- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

45 Motor courses in Manchester

Phoenix pottery and Art Studio offers pottery courses and classes, art and craft classes including The mindful Art Club, Glass fusing, festive workshops , painting , felting and many others. Close to Wigan and Warrington with easy Motorway access from Manchester and Liverpool and the Northwest.

Phoenix Pottery and Art Studio offer a Membership programme for experienced potters, with full use of the pottery studio. Alongside their regular pottery classes and courses. Situated in Golborne, near Warrington, St Helens, Wigan and with easy motorway access for the Northwest UK. Approx 20 miles from Manchester and Liverpool.

Operations, Maintenance and Testing of Power Transformer & Electric Motors

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Training (VILT) Electrical machines, mainly power transformers and electric motors are critical equipment that run production, and it must operate without any abnormalities. A wide variety of tests and standards have been developed to assist manufacturers and users of motors and transformer winding, assess the condition of the electrical insulation. The objective of this training course is to provide an understanding of power transformers and electric motors, their materials, components, and how they operate. It will also emphasize the importance of transformer life management, especially for those transformers and electric motors which have been in operation for than 10 years. The course will address in detail all aspects related to transformer principles, calculations, operation, testing and maintenance. Training Objectives This course aims to provide participants with the understanding of the fundamentals and constructional features of power transformers and electric motors, with particular reference to the design, testing, operation and maintenance of transformers in power systems. Delegates will gain a detailed appreciation of the following: Practical solutions for specifying, operating and maintaining power transformers and electric motors in a utility or plant environment Comprehensive understanding of principles, protection, maintenance and troubleshooting of power transformers and electric motors The necessary safe procedures relating to transformer operation and related circuitry Understand the principles of operation of the transformer and electric motors Identify the different features of power transformers and electric motors Appreciate the principles of transformer design, ratings, winding, core structure and materials, insulation and cooling methods, insulation and lifetime Utilize thermal limits and loading guides of transformers Analyze transformer and electric motors failure modes Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Course Level Basic or Foundation Training Methods The VILT will be delivered online in 4 half-day sessions comprising 4 hours per day, with 1 x 10 minutes break per day, including time for lectures, discussion, quizzes and short classroom exercises. Additionally, some self-study will be requested. Participants are invited but not obliged to bring a short presentation (10 mins max) on a practical problem they encountered in their work. This will then be explained and discussed during the VILT. A short test or quiz will be held at the end the course. Trainer Our key expert is actively involved in electrical inspections, energy audits, energy efficiency and technical consultation for M&E activities for industrial and commercial sectors. He is involved in testing and commissioning works of factory substations of up to 132kV system. He previously worked for Jimah coal-fired power plant in Port Dickson for 9 years with his last position being Electrical Maintenance Section Head. He was involved in the commissioning of coal-fired power plant mainly with 500kV generator transformer, 934 MVA generator, and up to 33kV MV motors and switchgear panels. Our key expert has managed the maintenance team to perform routine maintenance activities (together with supporting tools such as motor lube oil analysis, infrared thermography analysis, transformer oil analysis) & electrical troubleshooting and plant outages for critical and non-critical equipment. Besides that, our key expert has published several IEEE conference papers and journals such as: (2009). Effectiveness of auxiliary system monitoring & continuous hydrogen scavenging operation on hydrogen-cooled generator at power plant. In Energy and Environment, 2009. ICEE 2009. 3rd International Conference on (pp. 151-160). IEEE. (2010). Study on electric motor mass unbalance based on vibration monitoring analysis technique. In Mechanical and Electrical Technology (ICMET), 2010 2nd International Conference on (pp. 539-542). IEEE. (2012). Re-Design of AC Excitation Busduct based on Infrared (IR) Thermography: Condition-Based Monitoring (CBM) data analysis. eMaintenance, 101. (2016). Energy Saving Studies for a University Campus: An Educational-Based Approach, 3rd International Conference on Language, Education, Humanities and Innovation 2016. 'Grid-tied photovoltaic and battery storage systems with Malaysian electrcity tariff - A review on maximum demand shaving.' Energies 10.11 (2017): 1884 'Techno-Economic Optimization of Grid-Connected Photovoltaic (PV) and Battery Systems Based on Maximum Demand Reduction (MDRed) Modelling in Malaysia.' Energies 12.18 (2019): 3531 POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

