- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Hydronics Unlocked — 1-Day Course Design and install smarter heating systems with confidence. This full-day course is crafted for heating professionals who want to sharpen their design skills, understand system performance and build the knowledge they need for modern, efficient installs — with boilers, heat pumps or both. 💡 Who This Course Is For Whether you're: An experienced engineer looking to stay ahead of the curve, Newly qualified and craving clear, practical answers Installing gas or oil boilers and exploring the move into heat pumps, Already fitting heat pumps but missing key insights, Or designing systems on paper and want to bridge the gap to real-world installs… This course will help you take your next step to levelling up your career. 🧠 What You’ll Learn Build the confidence and skills to deliver systems that are more efficient, reliable and ready for the future. You'll learn: Our 10-Step Hydronics Process: your complete framework for design and installation Pump Setting: understand how to match pump performance to system needs Flow, Velocity, Resistance: calculations made simple and useful Pipe Sizing: learn how to size pipes correctly to minimise pressure loss Controls for Efficiency: understand how modern controls improve performance Low temperature design: build confidence and skills for heat pump work 🎁 What's Included 📍 In-person training led by Paul Leedham 📖 Take-home course book ☕ Tea, coffee, and biscuits provided throughout 🥪 Lunch provided ⭐ Paul Leedham Paul is an award-winning heat pump designer and one of the most respected voices in the low carbon heating space. A qualified electrician and heating engineer, he brings a rare depth of technical understanding, built on years of hands-on installation and high-end design work. He’s also actively involved in industry standards and policy discussions, keeping his training rooted in what’s coming next. 🗺 Where Matrix Energy Systems, Unit 5 Bradmarsh Way, Rotherham S60 1BW Google Maps link

8 Weeks Comprehensive Hair Cutting & Hair Colouring Course for Beginners

By Alan d Hairdressing Education

Ideal for those wanting a completely practical Hair Cutting and Colouring Course. You’ll learn the 9 Alan d foundation haircuts along with finishing techniques, shampooing, cutting, styling, blow-drying, client care and salon protocol. After 4 weeks (20 days), you will then move on to a 4 week (20 days) colour class covering basic product knowledge, root coverage, full-head colour, foils, meche & Balayage. You will be taught on both dummy heads & live models.

Gong Sound Bath at The Lady Olivia Centre, Brampton nr Huntingdon, Cambridgeshire ~ healing sound relaxation with experienced Sound Therapists Edwin and Harshani Ma of Mind Body Wellbeing https://mindbodywellbeing.co.uk/sound-therapy/

