- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

The Ultimate Guide to Event Planning - 1 Day Workshop in Heathrow

By Mangates

Event Planning 1 Day Training in Heathrow

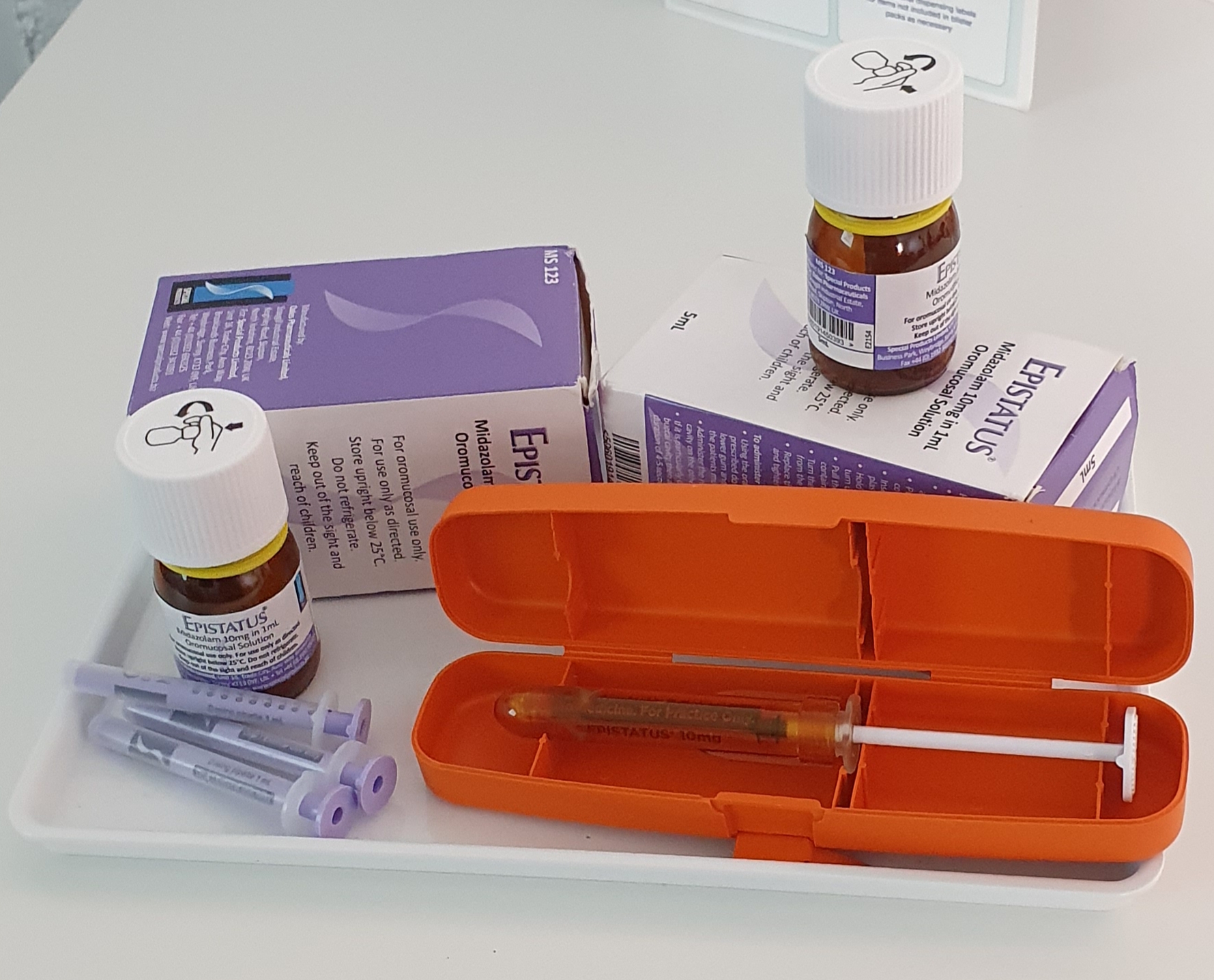

Epilepsy awareness Buccal medication training Seizure management course Epilepsy education program Neurological disorder training Emergency response to seizures Epilepsy care for healthcare professionals CPD accredited epilepsy course Nursing revalidation hours Healthcare professional seizure training Hands-on buccal administration practice Seizure recognition techniques Epilepsy management for caregivers Practical skills in epilepsy care Interactive epilepsy training sessions Expert instructors in epilepsy awareness Epilepsy impact on patients and families Effective communication in epilepsy care Real-life scenarios in epilepsy training High-quality epilepsy care certification

The “ISO 30414:2018 Lead Auditor” course provides comprehensive training for participants to be able to: Understand to audit each and every ISO 30414:2018 guidelines; Identify measurement opportunities; diagnose HR financial and operational measures, Quantify HR department’s contribution to the overall bottom line, through solid, factual, and verifiable data and analyze toughest workforce decisions with easy-to-use mathematical formulas. Learn fundamental auditing skills;

Stand Up for Yourself (Communication skills and assertiveness)

5.0(6)By The Sunflower Effect Confidence Courses

Are challenging people getting in the way of your happiness, well-being and success? You may find them at work, in social situations, you may live them or they may be members of your family? Even worse when you see them getting away with things; getting their way even though there is no sense to it; getting advantages over everyone else; and in many cases being rewarded for their abusive behaviour with promotion and other advantages! You probably would never want to behave the way they do. You don’t have it in you or you just couldn’t live with yourself if you behaved like that. Maybe your attempts to confront them have failed and you’ve ended up with egg on your face, with them having more opportunity to have a “dig” at you. As a result, you may have come to the conclusion that it’s the nasty people that get ahead, and someone like you just has to put up with this behaviour from others.

MA Filmmaking

By London Film School

An intensive two-year course with a School located in the heart of London, the MA Filmmaking trains to a professional level in a full range of filmmaking skills. Students leave with a portfolio of directing, cinematography, editing, producing, production design and sound credits. The school produces a huge output of films each year on this particular programme, many of which are screened at key festivals annually, previously winning many prizes, including at Locarno, Berlinale, Edinburgh, LaCinef (Cinéfondation). Learning is based on short film production and our students make a new film each term. Each term these film exercises become more technically sophisticated, more considered and more complex in their ambitions. The school specifies the skill base for each exercise, providing the equipment and training students to new levels in each of the various craft skills. Students make all aesthetic decisions while solving problems similar to those faced by professional units, on a steeply increasing slope of difficulty. The work is constantly assessed and critiqued. This is the core of the London Film School method. Students learn by applying themselves to aesthetic and practical problems generated by the actual process of filmmaking.

October In-Person 2025 Fundamentals of Organisation & Relationship Systems Coaching Training

By CRR UK

CRRUK equips professionals with the concepts, skills and tools to build conscious, intentional relationships, and to coach relationship systems of any size.

Search By Location

- Ski Courses in London

- Ski Courses in Birmingham

- Ski Courses in Glasgow

- Ski Courses in Liverpool

- Ski Courses in Bristol

- Ski Courses in Manchester

- Ski Courses in Sheffield

- Ski Courses in Leeds

- Ski Courses in Edinburgh

- Ski Courses in Leicester

- Ski Courses in Coventry

- Ski Courses in Bradford

- Ski Courses in Cardiff

- Ski Courses in Belfast

- Ski Courses in Nottingham