- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

2584 Courses in Horsham

Securing UNIX systems training course description This course teaches you everything you need to know to build a safe Linux environment. The first section handles cryptography and authentication with certificates, openssl, mod_ssl, DNSSEC and filesystem encryption. Then Host security and hardening is covered with intrusion detection, and also user management and authentication. Filesystem Access control is then covered. Finally network security is covered with network hardening, packet filtering and VPNs. What will you learn Secure UNIX accounts. Secure UNIX file systems. Secure UNIX access through the network. Securing UNIX systems course details Who will benefit: Linux technical staff needing to secure their systems. Prerequisites: Linux system administration (LPIC-1) Duration 5 days Securing UNIX systems course contents Cryptography Certificates and Public Key Infrastructures X.509 certificates, lifecycle, fields and certificate extensions. Trust chains and PKI. openssl. Public and private keys. Certification authority. Manage server and client certificates. Revoke certificates and CAs. Encryption, signing and authentication SSL, TLS, protocol versions. Transport layer security threats, e.g. MITM. Apache HTTPD with mod_ssl for HTTPS service, including SNI and HSTS. HTTPD with mod_ssl to authenticate users using certificates. HTTPD with mod_ssl to provide OCSP stapling. Use OpenSSL for SSL/TLS client and server tests. Encrypted File Systems Block device and file system encryption. dm-crypt with LUKS to encrypt block devices. eCryptfs to encrypt file systems, including home directories and, PAM integration, plain dm-crypt and EncFS. DNS and cryptography DNSSEC and DANE. BIND as an authoritative name server serving DNSSEC secured zones. BIND as an recursive name server that performs DNSSEC validation, KSK, ZSK, Key Tag, Key generation, key storage, key management and key rollover, Maintenance and resigning of zones, Use DANE. TSIG. Host Security Host Hardening BIOS and boot loader (GRUB 2) security. Disable useless software and services, sysctl for security related kernel configuration, particularly ASLR, Exec-Shield and IP / ICMP configuration, Exec-Shield and IP / ICMP configuration, Limit resource usage. Work with chroot environments, Security advantages of virtualization. Host Intrusion Detection The Linux Audit system, chkrootkit, rkhunter, including updates, Linux Malware Detect, Automate host scans using cron, AIDE, including rule management, OpenSCAP. User Management and Authentication NSS and PAM, Enforce password policies. Lock accounts automatically after failed login attempts, SSSD, Configure NSS and PAM for use with SSSD, SSSD authentication against Active Directory, IPA, LDAP, Kerberos and local domains, Kerberos and local domains, Kerberos tickets. FreeIPA Installation and Samba Integration FreeIPA, architecture and components. Install and manage a FreeIPA server and domain, Active Directory replication and Kerberos cross-realm trusts, sudo, autofs, SSH and SELinux integration in FreeIPA. Access Control Discretionary Access Control File ownership and permissions, SUID, SGID. Access control lists, extended attributes and attribute classes. Mandatory Access Control TE, RBAC, MAC, DAC. SELinux, AppArmor and Smack. etwork File Systems NFSv4 security issues and improvements, NFSv4 server and clients, NFSv4 authentication mechanisms (LIPKEY, SPKM, Kerberos), NFSv4 pseudo file system, NFSv4 ACLs. CIFS clients, CIFS Unix Extensions, CIFS security modes (NTLM, Kerberos), mapping and handling of CIFS ACLs and SIDs in a Linux system. Network Security Network Hardening FreeRADIUS, nmap, scan methods. Wireshark, filters and statistics. Rogue router advertisements and DHCP messages. Network Intrusion Detection ntop, Cacti, bandwidth usage monitoring, Snort, rule management, OpenVAS, NASL. Packet Filtering Firewall architectures, DMZ, netfilter, iptables and ip6tables, standard modules, tests and targets. IPv4 and IPv6 packet filtering. Connection tracking, NAT. IP sets and netfilter rules, nftables and nft. ebtables. conntrackd Virtual Private Networks OpenVPN server and clients for both bridged and routed VPN networks. IPsec server and clients for routed VPN networks using IPsec-Tools / racoon. L2TP.