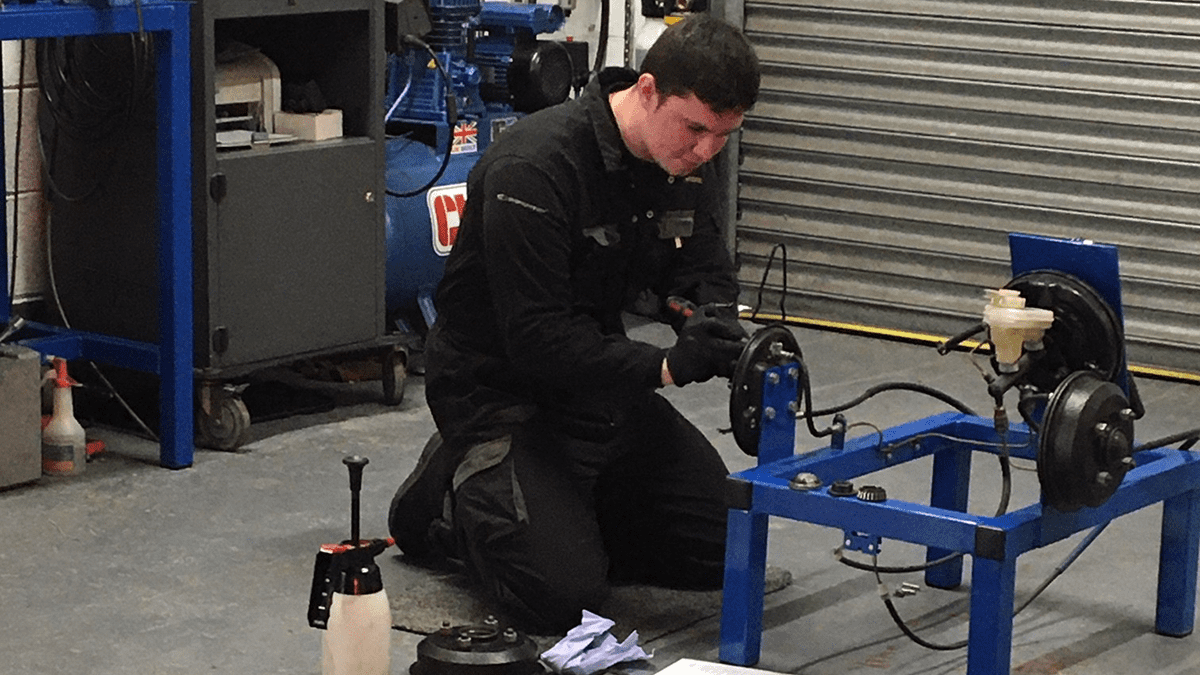

Light Vehicle Brake Fitting Course

By PFTP Ltd

The IMI PAC course in Light Vehicle Brake Fitting is 3 days in duration and is aimed at fitters who want to improve their knowledge and skills A minimum of 3 months practical experience is required as this is not an introductory course. An alternative course is available for those with no previous experience, contact us for more details Successful candidates will receive an IMI Professional Achievement Certificate in Light Vehicle Brake Fitting. Course Details: Classroom based theory session Workshop practice session Examination and assessment Course Fees £499.00 + VAT per candidate *Please contact us for group rates Course Content Theoretical Health & Safety Brake types (disc brake & drum brakes) Hydraulic operating systems Brake arrangements Brake valves Brake fluid Servo assistance Introduction to ABS and EPB Practical Brake pad and disc removal and re-fitting Brake drum and shoe removal and re-fitting Manufacturing a brake pipe Bleeding a hydraulic system IMI assessment and test A multi-choice theory question paper Five practical assessments, observed by an IMI approved assessor. What’s included Fully qualified and experienced trainers Course booklet Examinations Fees and Certification One year IMI membership To find out more, please use the live chat function, visit our contact page or call us on 024 76325880

High-Performance Car Tyre Fitting Course

By PFTP Ltd

The IMI PAC course in High Performance Light Vehicle Tyre Fitting is 3 days in duration and is aimed at light vehicle tyre fitters wishing to update their skills and knowledge for today’s modern tyre types and designs. A minimum of 3 months practical light vehicle tyre fitting experience is required as this is not an introductory course. We also run a 1 day basic, non certificated course if for those without the tyre fitting experience, please contact for further details. Successful candidates will receive an IMI Professional Achievement Certificate in High Performance Light Vehicle Tyre Fitting. As well as being recognised throughout the Motor Industry, this qualification will also count towards the NTDA tyre Technician Professional development Scheme’s Licenced Retail Tyre Technician licence (LRTT). / Course Details: One day classroom based theory session One day workshop practice session One day examination and assessment Course Fees £475.00 + VAT. per person Please contact us for group rates Course Content Theoretical Health & Safety Light Vehicle Tyre construction identification Run-flat technologies Light Vehicle Wheel rim identification Light Vehicle Tyre sidewall markings (including lyre labeling) Construction & Use regulations Limits of wear and serviceability Fault identification methods Tyre & Inner tube repairs conforming to BSAU159g Practical Tyre inspection and fault reporting Safe vehicle jacking Safe removal and replacement of road wheels Safe wheel balancing Safe tyre removal and replacement (High Performance & Run Flat) Safe tubeless tyre and inner tube repair IMI assessment and test A multi-choice theory question paper Four practical assessments, observed by an IMI approved assessor. What’s included Fully qualified and experienced trainers Course booklet Examinations Fees and Certification One year IMI membership To find out more, please use the live chat function, visit our contact page or call us on 024 76325880

