- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Manufacturing Engineering - Welding Training Course

By Study Plex

Highlights of the Course Course Type: Online Learning Duration: 1 Hour 17 Minutes Tutor Support: Tutor support is included Customer Support: 24/7 customer support is available Quality Training: The course is designed by an industry expert Recognised Credential: Recognised and Valuable Certification Completion Certificate: Free Course Completion Certificate Included Instalment: 3 Installment Plan on checkout What you will learn from this course? Gain comprehensive knowledge about welding Understand the core competencies and principles of welding Explore the various areas of welding Know how to apply the skills you acquired from this course in a real-life context Become a confident and expert manufacturing engineer Manufacturing Engineering - Welding Training Course Master the skills you need to propel your career forward in welding. This course will equip you with the essential knowledge and skillset that will make you a confident manufacturing engineer and take your career to the next level. This comprehensive manufacturing engineering - welding training course is designed to help you surpass your professional goals. The skills and knowledge that you will gain through studying this manufacturing engineering - welding training course will help you get one step closer to your professional aspirations and develop your skills for a rewarding career. This comprehensive course will teach you the theory of effective welding practice and equip you with the essential skills, confidence and competence to assist you in the welding industry. You'll gain a solid understanding of the core competencies required to drive a successful career in welding. This course is designed by industry experts, so you'll gain knowledge and skills based on the latest expertise and best practices. This extensive course is designed for manufacturing engineer or for people who are aspiring to specialise in welding. Enrol in this manufacturing engineering - welding training course today and take the next step towards your personal and professional goals. Earn industry-recognised credentials to demonstrate your new skills and add extra value to your CV that will help you outshine other candidates. Who is this Course for? This comprehensive manufacturing engineering - welding training course is ideal for anyone wishing to boost their career profile or advance their career in this field by gaining a thorough understanding of the subject. Anyone willing to gain extensive knowledge on this welding can also take this course. Whether you are a complete beginner or an aspiring professional, this course will provide you with the necessary skills and professional competence, and open your doors to a wide number of professions within your chosen sector. Entry Requirements This manufacturing engineering - welding training course has no academic prerequisites and is open to students from all academic disciplines. You will, however, need a laptop, desktop, tablet, or smartphone, as well as a reliable internet connection. Assessment This manufacturing engineering - welding training course assesses learners through multiple-choice questions (MCQs). Upon successful completion of the modules, learners must answer MCQs to complete the assessment procedure. Through the MCQs, it is measured how much a learner could grasp from each section. In the assessment pass mark is 60%. Advance Your Career This manufacturing engineering - welding training course will provide you with a fresh opportunity to enter the relevant job market and choose your desired career path. Additionally, you will be able to advance your career, increase your level of competition in your chosen field, and highlight these skills on your resume. Recognised Accreditation This course is accredited by continuing professional development (CPD). CPD UK is globally recognised by employers, professional organisations, and academic institutions, thus a certificate from CPD Certification Service creates value towards your professional goal and achievement. Course Curriculum Introduction Scope of the Course 00:05:00 What is Welding 00:03:00 Classification of Welding 00:02:00 Types of Weld Joints 00:02:00 Types of Welds 00:02:00 Welding Techniques 00:02:00 Joint Cleaning and Fluxing 00:02:00 Liquid State Welding Gas Welding 00:03:00 OAW - Oxy Acetylene (GAS) Welding 00:04:00 Advantages & Disvantages of OAW 00:01:00 Color of Flames in Gas Welding 00:02:00 Types of Flames 00:03:00 Torch Angle & Flame Density 00:01:00 Selection of Torch Angle 00:02:00 AAW - Air acetylene (GAS) welding 00:01:00 OHW - Oxy Hydrogen(GAS) Welding 00:01:00 Arc Welding 00:02:00 Power Supply in Arc Welding 00:02:00 Coding of Electrodes 00:07:00 Types of Arc Welding 00:06:00 Resistance Welding 00:01:00 Solid State Welding Explosive Welding 00:03:00 Friction Welding 00:01:00 Ultrasonic Welding 00:01:00 Diffusion Welding 00:02:00 Forge Welding 00:01:00 Liquid-Solid State Welding Brazing 00:01:00 Soldering 00:02:00 miscellaneous Weldability 00:01:00 Welding Defects 00:04:00 Obtain Your Certificate Order Your Certificate of Achievement 00:00:00 Get Your Insurance Now Get Your Insurance Now 00:00:00 Feedback Feedback 00:00:00

First Novel First Draft 1. Character

By London Writing School

The first session in the course First Novel, First Draft. Meet your main character, develop them by writing a scene, consider their character traits and examine their behaviour.

