- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

389 PPE courses

PVOL304: Solar Training - Advanced PV Stand-alone System Design (Battery-Based) - Online

By Solar Energy International (SEI)

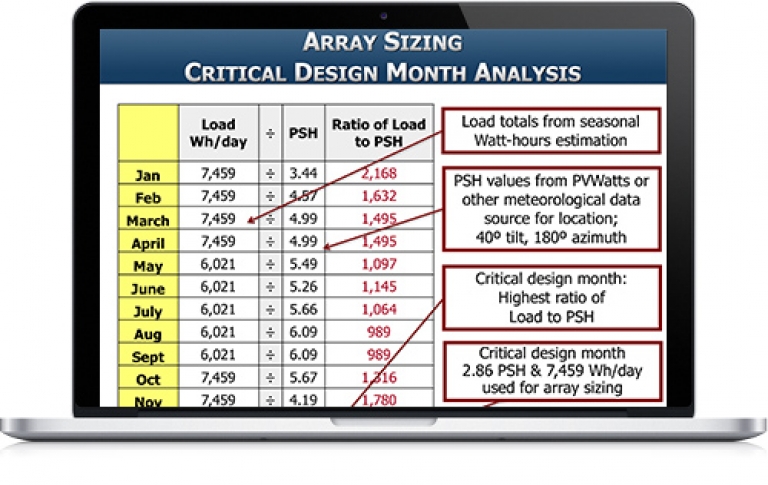

Define terms used in stand-alone systems Name common applications for stand-alone systems; describe basic component layouts Describe differences between AC and DC coupling State principle elements of a microgrid Define the importance of an accurate load analysis Review load analysis procedures; perform a load analysis based on daily data Review battery bank sizing for lead-acid and lithium-ion battery types Define array sizing variables and how they affect design for both MPPT and non-MPPT charge controllers Explain charge controller types and describe maximum power point tracking and voltage step-down Examine the calculations for PV array sizing Describe the difference between sizing for a non-MPPT and an MPPT charge controller Complete array configuration calculations for a system with a non-MPPT and an MPPT charge controller Summarize the parameters to check when selecting a charge controller Explain the purpose of DC load control and the three ways it can be implemented Identify design variables, advantages, and disadvantages of DC-only PV systems Describe how to size and integrate components for a recreational vehicle (RV) application Identify installation and maintenance considerations specific to mobile applications Identify applications and considerations for DC lighting systems Specify a battery-based inverter given electrical load and surge requirements Describe various configurations for stacking and clustering multiple inverters Examine inverter / charger size considerations Describe multiwire branch circuit wiring and concerns with single-phase supplies Describe the purpose and function of a generator Identify considerations that impact generator selection Solve for location-based performance degradation Specify a generator given electrical load, battery charging, and surge requirements Estimate approximate generator run time List generator maintenance Describe the National Electrical Code (NEC®) Articles that apply to the different parts of PV and energy storage systems (ESS) Identify NEC® requirements for workspace clearances, disconnects, and overcurrent protection devices (OCPD) that apply to PV systems Locate and apply specific requirements for storage batteries, stand-alone systems, and energy storage systems Identify labeling requirements List relevant building and fire codes Review installation considerations and best practices for stand-alone systems as related to batteries, design strategies, monitoring and metering, balance of system (BOS) equipment Review DC-coupled stand-alone residential system design Define operating modes of off-grid AC coupled PV systems Explain charge regulation of AC coupled PV inverters in a stand-alone system Discuss AC coupled PV system design strategies; evaluate equipment options for AC coupled off-grid applications Design a stand-alone microgrid system with PV (AC and DC coupled) and generator power sources Distinguish between isolated and non-isolated microgrids Compare concepts of centralized versus decentralized generation and controls Identify different types of microgrid analysis and planning software Review isolated microgrid use case examples Identify general PPE for battery system maintenance Develop a battery maintenance plan Identify methods to measure battery state of charge Identify common causes of battery problems and how to avoid them Identify PPE for lead-acid battery maintenance Develop a battery maintenance plan for lead-acid batteries Describe how to correctly add water to a flooded lead-acid (FLA) battery bank Identify methods to measure battery state of charge of FLA batteries Define when and why equalization is needed Identify common causes of battery problems and how to avoid them Note: SEI recommends working closely with a qualified person and/or taking PV 202 for more information on conductor sizing, electrical panel specification, and grounding systems. These topics will part of this course, but they are not the focus.

Platelet-rich Plasma (PRP) treatments Nationally Recognised Qualification No previous experience or qualifications needed Open College Network Accreditation Level 4 (as required for minimally invasive procedures) Covers standards set by HEE Employed (salon) or Self-Employed opportunities Basic understanding of English language required OPEN TO ALL APPLICANTS

Drawing techniques workshop with Thomasin Toohie

By Queen Street Gallery

Learn about line and form. Cover all aspects of tone. Make your pictures come alive with simple perspective tricks. Create realistic space. Introduction to shading.

