- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

58 Insulation courses

C205-MATERIALS

By CWCT

Outline: This course is intended to provide an introduction to some key materials and components used in contemporary building envelopes. This course will identify key British, European and CWCT standards and guides relevant to those elements. NOTE: The material for this course is based on previous MTCP and CWDC courses. Target audience: This course is aimed at those who specify and use the more common materials that are used in the construction of contemporary building envelopes. Learning objectives: Understand the factors affecting the durability of key façade metals, Understand commonly used coatings, Understand key performance criteria of key polymeric materials, Understand different insulation and thermal break materials, Appreciate different commonly used panel and board materials, Appreciate key production and fabrication issues relating to façade materials. Assessment: Assessment will be via a series of multiple-choice questions following the course, The assessment is timed and must be passed in order to receive a CPD certificate for the course, If the assessment is failed, one re-take will be permitted. Prerequisites: None, although C201 Introduction to contemporary cladding and façade systems is recommended. Course availability: 30 September - 27 October 2024 Lecture time: 1 day Price: Member price Non-Member price £180 + VAT £360 + VAT

Fire Alarm Foundation Course

By Hi-Tech Training

The Fire Alarm Foundation course is designed to give participants a practical knowledge of the operation and installation of Fire Alarm Systems at a foundation level. During this practical and theory-based course students will gain the skills and knowledge to install and wire up a Fire Alarm Control Panel to typical auxiliary equipment such as Break Glass Units, Smoke Detectors, Heat Detectors, Bells, and Sirens.