TARC EFT - The Advanced Somatic EFT Course of Emotional Mastery

By Rachel Earing, Live4Energy,

The most concise Somatic Emotional Intelligence unique micro learning course on the market! TARC EFT literally gives you something to do 24 hours a day. Excellent for tapping into for anxiety, stress, insomnia, courage, resilience and kindness and over 26 other emotions as well as physical symptoms. It is also a beautiful neurodivergent activity to learn with and can be adapted to all aspects of your life as you learn. This course take you on a journey within yourself like no other. This unique treasure hunt of your hidden gems is broken down into managable micro parts of yourself you will not have even thought to talk to, look at or engage with before. Getting intimate with your Small Intestine, Bladder, Lungs, Liver and so much more is a very unique journey and connects you to your family line, emotionally, mentally and physically in a very unique way. These short videos are incorporated into your every day life so it ties in with what your working on in real time, with real life daily examples. If you learn best through experience then this course is for you. TARF EFT takes you on a treasure hunt around your emotions, mind and body to collect those hidden gems you left behind, polish them up and get ready to use them for the rest of your life journey with pride and unconditional love. Broken down into bite size manageable pieces (5'-10' videos max) which you fit into your every day life. It's amazing how you see, feel and experience it working it's way through your relationships at home, work and play in real time. Students share experiences, stories, and make deeper connections to their own life events in the community get together social media groups and Sunday weekly 7pm (UK time) Zoom meeting, allowing the commuity to bond together deeper and deeper each week. Looking forward to seeing you in there! Blessings Rachel Founder | Trainer |Therapist | Podcaster| Speaker | Author Live4Energy Training College Bury's No1 Science & Consciousness College www.live4energy.co.uk