Acrylic techniques workshop with Thomasin Toohie

By Queen Street Gallery

Acrylic techniques Learn how to handle acrylics. Useful colour hints. Painting from a subject. Impasto techniques. This workshop could be a follow on for you from the 'Drawing techniques' day.

Making Egg Tempera Paint with Natural Materials with Susan Mann

By Queen Street Gallery

This course is suitable for all. You will learn how to make your own egg tempera paint from natural pigments and produce your own 10 x 12 " painting. All materials are included in the price but please bring old clothes/apron.

Water colour techniques workshop with Thomasin Toohie

By Queen Street Gallery

Watercolour techniques. Learn how to put a basic wash down, including gradiations. Colour pallettes explained. Techniques of wet into wet painting How to create a convincing sky. How to master trees. An all round guide to the properties of this beautiful medium.

Imagine walking into a laboratory, equipped not just with your intellect but a robust understanding of safety measures. Our course, 'Chemical Hygiene and Engineering: Safety in Laboratories,' serves as your comprehensive guide to maintaining a risk-free environment in scientific settings. From understanding toxicology to mastering the effective use of Personal Protective Equipment (PPE), we've got you covered. The curriculum unfolds across six meticulous modules that delve into the most pressing issues of laboratory safety. Get a detailed walk-through of chemical hazards, learn about storage and handling protocols, and understand what it takes to establish a culture of safety in your workspace. Module 4 even focuses on engineering controls, offering insights into the equipment designed to safeguard you from chemical exposure. Learning Outcomes Gain comprehensive insights into the principles of chemical hygiene and engineering. Develop a deep understanding of chemical hazards and toxicology. Acquire mastery in chemical storage and handling protocols. Become proficient in the use of PPE and engineering controls. Establish a culture of best practices for laboratory safety. Why buy this Chemical Hygiene and Engineering: Safety in Laboratories? Unlimited access to the course for forever Digital Certificate, Transcript, student ID all included in the price Absolutely no hidden fees Directly receive CPD accredited qualifications after course completion Receive one to one assistance on every weekday from professionals Immediately receive the PDF certificate after passing Receive the original copies of your certificate and transcript on the next working day Easily learn the skills and knowledge from the comfort of your home Certification After studying the course materials of the Chemical Hygiene and Engineering: Safety in Laboratories there will be a written assignment test which you can take either during or at the end of the course. After successfully passing the test you will be able to claim the pdf certificate for £5.99. Original Hard Copy certificates need to be ordered at an additional cost of £9.60. Who is this Chemical Hygiene and Engineering: Safety in Laboratories for? Aspiring scientists aiming to conduct experiments in a laboratory setting. Lab technicians seeking to improve their understanding of workplace safety. Safety officers responsible for implementing lab safety measures. Chemistry teachers focused on instilling safety measures in educational settings. Regulatory compliance specialists aiming to update their lab safety knowledge. Prerequisites This Chemical Hygiene and Engineering: Safety in Laboratories does not require you to have any prior qualifications or experience. You can just enrol and start learning.This Chemical Hygiene and Engineering: Safety in Laboratories was made by professionals and it is compatible with all PC's, Mac's, tablets and smartphones. You will be able to access the course from anywhere at any time as long as you have a good enough internet connection. Career path Laboratory Manager: Average salary range £35,000 - £50,000 Safety Officer: Average salary range £30,000 - £45,000 Chemical Engineer: Average salary range £40,000 - £70,000 Lab Technician: Average salary range £20,000 - £30,000 Chemistry Teacher: Average salary range £30,000 - £45,000 Regulatory Compliance Specialist: Average salary range £40,000 - £60,000 Course Curriculum Module 01: Introduction to Chemical Hygiene and Engineering Introduction to Chemical Hygiene and Engineering 00:11:00 Module 02: Chemical Hazards and Toxicology Chemical Hazards and Toxicology 00:17:00 Module 03: Chemical Storage and Handling Chemical Storage and Handling 00:20:00 Module 04: Personal Protective Equipment (PPE) and Engineering Controls Personal Protective Equipment (PPE) and Engineering Controls 00:24:00 Module 05: Laboratory Safety and Best Practices Laboratory Safety and Best Practices 00:27:00 Module 06: Chemical Process Safety Chemical Process Safety 00:20:00

