- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

REVIT ADVANCED ONE-TO-ONE COURSE

By Real Animation Works

3ds max and Photoshop face to face training customised and bespoke.

Revit Courses Personalize Your Learning Schedule with On-Demand Options

By Real Animation Works

Personalized Revit Training: One-to-One Sessions with Pay-as-You-Go Flexibility

REVIT ADVANCED ONE-TO-ONE COURSE

By Real Animation Works

Vray face to face training customised and bespoke.

Vectorworks Night Training Courses

By ATL Autocad Training London

Why Choose Vectorworks Night Training Courses? Flexibility: Learn around your work schedule. Personalized Attention: Small classes for focused guidance. Practical Learning: Hands-on training for immediate application. Convenience: Balance work and learning seamlessly. Check our Website Training Duration: 10 hours. Approach: Personalized 1-on-1 Training and customized training. Timings: Schedule a convenient hour, Mon to Sat, between 9 am and 7 pm. Course Outline: Mastering Vectorworks Basics I. Introduction to CAD and Vectorworks Software Understanding the role of Computer-Aided Design (CAD) in modern workflows. Comprehensive introduction to Vectorworks software. II. Workspace Setup and Fundamental Options Configuring the workspace for efficient navigation and operation. Exploring basic options to enhance user experience. III. Basic Skills in Drawing and Object Selection Mastering fundamental drawing techniques. Expertise in selecting and manipulating objects. IV. Advanced Editing Techniques Combining shapes, mirroring, rotating, and grouping objects effectively. Working with precise scaling, preferences, and templates. V. Detailed Object Manipulation and Attributes Drawing and moving objects accurately within the design space. Utilizing advanced editing tools like fillet and offset. Introduction to basic attributes and group editing. VI. Advanced Drawing Techniques and Graphics Creating room plans with walls, windows, and doors. Implementing graphic elements such as hatching, gradients, and image fills. Drawing elevations using various methods and techniques. VII. Resource Management and Design Layers Importing images for graphic illustration. Creating symbols and navigating the Resource Browser. Organizing the drawing effectively using design layers. VIII. Labels, Annotations, and User Interface Mastery Labeling drawings and incorporating simple title block text. Navigating the user interface, understanding key terminologies. Plotting, printing, creating sheets (A1, A2, A3), and working with viewports. IX. Advanced Object Manipulation and Customization Converting drawings into PDF files. Efficiently working with files, objects, and data. Utilizing object snaps, quick selection, division, and measurement. X. Dimensioning, Text, and Tool Palettes Implementing dimensioning and annotations effectively. Working with text, custom tool palettes, and organizing these palettes. Creating standard views and additional drawing objects (Arc, Donut, Ellipse). XI. 3D Modeling Introduction and Real-World Units Introduction to 3D modeling, focusing on creating extrudes. Working with real-world units for accurate representation. XII. Advanced Object Manipulation and Exporting Manipulating objects, changing object angles, creating mirror images. Dealing with architectural elements like walls, doors, windows, and floors. By the end of the Vectorworks Evening Training Course, participants will: Demonstrate proficiency in using the Vectorworks interface, tools, and navigation. Create and edit 2D drawings, including walls, doors, windows, floors, ceilings, stairs, and railings. Effectively manage layers, classes, and views for organized and controlled object placement. Create and edit dimensions and annotations for accurate measurements and documentation. Develop skills in creating, modifying, and utilizing symbols for increased efficiency. Generate and edit 3D geometry, apply textures, and create sections and elevations from 3D models. Create polished presentation drawings using viewports, annotations, and text for clarity. Summarize course content and confidently apply learned skills in Vectorworks projects. Utilize available resources for further learning and professional development. Who Should Attend? Perfect for those aiming to master Advanced 2D Plans, Sections, Elevations and Construction detailing, lighting, and rendering in Vectorworks. Schedule Flexibility: Book personalized 1-on-1 sessions, Monday to Saturday, 9 a.m. to 7 p.m. Split 10 hours to fit your schedule. Method: Choose in-person or Live Online 1-on-1 sessions with tailored content and individual support, including Zoom options. Why Vectorworks? A pioneering CAD software, Vectorworks seamlessly integrates 2D and 3D capabilities, making it ideal for architects and designers. Free Educational Access: Students and professors can access a complimentary Vectorworks Designer license via the Academic Portal. Explore Vectorworks: Transform your designs with Vectorworks, the leading 2D, 3D, CAD, BIM software. Download or try now: https://www.vectorworks.net Tailored Training Solutions: We offer customized and project-focused training programs, designed to meet your specific needs and goals. Individualized Coaching: Receive personalized one-on-one guidance tailored exclusively for you. Adaptable Timings: Choose training slots that align with your schedule, ensuring flexibility in your learning journey. Ongoing Assistance: Access continuous post-course support to enhance your understanding and resolve queries. Comprehensive Learning Resources: Receive detailed materials providing in-depth insights for effective learning and reference. Recognition of Participation: Earn a Certificate of Attendance upon completion of your personalized training. Affordable Learning: Benefit from cost-effective rates, making quality education accessible to all. Software Setup Guidance: Get expert assistance in setting up your software on your devices for seamless learning experiences. Rewards for Referrals: Recommend our courses to others and enjoy special rewards for each successful referral. Group Learning Benefits: Enjoy exclusive discounts when you opt for group training, making it an ideal choice for teams. Convenient Hours of Operation: Access our training services at your convenience, with operating hours extending to accommodate your busy schedule. Tailored Learning Paths: Experience courses curated specifically for your needs, ensuring targeted and effective learning outcomes.

