- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

32 Courses delivered Live Online

Day 1 Solenoids and actuators, principles of operation and maintenance State precautions that may be necessary when removing cores from energised AC solenoids Transformers, sizing, applications and uses Heaters, applications, uses and safety precautions to be observed Temperature controllers, various types, principles of operation and uses Thermal sensors, various types, principles of operation and uses. Day 2 Proximity devices, limit switches and proximity switches, various types, principles of operation and uses Practical workshop, gaining an understanding of typical connections of various proximity devices and the range of available supplies catered for, voltage levels and current type Development of a typical simple control system using push buttons, proximity devices, relays and indicator lamps. Day 3 Protection against overcurrent Protective devices, various types, suitability and uses Earthing, including principles of protection against indirect shock Undervoltage protection. Day 4 Cable and core termination techniques, including crimping and soldering Practical workshop terminating YY, SY, SWA and MICC cable Testing, basic principles of circuit protective conductor testing and insulation resistance testing, instruments used and expected values Practical workshop testing cables terminated previously and testing cables with faults on test rig. Day 5 Fault finding, safety precautions and principles Practical workshop on fault rigs Root cause analysis PPM and maximising uptime

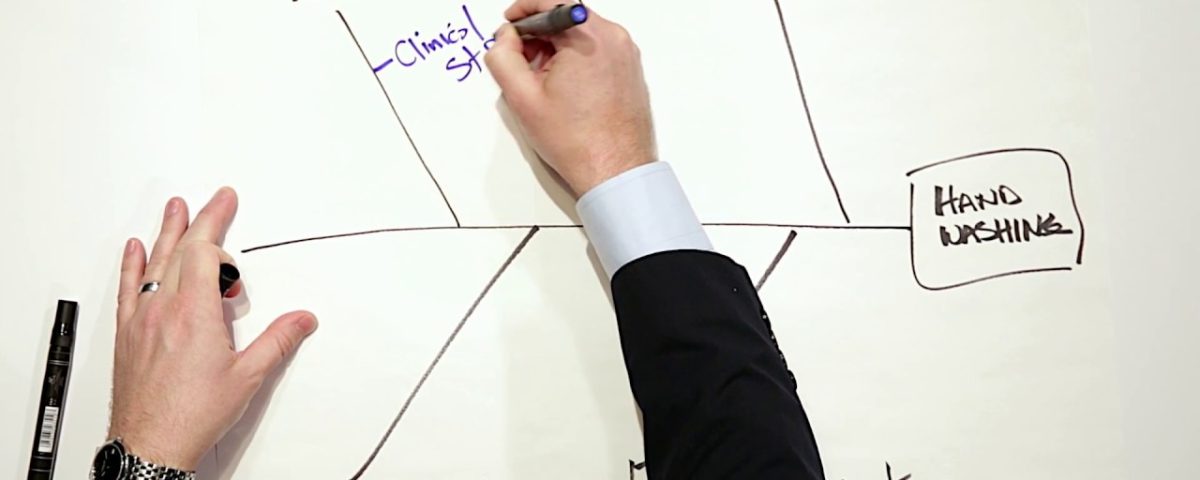

Root Cause Analysis

By M&K Update Ltd

A workshop designed specifically for healthcare professionals to meet the standards of the NHS Serious Incident Framework. The day will provide clinical leaders with practical skills to enable them to undertake a root cause analysis and develop an action plan in order to improve quality and safety in their clinical setting.

Root Cause Analysis (RCA) is used to analyse the root causes of focus events with both positive and negative outcomes, but it is most commonly used for the analysis of failures and incidents. Causes for such events can be varied in nature, including design processes and techniques, organizational characteristics, human aspects and external events. RCA can be used for investigating the causes of non-conformances in quality (and other) management systems as well as for failure analysis, for example in maintenance or equipment testing.