Commercial Mower Safety Online Training

By Compete High

ð¿ Mow with Confidence: Commercial Mower Safety Online Training! ð Elevate your commercial mowing operations with our comprehensive Commercial Mower Safety Online Training. Tailored for landscaping professionals, this program is designed to ensure the safety, efficiency, and longevity of your commercial mower operations. Join us on a journey where safety meets productivity, turning your workplace into a haven for precision mowing. ð Module 1: Introduction to Commercial Mower Safety Inspecting and Maintaining Kickstart your safety journey with Module 1, providing a comprehensive introduction to commercial mower safety, inspection, and maintenance. Learn the importance of regular inspections, identify potential hazards, and understand the critical role maintenance plays in ensuring a safe and efficient commercial mower operation. 𧤠Module 2: Safe Operating Procedures and PPE for Commercial Mower Operation Operate with confidence in Module 2, focusing on safe operating procedures and the use of Personal Protective Equipment (PPE). Master the art of safe mower operation, from startup to shutdown, and discover the essential role of PPE in minimizing risks and ensuring the well-being of operators. ð¾ Module 3: Understanding Terrain and Fueling Storage Practices for Commercial Navigate diverse terrains with Module 3, dedicated to understanding terrain and fueling storage practices. Learn how to assess different landscapes, adapt your mowing techniques, and implement proper fueling and storage practices to maintain a safe and environmentally friendly operation. ð ï¸ Module 4: Regular Inspections and Operator Training for Commercial Mowers Ensure ongoing safety with Module 4, focusing on regular inspections and operator training. Develop a systematic approach to inspections, empowering operators with the knowledge and skills needed to identify potential issues. Cultivate a culture of continuous improvement through operator training. ð¤ Module 5: Communication and Developing Teamwork for Commercial Mower Safety Harmonize your team in Module 5, emphasizing communication and teamwork. Explore effective communication strategies, build a collaborative team environment, and understand the pivotal role of communication in preventing accidents and ensuring a seamless mowing operation. ð Module 6: Assessing Commercial Mower Safety Continuous Improvement and Safety Culture Cap off your training with Module 6, where you'll focus on assessing commercial mower safety, continuous improvement, and fostering a safety culture. Learn to evaluate the effectiveness of safety measures, implement improvements, and instill a safety-first mindset within your team. ð Why Choose Our Commercial Mower Safety Online Training? Industry-Recognized Expertise: Learn from seasoned professionals with extensive experience in commercial mower safety. Accessible Online Learning: Conveniently access training materials online, allowing for flexible learning schedules. Interactive Modules: Engage in interactive modules, quizzes, and real-world scenarios to reinforce learning. Customizable Training: Tailor the training to your specific commercial mower operations for maximum relevance. Don't let safety be an afterthought in your commercial mowing operations! Enroll now in the Commercial Mower Safety Online Training and equip yourself and your team with the knowledge and skills needed to mow with precision and safety. Your journey to a safer and more efficient mowing operation begins here! ð¿â¨ð Course Curriculum Module 1 Introduction to Commercial Mower Safety Inspecting and Maintaining. Introduction to Commercial Mower Safety Inspecting and Maintaining. 00:00 Module 2 Safe Operating Procedures and PPE for Commercial Mower Operation. Safe Operating Procedures and PPE for Commercial Mower Operation. 00:00 Module 3 Understanding Terrain and Fueling Storage Practices for Commercial. Understanding Terrain and Fueling Storage Practices for Commercial. 00:00 Module 4 Regular Inspections and Operator Training for Commercial Mowers. Regular Inspections and Operator Training for Commercial Mowers. 00:00 Module 5 Communication and Developing Teamwork for Commercial Mower Safety. Communication and Developing Teamwork for Commercial Mower Safety. 00:00 Module 6 Assessing Commercial Mower Safety Continuous Improvement and Safety Culture. Assessing Commercial Mower Safety Continuous Improvement and Safety Culture. 00:00

Landscape in oils using palette knives with David Williams

By Queen Street Gallery

Introduction to palette knives, developing textures and depth in creating landscapes in oils. Learn key points in creating dynamic paintings using reference materials from the rural landscape of Neath. Teaching will be through demonstrating and one to one time with students.

Master the art of safe chainsaw operation with our comprehensive online course! From Chainsaw Basics to Advanced Techniques, learn essential skills, safety measures, and emergency procedures. Equip yourself with the knowledge to handle chainsaws confidently while prioritizing safety. Join now for a hands-on learning experience and become a proficient chainsaw operator.

Search By Location

- PPE Courses in London

- PPE Courses in Birmingham

- PPE Courses in Glasgow

- PPE Courses in Liverpool

- PPE Courses in Bristol

- PPE Courses in Manchester

- PPE Courses in Sheffield

- PPE Courses in Leeds

- PPE Courses in Edinburgh

- PPE Courses in Leicester

- PPE Courses in Coventry

- PPE Courses in Bradford

- PPE Courses in Cardiff

- PPE Courses in Belfast

- PPE Courses in Nottingham