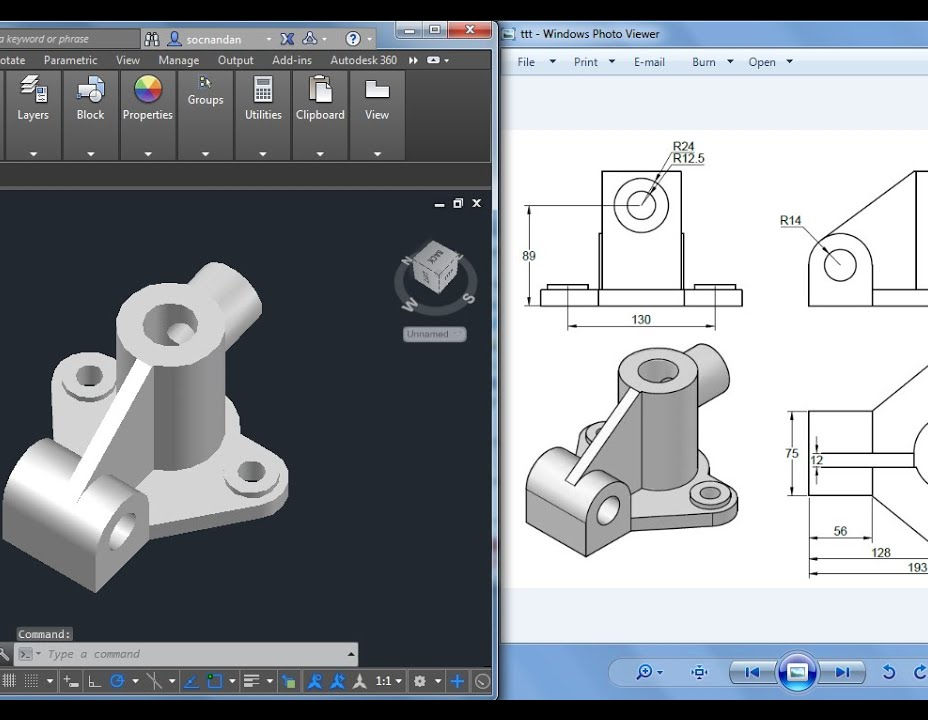

3D AutoCAD Basics to Advanced Training Course

By ATL Autocad Training London

Why Choose 3D AutoCAD Basics to Advanced Training Course? Students learn how to create and modify both solid and surface models. This AutoCAD Training course also teaches students how to present their designs in 3D products and designs. Check our Website Duration: 16 hours Approach: 1-on-1, Book your own day and time. We are open Monday to Saturday 9 am to 7 pm. How to Book this course? Call us on 02077202581 and we will book the dates and times you like. Flexible Schedule: 1-on-1 Face to Face or Live Online. AutoCAD 3D Training: Comprehensive Course Overview Exploration of 3D Modeling and Imaging Generating 3D Drawings Navigating the 3D Modeling Workspace Crafting 3D Shapes using Solid Tools Extruding Polylines into 3D Forms Isolating Coordinates with Point Filters Navigating and Orienting Your Model Achieving Visual Effects Converting 3D Views into 2D AutoCAD Drawings Advanced 3D Techniques Setting Up AutoCAD for 3D Mastering the User Coordinate System Leveraging UCS Options Utilizing Viewports for 3D Drawing Employing Array Tools Crafting Complex 3D Surfaces Constructing Spiral Forms Developing Surface Models Manipulating Objects in 3D Space Rendering and Visualization of 3D Drawings Introduction to Rendering Rapid Rendering Techniques Simulating Sunlight and Shadows Application and Adjustment of Materials Creating Effects with Lights and Materials Texture Mapping and Adjustments Exploration of Rendering Options Enhancing Views with Cameras Printing Rendered Drawings Simulating Natural Lighting Editing and Visualizing 3D Solids Overview of Solid Modeling Creation of Basic and Complex Solids Editing Solid Forms Improving the 2D Drawing Process Visualization and Analysis of Solids Exploration of 3D Mesh and Surface Modeling Introduction to 3D Meshes and Surfaces Creation and Editing of 3D Meshes Crafting Mesh Surfaces Conversion of Meshes to Solids Understanding and Editing 3D Surfaces Customization of Interface and Tools Customization of Workspaces Personalization of the User Interface Creation of Macros in Tools and Menus Working with Expanded Text Boxes Saving and Managing Customizations Exploration of the Diesel Macro Language Designing Custom Linetypes and Hatch Patterns Management and Sharing of Your Drawings Sharing Drawings Online ePublishing Your Work Managing Drawings with DesignCenter and Tool Palettes Exploring the Drawing Library with Content Explorer Establishment of Office Standards Conversion of Layer Settings https://www.autodesk.co.uk Download a free 30-day trial of AutoCAD Learning outcomes after completing the AutoCAD 3D course. Professional Presentation: Create dynamic walkthroughs and presentations that effectively communicate your 3D models and designs. Certification: Obtain a certification as proof of your proficiency in AutoCAD 3D modeling, validating your skills in the industry. Mastery of 3D Modeling: Possess comprehensive skills, from fundamental concepts to advanced techniques in 3D modeling. Enhanced Career Prospects: Improve your career opportunities and prospects in various design-related fields such as architecture, engineering, and product design. Realistic Rendering: Be able to create highly realistic visualizations that enhance the quality of your designs. Practical Hands-On Experience: Gain practical experience and confidence in 3D modeling through extensive hands-on practice. Personalized Learning: Benefit from one-on-one attention and tailored training to meet your specific learning needs and pace. Lifetime Email Support: Continue to receive assistance and guidance through lifetime email support, ensuring you are supported even after completing the course. 3D AutoCAD Training Courses Gain confidence and proficiency in AutoCAD. Discover the fundamentals of 3D modeling and object creation in this introductory AutoCAD 3D course. Booking Your Training Course: Experience personalized training with our adaptable 1-on-1 sessions. You have the freedom to customize your schedule by reserving a convenient hour at your discretion. Our booking slots are available from Monday to Saturday, spanning from 9 a.m. to 7 p.m. You can also reach us at 02077202581 to make a booking over the phone. Course Duration: 10 hours "You have the flexibility to divide these 10 hours across multiple days to suit your ideal schedule." Training Method: 1-on-1 (In-person face-to-face or Live Online) Expect personalized attention, tailor-made content, a flexible learning pace, and dedicated individual support throughout your training journey. This hands-on course provides ample opportunities to experiment with newly acquired techniques and seek answers to your questions. Key Features: An introductory course tailored to AutoCAD 3D's essential features. Abundant one-on-one guidance and dedicated question time. Friendly expert trainers, small class sizes, and a comfortable learning environment. Comprehensive course materials and additional resources. Ongoing support and assistance with post-course challenges. What Will You Learn? This course will equip you with the foundational knowledge and workflows necessary to create 3D models within AutoCAD 3D. You will delve into the creation and modification of both solid and surface models. Upon completion, you will be able to: Effortlessly fashion intricate shapes by combining simple elements. Precisely extract geometries and dimensions from your creations. Easily customize the view and presentation style of your objects. Is This Course Right for You? No prior experience with AutoCAD 3D is required. This course caters to individuals proficient in working with 2D objects who aspire to construct 3D models of their designs. Gain proficiency in the fundamental tools and functionalities to create precise and professional 2D and 3D drawings, advancing to more complex techniques. Enhanced Efficiency: Discover time-saving strategies, tips, and workflows that will boost your productivity and streamline your design process within AutoCAD 3D. Versatility in Design: Develop the skills needed to undertake a wide range of projects, from architectural plans and engineering drawings to mechanical components and electrical schematics. Industry-Recognized Expertise: Cultivate in-demand skills relevant to architecture, engineering, construction, and manufacturing, paving the way for career advancement and professional development. Accessible Lesson Recordings: Access recorded lessons at your convenience to review and reinforce course material whenever necessary. Continuous Email Support: Benefit from ongoing assistance with lifetime email support, ensuring you have access to guidance, answers, and clarifications even beyond the completion of the course.