Motorcycle Tyre Fitting

By PFTP Ltd

The IMI Motorcycle Tyre Fitting course is 3 days in duration for and is aimed at Fast Fit Technicians and Specialist Tyre Fitters involved with working on Motorcycle Tyres. Candidates must have a minimum of 3 months practical motorcycle tyre fitting experience. Successful candidates will receive an IMI Quality Approved Award in Motorcycle Tyre Fitting recognised throughout the industry. A basic tyre fitting course can be provided for those with little or no experience. Course Details: One day classroom based theory session One day workshop practice session One day examination and assessment Course Fees £475.00 + VAT per candidate Please contact us for group rates Course Content Theoretical Health & Safety Motorcycle Tyre construction identification Motorcycle Wheel rim identification MotorcycleTyre sidewall markings Construction & Use regulations Limits of wear and serviceability Fault identification methods Tyre and inner tube repairs Practical Tyre fault identification and reporting Safe wheel removal and replacement Safe wheel balancing Safe removal and replacement of tyres Safe tyre and inner tube repairs to BSAU159g IMI assessment and test A multi-choice theory question paper Four practical assessments, observed by an IMI approved assessor. What’s included Fully qualified and experienced trainers Course booklet Examinations Fees and Certification One year IMI membership To find out more, please use the live chat function, visit our contact page or call us on 024 76325880

Guitar Building Course The Aim The aim of this electric guitar building course is teach you how to assemble a Stratocaster, Telecaster or Jazzmaster style bolt-on-neck design electric guitar to a very high standard as well as gain understanding and knowledge in not only the assembly but also a good understanding of its inner workings and overall function. What to Expect In this electric guitar building course you’ll focus on making the most successful electric guitar of all time: the bolt-on-neck design. In almost any music store, these guitars outnumber others five-to-one. The course will cover Body & Neck assembly, Pickup Installation & Installation of all Electronics and the Professional Setting up of an Electric Guitar The course will commence daily at 09:30 with lectures & discussions on topics relating to each part of the guitar construction and then followed by the practical application of these topics under supervision, finishing at 17:30. The course and workshop located in Cross in Hand, East Sussex, designed for a maximum of 4 people per course enabling a very close learning experience. All Lutherie tools needed to complete the course are supplied. NO Experience necessary! Upon Completion Upon completion of the build your own guitar course you will leave with a great Custom made Guitar! The end product will be a Custom Tele, Strat or Jazzmaster that You will have made and one that will give many standard models a run for their money in tone and feel. Personal attention The course does have a set agenda but we often meander around topics and are happy to do so, most of us have had many different guitars and they nearly always have some curious tales and they are always good to discuss. Break down of guitar course topics by day DAY 1 Body & Neck Wood choice and body design play a large part in the tone of an electric guitar. If you were to play several solid body guitars unamplified you’ll notice distinct differences between various wood types. A solid body that sounds good acoustically generally will sound good amplified. We’ll discuss the different woods used to make electric guitars and the effect of different body styles on tone and sustain. Just as wood affects the body, when making a neck you have to pay attention to wood choice in order to have a good sounding guitar. The hardware that goes into making a great guitar also plays a large role, not only the quality in the parts but also their fitting. You will be instructed on how best to fit all the component parts with skill and accuracy enabling you to create a great custom made guitar.. Topics covered: Body & Neck styles Wood choices Neck joints Adjustable Truss Rods Fitting neck to body Scale lengths Tremolo Bridge placement (Incl Claw & Springs) Fretboard radius Machine head installation Preparing the Nut Slot Making & Cutting a Bone Nut (Requires working with the belt sander) All the hardware fitted to the guitar will be quality Japanese Gotoh vintage parts, these are particularly well made; tuners hold tune well and the Gotoh bridge is of very good quality, all of this goes together to make a great custom built guitar. DAY 2 Electronics & Fret Dressing Once you’ve learnt why and how a great guitar goes together as well as practically applying the previous topics, you now learn to install the best pickups and wiring. For these custom built guitars we will be using Bare Knuckle Boot Camp pickups: very high quality pickups designed to suit our specifications of wood choice and body style. These pickups are hand wound in the UK and are widely regarded as the best pickups on the market today. Choose between Old Guard, True Grit or Brute Force. The key to having a great sounding electric is not just down to the Pickups but also the choice of components that go with it, often overlooked with most mass manufactured guitars, the guitar you make will have highest quality components and will subsequently sound great and work extremely well. Custom CTS Pots, Sprague Capacitor and a CRL (USA) switch as well as vintage cloth wiring all go together to make a very well appointed loaded scratchplate! Topics covered: Schematics Pickup installation Wiring volume & tone pots Wiring 5 way selector switch Wiring output jack Bridge and string grounding Fret Dressing both Theory & Practise DAY 3 Final Assembly The guitar will now be ready for final assembly. Today you will learn how to fully assemble and set up your electric guitar to a professional standard. The topics covered will be very useful for your regular maintenance of the guitar you have made as well as any others that you may have. Topics covered: Professional Setups Theory Fitting and filing the Bone Nut Pickguard placement Installing strap buttons Installing Decals (Personalised custom Decals) Final Setting and fitting the neck Stringing up String tree placement Bridge set up Action height adjustment and setting Pick up height Intonation Customising Your Guitar Build inclusive from £999 We are more than happy to work with you in order to get the custom build you want, so please contact us if you have a specific body colour scheme or neck choice, which Bare Knuckle pickups you want as well as hardware and we will try help achieve exactly that. If you’re unsure what works best, just get in touch and we will advise where we can. All custom options are subject to availability and it is always best to have a 1st & 2nd choice, there are some colours/parts etc that may incur additional cost. Tweed hard cases are available for an additional £75, £90 for the Jazzmaster. (Soft gig bag included) Some additional charges can apply for custom colours or specs or if you would like specific made to order Bare Knuckle Pickups

