- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

NPORS Forward Tipping Mini Dumper (N139)

By Dynamic Training and Assessments Ltd

NPORS Forward Tipping Mini Dumper (N139)

NPORS Multi Directional Lift Truck (N135)

By Dynamic Training and Assessments Ltd

NPORS Multi Directional Lift Truck (N135)

Level 2 NVQ Certificate in Plant Operations - Processing

By Dynamic Training and Assessments Ltd

Level 2 NVQ Certificate in Plant Operations - Processing

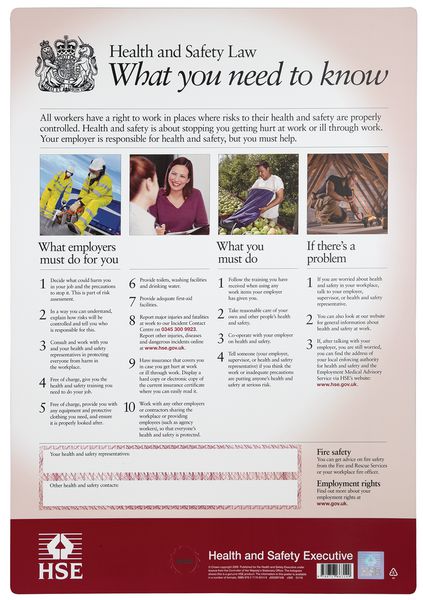

This course is suitable for all managers and supervisors who have a responsibility for providing high health and safety standards in the workplace. This qualification is applicable to any private or public sector working environment. Individuals working towards this qualification will learn that supervisors and managers have legal and moral obligations to ensure health and safety within a business and that these include obligations to employees, contractors, suppliers and members of the public.

Mastering Critical Conversations: In-House Training

By IIL Europe Ltd

Mastering Critical Conversations: In-House Training We will explore various obstacles to delivering 'challenging' messages effectively, including those that come from the external environment as well as those we encounter internally. After gaining insight into the brain science behind the biology of conflict and emotion, we will then examine a 5-step framework for delivering difficult messages. Paired and small group activities comprise a large portion of this interactive course, which culminates in a role play. What You Will Learn At the end of this program, you will be able to: Recognize how a perceived threat by the brain translates into a physiological response of fight, flight, or freeze Utilize various techniques to mitigate an 'amygdala hijack' state Leverage a 5-step model to deliver 'challenging' news effectively Managing Difficult Conversations Obstacles to managing difficult conversations Understanding human nature Brain Science and the Biology of Emotion The unique challenge of social and emotional learning The limbic system and the amygdala hijack Self-regulation strategy for the amygdala hijack Delivering Challenging Messages Managing difficult conversations 5 steps for delivering a challenging message Verbal active listening techniques Preparing to deliver a challenging message (scenarios) Conversations Involving Emotion and Conflict Two types of conflict Spectrum of responses to conflict Psychological type preferences and conflict Creating an action plan

NPORS Skidsteer Loader (N212)

By Dynamic Training and Assessments Ltd

NPORS Skidsteer Loader (N212)

NPORS Piling Rig Attendant (N022)

By Dynamic Training and Assessments Ltd

NPORS Piling Rig Attendant (N022)

Beach Lifeguard Course

By Freewavesurfacademy

The five day National Vocational Beach Lifeguard Qualification (NVBLQ) will provide the learner with the knowledge and skills required in order to provide professional patrolling and water services, in surf conditions, with rescue skills and advanced fitness requirements. Many aspects of the course are physically demanding and WILL include running, swimming to set times and some lifting. This award is comprised of a variety of units and all must be successfully passed to attain the qualification.

Level 6 NVQ Diploma in Construction Site Management

By Dynamic Training and Assessments Ltd

Level 6 NVQ Diploma in Construction Site Management

NPORS Telescopic Handler Suspended Loads (N138)

By Dynamic Training and Assessments Ltd

NPORS Telescopic Handler Suspended Loads (N138)

Search By Location

- Industry Courses in London

- Industry Courses in Birmingham

- Industry Courses in Glasgow

- Industry Courses in Liverpool

- Industry Courses in Bristol

- Industry Courses in Manchester

- Industry Courses in Sheffield

- Industry Courses in Leeds

- Industry Courses in Edinburgh

- Industry Courses in Leicester

- Industry Courses in Coventry

- Industry Courses in Bradford

- Industry Courses in Cardiff

- Industry Courses in Belfast

- Industry Courses in Nottingham