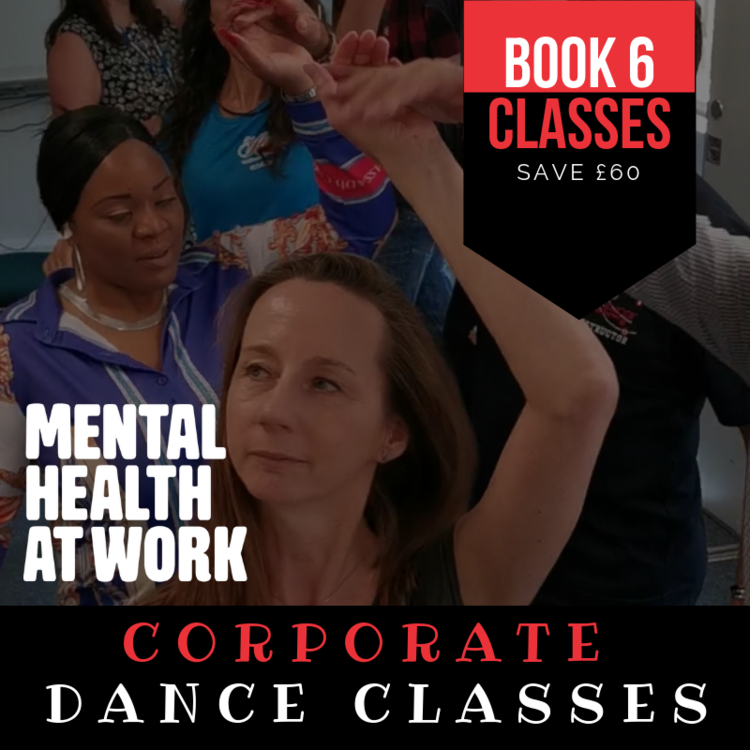

HOW DANCING CAN IMPROVE YOUR MENTAL AND PHYSICAL HEALTH Move your body to your favourite tunes – it’s the ultimate feel-good exercise and has some surprising effects on both the body and mind Music and dance have been fundamental parts of the human experience for thousands of years. No matter what your favourite tune may be, music can have a huge effect on your wellbeing – Charles Darwin even thought that our ability to make and understand rhythmic beats worked as an early form of communication. Whether or not we still share messages through music, we all know that it can change our mood and studies have shown that we share a natural sense of rhythm (no matter how much you might protest). Dance is therefore a natural outlet, and one which can do a lot to make us feel good. Club Azucar offers corporate dance packages for the workplace in order for your organisation (Companies, Institutions & Schools) not only function at its best, but to be happy and healthy in life. These are the expected benefits for the individual employee which have been also confirmed by the participants: Physical Health: Salsa/Zumba or any Latin Dance Classes improves mobility, coordination / motor skills and fitness level.while being a low-impact exercise which includes people of all ages, abilities and fitness levels Mental Health: Dancing requires full concentration so for one hour away from their desk ,participants will experience reduced stress levels, , feel refreshed and more alert and able to concentrate better following the lesson Music in combination with physical exercise has an uplifting effect through the release of endorphins and dopamine in the body & brain Learning a new skill is proven to train your brain, contribute to prevention of dementia and give the confidence to face new tasks and challenges in other areas of work and life The patience and encouragement of the teachers has furthered this new confidence and sense of achievement and contributed to participants’ belief in themselves and their ability to take themselves out of their “comfort zones” and take on new challenges Getting to know each other in a social rather than work context and learning a new skill together, dancing and laughing together, gives participants a sense of belonging and furthers team buildingDo you want more proof? Get involved and hire us!!! Booking Terms & Conditions 1. The above prices are only for Greater London 2. Fees are non refundable 3. Courses are subject to availability from both parties 4. Train, plane. petrol, or any sort of transport fares are to be refunded. 5. Cancellation must be before 24 hours every class