3D Printing Training Course for Product Designers

By ATL Autocad Training London

Who is this course for? The 3D Printing Bespoke 1-on-1 Training Course is designed for individuals seeking personalized instruction and hands-on experience in the field of 3D printing. Click here for more info: Website Training: 40 hrs, split as per your availability. When: 9 a.m. to 7 p.m., Mon-Sat. Call 02077202581 to reserve. Live online, or in-person. Option A: AutoCAD 10 hrs, Rhino 16 hrs, Vray 4 hrs, Photoshop 4 hrs, 3D Printing 6 hrs Option B: AutoCAD 12 hrs, 3ds Max 16 hrs, Vray 4 hrs, Photoshop 4 hrs, 3D Printing 4 hrs. Option A: AutoCAD, Rhino, Vray, Photoshop, 3D Printing (Total: 40 hours) AutoCAD (10 hours): Module 1: Introduction to AutoCAD (2 hours) Familiarization with AutoCAD interface and tools Creating, opening, and saving drawings Basic drawing and editing commands Module 2: Drawing and Editing (3 hours) Lines, circles, and arcs Polylines and polygons Modifying objects: Move, Copy, Rotate, and Scale Module 3: Precision Drawing (3 hours) Using coordinate systems Dimensioning and text Hatching and gradients Module 4: Advanced Tools (2 hours) Blocks and attributes Layers and object properties Creating layouts and plotting Rhino (16 hours): Module 1: Introduction to Rhino (2 hours) Navigating the Rhino interface Basic 2D and 3D modeling concepts Creating and manipulating objects Module 2: Advanced Modeling (6 hours) Modeling with curves and surfaces Editing and transforming geometry Building complex 3D structures Module 3: Visualization with Vray (4 hours) Understanding the Vray rendering engine Applying materials and textures Setting up lighting and cameras for realistic rendering Module 4: Presentation and Editing (2 hours) Exporting and sharing Rhino models Post-processing and enhancing designs Photoshop (4 hours): Module 1: Introduction to Photoshop (2 hours) Navigating Photoshop interface Image resolution and size Basic image editing tools Module 2: Image Editing and Enhancement (2 hours) Adjusting colors and tones Using layers and masks Retouching and image manipulation 3D Printing (6 hours): Module 1: Introduction to 3D Printing (2 hours) Basics of 3D printing technology Understanding file formats and requirements Module 2: Preparing 3D Models (2 hours) Model optimization for 3D printing Creating supports and rafts Ensuring successful prints Option B: AutoCAD, 3ds Max, Vray, Photoshop, 3D Printing (Total: 38 hours) AutoCAD (12 hours): Module 1: Introduction to AutoCAD (2 hours) Overview of AutoCAD interface and tools Creating, opening, and saving drawings Basic drawing and editing commands Module 2: Drawing and Editing (3 hours) Lines, circles, and arcs Polylines and polygons Modifying objects: Move, Copy, Rotate, and Scale Module 3: Precision Drawing (3 hours) Using coordinate systems Dimensioning and text Hatching and gradients Module 4: Advanced Tools (4 hours) Blocks and attributes Layers and object properties Creating layouts and plotting 3ds Max (16 hours): Module 1: Introduction to 3ds Max (2 hours) Exploring the 3ds Max interface Navigating viewports and objects Basic modeling techniques Module 2: 3D Modeling (6 hours) Creating and editing 3D objects Modifiers and deformations Working with shapes and splines Module 3: Visualization with Vray (4 hours) Setting up lights and cameras Rendering settings and options Post-production and compositing Photoshop (4 hours): Module 1: Introduction to Photoshop (2 hours) Navigating Photoshop interface Image resolution and size Basic image editing tools Module 2: Image Editing and Enhancement (2 hours) Adjusting colors and tones Using layers and masks Retouching and image manipulation 3D Printing (4 hours): Module 1: Introduction to 3D Printing (2 hours) Basics of 3D printing technology Understanding file formats and requirements Module 2: Preparing 3D Models (2 hours) Model optimization for 3D printing Creating supports and rafts Ensuring successful prints Training Duration: 40 hours Flexible Timings: Students can choose their preferred time slots based on our availability, operating from 9:00 am to 7:00 pm (Monday to Saturday). Pricing Details: Company Rate: £1200 (Plus 20% VAT) = £1440 inc VAT. Student, Self-Financed, and Live Online Rate: £1000 (Plus 20% VAT) = £1200 inc VAT. Who Should Enroll: This course caters to a wide range of individuals, including: Novices: Perfect for beginners unfamiliar with AutoCAD, 3ds Max, Adobe Photoshop, Rhino, Vray, and 3D printing, providing a solid foundational understanding. Architects and Interior Designers: Tailored insights for professionals seeking precision in enhancing their design skills, valuable for design firms. Industry Professionals: Establishes industry benchmarks, offering adaptable education applicable across sectors like interior design, architecture, and civil engineering. Learning Approach: Hands-On Practicality: Emphasizes practical, real-world skills through personalized one-on-one training, available in face-to-face or live online sessions. Step-by-Step Instruction: Experienced instructors guide you systematically through techniques using AutoDesk AutoCAD, Autodesk 3ds Max, Adobe Photoshop, and Trimble Sketchup. What You'll Receive: Certificate of Achievement: Upon completion, receive a certificate validating your expertise. Comprehensive Training Guide: Access an extensive PDF guide compatible with both Windows and MAC. Live Feedback: Connect with your tutor for real-time feedback during sessions and the option to record each session for future reference. Our Benefits: Price Assurance: Guaranteeing exceptional value for your career investment. Personalized Training: Tailored one-on-one sessions, adjusting to your learning pace and style. Flexible Scheduling: Choose your preferred training time and day, available Monday to Sunday, from 9 am to 8 pm. Lifetime Support: Ongoing email and phone support beyond the course completion. Computer Setup Assistance: We assist in configuring your computer for seamless software installation. Referral Benefits: Recommend a friend and enjoy discounts, including significant savings on group training courses. Advantages of Option A: Diverse Skill Enhancement: Acquire proficiency in AutoCAD, Rhino, Vray, Photoshop, and 3D Printing, expanding your skill repertoire. Career Opportunities: Access a wide range of career paths in design, architecture, and 3D printing fields, enhancing your professional prospects. Compelling Visualizations: Craft realistic and visually appealing 3D renderings using Vray, elevating the quality of your design presentations. Image Editing Expertise: Master the art of enhancing design projects with Photoshop, adding finesse to your creative work. Prototyping Prowess: Develop essential skills in 3D Printing, enabling you to create physical design prototypes for various applications. Advantages of Option B: Versatile Skill Mastery: Excel in AutoCAD, 3ds Max, Vray, Photoshop, and 3D Printing, gaining expertise in diverse areas of design and visualization. Career Advancement: Unlock opportunities in architecture, animation, and visualization fields, broadening your career horizons. High-Quality Renderings: Showcase your designs impressively with high-quality renderings generated through Vray, leaving a lasting impact on viewers. Image Editing Mastery: Polish your design concepts and presentations using advanced Photoshop techniques, ensuring your visuals are refined and professional. 3D Printing Expertise: Bring your digital designs to life across various industries, mastering the intricate art of 3D printing. Our training courses cater to both Mac and Windows operating systems and provide: Price Assurance: Ensuring the best value for your investment. Personalized Attention: Benefit from one-on-one training sessions tailored to your learning pace and style. Flexible Scheduling: Choose your preferred time and day for training sessions, available seven days a week from 9 am to 8 pm. Ongoing Support: Enjoy lifetime email and phone support, ensuring you're never alone on your learning journey. Technical Assistance: Receive guidance in configuring your computer for software installation, ensuring a seamless learning experience. Special Benefits: Avail special discounts when you refer a friend and significant savings on group training courses, maximizing the value of your training investment.