Manufacturer Engineer Training Course - Welding

By Lead Academy

Manufacturer Engineer Training Course - Welding Course Overview Are you looking to begin your welding career or want to develop more advanced skills in welding? Then this manufacturing engineering - all about welding course will set you up with a solid foundation to become a confident manufacturing engineer and help you to develop your expertise in welding. This manufacturing engineering - all about welding course is accredited by the CPD UK & IPHM. CPD is globally recognised by employers, professional organisations and academic intuitions, thus a certificate from CPD Certification Service creates value towards your professional goal and achievement. CPD certified certificates are accepted by thousands of professional bodies and government regulators here in the UK and around the world. Whether you are self-taught and you want to fill in the gaps for better efficiency and productivity, this manufacturing engineering - all about welding course will set you up with a solid foundation to become a confident manufacturing engineer and develop more advanced skills. Gain the essential skills and knowledge you need to propel your career forward as a manufacturing engineer. The manufacturing engineering - all about welding course will set you up with the appropriate skills and experience needed for the job and is ideal for both beginners and those currently working as a manufacturing engineer. This comprehensive manufacturing engineering - all about welding course is the perfect way to kickstart your career in the field of welding. This manufacturing engineering - all about welding course will give you a competitive advantage in your career, making you stand out from all other applicants and employees. If you're interested in working as a manufacturing engineer or want to learn more skills on welding but unsure of where to start, then this manufacturing engineering - all about welding course will set you up with a solid foundation to become a confident manufacturing engineer and develop more advanced skills. As one of the leading course providers and most renowned e-learning specialists online, we're dedicated to giving you the best educational experience possible. This manufacturing engineering - all about welding course is crafted by industry expert, to enable you to learn quickly and efficiently, and at your own pace and convenience. Who should take this course? This comprehensive manufacturing engineering - all about welding course is suitable for anyone looking to improve their job prospects or aspiring to accelerate their career in this sector and want to gain in-depth knowledge of welding. Entry Requirement There are no academic entry requirements for this manufacturing engineering - all about welding course, and it is open to students of all academic backgrounds. As long as you are aged seventeen or over and have a basic grasp of English, numeracy and ICT, you will be eligible to enrol. Career path This manufacturing engineering - all about welding course opens a brand new door for you to enter the relevant job market and also provides you with the chance to accumulate in-depth knowledge at the side of needed skills to become flourishing in no time. You will also be able to add your new skills to your CV, enhance your career and become more competitive in your chosen industry. Course Curriculum Introduction Scope of the Course What is Welding Classification of Welding Types of Weld Joints Types of Welds Welding Techniques Joint Cleaning and Fluxing Liquid State Welding Gas Welding OAW - Oxy Acetylene (GAS) Welding Advantages & disvantages of OAW Color of flames in Gas Welding Types of Flames Torch Angle & Flame Density Selection of Torch Angle AAW - Air acetylene (GAS) Welding OHW - Oxy Hydrogen(GAS) Welding Arc Welding Power Supply in arc Welding Coding of Electrodes Types of arc Welding Resistance Welding Solid State Welding Explosive Welding Friction Welding Ultrasonic Welding Diffusion Welding Forge Welding Liquid-Solid State Welding Brazing Soldering miscellaneous Weldability Welding Defects Recognised Accreditation CPD Certification Service This course is accredited by continuing professional development (CPD). CPD UK is globally recognised by employers, professional organisations, and academic institutions, thus a certificate from CPD Certification Service creates value towards your professional goal and achievement. CPD certificates are accepted by thousands of professional bodies and government regulators here in the UK and around the world. Many organisations look for employees with CPD requirements, which means, that by doing this course, you would be a potential candidate in your respective field. Certificate of Achievement Certificate of Achievement from Lead Academy After successfully passing the MCQ exam you will be eligible to order your certificate of achievement as proof of your new skill. The certificate of achievement is an official credential that confirms that you successfully finished a course with Lead Academy. Certificate can be obtained in PDF version at a cost of £12, and there is an additional fee to obtain a printed copy certificate which is £35. FAQs Is Cpd a Recognised Qualification in the UK? CPD is globally recognised by employers, professional organisations and academic intuitions, thus a certificate from CPD Certification Service creates value towards your professional goal and achievement. CPD-certified certificates are accepted by thousands of professional bodies and government regulators here in the UK and around the world. Are Qls Courses Recognised? Although QLS courses are not subject to Ofqual regulation, they must adhere to an extremely high level that is set and regulated independently across the globe. A course that has been approved by the Quality Licence Scheme simply indicates that it has been examined and evaluated in terms of quality and fulfils the predetermined quality standards. When Will I Receive My Certificate? For CPD accredited PDF certificate it will take 24 hours, however for the hardcopy CPD certificate takes 5-7 business days and for the Quality License Scheme certificate it will take 7-9 business days. Can I Pay by Invoice? Yes, you can pay via Invoice or Purchase Order, please contact us at info@lead-academy.org for invoice payment. Can I Pay via Instalment? Yes, you can pay via instalments at checkout. How to Take Online Classes From Home? Our platform provides easy and comfortable access for all learners; all you need is a stable internet connection and a device such as a laptop, desktop PC, tablet, or mobile phone. The learning site is accessible 24/7, allowing you to take the course at your own pace while relaxing in the privacy of your home or workplace. Does Age Matter in Online Learning? No, there is no age limit for online learning. Online learning is accessible to people of all ages and requires no age-specific criteria to pursue a course of interest. As opposed to degrees pursued at university, online courses are designed to break the barriers of age limitation that aim to limit the learner's ability to learn new things, diversify their skills, and expand their horizons. When I Will Get the Login Details for My Course? After successfully purchasing the course, you will receive an email within 24 hours with the login details of your course. Kindly check your inbox, junk or spam folder, or you can contact our client success team via info@lead-academy.org