Natural Gas Properties & Sulphur Recovery

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Training (VILT) This 5 half-day VILT course will comprehensively cover the technical aspects of gas processing. The scope will be from the wellhead through the typical gas processing plant and discuss gas gathering (pipeline hydraulics), natural gas treating (H2S, CO2 removal), acid gas injection and sulfur recovery. One unique aspect of this training course is the operations and troubleshooting discussions in each module. This VILT course is suited to technical personnel or technical management. Training Objectives After the completion of this VILT course, participants will be able to: Grasp the key specifications of natural gas and liquid products Understand the physical and transport properties of gases and liquids and liquid-vapor phase behavior Explore the various technologies for processing natural gas and to make the specifications Examine the design of the technologies Learn how to diagnose operating problems to keep facilities running reliably Target Audience This VILT course is intended for all surface technical personnel such as process engineers & technologists, facility engineers and production engineers & technologists. This VILT course will greatly benefit but not limited to: Process, petroleum and production engineers Field operators and technicians Personnel involved in gas treatment and processing Managers and Supervisors involved with gas processing operations Course Level Basic or Foundation Intermediate Training Methods The VILT course will be delivered online in 5 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. Course Duration: 5 half-day sessions, 4 hours per session (20 hours in total). The maximum number of participants for this course is 20 persons. Case studies and Exercises: This VILT course will use actual case references throughout its duration in various forms. This will allow the application of the participants' newly-acquired knowledge. Case studies also stimulate independent thinking and discussion among the participants Trainer Your expert course leader has written several papers that have been published in both academic and industry journals. He has over 30 years of industry experience, specializing in gas processing (pipeline hydraulics, separation, dehydration, treating, sulphur recovery and refrigeration processes) and also has experience with crude oil dehydration, stabilization and micro-refining topping plants. He has experience with developing new technology and is recently involved in lithium, waste biomass and used motor oil pyrolysis and geothermal projects. He has recognized expertise in thermodynamics and physical and transport properties of fluids. He has consulted for several EPC and operating companies through his company Chem-Pet Process Tech., and currently holds the role of Director of Technology in an integrated engineering and solutions provider to the energy industry. He is currently involved with a small power-based carbon capture project as well as helping clients determine the best options for utilities decisions. He has been involved with CO2 dehydration and CO2 flood gas treating as well as acid gas injection projects for several years. Highlighted Achievements: Developed ORC geothermal model to determine the available power from wells in Alberta Acting on the Technical Advisory Board for E3 Metals, extracting lithium from formation water. Acted as a Subject Matter Expert for assessing the performance of the Plains Midstream Canada, Empress 1 Deep Cut Straddle Plant in a potential litigation. Acted as an Expert Witness for JL Transportation patent defence of a dense phase technology. Process engineer lead on the addition of the new Orloff gas plant for Deltastream. Also troubleshooted the oil battery shipping pump, plate exchanger and FWKO and treater. Evaluated gas processing and sulphur recovery options for new feeds to the Zhaikmunai Zelenovsky Gas Plant, Kazakhstan (with PM Lucas, Serbia). Completed capacity analysis for hydrocarbon dew point versus liquid recovery of three trains at Birchcliff Pouce Coupe facility including amine unit, refrigerated gas plant and acid gas injection. Completed process design for CO2 flue gas dehydration for Husky Energy Inc (with Status Engineering) Provided simulations of EnCana Foster Creek and Christina Lake and Husky McMullen SAGD facilities (with Vista Projects). Performed process engineering for Cenovus Pelican Lake SAGD pilot (with GRB Engineering) Bear Lake heavy oil polymer injection pilot (with GRB Engineering). Lead process engineer on the design of IEC Kerrobert crude oil micro-refinery (topping plant). Provided engineering support and troubleshooting for Enerchem Slave Lake Crude tower and product blending (with Status Engineering). POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Directional, Horizontal and Multilateral Drilling – Simulator Assisted

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your drilling skills with our Directional, Horizontal, and Multilateral Drilling Simulator Assisted course. Join EnergyEdge for comprehensive training.

