- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

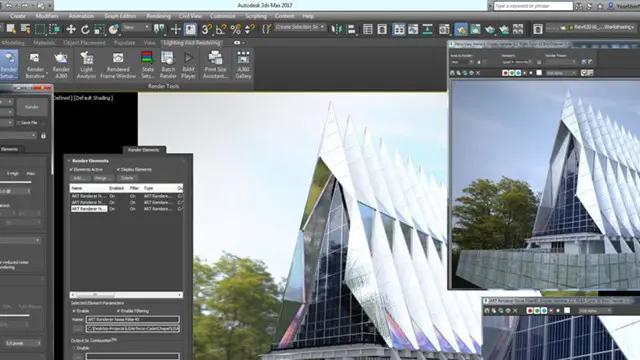

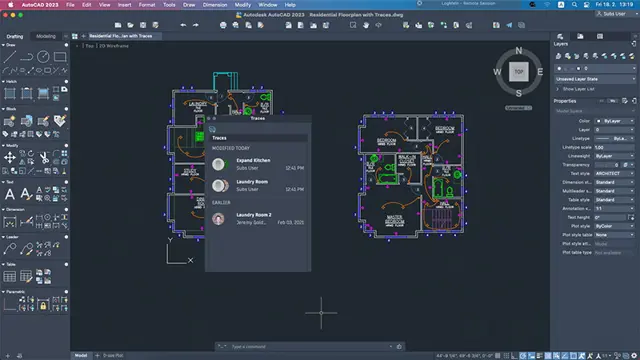

Autocad and 3ds max one day course one to one.

By Real Animation Works

Autocad face to face training customised and bespoke.

CAD Courses | Bespoke 1-2-1 in London

By Real Animation Works

Learn CAD in 10 hrs

Inclusive Leadership

By Mpi Learning - Professional Learning And Development Provider

Learn from two decades of specialist equality & inclusion expertise and the pitfalls to avoid, plus adventures in self-discovery. Participants enjoy the engaging and motivational style, building up the confidence to apply deepened insights and practical tools.

Intermediate Adobe InDesign Online

By Platform Training

During this 1 day Intermediate level InDesign course you will explore powerful layout and typographical controls, working with layers, creating multipage documents, using clipping paths and preparing for print. This course is ideal for anybody who already uses InDesign and wishes to progress to a professional level. Comprehensive colour management, typography and advanced graphics and effects are also covered.

Dealing with challenging customers (In-House)

By The In House Training Company

Wouldn't sales be a 'walk in the park' without challenging customers? Why is it that some customers are so difficult to please, so quick to call 'foul' at the slightest blip and so mean with their gratitude after we've bent over backwards to accommodate them? Whether we are looking at prospective or existing customers, there is a toolkit for dealing with the most challenging of them. This course will help participants: Use broad open questions to give the customer a platform for their opinions or issues Improve listening skills to really understand what's behind the customer's challenging style Probe specific phrases to show listening and earn deeper disclosure Use silence to let challenging customers 'blow off steam' Understand the negative impact of certain phrases on a challenging customer Summarise effectively and reassure the customer of our understanding of their needs Recognise the 'behaviour cycle' and avoid emotional escalation Understand 'transactional analysis' and how to bring people from 'child' to 'adult' state Create loyalty in customers who are slow to give trust 1 What makes a customer 'challenging'? Why customers challenge us - understanding their drivers 'Wearing their shoes' - seeing things from their perspective Understanding our own personality style How to flex with a style that is different from our own Ways to quickly recognise a customer's style The benefits of flexing with a challenging customer's style 2 Practical exercise - forum theatre Participants take it in turns to deal with the trainer (who plays the role of the challenging customer) Observers stop the action when they hear or see something they deem wrong The participant in the seat gets a chance to use a suggested alternative line The participant who makes the suggestion has the chance to occupy the seat and deliver it themselves Frequent feedback from the trainer as to how the participant's words are making him feel Opportunities to rewind the action if an ill-advised line is suggested and delivered Flipchart for capturing what worked, what didn't work and why Mehrabian principle - the importance of body language and tone over words used 3 Questioning and listening skills How to use open questions to get the customer talking What questions to avoid and why The use of pauses and silence to reduce tension and build trust What listening is and what it isn't Question funnelling - how to earn deeper disclosure through probing The power of summary 4 Transactional analysis explained What is transactional analysis (TA)? Exploring the TA states and why people behave in that way under pressure How to bring challenging customers to 'adult' state to reduce tension How 'parent' or 'child' behaviours can be inadvertently triggered Understanding the 'behavioural cycle' and how to break it Mini-role play 'vignettes' to demonstrate real time impact of ill-chosen words 5 How to build trust with challenging customers Techniques for placating current challenging customers Methods that the participants have already used effectively - understanding why those methods worked and how other participants can model them Participants' experiences of trust having been lost - understanding why those experiences had that negative outcome How to 'go the extra mile' with challenging customers 6 Bringing a 'real' challenging customer to life Participants give the trainer a brief profile of a specific challenging customer of theirs 5-10 minute roleplay in which the trainer brings that individual to life Observing participants - without interrupting - make notes on what is and isn't working Trainer stops the action half-way through to give feedback on how he is feeling Participant goes back into the roleplay having recalibrated their approach based on feedback Observers give feedback on what did and didn't work Trainer comes out of character to explain the impact of the participant's words and behaviours 7 Wrap-up Key learnings from each participant Individual action planning - steps that can and will be implemented in the workplace