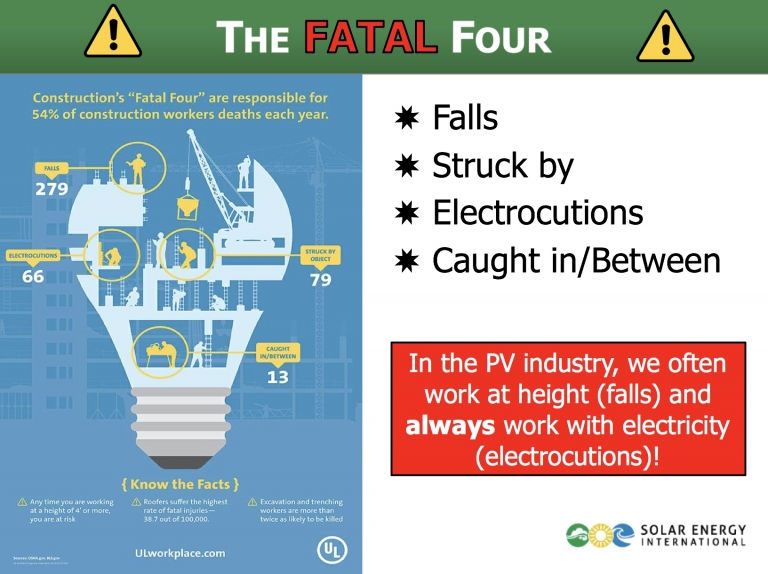

CE523: Residential/Commercial Roof-Mounted PV Installation Safety

By Solar Energy International (SEI)

This training includes four (4) three-hour lessons, for a total of 12 contact training hours. Each lesson will include presentations, videos, interactive exercises, and a quiz. 1- Ladder and Lift Safety: In this lesson, we learn about different ladder options and how to choose the appropriate ladder(s) for a PV installation, based on the specific job site and task (accessing different roof surfaces, running conduit, etc.). We discuss how to properly inspect, set up and use ladders, and through interactive exercises we evaluate different installation sites to determine the best location to set up an extension ladder to access the PV array. In the second part of this lesson, we identify equipment and methods for safely lifting PV modules (and other materials) to the roof, including ladder lifts, boom lifts, reach forklifts, scaffolding, and cranes. 2- Fall Protection: Here, we review OSHA fall protection requirements and present different equipment options for working safely AND efficiently on a PV job site. We discuss the differences between fall restraint, positioning, and fall arrest systems; look at different anchor options for roof surfaces commonly seen on PV installations; and via interactive exercises determine where to place those anchors on the roof. 3- PV Mounting Safety: In this lesson, we identify job site hazards specific to PV mounting work, from array layout through securing modules to the racking system. We go step-by-step through a roof-mounted PV installation and call out ways to eliminate and/or control hazards through safe work practices, engineering controls, and personal protective equipment (PPE). Through interactive exercises and videos, we show best practice methods to safely handle PV equipment and manage small parts on a sloped roof. 4- Solar Electric Safety: In the final lesson of this series, we take an in-depth look at electrical hazards specific to PV installation and maintenance work, and discuss the requirements of OSHA, the NEC, and NFPA 70E to assure safe working conditions. We discuss shock and arc flash hazards and identify protective measures (including PPE and lockout / tagout). We dive even further into lockout / tagout and safe electrical testing methods in our interactive exercises and videos.

