- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

11759 Professional Development courses in Wrexham delivered Online

Learn French - Video Animated Course

By Study Plex

Recognised Accreditation This course is accredited by continuing professional development (CPD). CPD UK is globally recognised by employers, professional organisations, and academic institutions, thus a certificate from CPD Certification Service creates value towards your professional goal and achievement. Course Curriculum How does it work? How Does It Work 00:04:00 Going to the restaurant Going To The Restaurant 00:04:00 Hobbies and family Hobbies And Family 00:04:00 Travelling by plane Welcome Video 00:04:00 Travelling By Plane 00:04:00 Going shopping Going Shopping 00:04:00 In the morning In the morning 00:04:00 Going to a hotel Going To a Hotel 00:04:00 Doing the chores Doing The Chores 00:04:00 At the beach At The Beach 00:04:00 Numbers Numbers 00:04:00 Colours Colours 00:04:00 Animals Animals 00:04:00 Going to school Going To School 00:04:00 Fruits and vegetables Fruits And Vegetables 00:04:00 Adjectives Adjectives 00:04:00 Going to the doctor Going To The Doctor 00:04:00 The weather and countries The Weather And Countries 00:04:00 Questions and answers Questions And Answers 00:04:00 Going out Going Out 00:04:00 Food and drinks Food And Drinks 00:04:00 Home stuff and prepositions Home Stuff And Prepositions 00:04:00 Assessment Assessment - Learn French - Video Animated Course 00:10:00 Obtain Your Certificate Order Your Certificate of Achievement 00:00:00 Get Your Insurance Now Get Your Insurance Now 00:00:00 Feedback Feedback 00:00:00

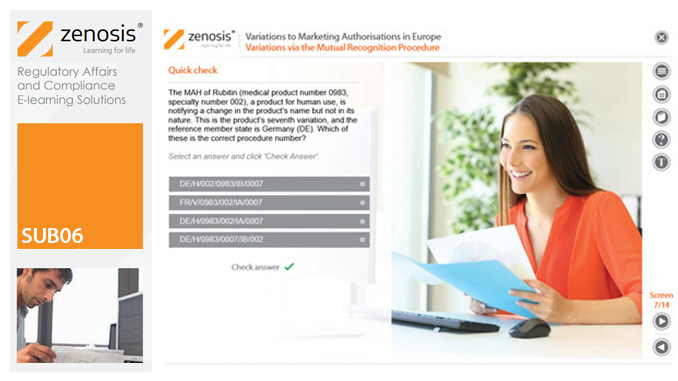

SUB06: Variations to Marketing Authorisations in Europe

By Zenosis

Changes to the terms of marketing authorisations for medicinal products, called variations in Europe, must be notified to or approved by the relevant regulatory authorities. Variations include changes to the composition of products, their manufacturing processes, the way they are used, or the indications for which they are authorised. Common approaches are adopted within the European Economic Area to variations to marketing authorisations approved through the Centralised, Decentralised or Mutual Recognition Procedures. Recent legislation has substantially modified the regulatory requirements and extended them to purely national authorisations by member states. This module, which is fully up to date with the new legislation, covers the classification of variations into their several types and the regulatory requirements, guidance and procedures to be followed for each type.

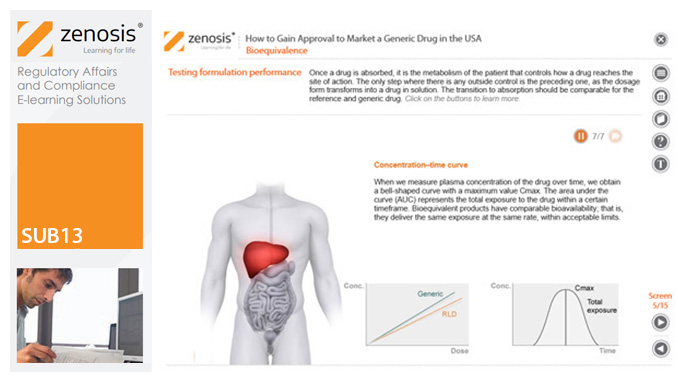

SUB13: How to Gain Approval to Market a Generic Drug in the USA

By Zenosis

This module outlines the legislative and regulatory context for the development of generic drugs and describes the essential role of the Abbreviated New Drug Application (ANDA) in gaining marketing approval. The use of information in the ‘Orange Book’ is explained, as is the role of patent certification in the application. The importance of establishing bioequivalence between a generic and its reference product is emphasised. The module specifies the content and format requirements for an ANDA submission and describes the FDA’s review and approval process. An outline is given of the Generic Drug User Fee Amendments (GDUFA) and the law’s effects on industry players.

