- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

NPORS Lift Supervisor Training The aim of the NPORS Lift Supervisor Training is to Provide candidates with underpinning knowledge to allow them to understand the role and responsibility of the Lift Supervisor. As a result of the Lift Supervisor Course, and following successful completion of the NPORS Crane Supervisor training candidates will be able to understand and follow safe systems of work for lifting operations. This Lift supervisor course is for 3 days and can be completed at your site or ours. It is important that all delegates have a good understanding of spoken and written English for NPORS Crane Supervisor Training. NPORS Lift Supervisor Experienced Test Book with Confidence at Vally Plant Training At Vally Plant Training, we guarantee unbeatable value with our Lift Supervisor Experienced Test Price Match Promise. When you choose us, you can book with confidence, knowing that we will not be beaten on price. If you find a lower price for the same NPORS Lift Supervisor Experienced Worker Test, we’ll match it—ensuring you receive top-quality training at the best possible rate. Click for our terms and conditions Your skills, our commitment—always at the best price. NPORS Lift Supervisor Experienced Worker Test is for operators who have received some form of Lift Supervisor Course in the past or alternatively has been working with Lifting equipment, like cranes, Excavators or Telehandlers for a number of years. If you are unsure if you qualify to go down the Lift Supervisor experienced test route please contact our team to discuss this in more detail. Discounts are available for multiple Lift Supervisor Course bookings There are two parts to the lift supervisor test, a theory section comprised of 25 questions and a practical session, however Lift Supervisor training revision notes will be sent once the test has been booked. It is important that all delegates have a good understanding of spoken and written English for NPORS Crane Supervisor Training Crane Supervisor Course Summary: Leading Safe and Efficient Lifting Operations Introduction Ever wonder who keeps construction sites and warehouses running smoothly and safely? That’s where lift supervisors come in. They’re the unsung heroes ensuring everything moves like clockwork. And when it comes to proving you’re the best in the biz, NPORS certification is your golden ticket. It’s not just a piece of paper; it’s your passport to climbing the career ladder. Choose our Lifting Supervisor Course Today. Why Choose Our NPORS Lift Supervisor Training? What makes our training stand out with our Lifting Supervisor Course? Imagine learning from folks who’ve been in the trenches, in training grounds that feel like the real deal, and schedules that bend to your life, not the other way around. We’re not about boring lectures; we’re about getting your hands dirty. Who Should Attend Lift Supervisor Training? Are you the go-to person when things need to get done? Whether you’re starting out or looking to step up, if you’re in the world of construction or logistics, this Lifting Supervisor Course is for you. It’s tailored for those who like to keep things moving, safely and efficiently. Course Objectives: 1. Understanding Regulatory Requirements: Familiarise participants with relevant regulations and industry standards governing crane operations, LOLER. Ensure compliance with legal requirements and best practices for safe lifting operations, BS7121. 2. Roles and Responsibilities of a Crane Lift Supervisor: Define the roles and responsibilities of a Lift supervisor within the context of lifting operations. Highlight the importance of effective communication, leadership, and decision-making skills. 3. Crane Safety Procedures: Provide an overview of crane safety procedures, including pre-operational checks, equipment inspection, and maintenance. Emphasize the importance of hazard identification, risk assessment, and mitigation strategies. 4. Lifting Plan Development: Guide participants in the understanding of the lifting plans tailored to specific lifting tasks and site conditions created by the Appointed Person(AP). Address factors such as load weight, size, shape, centre of gravity, and environmental considerations. 5. Site Safety and Hazard Awareness: Enhance participants’ awareness of potential hazards in the lifting environment, such as overhead power lines, unstable ground, and confined spaces. Implement effective measures to mitigate risks and ensure a safe working environment. 6. Communication and Coordination: Stress the importance of clear and effective communication between crane operators, riggers, signallers, and other personnel involved in lifting operations. Provide guidance on establishing communication protocols, using standardized hand signals, and conducting pre-lift briefings. 