Telephone Training - Cisco

By Telephone Trainers Ltd

78, 79, 88 and 99 series Handsets & Voicemail Cisco Call Manager (CCM) & Self Care Portal Jabber WebEx Meetings WebEx Training Centre WebEx Events Centre Attendant Console Standard and Advanced Console (ARC) UCCX/UCCE and Finesse Agent & Supervisor CUIC Reporting

Embark on a transformative journey into the world of modern manufacturing with our comprehensive Modern Manufacturing course. Delve into the cutting-edge technologies and advanced techniques that are revolutionizing the manufacturing industry, equipping yourself with the skills and knowledge to thrive in this dynamic field. Explore the intricacies of non-traditional machining processes, gaining in-depth understanding of electric discharge machining, electrochemical machining, abrasive jet machining, ultrasonic machining, laser beam machining, plasma arc machining, and electron beam machining. Discover the principles, applications, and advantages of each technique, mastering the art of selecting the most appropriate method for specific manufacturing tasks. Learning Outcomes Gain a comprehensive understanding of modern manufacturing principles and techniques Master the fundamentals of non-traditional machining processes Explore the principles, applications, and advantages of electric discharge machining Delve into the intricacies of electrochemical machining, abrasive jet machining, and ultrasonic machining Discover the power of laser beam machining, plasma arc machining, and electron beam machining Why choose this Modern Manufacturing course? Unlimited access to the course for a lifetime. Opportunity to earn a certificate accredited by the CPD Quality Standards and CIQ after completing this course. Structured lesson planning in line with industry standards. Immerse yourself in innovative and captivating course materials and activities. Assessments designed to evaluate advanced cognitive abilities and skill proficiency. Flexibility to complete the Course at your own pace, on your own schedule. Receive full tutor support throughout the week, from Monday to Friday, to enhance your learning experience. Unlock career resources for CV improvement, interview readiness, and job success. Who is this Modern Manufacturing course for? Aspiring and current manufacturing engineers seeking to enhance their skills and knowledge in modern manufacturing techniques Individuals interested in pursuing a career in manufacturing engineering or related fields Manufacturing professionals aiming to stay up-to-date with the latest advancements in manufacturing technology Anyone seeking to gain a comprehensive understanding of non-traditional machining processes Individuals interested in expanding their knowledge of modern manufacturing practices Career path Manufacturing Engineer (£35,000 - £55,000) Production Engineer (£40,000 - £60,000) Quality Control Engineer (£40,000 - £60,000) Process Engineer (£45,000 - £65,000) Manufacturing Manager (£50,000 - £70,000) Senior Manufacturing Engineer (£55,000 - £75,000) Prerequisites This Modern Manufacturing does not require you to have any prior qualifications or experience. You can just enrol and start learning.This Modern Manufacturing was made by professionals and it is compatible with all PC's, Mac's, tablets and smartphones. You will be able to access the course from anywhere at any time as long as you have a good enough internet connection. Certification After studying the course materials, there will be a written assignment test which you can take at the end of the course. After successfully passing the test you will be able to claim the pdf certificate for £4.99 Original Hard Copy certificates need to be ordered at an additional cost of £8. Course Curriculum Section 01: Introduction Introduction 00:05:00 Unconventional Machining 00:13:00 Types Of Energy 00:03:00 Section 02: Electric Discharge Machining Introduction 00:03:00 Principle And Working 00:11:00 Dielectric Medium 00:08:00 Tool And Wear 00:06:00 Parameters And Functions 00:10:00 Advantages And Applications 00:04:00 Process 00:06:00 Summary 00:02:00 Section 03: Electrochemical Machining Introduction 00:03:00 Principle 00:05:00 Working Mechanism 00:06:00 Tool And Electrolyte 00:13:00 Process Capabilities 00:06:00 Advantages And Applications 00:05:00 Process 00:02:00 Summary 00:02:00 Section 04: Abrasive Jet Machining Introduction 00:03:00 Principle 00:07:00 Setup And Components 00:07:00 Abrasives 00:07:00 Process Parameters 00:08:00 Material Removal Rate 00:09:00 Advantages and Applications 00:05:00 Process 00:02:00 Summary 00:03:00 Section 05: Ultrasonic Machining Introduction 00:02:00 Principle And Working 00:04:00 Machine And Elements 00:07:00 Abrasives 00:08:00 Material Removal Rate 00:10:00 Advantages And Applications 00:04:00 Process 00:03:00 Summary 00:03:00 Section 06: Laser Beam Machining Introduction 00:02:00 Principle 00:04:00 Types Of Laser 00:12:00 Working 00:06:00 Process Characteristics 00:08:00 Advantages And Applications 00:05:00 Process 00:03:00 Summary 00:03:00 Section 07: Plasma Arc Machining Introduction 00:02:00 Principle 00:06:00 Working System 00:07:00 Torches 00:12:00 Process Parameters 00:10:00 Advantages and Applications 00:06:00 Process 00:04:00 Summary 00:02:00 Section 08: Electron Beam Machining Introduction 00:03:00 Principle 00:05:00 Working And Mechanism 00:05:00 Major Components 00:08:00 Parameters And Characteristics 00:07:00 Advantages And Applications 00:05:00 Process 00:01:00 Summary 00:01:00 Section 09: The Finish Line Conclusion 00:01:00 Assignment Assignment - Modern Manufacturing 00:00:00