Drill String Design & Drilling Optimization

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course The drill string is the simplest piece of equipment in use on a drilling rig and at the same time, the most critical piece. We use the qualifier 'basic' because although 99% of the drill string comprises plain tubes that are just screwed together, the lowest section, just above the bit, can go to extreme loading and is fitted with highly sophisticated electronics packages providing both positional and lithological data as well as a steering system to drive and orient the bit. The principle tasks of the drill string are also deceptively simple. These are to: Convey each drill bit to the bottom of the hole and then to retrieve it when worn, Act as a conduit to convey drilling fluid at high pressure down to the bit and Transmit torque from surface to bit, occasionally in concert with a hydraulic motor to drive this bit. This 3 full-day course will cover in detail what it takes to decide on minimum drill string specifications, which are able to support the loads to which it will be subjected. In addition to the need to use a drill string with minimum strength requirements, we also need to ensure that we can prevent drill string failure. If the failure consists of a small split or leak of any kind, then the time involved may be little more than that required for a roundtrip to change the bit. If the string parts, then the recovery is likely to take a considerable amount of time. In a worst case scenario, the fish in the hole may prove impossible to retrieve, requiring a sidetrack. A less than optimal design of the string will reduce the efficiency of the operation and almost always leads to premature bit wear. This is particularly true when we are unable to measure and control the dynamics of the drill string as a whole and the bottomhole assembly in particular. Axial vibrations, torsional vibrations and lateral vibrations may take place in various degrees of severity. The behaviour of the drill string while operating under torsional vibrations is thought to be of great importance and may result in torsional buckling. This course will also cover the drilling optimization limiters, how to identify them and how to remove them. This is done by understanding the drill string dynamics - by operating under the most favourable conditions and by measuring the dynamics in the vicinity of the bit (or at the bit) in order to make timely adjustments. Training Objectives The course homes in what office staff needs to know and plan for and what field staff needs to know and implement. By the end of this course, participants will be familiar with: Critical dimensions of common drill pipe and weld-on tool joints and its relation to yield for calculation of tensile, torsional and burst resistance. Make-up torque of connections that relate to the tool joint dimensions and the torsional strength of that connection. Use of design factors and safety factors on tensile and torsional strength in relation to new and worn state. Conditions which could lead to drill pipe collapse. Situations where limitations on sinusoidal (snake) and helical buckling will apply and the influence of radial clearance and deviation. Failure of drill pipe (fatigue) and the circumstances under which these would occur (rotation across doglegs, pipe in compression etc). Mechanism under which hardbanding would induce casing wear and the methods applied to measure and prevent any significant wear. Drill pipe inspection methods we apply to identify early flaws/cracks/corrosion, to measure dimensions, to inspect tool joints etc. Common BHA components, including heavy wall drill pipe, their external/internal dimensions, connections (API, proprietary) and appearance (such as spiral). Significance of thread compounds to ensure the correct make-up torque is applied. Significance of drill string/BHA 'neutral point' in the context of drill string component failure. Basic design principles for a BHA make-up in a vertical, low/medium deviated and highly deviated well in terms of weight