7. Emergency Response and Crisis Management: Equip participants with the skills and knowledge to respond effectively to emergencies and crisis situations during lifting operations. Implement emergency procedures, evacuation protocols, and contingency plans to mitigate risks and ensure personnel safety. 8. Practical Exercises and Case Studies: Provide hands-on lift supervisor training opportunities for participants to apply theoretical knowledge in practical scenarios. Analyse real-life case studies to identify lessons learned, best practices, and areas for improvement in crane supervision. Learning Outcomes By the end, you’ll be a pro at keeping sites safe, managing lifts, and leading teams. You’ll walk away not just with knowledge, but with practical skills that meet and beat industry standards. It’s about making you the go to lift supervisor everyone wants on their team. Course Logistics Ready to jump in? We’ve got training spots across the UK, with dates and times that fit your life. Signing up is a breeze, and we’ll guide you through any paperwork or prerequisites. It’s all about making it easy for you to get started. Conclusion: A crane supervisor course aims to empower participants with the expertise and confidence to lead safe and efficient lifting operations on construction sites. By focusing on regulatory compliance, safety procedures, lifting plan development, hazard awareness, communication, and practical training, the course prepares crane supervisors to fulfil their roles effectively and ensure the well-being of all personnel involved in lifting activities. Investing in crane supervisor training is essential for promoting a culture of safety, minimising risks, and achieving excellence in crane operations management. Crane Supervisor Training Available 7 days a week to suit your business requirements. VPT have a team of friendly and approachable instructors, who importantly have a wealth of knowledge of lifting supervision and the construction industry We have our own training centre conveniently located close to the M5 junction 9, In Tewkesbury. With its own purpose-built practical training area to simulate an actual working environment for the supervisor course. Our Lift Supervisor training and test packages are priced to be competitive. Discounts are available for multiple bookings We can send a fully qualified NPORS supervisor Tester to your site nationwide, for instance to reduce the amount of time away from work More courses: Polish your abilities with our dedicated Lift Supervision Training, Slinger Signaller Training, Telehandler Training, Cat & Genny Training, Plant Loader Securer, Ride-On Road Roller, Abrasive Wheel Training, Lorry Loader Training and Scissor Lift Training sessions. Learn the safe and effective operation of these vital machines, crucial for construction and maintenance tasks. Elevate your skills and career prospects by enrolling in our comprehensive courses today. Frequently Asked Questions 1. What is Lift Supervisor Training? Lift Supervisor Training is a specialised course designed to equip individuals with the knowledge and skills required to supervise lifting operations safely and efficiently. This training typically covers topics such as planning lifts, managing lifting equipment, and ensuring compliance with safety regulations. 2. Who should attend The Lifting Supervisor Course? This training is ideal for individuals responsible for overseeing lifting operations on construction sites, in warehouses, or any environment where lifting equipment like cranes are used. It’s particularly beneficial for site supervisors, managers, and anyone involved in the planning and execution of lifting operations to attend the NPORS Lift supervisor Course. 3. What certifications are available through the Lift Supervisor Training? Participants can obtain several Lift Supervisor certifications, including: NPORS Traditional card: Valid for 5 years, widely accepted in various sectors. NPORS card with CSCS logo: Recognised by major building contractors, with an initial RED trained operator card that can be upgraded to a BLUE competent operator card after completing relevant Crane Supervisor NVQ. 4. Is a health and safety test required for the NPORS Crane Supervisor Red operator card with the CSCS logo? Yes, to qualify for this card, you must have completed the CSCS operatives health and safety test within the last two years. 5 . How long is the certification valid, and what is the renewal process? The NPORS Traditional card is valid for 5 years. The NPORS card with the CSCS logo’s RED trained operator card is valid for 2 years, after which it can be upgraded to a BLUE competent Crane Supervisor operator card upon completion of relevant NVQs. The renewal process typically involves undergoing a refresher course or assessment to ensure continued competence. For those looking for a “NPORS Crane Supervisor Training near me,” our widespread operations make it convenient for you to access Vally Plant Trainings top-quality training no matter where you are in the UK