Root Cause Analysis for Boilers and Steam Cycle Failures

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course Identifying and correcting the root cause of failures in boilers and steam power plant equipment is essential to help reduce the chance of future problems. A comprehensive assessment is the most effective method of determining the root cause of a failure. For example, a tube failure in a boiler is usually a symptom of other problems. To fully understand the root cause of the failure, one must investigate all aspects of boiler operation leading to the failure in addition to evaluating the failure itself. When a boiler tube failure occurs, the root cause of the failure must be identified and eliminated. This 5 full-day course starts by providing an in-depth understanding of root cause analysis methodology. This includes how to identify the problem, contain and analyze the problem, define the root cause of the problem, define and implement the actions required to eliminate the root cause, and validate that the corrective actions prevented recurrence of the problem. Many practical examples on how to apply root cause analysis for various industrial problems are discussed in detail. The course then provides an in-depth explanation of all failure mechanisms that occur in steam power plants including corrosion, erosion, creep, cavitation, under-deposit attacks, stress corrosion cracking, hydrogen embrittlement, flow accelerated corrosion, etc. This course also provides a thorough explanation of all the failure mechanisms that occur in boilers and steam power plant equipment including steam turbines, condensers, feedwater heaters, etc. The symptoms of the failures, possible causes, components typically affected and solutions are also provided in this course. This includes boiler waterside, fireside and general boiler failure mechanisms as well as all the causes and prevention of all steam turbine failures, condensers, and feedwater heaters. The course also includes detailed study of many case histories of failures in boilers, steam turbines, condensers and feedwater heaters. Training Objectives Electrical Equipment Testing and Maintenance: Gain a thorough understanding of all the testing and maintenance required for all key electrical equipment including transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries Root Cause Analysis Methodology: Understand root cause analysis methodology including: identification of the problem, defining the problem, understanding the problem, identification of the root cause of the problem, providing corrective action, and monitoring the system. Applying the Root Cause Analysis Method to Industrial Problems: Learn by studying many practical examples how to apply the root cause analysis method to various industrial problems. Damage Mechanisms in Boilers and Steam Power Plant Equipment: Gain a thorough understanding of all the damage mechanisms that occur in boilers and all steam power plant equipment including turbines, condensers and feedwater heaters. These mechanisms include corrosion, erosion, flow accelerated corrosion, stress corrosion cracking, creep, under-deposit attack, cavitation, hydrogen embrittlement, etc. Symptoms of Failures in Boilers and Steam Power Plant Equipment, Possible Causes, Components Typically Affected, and Solutions: Learn about all the symptoms of failures in boilers and steam power plant equipment including steam turbines, condensers, and feedwater heaters, their possible causes, components typically affected and proven solutions. Case Histories of Failures in Boilers, Steam Turbines, Condensers, and Feedwater Heaters: Learn by studying many case histories how failures occur in boilers, steam turbines, condensers, and feedwater heaters and the corrective actions taken to deal with them Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals (this seminar is suitable for individuals who do not have an electrical background) Course Level Basic or Foundation Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: Excerpt of the relevant chapters from the 'POWER GENERATION HANDBOOK' second edition published by McGraw-Hill in 2011 (800 pages) Excerpt of the relevant chapters from the 'POWER PLANT EQUIPMENT OPERATION AND MAINTENANCE GUIDE' published by McGraw-Hill in 2012 (800 pages) ROOT CAUSE ANALYSIS FOR BOILERS AND STEAM CYCLE FAILURES MANUAL (includes practical information and case histories - 500 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

BA10 - Understanding Root Cause Analysis

By Nexus Human

Duration 2 Days 12 CPD hours This course is intended for Executives, Project Managers, Business Analysts, Business and IT stakeholders working with analysts, Quality and process engineers, technicians, corrective action coordinators or managers; supervisors, team leaders, and process operators; anyone who wants to improve their ability to solve recurring problems. Overview Learn how to initiate a root cause analysis and gather data for investigating process and non-process incidentsDemonstrate how to collect data through interviews and analysisApply powerful techniques to identify and know the difference between symptoms and root causesLearn to know when to use the appropriate technique in root cause identification Learn how to avoid future incidents by developing appropriate recommendations to address causal factors and root causes Develop a process to identify systemic problem areas In this course, participants will learn to apply several practical, systematic methods for analyzing incidents and problems to uncover root causes. Understanding of these techniques will be reinforced by classroom exercises. Introduction & Objectives What is a 'Problem?' Why Problems Persist What is A Root Cause? Why Root Causes are important How to Organize for an RCA RCA Roles and Responsibilities Assemble your RCA Team Modes of Communication How to Resolve Conflict Case Study Exercise Select the Problem to Analyze Define the selection criteria Plan and estimate tasks for the team Finalize the plan and gain agreement among your stakeholders Case Study Exercise Define the Problem What to look for - Problem-as-Given (PAG) vs. Problem-as-Understood (PAU) Developing your problem statement Refining the problem specification Case Study Exercise Identify the Source of the Problem Discuss when to use the appropriate analysis technique to determine the problem source Process Diagram Forms & Checklists Statistical Sampling Fishbone Diagram Surveys Charts - Line, Scatter, Bar, & Pie Case Study Exercise Solution Options Analysis & Selecting the 'Best Fit' How to approach different solution options Brainstorming Weighted Evaluation Selecting the appropriate option Hold an Retrospective on your approach Planning the proposal Case Study Exercise Putting RCA into Practice Create a Root Cause Analysis program within your organization How to develop appropriate recommendations to address root causes at various levels to avoid future incidents Additional course details: Nexus Humans BA10 - Understanding Root Cause Analysis training program is a workshop that presents an invigorating mix of sessions, lessons, and masterclasses meticulously crafted to propel your learning expedition forward. This immersive bootcamp-style experience boasts interactive lectures, hands-on labs, and collaborative hackathons, all strategically designed to fortify fundamental concepts. Guided by seasoned coaches, each session offers priceless insights and practical skills crucial for honing your expertise. Whether you're stepping into the realm of professional skills or a seasoned professional, this comprehensive course ensures you're equipped with the knowledge and prowess necessary for success. While we feel this is the best course for the BA10 - Understanding Root Cause Analysis course and one of our Top 10 we encourage you to read the course outline to make sure it is the right content for you. Additionally, private sessions, closed classes or dedicated events are available both live online and at our training centres in Dublin and London, as well as at your offices anywhere in the UK, Ireland or across EMEA.