transfer and drag/torque. Stabilization principles for a pendulum (vertical), a stabilized (vertical or tangent), a build and a drop-off assembly. BHA design and stabilization in relation to mitigation/elimination of vibration and to the elimination of tension, torsion or fatigue failure. Matching bit aggressiveness, gauge length, BHA stabilization, steerability and Mechanical Specific Energy (MSE) to mitigate the severity of any vibration. Bit efficiency and reduction of wear by understanding mechanical and hydraulic limiters. How to perform a passive or active drill-off test. Importance of being conversant with API 7G RP and/or equivalent data books, to look up/check the recommended tensile/torque and other parameters for the drill string in use. Target Audience This course is intended for staff directly or indirectly involved in the delivery of challenging wells such as junior to senior well engineers, both in office-based planning and operations and field-based operator/contractor supervisory staff such as company men and toolpushers. Trainer Your expert course leader has over 45 years of experience in the Oil & Gas industry. During that time, he has worked exclusively in the well engineering domain. After being employed in 1974 by Shell, one of the major oil & gas producing operators, he worked as an apprentice on drilling rigs in the Netherlands. After a year, he was sent for his first international assignment to the Sultanate of Oman where he climbed up the career ladder from Assistant Driller, to Driller, to wellsite Petroleum Engineer and eventually on-site Drilling Supervisor, actively engaged in the drilling of development and exploration wells in almost every corner of this vast desert area. At that time, drilling techniques were fairly basic and safety was just a buzz word, but such a situation propels learning and the fruits of 'doing-the-basics' are still reaped today when standing in front of a class. After some seven years in the Middle East, a series of other international assignments followed in places like the United Kingdom, Indonesia, Turkey, Denmark, China, Malaysia, and Russia. Apart from on-site drilling supervisory jobs on various types of drilling rigs (such as helicopter rigs) and working environments (such as jungle and artic), he was also assigned to research, to projects and to the company's learning centre. In research, he was responsible for promoting directional drilling and surveying and advised on the first horizontal wells being drilled, in projects, he was responsible for a high pressure drilling campaign in Nigeria while in the learning centre, he looked after the development of new engineers joining the company after graduating from university. He was also involved in international well control certification and served as chairman for a period of three years. In the last years of his active career, he worked again in China as a staff development manager, a position he nurtured because he was able to pass on his knowledge to a vast number of new employees once again. After retiring in 2015, he has delivered well engineering related courses in Australia, Indonesia, Brunei, Malaysia, China, South Korea, Thailand, India, Dubai, Qatar, Kuwait, The Netherlands, and the United States. The training he provides includes well control to obtain certification in drilling and well intervention, extended reach drilling, high pressure-high temperature drilling, stuck pipe prevention and a number of other ad-hoc courses. He thoroughly enjoys training and is keen to continue taking classes as an instructor for some time to come. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Search By Location

- FITT Courses in London

- FITT Courses in Birmingham

- FITT Courses in Glasgow

- FITT Courses in Liverpool

- FITT Courses in Bristol

- FITT Courses in Manchester

- FITT Courses in Sheffield

- FITT Courses in Leeds

- FITT Courses in Edinburgh

- FITT Courses in Leicester

- FITT Courses in Coventry

- FITT Courses in Bradford

- FITT Courses in Cardiff

- FITT Courses in Belfast

- FITT Courses in Nottingham