Did you know that: An estimated 55% of pregnancies in the UK are planned; the remainder are unplanned or associated with ambivalence1 12% of women aged 15–44 in heterosexual relationships report not using any method of contraception2 NICE guidance (2016) stipulates that women asking for contraception are given information about, and offered a choice of, all methods including long-acting reversible contraception (LARC)2 Over 1/3 of all women in England and Wales have ever an abortion3 Of all woman in England and Wales who had an abortion in 2021, 43% had had a previous abortion4 Why is SHIP training relevant to YOU? Do you worry about how to bring up the topic of contraception out of the blue? Find out how to outline key points about different methods of contraception to patients in a concise and time-efficient way Learn how to assess women to safely reissue combined hormonal contraception, progesterone only pill and injections Do you know what to do if you see a woman has had a recent abortion? Learn quick simple strategies to work out which methods of emergency contraception you should offer women We will help you become confident in bringing up and discussing contraceptive choices and make meaningful changes to your clinical practice! Basic Contraception 1 Differentiate between methods of contraception, including LARCs (long acting reversible contraception) Practice how to bring up contraception & promote LARC appropriately Establish guidelines for re-issuing combined hormonal contraception & progesterone only pill Establish guidelines for administering & re-issuing the contraceptive injection Basic Contraception 2 Manage requests for emergency contraception Outline and practise applying Fraser Guidelines Assess whether a woman is at risk of pregnancy and identify criteria for ‘near patient’ pregnancy testing Understand your role as general practice nurse in abortion referrals & aftercare Each session provides you with up-to-date resources to take back to your practice to support your consultations. References: Wellings K, Jones KG, Mercer CH et al. (2013) The prevalence of unplanned pregnancy and associated factors in Britain: findings from the third National Survey of Sexual Attitudes and Lifestyles (Natsal-3).Lancet 382: 1807–16 NICE Contraception Quality standard Published: 8 September 2016 nice.org.uk/guidance/qs129\ UK Government Abortion statistics, England and Wales https://www.gov.uk/government/statistics/report-on-abortion-statistics-in-england-and-wales-for-2016 Abortion Statistics, England and Wales: 2021, Office for Health Improvement and Disparities https://www.nice.org.uk/sharedlearning/sexual-health-in-practice-training-increases-hiv-testing-in-primary-care Pillay TD, Mullineux J, Smith CJ, et al. Unlocking the potential: longitudinal audit finds multifaceted education for general practice increases HIV testing and diagnosis. Sexually transmitted infections 2013;89(3):191-6. doi: 10.1136/sextrans-2012-050655 Click here to see how SHIP training in Haringey led to increases in testing & changes in practice

