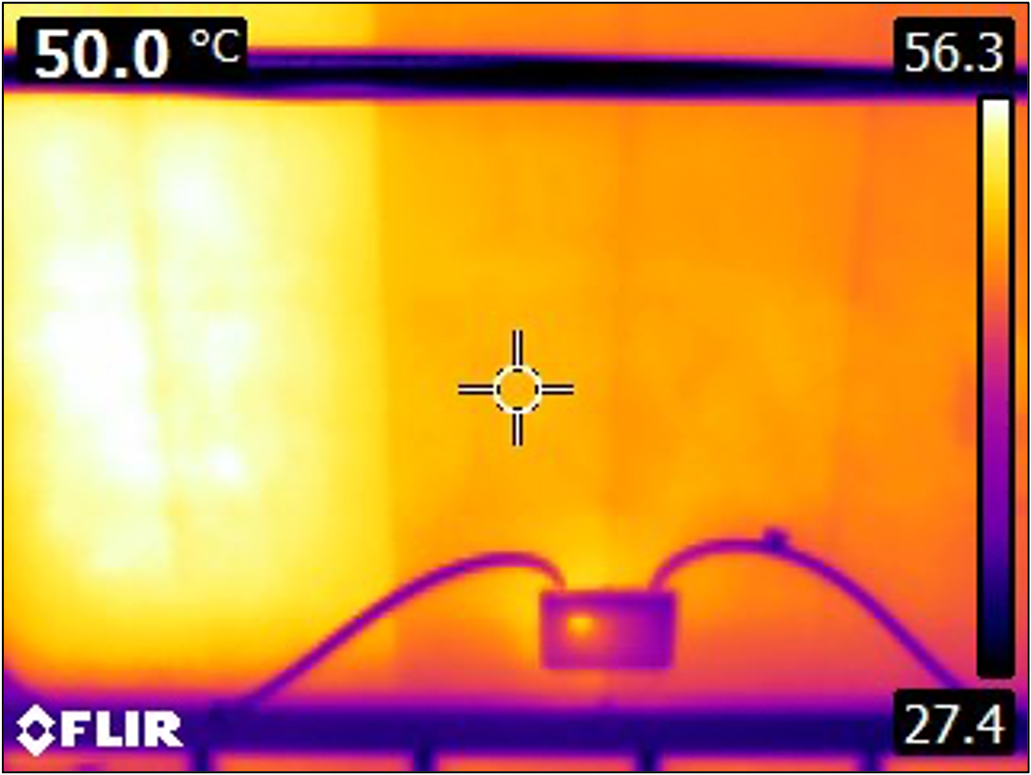

This advanced training features troubleshooting and repair of the components in solar thermal systems, including solar space heating systems. The target audience is installers and technicians that understand installation techniques and would like to increase their comprehension of drainback and antifreeze system service procedures. A section of the class includes newer differential controls, thermistors and RTD sensors, aquastats, relays, multiple differentials and space heating components. Troubleshooting and repair related to pumps, collectors, tanks, valves and safety devices are also part of the class. This course is presented by Chuck Marken, Solar Thermal Expert and longtime SEI Instructor.

CE534: Dive into Diodes: A PV Circuit Perspective

By Solar Energy International (SEI)

Join SEI curriculum developer and instructor Brian Mehalic for an in-depth look at this topic in eight parts: What does a diode do? Modeling PV - the basic equivalent circuit âBuildingâ PV modules I-V curve mismatch Bypass diodes in operation Bypass diode operation in PV modules and circuits Failures and issues Case studies

Search By Location

- Solar Installation Courses in London

- Solar Installation Courses in Birmingham

- Solar Installation Courses in Glasgow

- Solar Installation Courses in Liverpool

- Solar Installation Courses in Bristol

- Solar Installation Courses in Manchester

- Solar Installation Courses in Sheffield

- Solar Installation Courses in Leeds

- Solar Installation Courses in Edinburgh

- Solar Installation Courses in Leicester

- Solar Installation Courses in Coventry

- Solar Installation Courses in Bradford

- Solar Installation Courses in Cardiff

- Solar Installation Courses in Belfast

- Solar Installation Courses in Nottingham