Rhino 2D | 3D Training Course for Jewellery Design

By London Design Training Courses

Why Opt for the Rhino 3D Training Course in Jewelry Design? Click here for more info Within a span of 10 hours, you'll master the interface and gain insights into how Rhino leverages points, lines, surfaces, and solids to fashion printable 3D objects. Moreover, you'll explore the art of crafting repetitive and intricate geometric shapes, perfect for creating minimalist and elegant jewelry. Flexible Scheduling: 1-on-1 training sessions tailored to your schedule. Pick any hour between 9 am and 7 pm from Mon to Sat. Course Duration: 10 hours. Training Methods: Choose between in-person sessions or live online training. Why Choose Our Rhino 3D Training Course for Jewelry Design? Rhino, also known as Rhinoceros, stands as a robust 3D computer graphics and computer-aided design software extensively utilized in various industries, including architecture, industrial design, and multimedia. LDTC offers meticulously crafted Rhino courses to empower you in mastering this software. Led by experienced instructors, our courses ensure a comprehensive understanding of Rhino, equipping you to create exceptional designs, specifically tailored for jewelry creation. Rhino 3D Training for Jewelry Design: Our Rhino 3D training caters to both beginners and those aspiring to acquire advanced techniques, emphasizing its application in jewelry design. Course Highlights: Precise 3D Modeling: Master the art of crafting free-form 3D NURBS models with utmost precision. Advanced Functionality: Explore Rhino's advanced surfacing commands and features tailored for jewelry design. User Interface Mastery: Navigate Rhino's interface seamlessly and refine your skills in curves, surfaces, and solids. Expert Guidance: Acquire expertise in Rhino's modeling environment under the guidance of seasoned professionals. Modeling Why Choose Our Rhino 3D Training Course for Jewelry Design? Rhino, also known as Rhinoceros, stands as a robust 3D computer graphics and computer-aided design software extensively utilized in various industries, including architecture, industrial design, and multimedia. LDTC offers meticulously crafted Rhino courses to empower you in mastering this software. Led by experienced instructors, our courses ensure a comprehensive understanding of Rhino, equipping you to create exceptional designs, specifically tailored for jewelry creation. Rhino for Jewelry Design - 16-Hour Course Module 1: Introduction and Navigation Get acquainted with Rhino's interface, menus, and screen layout. Navigate Rhino models with precision in 2D lines, polylines, and NURBS curves. Use modeling setup features like snap, ortho, and planar constraints for accuracy. Leverage object snaps and Smart Track functionality for enhanced precision. Module 2: Solid and Surface Modeling Fundamentals Rapidly develop 3D solids and surfaces using Rhino's organized layering system. Utilize coordinates and constraints for meticulous modeling in 3D space. Create diverse shapes, including rectangles, circles, arcs, ellipses, and polygon curves. Enhance models with Rhino render, render color, and free-form curves. Efficiently handle model views with pan, zoom, and view management tools. Implement various editing commands for curve manipulation and transforming curves into surfaces and solids. Utilize history tracking for advanced editing and execute general editing actions. Module 3: Intermediate Edit and Surfacing Techniques Introduce essential NURBS modeling concepts and terminologies. Edit curves and surfaces through control point manipulation and rebuilding for optimal refinement. Use the nudge modeling aid for precise adjustments and generate deformable shapes. Create curves through projection techniques and split surfaces using curves and surfaces. Blend surfaces seamlessly, utilizing symmetry tools, lighting, and rendering effects. Convert intricate 3D objects into detailed 2D drawings and craft page layouts. Module 4: Advanced Surfacing and Solid Modeling Techniques Construct model primitives and solid text using techniques such as pipe and extrusion. Efficiently modify solids using Boolean tools, expanding surface modeling capabilities. Utilize techniques like extrusion, lofting, and revolving for intricate surfaces. Create sweeps using 1 and 2 rail curves and master surface network techniques for complex shapes. Downlaod Rhino. Upon completion of the Rhino 3D Training Course for Jewelry Design, participants can expect the following learning outcomes: Mastering Rhino Interface: Gain a comprehensive understanding of Rhino's interface, menus, and screen layout. Precision in Modeling: Navigate Rhino models with precision using 2D lines, polylines, and NURBS curves. Modeling Setup Proficiency: Utilize modeling setup features such as snap, ortho, and planar constraints for accurate designs. Enhanced Navigation Techniques: Leverage object snaps and Smart Track functionality for enhanced precision during navigation. Solid and Surface Modeling Skills: Rapidly develop 3D solids and surfaces with Rhino's organized layering system. Coordination and Constraint Application: Utilize coordinates and constraints for meticulous modeling in 3D space. Diverse Shape Creation: Create diverse shapes, including rectangles, circles, arcs, ellipses, and polygon curves. Rendering and Enhancement Techniques: Enhance models with Rhino render, render color, and free-form curves. Efficient Model View Handling: Efficiently handle model views with pan, zoom, and view management tools. Intermediate Edit and Surfacing Techniques: Edit curves and surfaces through control point manipulation and rebuilding for optimal refinement. NURBS Modeling Mastery: Introduce essential NURBS modeling concepts and terminologies. Advanced Editing and Modeling Skills: Use the nudge modeling aid for precise adjustments and generate deformable shapes. Complex Shape Creation: Create sweeps using 1 and 2 rail curves and master surface network techniques for intricate shapes. Solid Modeling Proficiency: Construct model primitives and solid text using techniques such as pipe and extrusion. Application of Boolean Tools: Efficiently modify solids using Boolean tools, expanding surface modeling capabilities. Advanced Surfacing Techniques: Utilize techniques like extrusion, lofting, and revolving for intricate surfaces. Conversion and Crafting of 2D Drawings: Convert intricate 3D objects into detailed 2D drawings and craft page layouts. Hands-On Project Experience: Engage in practical exercises and hands-on projects tailored for jewelry design applications. Upon mastering these skills, participants will be well-equipped to create sophisticated jewelry designs using Rhino 3D modeling software.

Smartphone video production

By Rough House Media

Do you use video as a tool to promote your charity, business, organisation or campaigns? And if you don’t, do you feel as if you ought to? Videos account for more than 80% of all consumer internet traffic. So the pressure to use video as a marketing and PR tool has increased enormously. But the cost can be prohibitive. Using a video production company, such as ours, might be ideal, but for many it is out of reach – particularly if, like many of our clients, you’re a charity. However, there is an alternative, which more and more organisations are choosing, especially those which need to produce regular digital content. That is to produce the video yourself. Nowadays, you do not even need to invest in a video camera. All you need is your smart phone, some simple equipment you can buy on Amazon for as little as £80, plus your laptop or PC. This is why we have developed a new smartphone video training course, Smart Video. Our smartphone video training course covers: Equipment – including setting up your phone, microphones, tripods and editing programmes Planning your video Techniques to give your films broadcast-quality polish Getting the perfect shot – including shot sizes, positioning the camera, framing, lighting, sound, sequences and backgrounds Filming interviews An introduction to editing Producing videos for social media Bespoke training The course can be tailored to the type of videos you need to make. If most of your videos will be interviews, we’ll focus on presenting your interviewee in the best possible light – literally. If, on the other hand, you need to film buildings, events or products, we’ll tailor the course accordingly. If your video needs a script, we’ll give you tips and techniques on how to “write to pictures”, so your messages comes across well. And on all our courses, we’ll give you a guide to the best equipment and apps to use to enhance your filming and editing. The smartphone video course will be led by Paul Curran who has many years experience producing, filming and editing films and videos, for the BBC and corporate clients.

Building services and maintenance - introduction (In-House)

By The In House Training Company

To provide a fundamental understanding of building services in the context of: The working environment The success of the core business The health and safety of the occupants Operating cost and environmental impact The optimisation of cost and value Strategies for continuous improvement DAY ONE 1 Building services fundamentals The function of services in commercial buildings and their importance to the core businessElectrical servicesLightingHeatingVentilation and air conditioningLiftsWater Understanding IT and communication systems Practical exercises 2 The provision of comfort and safety Statutory requirementsHealth and safety legislationControl of contractorsRisk assessmentFire precautionsLegionella, sick building and other risks Business requirementsUnderstanding user requirementsMatching systems to business needs Practical exercises 3 Getting the design right What the FM needs to know about design and its procurementSuccessful space planningRelationship between services, space planning and designGetting the brief rightSupplier selection and management Practical exercises DAY TWO 4 Operation and maintenance Why maintain?Maintenance contractsInput and output specificationsResource optionsContracts - principal elementsTendering - key stepsSelection criteriaOperational criteriaMaintenance trends Performance-based service provisionInput and output specificationsKPIs and thresholdsRisk containmentValue-add opportunitiesPerformance contract strategy Practical exercises 5 Contingency planning Being ready for the unexpected Identifying and reducing riskInternal risksExternal risksIdentifying threats at your site Managing riskProtective systemsOccupier obligationsFire managementTesting Practical exercises 6 Commissioning services systems Physical commissioning Common problems Typical costs Commissioning stages Continuous commissioning Energy efficiency and the scope for environmental improvement Practical exercises 7 Satisfying the occupants Obtaining and responding to feedbackWhen to get feedbackWhyHowWhat to do with it Practical exercises 8 'Air time' Sharing experience and addressing specific issues of interest to participants Course review Close

Abrasive Wheels Training Nearly half of the workplace accidents involving abrasive wheels are due to an unsafe work system or operator error. This indicates that many of these incidents can be avoided if the risks of working with abrasive wheels are clearly communicated, and the correct safety measures are adopted, Abrasive Wheels Training will eliminate most accidents with Abrasive Wheels. With the appropriate Abrasive wheels training in place, you could significantly reduce the risk of an injury such as friction burns, crushed fingers and loss of eyesight which are the most common amongst abrasive wheel operators with the misuse of machines. This Abrasive Wheels Training Course is designed to assist in reducing the risk of injury for anyone who uses abrasive wheels at work. It guides you through the different types of abrasive wheels, how to identify and store them, how they should be used safely, and how they should be inspected prior to use. Our Abrasive Wheels Training will give all candidates hands-on practical training. Book with Confidence at Vally Plant Training At Vally Plant Training, we guarantee unbeatable value with our Price Match Promise. When you choose us, you can book with confidence, knowing that we will not be beaten on price. If you find a lower price for the same NPORS Experienced Worker Test, we’ll match it—ensuring you receive top-quality training at the best possible rate. Your skills, our commitment—always at the best price. Abrasive Wheels Course Duration 3-4 Hours Petrol Cut Off Saw 1 Day for all candidates Certification NPORS Traditional card – lasts for 5 years and is mainly accepted with housebuilders, utilities, port and marine as proof of competence OR NPORS card with CSCS logo – accepted by all major building contractor’s. The initial card is the RED trained operator card which lasts for 2 years and can be upgraded to BLUE competent operator card further to completion of relevant NVQ. In house certificates: suitable as proof of operator competence accepted for insurance and HSE compliance. Introduction to Abrasive Wheels Definition of Abrasive Wheels Abrasive wheels are tools used for cutting, grinding, and polishing various materials. They are made from abrasive particles, like grit, bonded together to form a solid wheel. When these wheels spin at high speeds, they can shape or finish different surfaces effectively. Types of Abrasive Wheels Commonly Used in Industry Bonded Abrasive Wheels: These are made by combining abrasive particles with a bonding material to form a solid wheel. Bonded abrasive wheels are typically used for tasks like grinding, cutting, and finishing metal or stone. Coated Abrasive Wheels: These have an abrasive layer attached to a backing material, like paper or cloth. Coated abrasive wheels are commonly used for sanding and smoothing surfaces, often in woodworking or metalworking. Abrasive wheel training is essential for learning how to use these tools safely and effectively. Understanding the different types of abrasive wheels and their applications can help you choose the right wheel for your job, ensuring efficiency and safety. Importance of Proper Training Overview of the Risks Associated with Improper Use Using abrasive wheels without proper training can be very dangerous. The importance of proper training cannot be overstated when it comes to the safe and effective use of abrasive wheels. Improper use of abrasive wheels can lead to serious accidents, such as wheel breakage, which can cause flying debris and severe injuries. Other risks include cuts, burns, and eye injuries from sparks or fragments. Not knowing how to handle the equipment properly can also result in damaged materials and inefficient work, leading to wasted time and resources. Benefits of Trained Versus Untrained Usage Undergoing abrasive wheel training is crucial for several reasons: Safety: Trained individuals know how to handle abrasive wheels safely, reducing the risk of accidents and injuries. They learn to inspect the wheels for damage, choose the right type of wheel for the job, and use protective gear correctly. Efficiency: Training ensures that users understand how to use abrasive wheels effectively, leading to faster and more accurate work. Trained users can achieve better results with less effort and time. Cost-Effectiveness: Proper training helps prevent damage to the wheels and the materials being worked on, saving money on replacements and repairs. It also minimizes downtime due to accidents or improper usage. Compliance: Many industries require certification for using abrasive wheels. Completing abrasive wheel training ensures compliance with safety regulations and industry standards, which is essential for legal and insurance purposes. In summary, abrasive wheel training equips users with the knowledge and skills needed to use abrasive wheels safely and efficiently, making the workplace safer and more productive. Getting Started with Abrasive Wheels Essential Equipment and Setup Before using abrasive wheels, it’s important to have the right equipment and ensure everything is set up properly. Here’s what you need: Protective Gear: Always wear safety goggles, gloves, ear protection, and a dust mask to protect yourself from flying debris, noise, and dust. Abrasive Wheels: Have a selection of abrasive wheels suitable for the tasks you plan to perform. This includes grinding wheels, cutting wheels, and sanding discs. Mounting Equipment: Ensure you have the correct flanges, spacers, and mounting hardware to secure the wheel to the machine properly. Tools and Machines: Use the appropriate tools and machines for your abrasive wheels, such as grinders, sanders, or cut-off saws. Make sure these machines are in good working condition. Work Area: Set up your work area with adequate lighting, ventilation, and space to move around safely. Ensure there are no flammable materials nearby. Completing an abrasive wheels training course will guide you on how to properly set up and use this equipment. Selecting the Right Wheel for the Job Choosing the right abrasive wheel is crucial for getting the job done efficiently and safely. Here’s how to select the right wheel: Material to Be Worked On: Different materials require different types of wheels. For example, use a grinding wheel for metal and a sanding disc for wood. Wheel Specification: Check the specifications of the wheel, including its grit size, bonding material, and hardness. Finer grits are better for finishing, while coarser grits are used for rough grinding. Machine Compatibility: Ensure the wheel is compatible with your machine. Check the wheel’s size, speed rating, and mounting requirements. Type of Task: Match the wheel to the task. Use cutting wheels for cutting, grinding wheels for grinding, and polishing wheels for finishing tasks. Enrolling in a grinding wheel training course can provide detailed guidance on selecting and using the right wheels for different jobs. Proper selection and setup not only improve efficiency but also enhance safety and prolong the life of the abrasive wheels. Safe Operation Techniques Step-by-Step Guide on How to Operate Abrasive Wheels Safely Inspect the Wheel: Before using any abrasive wheel, inspect it for cracks, chips, or other damage. Do not use a damaged wheel. Mount the Wheel Properly: Ensure the wheel is properly mounted on the machine. Follow the manufacturer’s instructions for correct mounting and balancing. Check Machine Guards: Make sure all safety guards are in place and functioning correctly. Guards help protect you from flying debris and accidental contact with the wheel. Wear Protective Gear: Always wear safety goggles, gloves, ear protection, and a dust mask to protect against sparks, noise, and dust. Start the Machine Safely: Stand to the side of the machine when starting it, not directly in front of the wheel. Allow the wheel to reach full speed before using it. Use Proper Technique: Apply light, even pressure to the workpiece. Avoid forcing the wheel or using excessive pressure, as this can cause the wheel to break. Maintain Control: Keep a firm grip on the tool or workpiece to prevent it from slipping or catching. Avoid Overheating: Use intermittent cuts and allow the wheel to cool down to avoid overheating, which can weaken the wheel and cause it to break. Regular Breaks: Take regular breaks to avoid fatigue, which can lead to mistakes and accidents. Completing an abrasive wheel training course can provide practical demonstrations of these safety techniques. Comparison with Other Cutting Methods Feature Abrasive Wheels Saws (Circular/Band) Laser Cutters Versatility High: Can cut metals, stone, ceramics. Moderate: Best for wood and certain metals. High: Can cut metals, plastics, composites. Precision High: Provides precise cuts and finishes. Moderate: Effective for straight cuts, less precise for intricate designs. Very High: Capable of intricate designs and clean cuts. Cost Low: Generally cheaper initial and maintenance costs. Moderate: Higher initial cost than abrasive wheels but longer lifespan. High: Expensive initial investment and maintenance costs. Portability High: Many tools are portable for on-site cutting and grinding. Low: Often require stationary setups. Low: Typically not portable and integrated into fixed setups. Safety Risks High: Requires proper training to prevent accidents (e.g., HSE, OSHA). Moderate: High-speed blades can be dangerous, need safety measures. Moderate: Requires specialized training to handle safety risks (e.g., reflective materials). Dust/Debris High: Generates significant dust and debris. Low: Produces less dust and debris. Very Low: Minimal dust and debris, cleaner cutting process. Wear and Tear High: Abrasive wheels wear down with use and need regular replacement. Low: Blades have a longer lifespan, less frequent replacement needed. Low: Lasers do not wear down, but components may need maintenance. Training Availability High: Numerous training courses available (e.g., HSE, OSHA). Moderate: Training available but not as comprehensive as abrasive wheel training. High: Specialized training required for safe operation and maintenance. Compliance High: Training helps meet regulatory requirements (e.g., PUWER 1998). Moderate: Safety training helps meet general safety regulations. High: Requires adherence to safety standards and protocols. Operational Speed Moderate: Suitable for detailed work, not as fast as saws for straight cuts. High: Faster cutting speeds for straight cuts. Moderate: Speed depends on material and thickness, generally slower than saws for thicker materials. Common Mistakes and How to Avoid Them Using a Damaged Wheel: Mistake: Using an abrasive wheel with cracks or chips. Solution: Always inspect the wheel before use and replace damaged wheels immediately. Improper Mounting: Mistake: Incorrectly mounting the wheel, leading to imbalance and breakage. Solution: Follow the manufacturer’s instructions and ensure the wheel is securely mounted. Skipping Protective Gear: Mistake: Not wearing safety gear, increasing the risk of injury. Solution: Always wear the recommended protective equipment, including goggles, gloves, and ear protection. Excessive Pressure: Mistake: Applying too much pressure, which can cause the wheel to break. Solution: Use light, even pressure and let the wheel do the work. Incorrect Wheel for the Job: Mistake: Using the wrong type of wheel for the material or task. Solution: Select the appropriate wheel based on the material and the task. Refer to the specifications and guidelines provided during abrasive wheels training. By understanding and avoiding these common mistakes, you can ensure safer and more efficient use of abrasive wheels. Proper training, like an abrasive wheel course, is essential to master these techniques and avoid potential hazards. Maintenance and Care Tips for Maintaining Abrasive Wheels Regular Cleaning: Clean the abrasive wheels regularly to remove any debris or buildup. Use a brush or compressed air to clean the wheel, ensuring it remains effective and prevents clogging. Proper Storage: Store abrasive wheels in a dry, cool place to prevent moisture damage. Keep them on a flat surface or in a vertical position to avoid warping or deformation. Wheel Dressing: Dress the wheel regularly using a wheel dresser to maintain its shape and expose fresh abrasive particles. This helps keep the wheel sharp and efficient. Avoid Overloading: Do not overload the wheel by forcing it to cut or grind faster than its capacity. Overloading can cause excessive wear and reduce the wheel’s lifespan. Use Correct Speed: Always operate the wheel at the recommended speed. Check the maximum speed rating of the wheel and ensure your machine does not exceed this limit. Balanced Use: Use the entire surface of the wheel evenly to prevent uneven wear. Avoid focusing on one spot for too long, which can create grooves and weaken the wheel. Lubrication: If applicable, use the appropriate lubricant to reduce friction and heat buildup. This can extend the life of the wheel and improve performance. How to Check for Wear and Damage Visual Inspection: Before each use, visually inspect the wheel for cracks, chips, or other damage. A damaged wheel can be dangerous and should be replaced immediately. Sound Test: Perform a sound test by gently tapping the wheel with a non-metallic object (like a wooden handle). A clear ringing sound indicates the wheel is intact, while a dull sound suggests it may be cracked and unsafe to use. Check for Unusual Vibrations: When the wheel is running, check for unusual vibrations or wobbling. This can indicate imbalance or damage. Stop using the wheel if you notice these signs and inspect it further. Measure Wheel Wear: Measure the diameter of the wheel regularly to monitor wear. Replace the wheel when it reaches the minimum usable diameter specified by the manufacturer. Surface Condition: Examine the surface of the wheel for glazing or loading. A glazed wheel appears shiny and smooth, indicating it is worn out and needs dressing or replacement. A loaded wheel is clogged with material and may require cleaning or dressing. Mounting Hardware: Check the flanges, spacers, and other mounting hardware for wear or damage. Ensure they are secure and in good condition to maintain proper wheel alignment. Regular maintenance and careful inspection of abrasive wheels can significantly extend their lifespan and ensure safe, efficient operation. Abrasive wheels training provides detailed guidelines on maintaining and checking wheels for wear and damage, helping users develop good maintenance habits. Health and Safety Guidelines Detailed Safety Precautions and Protective Gear Wear Appropriate Protective Gear: Safety Goggles or Face Shield: Protect your eyes and face from flying debris and sparks. Gloves: Wear sturdy gloves to protect your hands from sharp edges and hot materials. Ear Protection: Use earplugs or earmuffs to protect your hearing from the noise produced by grinding operations. Dust Mask or Respirator: Prevent inhalation of dust and particles, especially when working with materials that produce harmful dust. Apron or Protective Clothing: Wear a durable apron or long-sleeved clothing to shield your body from sparks and debris. Machine Safety Checks: Guarding: Ensure all machine guards are in place and secure before operation. Speed Check: Confirm that the machine’s speed does not exceed the wheel’s maximum rated speed. Work Area: Keep the work area clean and free of clutter to prevent tripping hazards. Safe Operation Practices: Proper Setup: Mount the abrasive wheel correctly, following the manufacturer’s instructions. Ensure it is balanced and secure. Correct Usage: Use the abrasive wheel only for its intended purpose. Avoid side grinding unless the wheel is specifically designed for it. Pressure Application: Apply light, even pressure to avoid overloading the wheel and causing it to break. Regular Inspections: Pre-Use Inspection: Check the wheel for any cracks, chips, or signs of wear before each use. During Use: Monitor the wheel for unusual vibrations or noises, and stop the machine immediately if any issues arise. What to Do in Case of an Accident Immediate Response: Stop the Machine: Turn off the machine immediately to prevent further injury. First Aid: Administer first aid for minor injuries. This may include cleaning cuts, applying bandages, and using cold compresses for burns or abrasions. Seek Medical Help: For serious injuries, seek professional medical assistance immediately. Call