SUB14: The Regulatory Pathway to Licensure of Follow-on Biologics (Biosimilars) in the USA

By Zenosis

The regulation of biological medicinal products is governed by different laws from those that apply to small-molecule synthetic drugs. Producing faithful copies of therapeutic proteins is more challenging than producing generic drugs. The US legal framework for the licensure of follow-on biologics, and accompanying regulatory guidance from the Food and Drug Administration (FDA), have been established only in recent years.

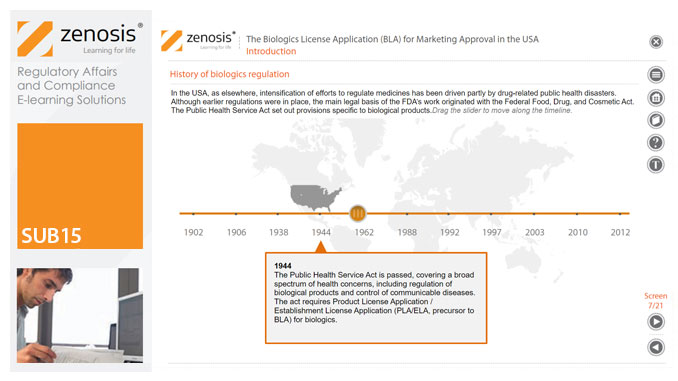

SUB15: The Biologics License Application (BLA) for Marketing Approval in the USA

By Zenosis

This module describes the requirements that must be met to obtain licensure of a biological product. Subjects covered include the regulatory context, the content and format of the BLA submission, the review process, and provisions for expedited development and review.

VAL06: Computer Systems Validation, Part 1: Planning

By Zenosis

In the medicines and healthcare products industries, computerised systems used in automated manufacturing or laboratory processes to which Good Manufacturing Practice requirements apply need to be validated. This module describes the planning of such validation. It follows the work of a pharmaceutical company's team as they validate the dispensary control system for a new production line.

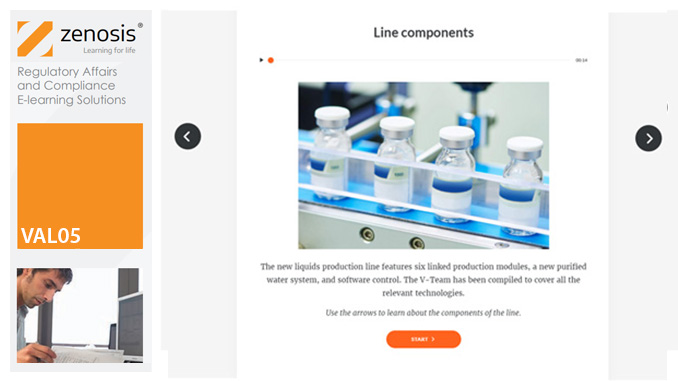

VAL05: Equipment Cleaning Validation

By Zenosis

Manufacturers of medicines and healthcare products must establish, validate and maintain an equipment cleaning programme. This is a regulatory requirement because validated cleaning procedures contribute to the assurance of product purity and safety. This module provides a comprehensive account of equipment cleaning validation requirements and procedures. It follows the work of a pharmaceutical company's validation team as they establish and validate the cleaning program for a new production line.

VAL03: Commissioning and Installation Qualification

By Zenosis

Before equipment can be used routinely in production, it must first be commissioned and, if necessary, undergo Installation Qualification (IQ). This module describes commissioning and IQ requirements and procedures in the medicines and healthcare products industries. It follows the activities of a typical validation team as they carry out a project for a pharmaceutical company.

VAL02: Validation Plans and Documentation

By Zenosis

Essential to validation is the provision of documented evidence verifying that manufacturing processes will consistently result in products meeting predetermined quality standards. This module describes the purpose, content and use of validation master plans, project validation plans, and other documentation for validation projects in the medicines and healthcare products industries. It describes the activities of a typical validation team as they carry out a project for a pharmaceutical company.

VAL07: Computer Systems Validation, Part 2: Implementation

By Zenosis

This module describes the design, development and installation phase, the validation phase, and the operation and maintenance phase of the validation of computerised systems in medicines and healthcare products manufacturing environments. It continues to follow the progress of a pharmaceutical company's project to validate a new dispensary control system.