Finance for project managers and engineers (In-House)

By The In House Training Company

What do engineers and project managers need to know of finance? 'Nothing - leave it to the accountants!' No, no, no! Engineers must be conversant with the terminology and statements that accountants use. Technical expertise in projects, service delivery, production or other areas can only really be harnessed if the managers understand the accounting and reporting that drives businesses. This course gives the necessary understanding to project, production and technical managers. It develops their skills in understanding financial and management accounting. Accountants may not always like it but a major part of their work is to be the 'servants of business' and to gather, compile and present your figures. So you must understand the figures - they belong to you, your processes or projects. There are many reasons for maintaining accurate accounts. This course focuses on the strategic issues (those over-used words) - what figures reveal about the drivers of business and what they reveal about the day-to-day issues that accountants bother you with. The course will enhance your understanding of finance and of the accounting issues which affect your projects, production and technical areas of business. This course will help you: Understand the business world in figures - make sense of what the accountants are telling you Appreciate what drives business - and how this affects your role in your part of the business Relate your activities to the success of the business - through figures Gain the skills to advance in management - financial awareness is a 'must have' if you are to progress in your career 1 What do accountants do? The finance function, types of accountant, financial v management accounting and the treasury function Understanding the role of the finance function and how the information you provide may be used 2 The basic financial statements Balance sheets and income statements (P&L accounts) What they are, what they contain and above all what they can reveal - how to read them The accounting process - from transactions to financial statements What underpins the statements - accounting systems and internal controls 3 Why be in business - from a financial perspective The driving forces behind financial information Performance measures - profitability, asset utilisation, sales and throughput, managing capital expenditure 4 Accounting rules - accounting standards Accounting concepts and the accounting rules: accruals, 'going concern' - substance over form and other 'desirable qualities' Accruals - why the timing of a transaction is so important to the finance function Depreciation and amortisation - the concepts and practice Accounting standards - the role of International Financial Reporting Standards 5 Cash The importance of cash flow - working capital management Cash flow statements - monitoring overall cash flows Raising cash - levels of borrowing, gearing Spending cash - an outline of capital expenditure appraisal 6 Budgeting Why budget? - good and bad practice Determining why budgets play a key role and should not be simply an annual ritual Justifying your budgets - the link between the strategic plan and day-to-day budgeting - alignment of company culture Budgets as motivators - the importance of the right culture Techniques to improve budgeting - whether day-to-day or capital budgeting 7 Costing The type and detail of costing very much depends on your business - eg, manufacturing piston rings is quite different from the construction of a power plant Issues with overhead allocation Accounting for R&D 8 Reading financial statements Annual financial statements - why they are produced, what's in them and what you should look for Learning what a set of accounts reveals about a company's current situation, profitability and future prospects 9 Performance measurement - analytical reviews and ratio analysis ROI/ROCE Profitability, margins and cost control Sales - asset turnover Efficiency (asset / stock turnover, debtor / creditor days) 'City' measures Investment (interest / dividend cover, earnings per share, dividend yield)

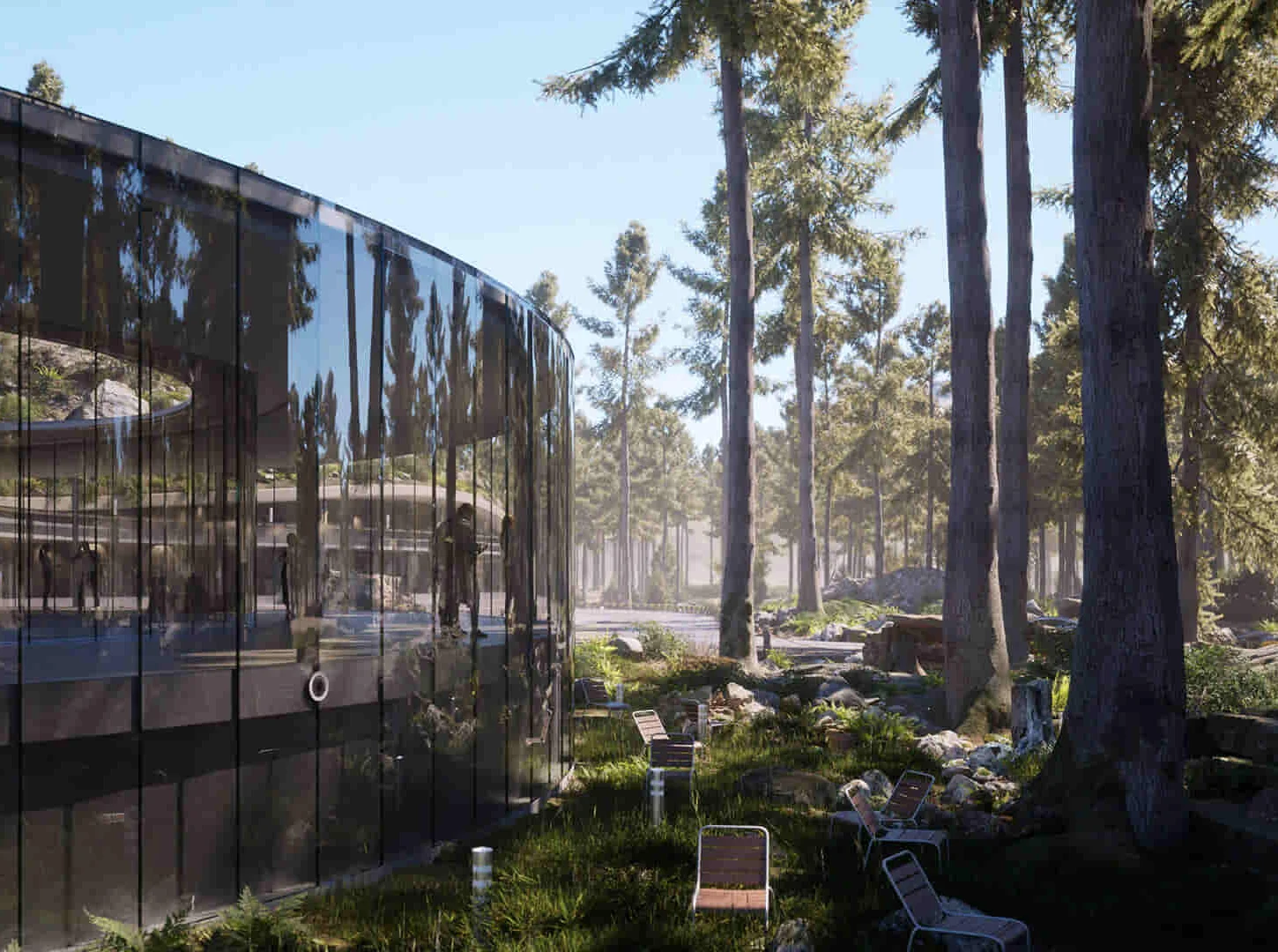

Lumion Training Course

By ATL Autocad Training London

Who is this coure for? Lumion Training Course. Whether you're an architect, designer, 3D artist, or simply someone passionate about crafting captivating architectural visualizations, this course equips you with the essential skills to harness Lumion as a potent tool within your creative process. Click here for more info: Website Duration: 10 Hours Customize your training. Choose any hour from Mon to Sat, 9 a.m. to 7 p.m. Call 02077202581 or WhatsApp at 07970325184 to book. Lumion 3D Course Outline Module 1: Introduction to Lumion 3D Explore Lumion 3D's Features and Navigate the Interface. Master Efficient Workflow with Shortcut Keys. Customize Settings for Optimal Performance. Module 2: 3D Models and Materials Import 3D Models in Various Formats. Apply and Fine-Tune Materials. Create Procedural Materials and Achieve Glass Effects. Troubleshoot Common Issues. Module 3: Building Projects in Lumion Craft Scenes and Sculpt Terrain. Enhance Realism with Alpha and Height Maps. Module 4: The 3D World Manage Multiple 3D Objects and Their Properties. Implement Grass and Scattering Elements. Module 5: Lighting in Lumion 3D Utilize Weather Settings for Dynamic Scenes. Master Lumion Lights, Interior and Exterior Illumination. Create 3D Reflections and Spotlight Effects. Module 6: Realistic Visualizations Integrate Special Effects like Fire, Smoke, and Fog. Achieve Realism with Camera Effects and Shadow Manipulation. Render Still Images and Dynamic Animations. Module 7: NPR Visualizations Create Non-Photorealistic Visualizations with Artistic Effects. Implement Unique Styles for Enhanced Visual Impact. Module 8: Artistic Effects in Lumion 3D Explore Conceptual Visualizations with Painting and Sketch Effects. Craft Cartoon Effects and Understand Perspective Concepts. Module 9: Animation in Lumion 3D Master Timing and Camera Techniques for Dynamic Shots. Compose Animation Clips and Incorporate Effects. Utilize Layers and Control Objects for Precise Animation. Module 10: Advanced Features Understand Import and Output Formats in Lumion. Expand Your Asset Library with the 3D Model Library. Integrate Animated Characters and Sound Effects. Maximize the Advanced Material Library's Potential. Control Environments and Weather for Dynamic Scenes. Efficient Scene Management and Movie Editing in Lumion 3D. For students, download Lumion at: Lumion for Students Download Lumion for Students https://lumion.com⺠Upon completing the Lumion 3D course, participants will: Master Lumion Tools: Navigate the interface, optimize settings, and use shortcuts efficiently. 3D Modeling and Materials: Import models, refine materials, troubleshoot, and enhance realism. Scene Crafting: Create detailed scenes, manage objects, and implement elements for lifelike environments. Lighting Mastery: Utilize weather settings, create reflections, and manage dynamic lighting. Visual Effects Integration: Add special effects, manipulate shadows, and create still images and animations. Artistic Visualization: Explore artistic effects, conceptual visualizations, and cartoon techniques. Advanced Animation: Master timing, camera techniques, and precise animation control. Advanced Features: Understand formats, expand asset libraries, and manage scenes efficiently. Effective Communication: Communicate design concepts effectively to clients and stakeholders. Independence in 3D Rendering: Gain expertise to create complex visualizations independently. Course Overview: What is Lumion? Lumion is specialized 3D rendering software designed for architects and designers. It enables the swift transformation of 3D design models, allowing application of materials, interior and exterior furnishing, and showcasing lighting and shadows without specialized training. Course Objectives: This course focuses on initiating Lumion projects, integrating environments, cameras, lighting, populating scenes, creating terrains, and producing animations. Expectations from the Course: By enrolling, you'll master high-quality render creation, enhance your portfolio, impress clients with top-tier visuals, and gain confidence to elevate your service rates. This course equips you with tools and skills to craft exquisite architectural renders, elevating your work significantly. Intended Audience: Architects, landscape architects, interior architects, civil engineers interested in 3D visualization, and students exploring the realm of 3D visualization. Course Benefits: Delve into Lumion's world-class rendering with speed and precision. This course emphasizes achieving superior quality and realism in the shortest rendering time. Whether you're an architect, interior designer, 3D visualization artist, or Lumion enthusiast, this course empowers you to create exceptional 3D render images. Essential assets, including 3D models and textures, are provided, allowing you to follow the step-by-step process at your own pace. Advantages of Personalized Training: Expertise in Real-Time Rendering: Gain in-depth mastery of Lumion, mastering its features for creating stunning real-time visualizations. Navigate the interface seamlessly and leverage powerful tools for immersive architectural experiences. Enhanced Design Presentations: Elevate design presentations with dynamic visualizations that effectively communicate concepts, lighting nuances, material details, and spatial relationships. Rich Asset Repository: Access a wide variety of high-quality assets, from vegetation to weather effects, enhancing realism and creating captivating scenes that engage viewers. Authentic Landscapes and Effects: Develop skills to create lifelike landscapes, atmospheric weather effects, and unique visual elements that add depth and intrigue to your projects. Flexible Learning Options: Choose between in-person or live online sessions, ensuring convenient and accessible learning tailored to your preferences. Additionally, access recorded lessons for self-paced review and revision. Continuous Support: Benefit from lifelong email support, allowing you to stay connected with instructors for ongoing learning and guidance, even after completing the course.

Twinmotion Training Course

By ATL Autocad Training London

Who is this course for? Twinmotion Training Course. The Twinmotion course is designed for architects, interior designers and urban planners. Learn how to create architectural visualizations and real-time animations. Students interested in exploring the world of architectural rendering and visualization using Twinmotion software. Click here for more info: Website Duration: 10 hours Approach: 1-on-1 training with tailored content. Schedule: Book a time that suits you, Mon to Sat, from 9 am to 7 pm, and create your own schedule. Course Outline for Twinmotion Real-time 3D Architecture Visualization: Module 1: Twinmotion Introduction Explore the real-time 3D visualization capabilities of Twinmotion Master efficient scene manipulation through the Twinmotion interface Prepare 3D files for import and manage the workflow effectively Module 2: Materials and Realism Enhancement Enhance scenes with realistic materials and elevate visual quality Utilize videos as materials and apply glowing effects Create grunge materials to add texture and realism Employ the X-ray material for specific visualization needs Module 3: Landscape and Vegetation Integration Integrate vegetation using Twinmotion's scatter, HQ trees, and growth features Customize grass and utilize HQ vegetation assets for realistic landscapes Create time-lapse effects for dynamic vegetation growth Module 4: Library and Object Management Access the Twinmotion library for furniture and objects Seamlessly import external 3D objects into your scenes Obtain high-quality 3D assets from the internet and add them to your user library Utilize BIM-objects for additional assets Module 5: Lighting and Animation Techniques Work with various lighting options, including area light and volumetric light, to enhance scenes Add animated characters and vehicles to infuse dynamism into your visuals Incorporate construction vehicles and aircraft for realistic scenes Module 6: Volumes and Interactive Elements Utilize volumes and the animator feature to create dynamic scenes Implement urban elements and measurement tools for precision and accuracy Module 7: Nature and Weather Effects Utilization Harness Twinmotion's nature features, such as physical sky and weather effects, to create lifelike outdoor scenes Establish realistic lighting for outdoor environments Add ocean effects to enhance water elements in your scenes Module 8: Advanced Rendering Techniques Master rendering processes, from creating images to exporting panoramas and animations Implement depth of field improvements to create visually captivating scenes Create BIM motion virtual reality phases for immersive experiences Utilize the Twinmotion presenter feature for seamless presentations Module 9: Final Project Apply acquired knowledge and skills to complete a final rendering project in Twinmotion Download Twinmotion https://www.twinmotion.com ⺠download Learn how to download and install Twinmotion, the fast, easy real-time archvis tool. Learning Outcomes of Real-Time Rendering: Efficient Scene Creation: Rapid development of immersive 3D environments using essential tools and techniques. Realistic Material Application: Expertise in applying authentic textures and shaders for visually convincing scenes. Dynamic Lighting: Understanding dynamic lighting effects for visually compelling, realistic scenes. Interactive Elements: Integration of animations and dynamic objects for engaging user experiences. Performance Optimization: Optimizing assets and scenes for smooth real-time rendering across diverse hardware. Library Utilization: Efficient use of asset libraries to enhance scene complexity without compromising performance. Visual Effects: Application of weather conditions, particle systems, and post-processing effects for stunning environments. Collaborative Rendering: Mastering real-time collaborative rendering techniques for teamwork and live interactions. Future Trends in Real-Time Rendering: Ray Tracing Advancements: Real-time ray tracing for realistic lighting, shadows, and reflections. AI-Powered Rendering: AI-driven predictive rendering for faster, high-quality outcomes. Immersive Experiences: Real-time rendering enabling immersive simulations in gaming, education, and architecture. Cross-Platform Compatibility: Seamless experiences across devices, from gaming consoles to VR headsets. Blockchain Integration: Blockchain tech ensuring asset authenticity and ownership verification. Real-Time Cinematography: Revolutionizing film and animation with efficient real-time visual effects. Environmental Sustainability: Focus on energy-efficient algorithms for reduced environmental impact. Collaborative Design: Real-time rendering facilitating interactive design reviews and creative collaboration. Twinmotion Course: Expertise in Real-Time Visualization: Develop mastery in Twinmotion, enabling the creation of captivating architectural environments in real-time. Improved Design Communication: Enhance concept communication by utilizing dynamic visualizations, elevating the quality of design presentations. Access to High-Quality Assets: Utilize an extensive library of premium assets to enrich scenes, adding realism and creativity to your projects. Crafting Lifelike Environments: Learn to create realistic landscapes, water effects, weather conditions, and special effects, providing immersive and lifelike experiences. Flexible Learning Options: Choose between in-person or live online sessions, ensuring a personalized and convenient learning experience tailored to your needs. Lifetime Access and Support: Benefit from perpetual access to lesson recordings and receive continuous support through lifetime email assistance, allowing you to stay connected with knowledgeable instructors for ongoing guidance. Course Advantages: Mastery of Real-Time Visualization: Acquire expertise in Twinmotion for creating captivating architectural environments. Enhanced Design Communication: Improve concept communication through dynamic visualizations, elevating design presentations. Abundant High-Quality Assets: Utilize an extensive library of top-notch assets, enriching scenes with realism and creativity. Creation of Lifelike Environments: Craft realistic landscapes, water effects, weather conditions, and special effects for immersive experiences. Flexible Learning Options: Choose between in-person or live online sessions, ensuring a personalized and convenient learning experience. Lifetime Access and Support: Enjoy perpetual access to lesson recordings and receive continuous support through lifetime email assistance, staying connected with knowledgeable instructors.

Search By Location

- Power Courses in London

- Power Courses in Birmingham

- Power Courses in Glasgow

- Power Courses in Liverpool

- Power Courses in Bristol

- Power Courses in Manchester

- Power Courses in Sheffield

- Power Courses in Leeds

- Power Courses in Edinburgh

- Power Courses in Leicester

- Power Courses in Coventry

- Power Courses in Bradford

- Power Courses in Cardiff

- Power Courses in Belfast

- Power Courses in Nottingham