emergency services if necessary. Report the Incident: Inform Supervisors: Report the accident to your supervisor or safety officer. Provide details about how the incident occurred and the extent of the injuries. Document the Incident: Fill out an accident report form, including information about the equipment used, the nature of the injury, and any contributing factors. Review and Improve Safety Practices: Incident Analysis: Analyze the accident to determine its cause. Review whether safety protocols were followed and identify any gaps in training or equipment maintenance. Safety Training: Consider additional abrasive wheels training or a refresher course to reinforce safe practices and prevent future accidents. Online courses can be a convenient way to update your knowledge. Preventive Measures: Review Procedures: Ensure that all safety procedures are up-to-date and that all employees are familiar with them. Safety Drills: Conduct regular safety drills to prepare for potential accidents and improve response times. Legal Requirements and Certifications Overview of Relevant Laws and Regulations Using abrasive wheels involves adhering to specific safety laws and regulations to ensure the safety and health of workers. Here’s an overview of the key legal requirements: Occupational Safety and Health Administration (OSHA): In the United States, OSHA sets standards for the safe use of abrasive wheels. Employers must comply with OSHA regulations, including proper machine guarding, employee training, and the use of personal protective equipment (PPE). Provision and Use of Work Equipment Regulations (PUWER): In the UK, PUWER requires that work equipment, including abrasive wheels, is suitable for its intended use, properly maintained, and only operated by trained personnel. European Safety Standards: In Europe, EN 12413 is the standard for bonded abrasive products. It sets out requirements for safety, marking, and product testing to ensure the safe use of abrasive wheels. Regular Inspections and Maintenance: Laws often require regular inspections and maintenance of abrasive wheels and related machinery to ensure they remain in safe working condition. Record Keeping: Employers must keep records of all training, inspections, and maintenance activities related to abrasive wheels. How to Get Certified in Abrasive Wheels Training Getting certified in abrasive wheels training involves completing a recognized course and passing the necessary assessments. Here’s how you can achieve certification: Find a Training Provider: Look for accredited training providers that offer courses on abrasive wheels. Valley Plant Training is a well-known provider that offers comprehensive abrasive wheel training courses. You can also search for “abrasive wheel training near me” to find local providers or explore online options. Enroll in an Abrasive Wheel Course: Choose a course that covers both theoretical and practical aspects of abrasive wheel safety. The course should include topics such as wheel selection, proper mounting, safe operation techniques, and maintenance. Valley Plant Training offers courses that meet these criteria. Complete the Training: Attend the training sessions and participate actively. Training can be done in-person or online, depending on your preference and availability. Online courses can be convenient and flexible for busy schedules. Pass the Assessment: At the end of the course, you’ll need to pass an assessment to demonstrate your understanding of the material. This may include a written test and a practical demonstration of your skills. Receive Your Abrasive Wheels Certificate: Upon successful completion of the course and assessment, you will receive an abrasive wheels certificate. This certificate is proof that you have been trained in the safe use of abrasive wheels. Regular Refresher Courses: It’s important to stay updated with the latest safety practices and regulations. Consider taking refresher courses periodically to keep your skills and knowledge current. Valley Plant Training also offers refresher courses to help you stay up-to-date. Obtaining an abrasive wheel training certification from Valley Plant Training or another reputable provider not only enhances your safety and efficiency but also ensures compliance with legal requirements. It demonstrates to employers and regulatory bodies that you are qualified to handle abrasive wheels safely and effectively. Frequently Asked Questions What is abrasive wheel training? This is a training course that teaches you how to safely use and take care of machines that have abrasive wheels, like grinders. It covers choosing the right wheel, setting it up, and learning safety rules to prevent accidents. How much does abrasive wheels training cost? The price can change depending on where you are and who’s teaching the course. Generally, it might cost between £150.00 and £250 for the basic training. How long does abrasive wheels training last? Most basic courses take about a day to complete, around 6 to 8 hours. More detailed courses might take longer, especially if they include hands-on practice. Can abrasive wheel training be done online? Yes, you can learn the theory part online at your own pace. For learning how to actually use the wheels, you might need to attend a session in person to get practical experience. What are the two types of abrasive wheels? There are two main kinds: bonded and coated abrasive wheels. Bonded wheels are made of abrasive particles stuck together and are used for tasks like grinding or cutting. Coated wheels have a layer of abrasive glued to a backing material and are used for smoothing surfaces. What are the rules for abrasive wheels? The main rules include setting up the wheel correctly, wearing the right safety gear, checking the wheel regularly for damage, and following specific steps when using it to stay safe. There are also official safety standards you need to follow. Testing Of Candidates We will assess the delegates throughout the course on their levels of participation and understanding, they will demonstrate the inspection of various Abrasive wheels for damage and suitability. Then the delegates will complete a 25 question assessment paper at the end of the course. Successful delegates will be issued with the NPORS operator card Abrasive Wheels Training Covers: The requirements of the HASAW and PUWER and all associated regulations in respect of Abrasive Wheels. Hazards arising from the use of Abrasive Wheels and the precautions that should be taken. How to identify the Abrasive Wheel types and characteristics. Storage, handling and transportation of Abrasive Wheels. Inspecting and testing Abrasive Wheels. Personal protective equipment. Abrasive Wheels Training Available 7 days a week to suit your business requirements. VPT have a team of friendly and approachable instructors, who have a wealth of knowledge of abrasive wheels and the construction industry We have our own training centre for abrasive wheels conveniently located close to the M5 junction 9, In Tewkesbury. With its own purpose-built practical training area to simulate an actual working environment. Our abrasive wheels training and test packages are priced to be competitive. Discounts are available for multiple bookings We can send a fully qualified NPORS abrasive wheels Tester to your site nationwide, to reduce the amount of time away from work Other course: Enhance your skills with our specialized courses, including Lift Supervision Training, Appointed Person Training, Telehandler Training, Cat & Genny Training, Slinger Signaller Training, Lorry Loader Training and Crusher Training. Each program is designed to equip you with the expertise needed for excellence in your field.

Educators matching "Lighting"

Show all 31Search By Location

- Lighting Courses in London

- Lighting Courses in Birmingham

- Lighting Courses in Glasgow

- Lighting Courses in Liverpool

- Lighting Courses in Bristol

- Lighting Courses in Manchester

- Lighting Courses in Sheffield

- Lighting Courses in Leeds

- Lighting Courses in Edinburgh

- Lighting Courses in Leicester

- Lighting Courses in Coventry

- Lighting Courses in Bradford

- Lighting Courses in Cardiff

- Lighting Courses in Belfast

- Lighting Courses in Nottingham