Level 2 Award in Principles of Safe Handling & Administration of Medication (POSHAM) (RQF)

By NR Medical Training

This Level 2 Award in Principles of Safe Handling and Administration of Medication (POSHAM) course has been specifically designed for those working within a health and social care setting, such as support workers or care workers, and have a responsibility for the safe handling and administration of medication. This qualification is also perfect for those looking to refresh their knowledge.

“You don't take a photograph. You make it" - Ansel Adams Photography For Parents - Editing In Lightroom Next course starts 11 March 2024 Editing is an essential skill for anyone with even just a passing interest in photography. Much as we try, we can't always get everything right in camera and editing tools help us bring our vision to life, help correct problems and allow our images to look beautifully polished. We teach how to do all these things in Adobe Lightroom because it's a powerful, intuitive and affordable tool used by Pros around the world for that very reason. KEY COURSE INFO: Course type: Instructor-led Course duration: 4 weeks + prep module Course format: Online course with interactive edit-along live classes, feedback on your learning and support group WHAT YOU LEARN: From being able to correct issues such as over/under exposure, issues with colour or graininess to bringing your vision to life, creating mood and tone to your images, knowing how to use editing software is a must. But good and purposeful editing goes way beyond just slapping on a preset or a filter - in our course we teach you all about the tools - not just what all of them do but how, and we teach you how to know what to use and when to achieve certain effects.everything you need to allow you to style your photos, confidently use the software and fix common problems. editing to correct common photo problems creating good editing workflow using powerful precision tools editing to achieve beautiful skin tones using light and colour creatively editing to bring out a mood of a feel THIS IS THE COURSE FOR YOU IF : Love taking photos but want them to look more polished - with colours that pop and light that's perfectly balanced You want to be able to fix common issues such as under- or overexposure, white balance or colour casts so that you never need to bin an image just because it wasn't right straight out of camera You want to get more creative with light and colour to make the images look just like the moment felt. Bring on the moody edits or sun soaked edits or light kissed skin tones or creative black and white conversions You want to confidently use the editing techniques so you can bring your vision to life every time, without guesswork You want to be able to prepare your images for print so that your walls can beam with pride at the beauty that you captured Next Editing in Lightroom course starts 11 March 2024 4 core course modules plus prep module Support Facebook group Weekly edit-along live webinar Practice files to learn on Feedback on your images HERE IS WHAT YOU WILL LEARN in this course : Our Photo Editing in Lightroom course guides you through the photo editing process in Adobe Lightroom from start to finish – from setting it up correctly, organising your collections and creating a workflow that works for you, through learning the capabilities of all the editing tools - such as adjusting exposure, colours, light or sharpening the images; all the way to printing and creating photo books. We’ll show you how to create specific artistic effects ( high impact Black and white, vintage, light and airy, dark and moody etc ), and how to fix common photography problems ( grainy images, underexposed images, wrong colours etc). At the end of the course you will be able to confidently manage your photo collection with Lightroom, achieve desired artistic effects and make your photos truly stand out. Getting around in Lightroom and Lightroom Classic - shooting in full manual - but with clarity and purpose Correcting common problems - whether your photo started too dark or too bright, your child's face was in a shade, the white balance and colours were off, the grain was heavy, the light looked dull - you can fix it all within a couple of clicks in Lightroom Using Lightroom's super powerful intelligent masking tools to quickly and efficiently edit specific parts of your image - from brightening up the eyes to rescuing overblown skies Enhancing and adding beautiful light - light makes images stand out, but it can be hard capturing the atmosphere it creates in camera at times. Lightroom is where you can bring light to life and make your images feel how what you saw in real life Knowing how to shoot in camera so you can get the most in editing - photographers will often purposefully under or overexpose images in camera so that they have more chance of balancing the image just they way they want in Lightroom. INSIDE THE MODULES - aka WHAT DO YOU LEARN? Module 0: Getting set up in Lightroom This module is released a week before the course starts to give you a chance to fully familiarise yourself with the layout, structure and the best way of working in Lightroom Classic, including guidance of creating a smooth selection and culling process that helps you see and keep the best of your images, without getting bogged down with 100s near duplicates. Module 1: Getting Started In Lightroom - Global Edits In this module we introduce you to Lightroom's most powerful tools - the global edits. We help you understand how to tweak your images to achieve the effects you're after quickly - from adjusting over and under exposure, to correcting white balance in a few different ways, to having a play with my favourite Lightroom tool - the tone curve. Major Takeaways: At the end of the module you will have gained full control of lightroom key global tools and will be able to use them to correct any global - as in affecting the whole image - issues with your images. This includes perfecting your exposure, balancing your colour and white balance, sharpening and creating clarity and more. Module 2: Targeted Edits - Masks! Lightroom allows us to apply edits to selected parts of the image through a range of its very powerful, intelligent and manual masks. This means you can now effortlessly select your subject from the photo to adjust them separately with just one click, you can pick only the sky, the subject's eyes or only colour green or any other element and treat them differently to the rest. Major Takeaways: You will be able to use the full range of masks in lightroom and apply your edits exactly where they are needed, and nowhere else. This includes working with with the new AI powered masks which can detect a person's individual features and allow you to selectively edit them in a few simple steps, as well as those more manual tools, that allow you to literally paint with light and colour on your photographs. Module 3: Creative Editing in Lightroom This is a brand new module in our course where we take all the tools introduced in Modules 1 and 2 and actually use them to achieve different effects on our photos. Wer show you how to be guided by light when editing, how to achieve a light and airy or a moody edit on your images, how to add light and how to convert to black and white, as well as how to edit skin in Lightroom! This module is all play! Major Takeaways: You will learn how to create yoru own editing process - from knowing where to start and to understanding what elements of your photograph may need or benefit from adjusting and knowing how you can do so to achieve different outcomes. You will also learn how to edit your skin tones so they look delightful - no matter what your subject's complexion. Module 4: After the edits We close the course with a module centered around all the things you might want to do after the edits - from preparation for print, creating photo books, but also sharing your images online and syncing them between different machines and adobe workplaces. PLUS there is a little Photoshop intro so you get a glimpse at how it's different and what it can do. Major Takeaways: You will learn how to connect all of your Adobe ecosystem and sync and share your images across multiple devices. You will learn how to prepare your images for print so they look their very best and how to create photobooks. Next course starts 11 March 2024 Absolutely, without a doubt book Editing. I was very unsure at first. My interest in photography is to capture those memories so it felt like it was 'cheating' to edit. I can honestly say it's like magic.To finish off the pictures you love and just give you complete control over the exposure, colours to make them perfect, to rescue the disasters etc. I learnt so much in those few weeks and it made the biggest difference to my photos. Kerry White Editing in LIGHTROOM Book your space now: COURSE STARTS : 11 March 2024 ( 4 weeks + 1 prep week)COURSE COST : £179 ( payment plans available ) What’s included: 4 weekly modules with step by step illustrated tutorials and videos + prep module weekly edit along class online class ( also recorded) - on Wednesday evenings feedback and advice on your edits private support group PDF workbook and downloadable videos Practice images to learn on Join our next group to really bring life to your images and make them look sleep, polished and full of light COURSE PREREQUISITES: Lightroom or Lightroom Classic CC software installed on your computer or tablet. RECOMENDED : Lightroom Photography Plan 25GB – a monthly subscription at approx £9pm – including Lightroom CC, Lightroom Classic CC and Photoshop. This plan can also be occasionally purchased at a lower price via Amazon or Groupon if you purchase a year’s worth of subscription in one go ( average savings – around 2-4 months worth depending on the deal) Please note that Adobe also has a Lightroom Plan with 1TB of storage – we do not recommend this plan as it restricts you to one version of software only. The increased Cloud storage can always be purchased as an add on or your plan can be switched from Photographer plan to CC only at a later stage if you prefer.