Transmission Lines: Design, Analysis and Applications

By EnergyEdge - Training for a Sustainable Energy Future

About this training course Transmission lines and sub-stations are essential components in the electrical power systems. Proper design and maintenance are crucial for transmission lines to maintain a continuous operation. The objective of this 5-day training course is to deal appropriately with control systems, design characteristics and electric & magnetic fields. Participants will gain a better understanding on the corona and gap discharge phenomena, constructional features, and optimization of the transmission lines. Training Objectives By participating in this course, you will be able to: Understand transmission line design and its application Examine different types of conductors and electrical characteristics Explore basic and general transmission line parameters Prevent overvoltage through insulation design Determine surge impedance and corona effects Calculate and measure electric and magnetic fields Comprehend the impact of audible noise and electromagnetic interference Identify interference within the transmission line systems Target Audience The course will greatly benefit the following groups but not limited to: Electrical Engineers Civil Engineers Transmission & Distribution Engineers Substation Operators Safety Engineers Reliability Engineers Facility & Plant Engineers Technical Engineers Design Engineers Plant Supervisors Electrical Contractors Course Level Basic or Foundation Intermediate Training Methods The training instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught in their own organization. Course Duration: 5 days in total (35 hours). Training Schedule 0830 - Registration 0900 - Start of training 1030 - Morning Break 1045 - Training recommences 1230 - Lunch Break 1330 - Training recommences 1515 - Evening break 1530 - Training recommences 1700 - End of Training The maximum number of participants allowed for this training course is 25. This course is also available through our Virtual Instructor Led Training (VILT) format. Trainer Your expert course leader is a professional engineer with extensive experience in power system studies, substation design field-testing, and EHS programs settings for Mining and Electrical Utilities sectors. He was formally the Engineering Manager at GE Canada in Ontario. He received his M.Sc. in electrical engineering from the University of New Brunswick and his MBA from Laurier School of Business in Waterloo. He has managed and executed more than 150 engineering projects on substation design EMF audits and power system studies and analyses, EMF audits and grounding audits, for major electrical utilities, mines, oil and gas, data centers, industrial and commercial facilities in Canada and the U.S. He is a certified professional engineer in the provinces of Ontario and Alberta. He has various IEEE publications, has served as a technical reviewer for many IEEE journals in power systems and control systems, and is the chair of the Industry Application Chapter (IAS) for IEEE Toronto Section. He remains a very active member for the IEEE substation committee of IEEE Std. 81 ground testing (WGE6) and IEEE Std. 80 ground design (WGD7). A certified electrical safety trainer by GE Corporate and a Canadian Standard Association (CSA) committee member at the mining advisory panel for electrical safety, he also taught many technical courses all over Canada to industrial customers, electrical consultants as well as to electrical utilities customers. Highlighted Projects: Various Power System Studies for 345/230 kV Stations - Nova Scotia Power (EMERA) RF audits for Telecom tower and antennas - Cogeco/Rogers Mobile Power System analysis - Powell Canada Structural/Geotechnical Design and upgrades - Oakville Hydro Underground Cables testing and sizing - Plan Group Relay programming and design optimization - Cenovus Canada Different Arc Flash Analysis and BESS Design - SNC Lavalin Environmental site assessment (ESA) Phase I/II for multiple stations - Ontario Electromagnetic compatibility (EMC) assessment for Toronto LRT expansion - MOSAIC Battery energy storage system (BESS) installation at City of London - Siemens Canada EMF audits for 500 kV Transmission Lines - Hydro One EMF audits for 500 kV Transmission Lines - Hydro Quebec AC interference for 138 kV line modeling and mitigations - HBMS Mine POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Description: Want to develop your practical skills