AZ-900T00 Microsoft Azure Fundamentals

By Nexus Human

Duration 1 Days 6 CPD hours This course is intended for This course is suitable for IT personnel who are just beginning to work with Azure. This audience wants to learn about our offerings and get hands-on experience with the product. This course primarily uses the Azure portal and command line interface to create resources and does not require scripting skills. Students in this course will gain confidence to take other role-based courses and certifications, such as Azure Administrator. This course combines lecture, demonstrations, and hands-on labs. This course will also help prepare someone for the AZ-900 exam. This course will provide foundational level knowledge on cloud concepts; core Azure services; and Azure management and governance features and tools. Prerequisites There are no prerequisites for taking this course. Familiarity with cloud computing is helpful, but isn't necessary. 1 - Describe cloud computing What is cloud computing Describe the shared responsibility model Define cloud models Describe the consumption-based model 2 - Describe the benefits of using cloud services Describe the benefits of high availability and scalability in the cloud Describe the benefits of reliability and predictability in the cloud Describe the benefits of security and governance in the cloud Describe the benefits of manageability in the cloud 3 - Describe cloud service types Describe Infrastructure as a Service Describe Platform as a Service Describe Software as a Service 4 - Describe the core architectural components of Azure What is Microsoft Azure Get started with Azure accounts Describe Azure physical infrastructure Describe Azure management infrastructure 5 - Describe Azure compute and networking services Describe Azure Virtual Machines Describe Azure Virtual Desktop Describe Azure Containers Describe Azure Functions Describe application hosting options Describe Azure Virtual Networking Describe Azure Virtual Private Networks Describe Azure ExpressRoute Describe Azure DNS 6 - Describe Azure storage services Describe Azure storage accounts Describe Azure storage redundancy Describe Azure storage services Identify Azure data migration options Identify Azure file movement options 7 - Describe Azure identity, access, and security Describe Azure directory services Describe Azure authentication methods Describe Azure external identities Describe Azure conditional access Describe Azure role-based access control Describe zero trust model Describe defense-in-depth Describe Microsoft Defender for Cloud 8 - Describe cost management in Azure Describe factors that can affect costs in Azure Compare the Pricing and Total Cost of Ownership calculators Describe the Microsoft Cost Management tool Describe the purpose of tags 9 - Describe features and tools in Azure for governance and compliance Describe the purpose of Microsoft Purview Describe the purpose of Azure Policy Describe the purpose of resource locks Describe the purpose of the Service Trust portal 10 - Describe features and tools for managing and deploying Azure resources Describe tools for interacting with Azure Describe the purpose of Azure Arc Describe Azure Resource Manager and Azure ARM templates 11 - Describe monitoring tools in Azure Describe the purpose of Azure Advisor Describe Azure Service Health Describe Azure Monitor Additional course details: Nexus Humans AZ-900T00 Microsoft Azure Fundamentals training program is a workshop that presents an invigorating mix of sessions, lessons, and masterclasses meticulously crafted to propel your learning expedition forward. This immersive bootcamp-style experience boasts interactive lectures, hands-on labs, and collaborative hackathons, all strategically designed to fortify fundamental concepts. Guided by seasoned coaches, each session offers priceless insights and practical skills crucial for honing your expertise. Whether you're stepping into the realm of professional skills or a seasoned professional, this comprehensive course ensures you're equipped with the knowledge and prowess necessary for success. While we feel this is the best course for the AZ-900T00 Microsoft Azure Fundamentals course and one of our Top 10 we encourage you to read the course outline to make sure it is the right content for you. Additionally, private sessions, closed classes or dedicated events are available both live online and at our training centres in Dublin and London, as well as at your offices anywhere in the UK, Ireland or across EMEA.