Visible Mending Class - Sashiko & Kantha stitching for Clothes repair

By isifiso

In this fun and creative course, you'll learn how to use sashiko mending techniques to patch your jeans with elegance. You will learn the fundamentals of visible mending jeans, which uses simple stitches to create stunning patterns and designs on the cloth. A step-by-step demonstration and guidance on how to execute sashiko stitching on jeans will be provided. You must bring your own ripped jeans or work on the sampler provided by us. Join us for this enjoyable and relaxing course to experience the delight of visible mending jeans!

Dry Needling 3 hour evening CPD

By Just Therapy

3 hour theory and practical session covering important trigger points related to common lower limb conditions such as knee pain, plantar fasciitis and achilles tendonitis. Small groups so lots of supervision and guidance. Courses taught by Justine Munur, 20+ years experienced in physiotherapy and dry needling/acupuncture, MSc in acupuncture and Chinese medicine. For more information please see the website www.just-therapy.co.uk/education

Health and Safety Representatives - Roles and Responsibilities (In-House)

By The In House Training Company

This practical course gives participants a brief overview of a range of legal aspects and also incorporates a topical perspective of health and safety matters in the workplace today. The programme will help elected staff safety representatives to grasp in more detail how to comply with the law in practice. 1 The legal framework Management of Health and Safety at Work Regulations (MHSWR) Safety Representatives and Safety Committees Regulations Representatives' functions H&S Consultation with Employees Regulation HSG 263 2 'The six pack' Management of Health and Safety at Work Regulations (MHSWR) Display Screen Equipment Regulation (DSE) Manual Handling Health, Safety and Welfare Provision and Use of Work Equipment Regulation Personal Protective Equipment Regulation 3 Accident reporting and procedures Reporting Injuries, Diseases and Dangerous Occurrences Regulation (RIDDOR) Accident investigation guidance

Emergency First Aid at Work

By Prima Cura Training

This one-day course will help you meet your regulatory requirements if your risk assessment indicates that first aid training covering emergency protocols only, is sufficient for your workplace.

COSHH & RIDDOR

By Prima Cura Training

This course is designed to provide delegates with awareness in the Control of Substances Hazardous to Health (COSHH) and how it may affect them, their colleagues, and their employer.