Drill String Design & Drilling Optimization

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course The drill string is the simplest piece of equipment in use on a drilling rig and at the same time, the most critical piece. We use the qualifier 'basic' because although 99% of the drill string comprises plain tubes that are just screwed together, the lowest section, just above the bit, can go to extreme loading and is fitted with highly sophisticated electronics packages providing both positional and lithological data as well as a steering system to drive and orient the bit. The principle tasks of the drill string are also deceptively simple. These are to: Convey each drill bit to the bottom of the hole and then to retrieve it when worn, Act as a conduit to convey drilling fluid at high pressure down to the bit and Transmit torque from surface to bit, occasionally in concert with a hydraulic motor to drive this bit. This 3 full-day course will cover in detail what it takes to decide on minimum drill string specifications, which are able to support the loads to which it will be subjected. In addition to the need to use a drill string with minimum strength requirements, we also need to ensure that we can prevent drill string failure. If the failure consists of a small split or leak of any kind, then the time involved may be little more than that required for a roundtrip to change the bit. If the string parts, then the recovery is likely to take a considerable amount of time. In a worst case scenario, the fish in the hole may prove impossible to retrieve, requiring a sidetrack. A less than optimal design of the string will reduce the efficiency of the operation and almost always leads to premature bit wear. This is particularly true when we are unable to measure and control the dynamics of the drill string as a whole and the bottomhole assembly in particular. Axial vibrations, torsional vibrations and lateral vibrations may take place in various degrees of severity. The behaviour of the drill string while operating under torsional vibrations is thought to be of great importance and may result in torsional buckling. This course will also cover the drilling optimization limiters, how to identify them and how to remove them. This is done by understanding the drill string dynamics - by operating under the most favourable conditions and by measuring the dynamics in the vicinity of the bit (or at the bit) in order to make timely adjustments. Training Objectives The course homes in what office staff needs to know and plan for and what field staff needs to know and implement. By the end of this course, participants will be familiar with: Critical dimensions of common drill pipe and weld-on tool joints and its relation to yield for calculation of tensile, torsional and burst resistance. Make-up torque of connections that relate to the tool joint dimensions and the torsional strength of that connection. Use of design factors and safety factors on tensile and torsional strength in relation to new and worn state. Conditions which could lead to drill pipe collapse. Situations where limitations on sinusoidal (snake) and helical buckling will apply and the influence of radial clearance and deviation. Failure of drill pipe (fatigue) and the circumstances under which these would occur (rotation across doglegs, pipe in compression etc). Mechanism under which hardbanding would induce casing wear and the methods applied to measure and prevent any significant wear. Drill pipe inspection methods we apply to identify early flaws/cracks/corrosion, to measure dimensions, to inspect tool joints etc. Common BHA components, including heavy wall drill pipe, their external/internal dimensions, connections (API, proprietary) and appearance (such as spiral). Significance of thread compounds to ensure the correct make-up torque is applied. Significance of drill string/BHA 'neutral point' in the context of drill string component failure. Basic design principles for a BHA make-up in a vertical, low/medium deviated and highly deviated well in terms of weight transfer and drag/torque. Stabilization principles for a pendulum (vertical), a stabilized (vertical or tangent), a build and a drop-off assembly. BHA design and stabilization in relation to mitigation/elimination of vibration and to the elimination of tension, torsion or fatigue failure. Matching bit aggressiveness, gauge length, BHA stabilization, steerability and Mechanical Specific Energy (MSE) to mitigate the severity of any vibration. Bit efficiency and reduction of wear by understanding mechanical and hydraulic limiters. How to perform a passive or active drill-off test. Importance of being conversant with API 7G RP and/or equivalent data books, to look up/check the recommended tensile/torque and other parameters for the drill string in use. Target Audience This course is intended for staff directly or indirectly involved in the delivery of challenging wells such as junior to senior well engineers, both in office-based planning and operations and field-based operator/contractor supervisory staff such as company men and toolpushers. Trainer Your expert course leader has over 45 years of experience in the Oil & Gas industry. During that time, he has worked exclusively in the well engineering domain. After being employed in 1974 by Shell, one of the major oil & gas producing operators, he worked as an apprentice on drilling rigs in the Netherlands. After a year, he was sent for his first international assignment to the Sultanate of Oman where he climbed up the career ladder from Assistant Driller, to Driller, to wellsite Petroleum Engineer and eventually on-site Drilling Supervisor, actively engaged in the drilling of development and exploration wells in almost every corner of this vast desert area. At that time, drilling techniques were fairly basic and safety was just a buzz word, but such a situation propels learning and the fruits of 'doing-the-basics' are still reaped today when standing in front of a class. After some seven years in the Middle East, a series of other international assignments followed in places like the United Kingdom, Indonesia, Turkey, Denmark, China, Malaysia, and Russia. Apart from on-site drilling supervisory jobs on various types of drilling rigs (such as helicopter rigs) and working environments (such as jungle and artic), he was also assigned to research, to projects and to the company's learning centre. In research, he was responsible for promoting directional drilling and surveying and advised on the first horizontal wells being drilled, in projects, he was responsible for a high pressure drilling campaign in Nigeria while in the learning centre, he looked after the development of new engineers joining the company after graduating from university. He was also involved in international well control certification and served as chairman for a period of three years. In the last years of his active career, he worked again in China as a staff development manager, a position he nurtured because he was able to pass on his knowledge to a vast number of new employees once again. After retiring in 2015, he has delivered well engineering related courses in Australia, Indonesia, Brunei, Malaysia, China, South Korea, Thailand, India, Dubai, Qatar, Kuwait, The Netherlands, and the United States. The training he provides includes well control to obtain certification in drilling and well intervention, extended reach drilling, high pressure-high temperature drilling, stuck pipe prevention and a number of other ad-hoc courses. He thoroughly enjoys training and is keen to continue taking classes as an instructor for some time to come. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Compressors & Pumps: Selection, Applications, Operation, Troubleshooting and Maintenance

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your expertise in compressor and pump selection, operation, troubleshooting, and maintenance with EnergyEdge's comprehensive classroom training. Elevate your skills today!

Phoenix pottery and Art Studio is an Artist owned studio, offering pottery and art/craft classes in Cheshire. We have a range of pottery classes and ceramic art workshops, for beginners to experienced. We are close to the towns of Warrington, Wigan, St Helens and cities of Liverpool and Manchester . With easy motorway access from, M6 , M62 and East Lancs Rd.

Educators matching "Motor"

Show all 142Search By Location

- Motor Courses in London

- Motor Courses in Birmingham

- Motor Courses in Glasgow

- Motor Courses in Liverpool

- Motor Courses in Bristol

- Motor Courses in Manchester

- Motor Courses in Sheffield

- Motor Courses in Leeds

- Motor Courses in Edinburgh

- Motor Courses in Leicester

- Motor Courses in Coventry

- Motor Courses in Bradford

- Motor Courses in Cardiff

- Motor Courses in Belfast

- Motor Courses in Nottingham