around the house? Are you a plumber, electrician or technician in training? This Diploma in Professional Repair Expert Course is the ultimate guide to home improvement, repairs and maintenance. In this online course, you will discover the tools, techniques and health and safety measures you will need to become handier around the home. Develop valuable practical skills and expand your knowledge of home maintenance with tips and expert course material that will help you save money and time. This handyman course will teach you to fix everyday issues such as malfunctioning tools, faulty wiring and basic plumbing emergencies. You'll also learn more advanced home improvements such as bathroom remodelling, insulation, woodwork and roof repair. This training course will benefit anyone who wants to be able to fix minor issues around the home, or wants a general introduction to DIY and professional repair. Who is the course for? Professionals who want to learn about Repair and make a business out of it. People who have an interest in home improvements by repairing it themselves. Entry Requirement: This course is available to all learners, of all academic backgrounds. Learners should be aged 16 or over to undertake the qualification. Good understanding of English language, numeracy and ICT are required to attend this course. Assessment: At the end of the course, you will be required to sit an online multiple-choice test. Your test will be assessed automatically and immediately so that you will instantly know whether you have been successful. Before sitting for your final exam you will have the opportunity to test your proficiency with a mock exam. Certification: After you have successfully passed the test, you will be able to obtain an Accredited Certificate of Achievement. You can however also obtain a Course Completion Certificate following the course completion without sitting for the test. Certificates can be obtained either in hardcopy at a cost of £39 or in PDF format at a cost of £24. PDF certificate's turnaround time is 24 hours and for the hardcopy certificate, it is 3-9 working days. Why choose us? Affordable, engaging & high-quality e-learning study materials; Tutorial videos/materials from the industry leading experts; Study in a user-friendly, advanced online learning platform; Efficient exam systems for the assessment and instant result; The UK & internationally recognised accredited qualification; Access to course content on mobile, tablet or desktop from anywhere anytime; The benefit of career advancement opportunities; 24/7 student support via email. Career Path: The Diploma in Professional Repair Expert is a useful qualification to possess, and would be beneficial for the following careers: Electrician Handyman Plumber Professional Repair Expert Repairs and Maintenance Manager Technician. Module 1: Home Improvements Choosing A Contractor 01:00:00 Pollution and Remodeling 00:30:00 Do It Yourself Bathroom Remodeling 00:30:00 Tips for Installing Leak-proof Showers 00:30:00 Do It Yourself Kitchen Remodeling 00:30:00 Installing Kitchen Cabinets 00:30:00 Choosing Countertops 00:30:00 Adding A Bedroom 00:30:00 Basement Problems Turned Around 00:30:00 Options for Lighting Your Home 00:30:00 How To Lay Indoor-Outdoor Carpet 00:30:00 Tips for Installing A Tile Floor 00:30:00 How To Prepare to Install Moulding 01:00:00 TV Stand Design Ideas 00:30:00 Home Air Conditioning Maintenance Made Easy 01:00:00 How To Diagnose Central Heating Systems 00:30:00 Insulation 00:30:00 Fixing Your Sink 00:30:00 Fixing Clogged Pipes and Drains 00:30:00 Replacing Screens 00:30:00 Replacing Doors 01:00:00 Six Tips For Decks Built to Last 00:30:00 Three Steps To Refinish Your Decks 00:30:00 Installing Your Hot Tub 00:30:00 Low Hassle Exterior Painting 00:30:00 Low Hassle Roof Repair 00:30:00 Gardens for Profit and Beauty 01:00:00 Judging Construction - Ground and Walls 00:30:00 Judging Construction - Ground and Walls 00:30:00 Choosing An Alarm System, Hardware AND People 00:30:00 Module 2: Professional Repairing Essential Tools For Your Toolbox 00:30:00 Woodworking Ideas And Skills 00:30:00 Basic Ideas Of Plumbing 00:30:00 Basic Ideas Of Electronics 01:00:00 Advanced Ideas And Skills Of Electronics 00:30:00 How To Protect Yourself From Injuries 01:00:00 Mock Exam Mock Exam- Diploma in Professional Repair Expert 00:30:00 Final Exam Final Exam- Diploma in Professional Repair Expert 00:30:00 Order Your Certificates and Transcripts Order Your Certificates and Transcripts 00:00:00

An Introduction to HTC

By NJV LTD BetaTeach

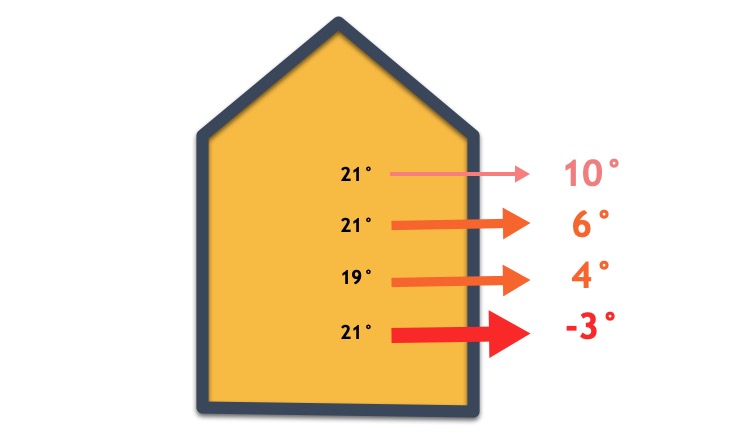

Understanding a buildings heat loss for heating engineers

Piping Stress Engineering

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Training (VILT) The 5 half-day Piping Stress Engineering Virtual Instructor Led Training (VILT) course will systematically expose participants to: The theory and practice of piping stress engineering, with special reference to ASME B 31.1 and ASME B 31.3 Standards. The basic principles and theories of stress and strain and piping stress engineering, through a series of lessons, case study presentations, in-class examples, multiple-choice questions (MCQs) and mandatory exercises. Principal stresses and shear stresses which form the backbone of stress analysis of a material. Expressions for these quantities will be derived using vector algebra from fundamentals. Thermal stress-range, sustained and occasional stresses, code stress equations, allowable stresses, how to increase flexibility of a piping system, cold spring. The historical development of computational techniques from hand calculations in the 1950s to the present-day software. Training Objectives On completion of this VILT course, participants will be able to: Identify potential loads the piping systems and categorise the loads to primary and secondary. Determine stresses that develop in a pipe due to various types of loads and how to derive stress-load relationships, starting from scratch. Treat the primary and secondary stresses in piping system in line with the intent of ASME Standards B 31.1 and B 31.3 and understand how the two codes deal with flexibility of piping systems, concepts of self-springing and relaxation/shake down, displacement stress range and fatigue, what is meant by code compliance. Understand the principles of flexibility analysis, piping elements and their individual effects, flexibility factor, flexibility characteristic, bending of a curved beam and importance of virtual length of an elbow in the flexibility of a piping system. Learn stress intensification factors of bends, branch connections and flanges. Understand how the stresses in the material should be controlled for the safety of the piping system, the user and the environment. Examine how codes give guidance to determine allowable stresses, stress range reduction due to cyclic loading, and effects sustained loads have on fatigue life of piping. Confidently handle terminal forces and moments on equipment. Understand the supplementary engineering standards required to establish acceptance of the equipment terminal loads and what can be done when there are no engineering standard governing equipment terminal loads is available and learn the techniques of local stress analysis. Get a thorough understanding of the concepts and the rules established by the ASME B 31.1 and ASME B 31.3 Standards. Perform flange load analysis calculations based on Kellogg's Equivalent Pressure method & Nuclear Code method. Perform the same using a piping stress analysis software and check for flange stresses and leakage. Confidently undertake formal training of piping stress analysis using any commercial software, with a clear understanding of what happens within the software rather than a 'blind' software training and start the journey of becoming a specialist piping stress engineer. Target Audience The VILT course is intended for: Recent mechanical engineering graduates who desire to get into the specialist discipline of Piping Stress Engineering. Junior mechanical, chemical, structural and project engineers in the industry who wish to understand the basics of Piping Stress Engineering. Engineers with some process plant experience who desire to progress into the much sought-after specialist disciplines of Piping Stress Engineering. Mechanical, process and structural engineers with some process plant experience who desire to upskill themselves with the knowledge in piping stress engineering and to become a Piping Stress Engineer. Any piping engineer with some pipe stressing experience in the industry who wish to understand the theory and practice of Piping Stress Engineering at a greater depth. A comprehensive set of course notes, practice exercises and multiple-choice questions (MCQs) are included. Participants will be given time to raise questions and participants will be assessed and graded based on responses to MCQs and mandatory exercises. A certificate will be issued to each participant and it will carry one of the three performance levels: Commendable, Merit or Satisfactory, depending on how the participant has performed in MCQs and mandatory exercises. Training Methods The VILT course will be delivered online in 5 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. Course Duration: 5 half-day sessions, 4 hours per session (20 hours in total). Trainer Your expert course leader is a fully qualified Chartered Professional Engineer with over 40 years of professional experience in Oil & Gas (onshore and offshore), Petrochemical and Mining industries in engineering, engineering/design management and quality technical management related to plant design and construction. At present, he is assisting a few Perth based oil & gas and mining companies in detail engineering, piping stress analysis, feasibility study and business development work related to plant design. He is a pioneer in piping stress engineering in Western Australia. His recent major accomplishments include the following roles and challenges: Quality Technical Support Manager of USD 54 billion (Gorgon LNG Project). This encompassed management of quality technical services connected with Welding, Welding Related Metallurgy, Non-Destructive Examination, Insulation /Refractory /Coating, AS2885 Pipelines Regulatory Compliance and Pressure Vessel Registration. Regional Piping Practice Lead and Lead Piping Engineer of Hatch Associates. In this role, he was responsible for providing discipline leadership to several mining projects for BHP Billiton (Ravensthorpe), ALCOA-Australia (Alumina), Maáden Saudi Arabia (Alumina), QSLIC China (Magnesium), COOEC China (O&G Gorgon). He was actively involved in the development of piping engineering practice in WA, including training and professional development of graduate, junior and senior engineers. This also includes the formation of the Piping Engineering Specialist Group. Lead Piping/Pipe Stress Engineer on ConocoPhillips' (COP) Bayu Undan Gas Recycle, Condensate production and processing platform. He was able to develop several novel design methodologies for the project and provided training to engineers on how to implement them. These methodologies were commended by COP and the underwriters of the project Lloyds Register of Shipping, UK. Creator of Piping Engineering Professional Course aimed at global engineering community. Professional Affiliations: Fellow, Institution of Mechanical Engineers, UK (IMechE) Fellow, Institution of Engineers, Australia (EA), National Register of Engineers (NER) Member American Society of Mechanical Engineers, USA (ASME) Honorary Life Member, Institution of Engineers, Sri Lanka (IESL) POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

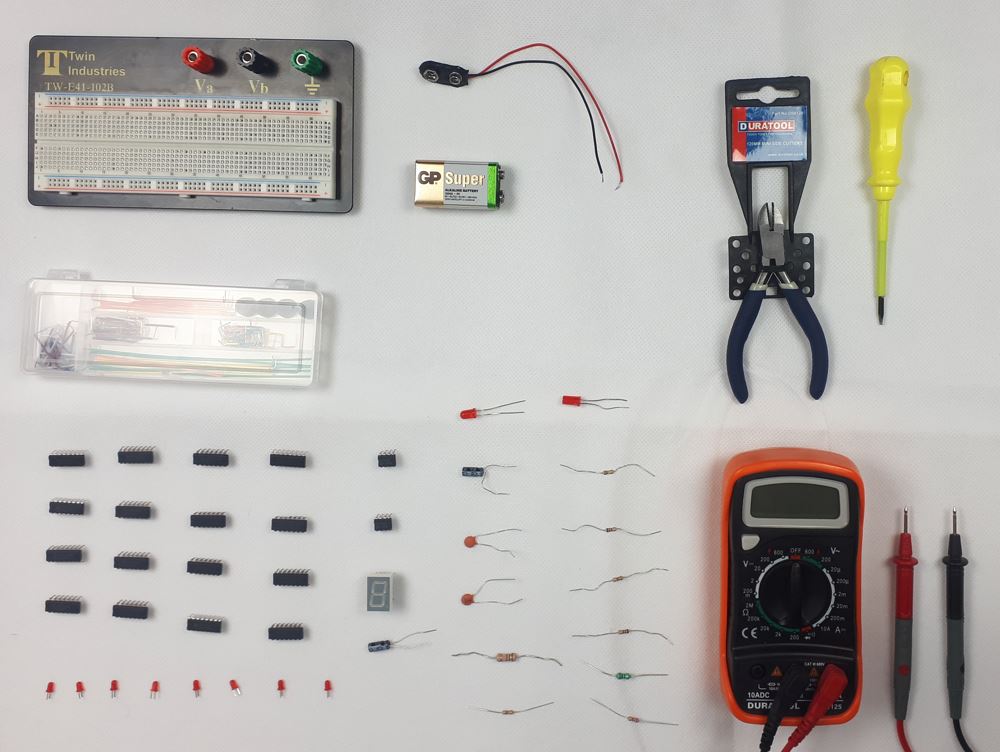

Digital Electronics

By Hi-Tech Training

The course will be delivered through 9 online virtual classroom sessions. The 10th and last session will involve the additional practical work for the course as well as the written examination (multiple choice for City & Guilds and written for Hi-Tech Training) which will take place at our training centre at 43 North Great Georges Street, Dublin 1 (completed online for non ROI learners). During the virtual classroom sessions, trainees will have a live video feed with their instructor talking to them, doing practical live demonstrations on equipment being involved actively in the learning. We will send out a practical kit so that trainees can complete assignments and practical work at home. The kit is the property of Hi-Tech Training and will be returned to Hi-Tech Training on the last day of the course. (The kits may also be purchased by the learner….see the Kits Page Link for more details). The kit consists of power supply unit breadboard, multimeter, cables, The kit consists of breadboard, multimeter, oscilloscope, battery and connectors, components including resistors, LEDs and ICs (AND, NAND, OR, NOR, X-OR, X-NOR, Inverter, Buffer, Latches, Flip-Flops, Timers, etc). Trainees will build various projects as part of the course. The kit forms an integral part of the course, so full course fees need to be paid at least 7 days prior to course commencement to allow time to ship the kit in time for the course.

Revit MEP Training for 15 hours - Live and Online

By FirstScale Revit Consultant and Training

The Revit MEP course (£525), offers you individual learning (One to One) to improve your skills in Revit, and this course extends to 15 hours.

Digital Electronics Course Online

By Hi-Tech Training

This Digital Electronics Course is designed to give practical knowledge of the type of electronic circuitry used in a modern Computer System or in any type of Computer Controlled equipment such as Photocopiers, Cash Registers, Tablets, mobile phones and many other types of IT equipment. Digital Electronics involves the use of Silicon chips (Integrated Circuits). The internal structure of a computer is to a large extent comprised of Digital Electronic Circuits.