Transmission Lines: Design, Analysis and Applications

By EnergyEdge - Training for a Sustainable Energy Future

About this training course Transmission lines and sub-stations are essential components in the electrical power systems. Proper design and maintenance are crucial for transmission lines to maintain a continuous operation. The objective of this 5-day training course is to deal appropriately with control systems, design characteristics and electric & magnetic fields. Participants will gain a better understanding on the corona and gap discharge phenomena, constructional features, and optimization of the transmission lines. Training Objectives By participating in this course, you will be able to: Understand transmission line design and its application Examine different types of conductors and electrical characteristics Explore basic and general transmission line parameters Prevent overvoltage through insulation design Determine surge impedance and corona effects Calculate and measure electric and magnetic fields Comprehend the impact of audible noise and electromagnetic interference Identify interference within the transmission line systems Target Audience The course will greatly benefit the following groups but not limited to: Electrical Engineers Civil Engineers Transmission & Distribution Engineers Substation Operators Safety Engineers Reliability Engineers Facility & Plant Engineers Technical Engineers Design Engineers Plant Supervisors Electrical Contractors Course Level Basic or Foundation Intermediate Training Methods The training instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught in their own organization. Course Duration: 5 days in total (35 hours). Training Schedule 0830 - Registration 0900 - Start of training 1030 - Morning Break 1045 - Training recommences 1230 - Lunch Break 1330 - Training recommences 1515 - Evening break 1530 - Training recommences 1700 - End of Training The maximum number of participants allowed for this training course is 25. This course is also available through our Virtual Instructor Led Training (VILT) format. Trainer Your expert course leader is a professional engineer with extensive experience in power system studies, substation design field-testing, and EHS programs settings for Mining and Electrical Utilities sectors. He was formally the Engineering Manager at GE Canada in Ontario. He received his M.Sc. in electrical engineering from the University of New Brunswick and his MBA from Laurier School of Business in Waterloo. He has managed and executed more than 150 engineering projects on substation design EMF audits and power system studies and analyses, EMF audits and grounding audits, for major electrical utilities, mines, oil and gas, data centers, industrial and commercial facilities in Canada and the U.S. He is a certified professional engineer in the provinces of Ontario and Alberta. He has various IEEE publications, has served as a technical reviewer for many IEEE journals in power systems and control systems, and is the chair of the Industry Application Chapter (IAS) for IEEE Toronto Section. He remains a very active member for the IEEE substation committee of IEEE Std. 81 ground testing (WGE6) and IEEE Std. 80 ground design (WGD7). A certified electrical safety trainer by GE Corporate and a Canadian Standard Association (CSA) committee member at the mining advisory panel for electrical safety, he also taught many technical courses all over Canada to industrial customers, electrical consultants as well as to electrical utilities customers. Highlighted Projects: Various Power System Studies for 345/230 kV Stations - Nova Scotia Power (EMERA) RF audits for Telecom tower and antennas - Cogeco/Rogers Mobile Power System analysis - Powell Canada Structural/Geotechnical Design and upgrades - Oakville Hydro Underground Cables testing and sizing - Plan Group Relay programming and design optimization - Cenovus Canada Different Arc Flash Analysis and BESS Design - SNC Lavalin Environmental site assessment (ESA) Phase I/II for multiple stations - Ontario Electromagnetic compatibility (EMC) assessment for Toronto LRT expansion - MOSAIC Battery energy storage system (BESS) installation at City of London - Siemens Canada EMF audits for 500 kV Transmission Lines - Hydro One EMF audits for 500 kV Transmission Lines - Hydro Quebec AC interference for 138 kV line modeling and mitigations - HBMS Mine POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations