- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

388 Organisation courses in Bristol

Exploration & Production (E&P) Accounting Level 3

By EnergyEdge - Training for a Sustainable Energy Future

About this training course This highly interactive 5-day training is aimed at those who wish to take their E&P accounting skills to a more advanced level than our introductory course, E&P Accounting - Level 1, and our intermediate course, E&P Accounting - Level 2. It will help equip you for more demanding analytical roles within your organisation. Training Objectives After the completion of this training course, participants will be able to: Carry out and manage the day-to-day financial accounting activities associated with participation in E&P joint ventures Prepare, analyse and present information for effective financial reporting Understand the impact of a comprehensive range of activities on the financial statements of an upstream oil and gas company Practically apply IFRS in accounting for a wide range of typical oil and gas industry activities Target Audience This is an advanced level course designed for: those who have already attended E&P Accounting - Level 1 and E&P Accounting - Level 2, or those who can demonstrate, by a combination of relevant experience and previous study, sufficient prior knowledge to contribute and benefit from attending this workshop Course Level Advanced Training Methods Training Method - Scenario Based Learning Learning centers around highly realistic E&P company scenarios. A computer-based simulation is used to plan, record and report the progress of your company through several years of international E&P activities. Teams of 2 - 3 people participate in the financial management of these activities, including Operator and Non-operator accounting, recording of transactions, updating of financial statements and analysis of results. The highly interactive laptop-based scenario approach will enable you to follow the impact of each activity from initiation through to final results and analysis of company performance. You will need to bring with you to the course your own laptop PC with MS Excel⢠pre-installed. Prior knowledge of spreadsheet techniques is assumed. Trainer will provide various Excel files which participants may retain at the end of the course. Course Duration: 5 days in total (35 hours). Training Schedule 0830 - Registration 0900 - Start of training 1030 - Morning Break 1045 - Training recommences 1230 - Lunch Break 1330 - Training recommences 1515 - Evening break 1530 - Training recommences 1700 - End of Training The maximum number of participants allowed for this training course is 25. Trainer Your expert course leader has more than 30 years of experience in the international oil and gas industry, covering all areas of Finance and Audit, including involvement in Commercial roles. During her 19 years with ENI she worked in Italy, Netherlands, Egypt and UK and was CFO for 2 major ENI subsidiaries. She has delivered training courses in Accounting, Audit, Economics and Commercial topics in many Countries. She has a Degree in Economics & Accounting and is a Certified Chartered Accountant. She is also a Chartered Auditor and an International Petroleum Negotiator. Outside of work, she is inspired by the beauty of nature and art, helping disadvantaged people, sports (football, golf) and her cat. Courses Delivered Internationally: E&P Accounting, Auditing in the Oil & Gas Industry Cost Control & Budgeting Introduction to the Oil & Gas Industry Petroleum Project Economics Contracts Strategy International O&G Exploitation Contracts POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Leadership & Team Dynamics in Oil & Gas

By EnergyEdge - Training for a Sustainable Energy Future

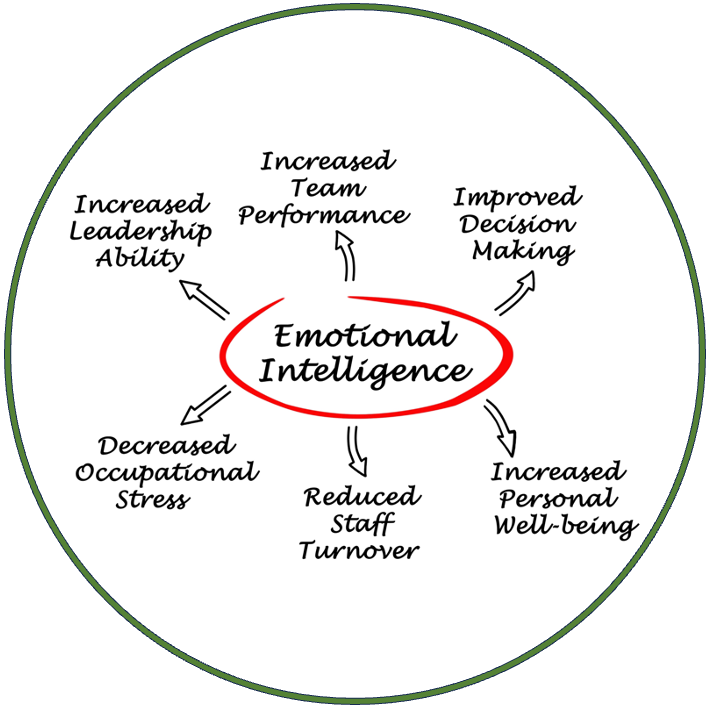

About this Training Course One of the main challenges for today's managers is effectively leading and successfully communicating vision that inspires employees to perform. Good leadership engages people and employees who feel both engaged and enabled contribute to higher levels of growth and productivity. They will remain longer with the organisation, perform better and ultimately deliver better service to your customers. This popular 3 full-day course will equip you with key skills that you can utilise to maximise your staff's performance in line with the company's objectives. This interactive course will also empower you with strategic approaches to overcome the people challenges that you may encounter while enabling you to optimise your business strategies successfully. An ILM Recognised programme. Training Objectives What are the benefits that you will gain from attending this course? * Enhance your personal effectiveness and decision-making * Learn how to boost your influencing capability * Inspire enthusiasm, motivation and commitment * Communicate effectively across a multi-cultural team * Nurture your relationships and strengthen your team * Develop an empowering partnership team culture Target Audience Who should attend this course? Anyone involved in leading a business unit or a project team can attend. It covers relationships with host governments, contractors, suppliers and local communities which constitute critical alliances for the development of a project. This course is essential for team leaders, supervisors or managers from the following functions: Project management engineers from various technical disciplines Ad-hoc or special project team leaders in legal, technical & financial disciplines Country managers or business development officers of contractors JV management executives or officers Government officials or industry liaison officers Procurement or contracts executives or officers Trainer Your course leader is the author of Spirit IntelligenceTM and specialises in executive leadership facilitation and management development. He gained a first class honours degree in chemical engineering from Edinburgh University in Scotland and has undertaken postgraduate studies in psychology at Macquarie University in Sydney, Australia. Your course leader's corporate career spanned 14 years in Oil and Gas with BP, Amoco and AGL. Since 1993, he has worked across five continents with more than 170 clients including Rothschild, QBE, AT&T, Intel, Towers Perrin, Thomas Cook, Fujitsu, Nortel, Frank Russell, Electrolux, Arab Bank, Cable and Wireless, GSK, Merck, Sharpe and Dome, World Vision, Ericsson, IBM, Placer Dome Gold, Jim Beam, Ernst & Young and Commonwealth Bank of Australia. He focuses on what he calls tapping The Hidden Advantage to unleash the power of the whole person - the power of the body and mind, the passion of the emotions and the enthusiasm, motivation, commitment, initiative, creativity, resilience and persistence of the spirit in business. He is very experienced internationally in both skills enhancement and the strategic facilitation of tough and intractable client challenges. His approach is pragmatic. He provides his clients with a powerful range of practical tools and approaches to enable management to tap The Hidden Advantage latent in their staff and achieve optimum performance and results. A powerful and compelling speaker, he combines humour, energy and passion. He draws on a wealth of personal experience and thorough research. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Reliability Centred Maintenance

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course In today's business environment, there has never been more of a need to make Asset Management and Maintenance more cost effective and efficient. By utilising the Reliability Centred Maintenance process (RCM), you can increase safety performance, reduce maintenance costs, improve the effectiveness of your operations, boost machine uptime, and gain a greater understanding of the level of risk your organisation manages. RCM is just one component of an overall integrated Asset Management Process. All participants will complete detailed pre-course questionnaires before this 3 full-day course, enabling the trainer to tailor course content in order to meet specific delegate needs. Participant objectives are re-visited before, during and after the course, allowing the trainer to focus on outcomes and address any participant concerns and specific issues during the program. Training Objectives At the end of this course, participants will be able to: Develop skills to carry out successful RCMs and introduce the RCM process into their own and their company's daily activities. Be aware of our changing business environment and the need to apply RCM to drive continuous improvement, in safety, cost reduction, and minimise their environmental footprint Understand the impact of human reliability and the various methods used to improve this important area Understand the basics of Change Management and the methods used to securely anchor this process and make it routine Develop an appreciation for a holistic 'Asset Management' program, and know where the RCM process fits in, and the benefits it will deliver Target Audience Reliability Centred Maintenance is primarily a team activity and benefits from a cross functional team participation. This course is aimed at managers, engineers, technicians and operators at all levels who are responsible for the operation and maintenance of plant equipment and who will benefit from the elimination of bad actors (recurring equipment failure) and continuous improvement in the areas of safety, environmental impact, reliability and integrity. Trainer Your expert course leader has enjoyed a 37-year career with Shell International in a variety of leadership roles predominantly in Turnaround, Maintenance and Engineering Management before he left in late 2017 to pursue his interest in Turnaround and Maintenance Management consultancy. He has undertaken several Asset Management and Engineering positions within Shell Australia including the implementation and establishment of formal Reliability Studies including FMEA, RCA, RCM, Maintenance Planning and Turnaround Management programs at Geelong Refinery. Additionally, he was appointed Shell's Regional Turnaround Advisor within Australia and South East Asia supporting Shell Operating Companies throughout several Australasian and European sites. In more recent times, he had been engaged to implement and establish a formal Turnaround Management program within Brunei Shell Petroleum as well as becoming the appointed Regional Turnaround Management Subject Matter Expert (SME), TA Network and Governance & Assurance lead for Shell within the Shell Australasian, Russian Federation and Indian Sub-Continent OpCo community. His career repertoire includes hands-on practitioner, supervisory, reliability, contracts and management roles and he holds several maintenance and engineering tertiary qualifications including an Associate Diploma in Mechanical Engineering. He has presented at several Maintenance, Reliability, Asset Management & Turnaround forums and conferences. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Good Induction Practices

By SAVO CIC

Often your recruitment and induction processes determine whether you retain your staff and volunteers. A poor induction often leads to a lack of productivity and motivation. This half day course is designed to help participants ensure that new staff receive a comprehensive and welcoming induction so that they can settle into their job or role quickly and with confidence. The course can be run as a one-off session or can be incorporated into a series of sessions on managing staff.

Leadership Skills

By Step Into Learning

Individuals with great leadership skills empower teams to achieve their full potential, make decisions, and stategise well to help organisations thrive. This course provides the knowledge and skills to help you hone your leadership skills.

Auditing in the Exploration & Production (E&P) Industry Level 1

By EnergyEdge - Training for a Sustainable Energy Future

About this training course This 3-day introductory-level course provides a comprehensive overview of Auditing in the Exploration & Production (E&P) industry. It is suitable for anyone who wants to gain a broader understanding of Upstream Oil & Gas Auditing - including joint venture, financial and contractual audits by government and regulatory authorities in the various granting regimes (Production Sharing Contracts, Risk Service Contracts, Concessionary). Training Objectives After the completion of this training course, participants will be able to: Gain knowledge of the unique features or key phases of the E&P Business Understand the general principles and objectives of the various different types of Upstream Oil & Gas audits Add value to your organisation by improving your audit techniques and auditing skills Review the importance of following process in order to avoid costly audit related findings. Utilize industry specific examples and exercises, develop your understanding of the most common E&P industry audit issues Target Audience This training course is suitable and will greatly benefit the following specific groups: Audit staff who are new or relatively new to the industry and who require a grounding in the various aspects of E&P Audit Finance or Accounting personnel involved in supporting audits Staff from a wide range of other business functions who are connected to / impacted by audit, such as, Supply Chain, Operations, Contracts Holders, IT, Tax and Treasury Topics will be covered from both the perspective of being part of an audit team plus that of the team being audited. Therefore, the course will appeal to staff from IOC's, NOC's and those from Government and/or Regulatory Authorities. Course Level Basic or Foundation Training Methods The training instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught in their own organization. Course Duration: 3 days in total (21 hours). Training Schedule 0830 - Registration 0900 - Start of training 1030 - Morning Break 1045 - Training recommences 1230 - Lunch Break 1330 - Training recommences 1515 - Evening break 1530 - Training recommences 1700 - End of Training The maximum number of participants allowed for this training course is 25. This course is also available through our Virtual Instructor Led Training (VILT) format. Trainer Your expert course leader has more than 30 years of experience in the international oil and gas industry, covering all areas of Finance and Audit, including involvement in Commercial roles. During her 19 years with ENI she worked in Italy, Netherlands, Egypt and UK and was CFO for 2 major ENI subsidiaries. She has delivered training courses in Accounting, Audit, Economics and Commercial topics in many Countries. She has a Degree in Economics & Accounting and is a Certified Chartered Accountant. She is also a Chartered Auditor and an International Petroleum Negotiator. Outside of work, she is inspired by the beauty of nature and art, helping disadvantaged people, sports (football, golf) and her cat. Courses Delivered Internationally: E&P Accounting, Auditing in the Oil & Gas Industry Cost Control & Budgeting Introduction to the Oil & Gas Industry Petroleum Project Economics Contracts Strategy International O&G Exploitation Contracts POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Process Safety Management & Engineering Applications

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This 5 full-day course covers all the main elements of IChemE's Process Safety Competency framework: culture, knowledge and competence, engineering and design, human factors, systems and procedures, and assurance. Participants will achieve at least the second level of competence 'Basic Application', which is defined as 'Performs fundamental and routine tasks. Requires occasional supervision. Increased functional expertise and ability. Works with others.' This course examines the interrelation of the various techniques of process safety for analysing and managing process hazards in the hydrocarbon and chemical processing industries. There is a particular emphasis on engineering design aspects with extensive participation in individual and group exercises, tutored exercises and video case studies throughout the course to underpin key learning points. The learning is consolidated in a comprehensive case study and requires collaboration between members of each syndicate. This course has been reviewed and approved by the Institution of Chemical Engineers. IChemE is the global professional membership organisation for chemical, biochemical and process engineers and other professionals involved in the chemical, process and bioprocess industries. Their knowledge of professional standards, close involvement with industry, education and regulators, and their expertise as a leading global training provider, means they are uniquely positioned to independently assess and approve training courses and professional development programmes across the world. Training Objectives By the end of this course, participants will be able to: Acquire the underpinning knowledge required to achieve process safety competency Gain a comprehensive understanding of process safety management Understand the concept of the safety life cycle of a process plant from conceptual design onwards including operation, maintenance and modification Understand the hazard scenarios associated with a process plant Understand how risks can be controlled by hardware and procedural measures Identify and analyse hazard causes and consequences Recognise when specialist analytical expertise is required Generate effective and appropriate measures to reduce risks Justify and communicate practical solutions to non-technical personnel Explain the rationale for process safety measures to decision makers Target Audience This course is suitable for process industry professionals who need to acquire a comprehensive understanding of process safety management, those moving into process safety positions or those who wish to broaden their process safety knowledge within their existing discipline. It is particularly suited for anyone involved in the design, operation, modification or maintenance of a major hazard installation. This includes: Supervisors, operators and maintainers in Oil & Gas, Petrochemical and Chemical industries, process, mechanical and chemical engineers and technicians Design engineers, project engineers and HSE managers Control, automation and instrumentation engineers It will also demonstrate a substantial understanding of process safety for those engaged in Continuous Professional Development or aiming for the Chartered Engineer status. Course Level Basic or Foundation Trainer Your expert course leader has 50 years' experience in chemical and process safety engineering. His early career included 20 years in design and project engineering with various fine chemical and pharmaceutical companies where he designed chemical processes, specified plant equipment and selected materials for highly corrosive and toxic processes, often where textbook data was not available. This was followed by 10 years in offshore oil and gas design projects where he was responsible for setting up a Technical Safety group to change design safety practices in the aftermath of the 1988 Piper Alpha disaster. In recent years, he has been called upon to conduct various offshore and onshore incident investigations. His career has given him experience in project engineering, project management, process design and operations, safety engineering and risk management. He is a Fellow of the UK Institution of Chemical Engineers. He served on the Scottish Branch committee, and was elected chairman for a two-year term in 1991. He has also been chairman of the Safety and Reliability Society - North of Scotland Branch. He has delivered training courses in Process Hazard Analysis (HAZOP and HAZID), Process Safety Management, Hazard Awareness, Risk Assessment, Root Cause Analysis, Failure Modes & Effect Analysis and has lectured on Reliability Analysis to the M.Sc. course in Process Safety and Loss Prevention at Sheffield University. In addition to delivering training courses, he currently facilitates HAZOP / HAZID / LOPA studies and undertakes expert witness roles advising lawyers engaged in contractual disputes, usually involving the design or construction of chemical plants or Oil & Gas production facilities, or criminal prosecutions. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