BA17 - Advanced Root Cause Analysis

By Nexus Human

Duration 2 Days 12 CPD hours This course is intended for Executives, Project Managers, Business Analysts, Business and IT stakeholders working with analysts, Quality and process engineers, technicians, corrective action coordinators or managers; supervisors, team leaders, and process operators; anyone who wants to improve their ability to solve recurring problems. Overview At the completion of this course, you should be able to:Identify the different types of tools and techniques availableApply change management successfullyReview what to look for when applying business case thinking to Root Cause AnalysisDevelop a process to systematically approach problems Problem determination skills cannot be acquired by reading a book. They mostly come from experience. After this course, you will have a general understanding of a structured problem determination approach, which you can then apply in your daily work. RCA Foundation Concepts and Objectives Section Learning Objectives Discuss Definitions ? IT Perspective Discuss What is a problem and why do they exist? Exercise 1a: Why is RCA important What is Root Cause? RCA Benefits and Approaches Exercise 1b: Why are multiple approaches important? Event and Casual Analysis Exercise 1c: Apply Event and Causal Analysis Event and Causal Analysis: Exercise 1c Worksheet RCA Tools for each approach Exercise 1D: Prepare for Case Study Section Summary and Conclusions Enhance Use of RCA Tools Why use a Particular Method Tool: Change Analysis Change Analysis Examples Exercise 2a: Apply Change Analysis Exercise 2b: Change Analysis Worksheet Tool: How to Resolve Conflict Tool: 5 Why?s Example Learning Management Problem Exercise 2b: Apply 5 Why?s Sequence-of-Events Exercise 2b: Worksheet Tool: Cause and Effect Exercise 2c: Apply Cause and Effect Exercise 2c: Cause and Effect Worksheet Tool: Fault Tree Analysis Why do we use Fault Tree Analysis? How does it work? Fault Tree Diagram Symbols Example #1 of FTA: Car Hits Object Exercise 2D: Apply Fault Tree Analysis Tool: Failure Modes and Effects Analysis (FMEA) Example: Failure Modes and Effects Analysis Exercise 2E: Apply FMEA Tool: Design / Application Review Exercise 2d: Apply Design/Application Review Section summary & conclusions Problem Resolution & Prevention Section Objectives The Secret of Solving Problems A Note about Statistical Control A Note about Fire Fighting Technique: Business Process Mapping Example: IGOE Exercise 3A: Problem as IGOE Exercise 3A: IGOE Template Technique: Lean Six Sigma and DMAIC Lean Six Sigma Benefits Exercise 3B: Apply Lean Six Sigma Importance of Understanding the Business Process The Business Process Mandate Technique: Process Modeling Graphical Notation Standard (BPMN) What is Business Process Modeling Notation (BPMN)? Benefits of BPMN Basic Components of BPMN Exercise 3C: Use BPMN to Document a Current State Technique: Business Process Maturity Model Five Levels of Maturity Exercise 3D: Appraise Business Process Maturity Level Section Summary and Conclusions Capability Improvement for RCA Section Learning Objectives Steps in Disciplined Problem Solving RCA as a RCA Process Key RCA Role Considerations Exercise 4A: Apply RCA to RCA Process Sustainable RCA Improvement Organizational Units Process Area Goals, Practices Specific and General Practices Specific Practice Examples Software Maturity Survey Exercise 4B: Apply Strengths, Weakness, Opportunities and Threats (SWOT) to RCA SWOT Analysis Worksheet Recognize the importance of the Change Management component in your RCA implementation Using the ADKAR Model to Communicate Change Review ADKAR© Model ? Awareness of the need for change Desire to participate and support the change Knowledge on how to change Ability to implement required skills and behaviors Reinforcement to sustain the change Exercise 4C: Create an Ability Checklist The ADKAR Model: Reinforcement Exercise 4D: Find two examples of how ADKAR will be different Section Summary and Conclusions Course Summary & Conclusions Plan the Proposal and Business Case Example: 1 Page Business Case Exercise 5A: Creating Action Plans Resource Guide Questions Additional course details: Nexus Humans BA17 - Advanced Root Cause Analysis training program is a workshop that presents an invigorating mix of sessions, lessons, and masterclasses meticulously crafted to propel your learning expedition forward. This immersive bootcamp-style experience boasts interactive lectures, hands-on labs, and collaborative hackathons, all strategically designed to fortify fundamental concepts. Guided by seasoned coaches, each session offers priceless insights and practical skills crucial for honing your expertise. Whether you're stepping into the realm of professional skills or a seasoned professional, this comprehensive course ensures you're equipped with the knowledge and prowess necessary for success. While we feel this is the best course for the BA17 - Advanced Root Cause Analysis course and one of our Top 10 we encourage you to read the course outline to make sure it is the right content for you. Additionally, private sessions, closed classes or dedicated events are available both live online and at our training centres in Dublin and London, as well as at your offices anywhere in the UK, Ireland or across EMEA.