CERTIFICATE IN CAVITY WALL SURVEYING, EXTRACTION &/OR INSPECTION OCCUPATIONS

By Oscar Onsite

REFERENCE CODE 603/4678/4 COURSE LEVEL NVQ Level 2 THIS COURSE IS AVAILABLE IN Course Overview This is a work-based learning qualification for those involved in cavity wall surveys/inspections and/or clearance. The qualification has been developed at the request of and in partnership with OSCAR OSNITE https://oscaronsite.co.uk The OSCAR and this qualification are recognised by a number of UKAS Certification bodies, industry bodies, Local Authorities and industry stakeholders. Prior to registering on this qualification, individuals must be registered with OSCAR. The clearance pathway enables individuals to carry out the extraction of cavity wall insulation to create a clear cavity that can be reinsulated or insulated if the system has been used to remove debris only. Candidates must also prove knowledge and competence to create a clear cavity to be able to facilitate External Rendering and External Wall Insulation complying with current Building Regulations. All work must be completed following safe working practices, relevant legislation, and comply with contract information and the allocated timescales. The surveyor/inspection pathway requires candidates to demonstrate the skills and knowledge required to interpret information to be able to carry out a Cavity Clearance survey in accordance with the job specifications, following safe working practices and within the allocated time. The Surveyor must also understand how to communicate with others to ensure work is carried out effectively. This pathway includes identifying and selecting the correct quality of equipment, additionally candidates must understand how to calculate quantity, area and wastage. To achieve this pathway unit the survey work must be carried out in ways that will minimise the risk of damage to the work and surrounding area and using and maintaining equipment effectively. This qualification is made up of 3 mandatory units and 2 pathways. Candidates must complete the mandatory units and one or both of the pathways. The minimum credit value of this qualification is 24 credits. There is also an entirely optional additional unit, if achieved this will appear on the qualification certificate but does not count towards the minimum credit value of the qualification. Qualifications are now required to indicate the total qualification time (TQT), this is to show the typical time it will take someone to attain the required skills and knowledge to meet the qualification criteria, this qualification has a TQT of 240 hours. Qualifications are also required to indicate the number of hours of teaching someone would normally need to gain the skills and knowledge to achieve the qualification. These are referred to as Guided Learning Hours (GLH). The GLH for this qualification is 84. Mandatory Units Level Credit Conforming to General Health, Safety and Welfare in the Workplace Conforming to Productive Working Practices in the Workplace Handling and Storing Resources in the Workplace 2 5 Pathway 1 Cavity Wall Clearance Cavity wall clearance in the workplace CWC1 Pathway 2 – Cavity Extraction Specialist Surveyor/Inspector Surveying/Inspection of Cavity wall clearance in the workplace Summary of the: GQA NVQ LEVEL 2 CERTIFICATE IN CAVITY WALL EXTRACTION OCCUPATIONS SICW1 Additional Unit Erecting and Dismantling Access/Working Platforms in the Workplace Achieving the combination of Mandatory units and the correct choice of Optional credits will mean the qualification has been completed and GQA will provide the qualification title. Where a candidate has completed additional credits, the qualification will list these as “additional credits”, in cases where the candidate has not completed the full qualification and will not go on to do so, a Certificate of credit can be issued for the credits achieved. Assessment guidance: Evidence should show that you can complete all of the learning outcomes for each unit being taken. Types of evidence: Evidence of performance and knowledge is required. Evidence of performance should be demonstrated by activities and outcomes, and should be generated in the workplace only, unless indicated under potential sources of evidence (see below). Evidence of knowledge can be demonstrated though performance or by responding to questions. Quantity of evidence: Evidence should show that you can meet the requirements of the units in a way that demonstrates that the standards can be achieved consistently over an appropriate period of time. Potential sources of evidence: The main source of evidence for each unit will be observation of the candidate’s performance and knowledge demonstrated during the completion of the unit. This can be supplemented by the following types of physical or documentary evidence: Accident book/reporting systems Photo/video evidence Safety records Work diaries Training records Timesheets Audio records Telephone Logs Job specifications and documentation Meeting records Delivery Records Records of toolbox talks Witness testimonies Equipment Correspondence with customers Prepared materials and sites Notes and memos Completed work Please Note that photocopied or downloaded documents such as manufacturers or industry guidance, H&S policies, Risk Assessments etc, are not normally acceptable evidence for GQA qualifications unless accompanied by a record of a professional discussion or Assessor statement confirming candidate knowledge of the subject. If you are in any doubt about the validity of evidence, please contact Oscar Onsite Academy

Search By Location

- Insulation Courses in London

- Insulation Courses in Birmingham

- Insulation Courses in Glasgow

- Insulation Courses in Liverpool

- Insulation Courses in Bristol

- Insulation Courses in Manchester

- Insulation Courses in Sheffield

- Insulation Courses in Leeds

- Insulation Courses in Edinburgh

- Insulation Courses in Leicester

- Insulation Courses in Coventry

- Insulation Courses in Bradford

- Insulation Courses in Cardiff

- Insulation Courses in Belfast

- Insulation Courses in Nottingham