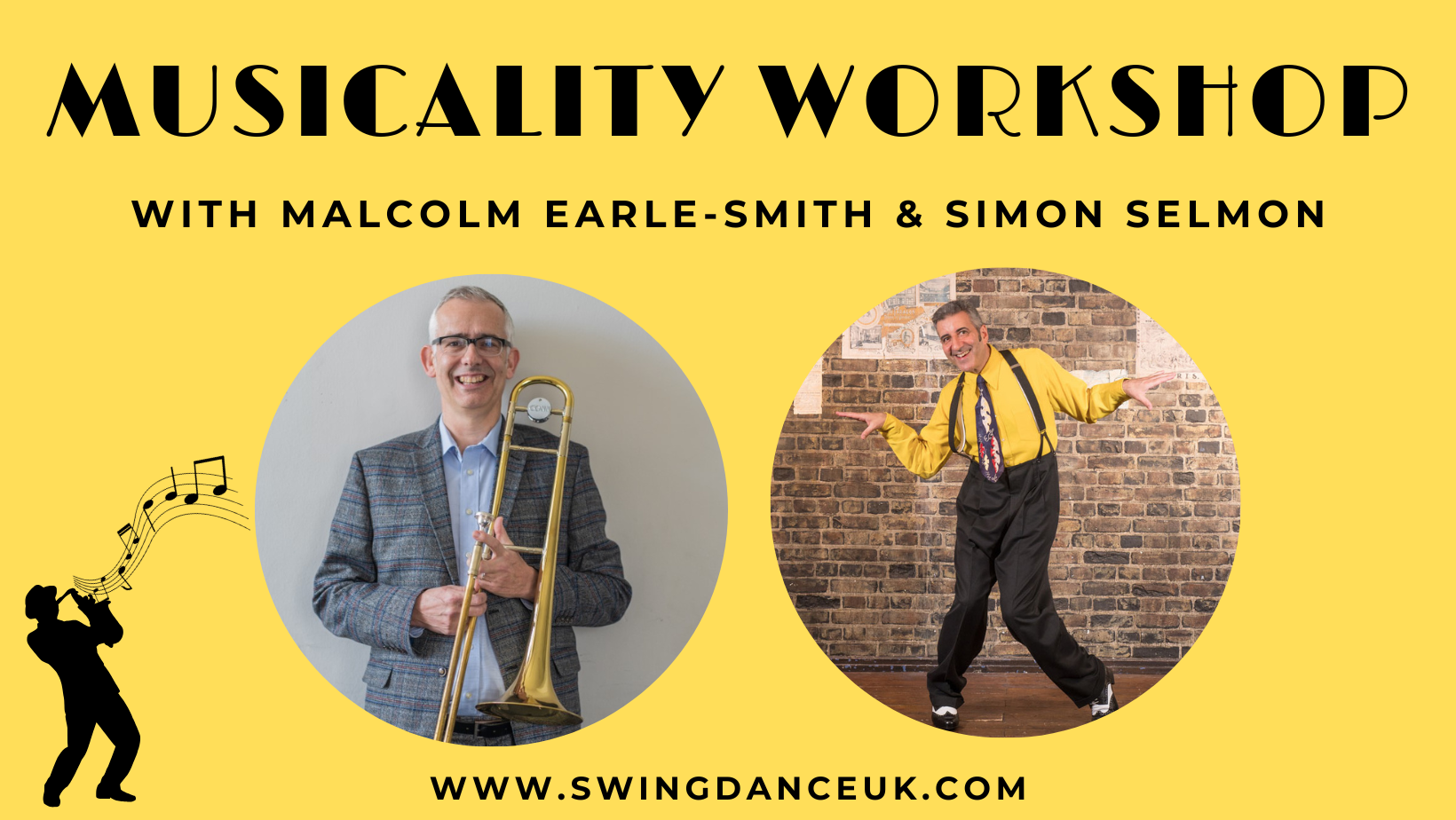

Musicality workshop featuring musician Malcolm Earle-Smith and dancer Simon Selmon. Using both Solo Jazz & Lindy Hop you will explore the music using rhythm, scatting and movement exercises to become more musical and creative in your dancing. With a mix of group exercises and one-to-one feedback, you'll have plenty of opportunities to dance and develop your skills to both recorded and live music.

Search By Location

- guidance Courses in London

- guidance Courses in Birmingham

- guidance Courses in Glasgow

- guidance Courses in Liverpool

- guidance Courses in Bristol

- guidance Courses in Manchester

- guidance Courses in Sheffield

- guidance Courses in Leeds

- guidance Courses in Edinburgh

- guidance Courses in Leicester

- guidance Courses in Coventry

- guidance Courses in Bradford

- guidance Courses in Cardiff

- guidance Courses in Belfast

- guidance Courses in Nottingham