BA17 - Problem Determination Root Cause Analysis (RCA)

By Nexus Human

Duration 2 Days 12 CPD hours This course is intended for Executives, Project Managers, Business Analysts, Business and IT stakeholders working with analysts, Quality and process engineers, technicians, corrective action coordinators or managers; supervisors, team leaders, and process operators; anyone who wants to improve their ability to solve recurring problems. Overview At the completion of this course, you should be able to: Identify the different types of tools and techniques available Apply change management successfully Review what to look for when applying business case thinking to Root Cause Analysis Develop a process to systematically approach problems Business success is dependent on effective resolution of the problems that present themselves every day. Often the same or similar problems continue causing repeated losses in time or money and your staff become experts at fixing rather than preventing the problems. Learn to find and fix root causes and develop corrective actions that will effectively eliminate or control these problems. Section 1: RCA Foundation Concepts and Objectives Section Learning Objectives Discuss Definitions ? IT Perspective Discuss What is a problem and why do they exist? What is Root Cause? RCA Benefits and Approaches Event and Casual Analysis Event and Causal Analysis: Exercise 1c Worksheet RCA Tools for each approach Section Summary and Conclusions Section 2: Enhance use of RCA tools Why use a Particular Method Tool: Change Analysis Change Analysis Examples Tool: How to Resolve Conflict Tool: 5 Why?s Example Learning Management Problem Tool: Cause and Effect Tool: Fault Tree Analysis Why do we use Fault Tree Analysis? How does it work? Fault Tree Diagram Symbols Example #1 of FTA: Car Hits Object Tool: Failure Modes and Effects Analysis (FMEA) Example: Failure Modes and Effects Analysis Tool: Design / Application Review Section 3: Problem Resolution and Prevention Section Objectives The Secret of Solving Problems: -A Note about Statistical Control -A Note about Fire Fighting Technique: Business Process Mapping Example: IGOE Technique: Lean Six Sigma and DMAIC Lean Six Sigma Benefits Importance of Understanding the Business Process The Business Process Mandate Technique: Process Modeling Graphical Notation Standard (BPMN): -What is Business Process Modeling Notation (BPMN)? -Benefits of BPMN -Basic Components of BPMN Technique: Business Process Maturity Model Five Levels of Maturity Section 4: Capability Improvement for RCA Steps in Disciplined Problem Solving RCA as a RCA Process Key RCA Role Considerations Sustainable RCA Improvement Organizational Units Process Area Goals, Practices Specific and General Practices Specific Practice Examples Software Maturity Survey SWOT Analysis Worksheet Recognize the importance of the Change Management component in your RCA implementation Using the ADKAR Model to Communicate Change Review ADKAR© Model ? -Awareness of the need for change -Desire to participate and support the change -Knowledge on how to change -Ability to implement required skills and behaviors -Reinforcement to sustain the change The ADKAR Model: Reinforcement Section 5: Course Summary and Conclusions Plan the Proposal and Business Case Example: 1 Page Business Case Resource Guide Questions

ISO 3834:2021 (Quality requirements for fusion welding of metallic materials) Lead Auditor” course provides comprehensive training for participants to be able to understand and audit each and every ISO 3834:2021 guidelines in ensuring orgnaisation compliance and continual improvement in the welding industry

Overview The course focuses on topics such as the fundamental concepts of auditing and quality management, principles of internal and external audit, auditing processes and tools, principles and practice of root cause analysis, communication and people skills, and other related topics. Students who successfully complete this course will gain the essential knowledge and skills necessary to become successful auditors and work with confidence to improve the processes in their organizations.