- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

255 Health & Safety courses in Manchester

Our 6 hour Emergency First Aid at Work course gives the participant the knowledge, skills and confidence to deal with with first aid incidents in the work environment. Employers can book this course for their employees in the knowledge that they are fulfilling their duty to provide quality first aid training to their employees.

HACCP Trainer - RSPH HACCP Level 3 Training Course - Onsite - Nationwide

By Kitchen Tonic Training Company and Food Safety Consultants

HACCP Level 3 Training Courses

RSPH - Level 3 Award in Asbestos Air Monitoring and Clearance Procedures

By Airborne Environmental Consultants Ltd

This course provides the theory, practical knowledge and skills required for use of microscopes and fibre counting to WHO rules, air sampling and four-stage clearance procedures. The course is based around 'HSG248 Asbestos: The Analysts Guide for Sampling, Analysis and Clearance Procedures'.

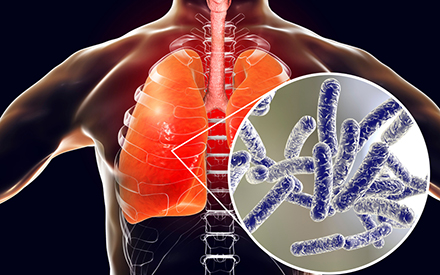

Legionella Responsible Person Course

By Airborne Environmental Consultants Ltd

Legionella Responsible Person is suitable for any persons wanting to gain an understanding of Legionella and how to prevent or control the risk of exposure to Legionella bacteria.

This full day workshop is designed to follow on and build on the learning from the 1-hour webinar to provide an embedded learning experience leading to acceptance and change of culture around neurodiversity. We understand the pressure managers can experience working within a neurodiverse team, this training is designed with managers in mind.

Legionella Responsible Person Course Online

By Airborne Environmental Consultants Ltd

Legionella Responsible Person Online is suitable for any persons wanting to gain an understanding of Legionella and how to prevent or control the risk of exposure to Legionella bacteria.

An emergency can happen anywhere, so it's better to be prepared at all instances, specially at the workplace. Come to Knight Training and ensure your employees are safe with our Emergency First Aid At Work Course now!

Emergency First Aid at Work

By Prima Cura Training

This one-day course will help you meet your regulatory requirements if your risk assessment indicates that first aid training covering emergency protocols only, is sufficient for your workplace.

NVQ DIPLOMA IN WOOD OCCUPATIONS (CONSTRUCTION) V2

By Oscar Onsite

REFERENCE CODE 610/0134/X COURSE LEVEL NVQ Level 3 THIS COURSE IS AVAILABLE IN Course Overview Who is this qualification for? This qualification is aimed at those who are involved in either site carpentry including first and second fixing, those who are involved in shopfitting site work or those who carry out shopfitting bench work. The qualification is at level 3 although there may be some units at different levels. Level 3 qualifications are primarily aimed at those who are fully trained and experienced in a wide range of work activities, It is not expected that candidates working in this industry all do the same activities or use the same equipment and machinery so the qualification has been developed to make it as widely available as possible. All work completed must be carried out in accordance with Building Regulations and Industry recognised safe working practices, including the disposal of waste. The qualification is structured to ensure that there is a high degree of flexibility within the pathways and units available and will allow employees from companies of all sizes and specialisms equal opportunity to complete. The qualification consists of 3 pathways. What is required from candidates? Qualifications are also required to indicate the number of hours of teaching someone would normally need to receive in order to achieve the qualification. These are referred to as Guided Learning Hours (GLH). The GLH for this qualification is 404. Pathway 1 Site Joinery, Pathway mandatory units Level Credits Installing bespoke first fixing components in the workplace Installing bespoke second fixing components in the workplace Setting up and using transportable cutting and shaping machines in the workplace Erecting roof structure carcassing components in the workplace Confirming work activities and resources for an occupational work area in the workplace Developing and maintaining good occupational working relationships in the workplace Confirming the occupational method of work in the workplace Conforming to general health, safety and welfare in the workplace Pathway 1 Site joinery – Optional units minimum of 1 unit must be achieved Erecting structural carcassing components in the workplace Maintaining non-structural and structural components in the workplace Pathway 2-Shopfitting site work-Pathway mandatory units Marking out from setting out details for routine shopfitting products in the Summary of the: GQA LEVEL 3 NVQ DIPLOMA IN WOOD OCCUPATIONS (CONSTRUCTION) Installing shopfitting frames and finishings in the workplace Installing shopfitting fitments in the workplace Installing shopfronts and finishings in the workplace Setting up and using transportable cutting and shaping machines in the workplace Confirming work activities and resources for an occupational work area in the workplace Developing and maintaining good occupational working relationships in the workplace Confirming the occupational method of work in the workplace Conforming to general health, safety and welfare in the workplace Pathway 3 – Shopfitting-Bench Work – Pathway mandatory units Producing setting out details for routine shopfitting products in the workplace Marking out from setting out details for routine shopfitting products in the workplace Manufacturing routine shopfitting products in the workplace Confirming work activities and resources for an occupational work area in the workplace Developing and maintaining good occupational working relationships in the workplace Confirming the occupational method of work in the workplace Manufacturing bespoke shopfitting products in the workplace Setting up and using fixed machinery in the workplace Conforming to general health, safety and welfare in the workplace Pathway 3 – Shopfitting – Bench work – Pathway optional units a minimum of 1 unit must be achieved Producing CAD setting out details in the workplace Producing wood and wood-based products using computer numerically controlled/numerically controlled (CNC/NC) machinery in the workplace Producing setting out details for bespoke shopfitting products in the workplace Assessment Guidance: Evidence should show that you can complete all of the learning outcomes for each unit being taken. Types of evidence: Evidence of performance and knowledge is required. Evidence of performance should be demonstrated by activities and outcomes, and should be generated in the workplace only, unless indicated under potential sources of evidence (see below). Evidence of knowledge can be demonstrated though performance or by responding to questions. Quantity of evidence: Evidence should show that you can meet the requirements of the units in a way that demonstrates that the standards can be achieved consistently over an appropriate period of time. Potential sources of evidence: The main source of evidence for each unit will be observation of the candidate’s performance and knowledge demonstrated during the completion of the unit. This can be supplemented by the following types of physical or documentary evidence: Accident book/reporting systems Photo/video evidence Safety records Work diaries Training records Timesheets Audio records Telephone Logs Job specifications and documentation Meeting records Delivery Records Records of toolbox talks Witness testimonies Equipment Correspondence with customers Prepared materials and sites Notes and memos Completed work Please Note that photocopied or downloaded documents such as manufacturers or industry guidance, H&S policies, Risk Assessments etc, are not normally acceptable evidence for GQA qualifications unless accompanied by a record of a professional discussion or Assessor statement confirming candidate knowledge of the subject. If you are in any doubt about the validity of evidence, contact Oscar Onsite Academy

Ladders & Steps

By Browns Safety Services

Safe Use & Pre-Use Inspection of Ladders & Steps

Search By Location

- Health & Safety Courses in London

- Health & Safety Courses in Birmingham

- Health & Safety Courses in Glasgow

- Health & Safety Courses in Liverpool

- Health & Safety Courses in Bristol

- Health & Safety Courses in Manchester

- Health & Safety Courses in Sheffield

- Health & Safety Courses in Leeds

- Health & Safety Courses in Edinburgh

- Health & Safety Courses in Leicester

- Health & Safety Courses in Coventry

- Health & Safety Courses in Bradford

- Health & Safety Courses in Cardiff

- Health & Safety Courses in Belfast

- Health & Safety Courses in Nottingham