NPORS Safe Working at Height (N404)

By Dynamic Training and Assessments Ltd

Who Should Attend This course is aimed at candidates that require the knowledge to enable them to comply with working at height regulations, and go in depth into industry dangers and respectability when working at height. This course can be completed by both novice and experienced candidates. We also offer refresher tests. Novice course- 1/2 day Experienced worker tests- 1/2 day. Course information Category N404 Safe Working At Height It is envisaged that by the end of this course of training the learner will be able to answer questions on and perform the following: ➢ Have a basic understanding of the industry, the dangers of working in the industry and their responsibilities when working at height ➢ Be able to define height work and identify the hazards of work above ground level and outline the general requirements necessary to control them ➢ Be able to identify accident causation in work at height ➢ Have an appreciation of planning and organisation of work at height ➢ Set up exclusion zone explaining actions required for emergency actions, identifying any overhead hazards ➢ Identify and maintain PPE appropriate for safe working at height use ➢ Demonstrate working at height and explain all safety issues that could arise Assessment Assessment will be to NPORS standards consisting of a theory test.

Adobe Lightroom - Photography Course

By Paul Chapman

Transform your photos into stunning images with Adobe Lightroom! With our comprehensive one-to-one Lightroom course, you will learn how to edit and enhance your images like a pro. From basic adjustments to advanced techniques, you'll discover how to make your photos pop and create a signature style for your website, social media or printed materials. Enrol now and unlock your creative potential! You will learn about: Library module Image import Collections Effective image organisation Image export (different sizes and resolutions for uses such as printing, Facebook etc) Develop module Fix image problems (e.g. under/over exposure, colour temperature, noise etc) Enhance your images (sharpness, clarity, contrast, colour etc) Using AI masking The important stuff The price for a four-hour course is £300 We will come to you at your office or home

Search By Location

- Organisation Courses in London

- Organisation Courses in Birmingham

- Organisation Courses in Glasgow

- Organisation Courses in Liverpool

- Organisation Courses in Bristol

- Organisation Courses in Manchester

- Organisation Courses in Sheffield

- Organisation Courses in Leeds

- Organisation Courses in Edinburgh

- Organisation Courses in Leicester

- Organisation Courses in Coventry

- Organisation Courses in Bradford

- Organisation Courses in Cardiff

- Organisation Courses in Belfast

- Organisation Courses in Nottingham