MEF Carrier Ethernet training course description The course progresses from a overview of the Carrier Ethernet service and how it works onto looking at the concepts in depth. Service attributes and management follow with the course finishing with studies of practical Carrier Ethernet. What will you learn Discuss and understand key Carrier Ethernet Concepts. Understand tasks related to designing, deploying and maintaining a Carrier Ethernet network. Offer effective solutions to implementing a Carrier Ethernet enterprise network given available customer resources and requirements. Carry out informed discussions using industry Carrier Ethernet 'vocabulary. Pass the MEF CECP 2.0 professional accreditation exam. MEF Carrier Ethernet training course details Who will benefit: Anyone working with Carrier Ethernet Prerequisites: The course attendees need to be conversant with data networks, as well as Ethernet and IP technologies. Duration 5 days MEF Carrier Ethernet training course contents Section One: Introduction to Carrier Ethernet Introduction to Carrier Ethernet: What is Carrier Ethernet? Evolution, advantages, The MEF, MEF specifications; UNI, EVC, OVC, EPL/EVPL, EP-LAN/ EVP-LAN, EP-Tree/EVP-Tree, etc, overview. How Carrier Ethernet Works: Service Frame Handling. Carrier Ethernet at Customer Premises, metro and core. Carrier Ethernet Workings, UNI attributes, Service Attributes (EVC and EVC per UNI attributes), Bandwidth Profiles, service multiplexing, L2 protocol processing; Carrier Ethernet equipment, CPE, aggregation and homing nodes, core equipment; management systems. The Setting Up of a Carrier Ethernet Service: Step 1: Choose service type, EPL/EVPL, EP-LAN/EVP-LAN, EPTree/EVP-Tree, EVLine...; Step 2: CPE tasks, UNI-C tasks (UNI attributes, service attributes (EVC and EVC per UNI) and bandwidth profiles), UNI-N tasks (L2 protocol handling). Step 3: Non-CPE tasks, Access, metro and core connections set up. Section Two: Carrier Ethernet Concepts in depth Carrier Ethernet Definitions in Depth: UNI, UNI I & II, UNI-N and UNI-C, etc.; NNI/ENNI; EVC; OVC, OVC type (P2P, M2M, Rooted MP), OVC end point (root, leaf, trunk), OVC end point map, OVC end point bundling; Service types in detail, EPL/EVPL, EP-LAN/EVP-LAN, EP-Tree/EVP-Tree, EVLine, Access EPL, Access EVPL . Carrier Ethernet Service Frame Handling: Unicast, multicast and broadcast frame delivery, Tagged, untagged and priority; Tagging, C and S-Tags, 802.3, 802.1d, 802.1q, 802.1ad, 802.1ah evolution, VLAN ID translation/preservation. CoS preservation. Other Key Carrier Ethernet Concepts: MTU, MTU at UNI, MTU at ENNI; Physical Layer Attributes, FE, GbE and 10GbE, Service Multiplexing and Bundling Concept and detail, rules and implications; Hairpin Switching Managing Bandwidth in a Carrier Ethernet Network: Token Bucket Algorithm, EIR, CIR, CBS, EBS, Coupling Flag; Frame Colors, recoloring, Color Awareness attribute, Color Forwarding; Bandwidth Profiles, rules and concepts. MEF CoS identifiers, DEI bit (in S-Tag), PCP bit (in C-Tag or S-Tag), or DSCP (in IP header), Multiflow bandwidth concepts; CoS Label/Color Identification. Section Three: Carrier Ethernet Service Attributes Overview: Carrier Ethernet 2.0; Blueprint C Service Attributes: Per UNI, Physical interfaces, Frame format, Ingress/egress Bandwidth Profiles, CEVLAN ID/EVC Map, UNI protection. EVC per UNI, Ingress/egress Bandwidth Profiles, etc.; Per EVC, CEVLAN ID Preservation, CoS ID Preservation, Relationship between SLA and SLP, Class of Service, etc. OVC, ENNI, OVC End Point per UNI and OVC End Point per ENNI, Ingress/egress bandwidth profiles, etc. Section Four: Managing Carrier Ethernet Networks Overview: MEF Service Lifecycle.Carrier Ethernet maintenance: Port, Link & NE failure, Service Protection Technologies, Fault Identification and Recovery, LAG, Active/Standby EVC, Single EVC with transport protection, G.8031, G.8032, MPLS FRR. SOAMs: Connectivity fault management, connectivity Monitoring, Loopback, Linktrace; Performance Management, Frame Delay, Inter Frame Delay Variation, Availability, Frame Loss Ratio, Resiliency, HLI, DMM, DMR, SLM, SLR; Key Concepts, Single vs dual ended, ordered UNI pair calculations. LOAMs: Link discovery, link monitoring, etc. Terminology and Concepts: MEG levels, MIPs. Section Five: Practical Carrier Ethernet Carrier Ethernet Transport Technologies:Layer 1: SDH. Layer 2: Bridging, provider bridging, PBB, PBBTE. Layer 2.5: MPLS VPWS, MPLS VPLS, MPLS-TP. Carrier Ethernet Access Technologies: fiber, SDH, active fiber, PON, GPON, 10G PON, OTN, WDM; copper, PDH, G-SDSL, 10Pass-TS, HFC; packet radio. Optimising mobile backhaul with Carrier Ethernet Key challenges solutions: Market pressure, LTE evolution, elements and architecture (RAN BS, NC, GWIF.), synchronization, bandwidth management. Circuit Emulation over Ethernet: Purpose, needs and applications. Synchronization: Phased, ToD, External Reference source, SynchE ,NTP, IEEE-1588 v2/ PTP, ACR; MEF Service Definitions for emulated circuits. Applying what you know: Practical examples and scenarios, Carrier Ethernet solutions; Practice Scenarios, Given a scenario, determine appropriate Ethernet services

Objective-C programming training course description A hands on introduction that will allow you to master Objective-C and start using it to write powerful native applications for even the newest Macs and iOS devices! Using The step-by-step approach, will let you get comfortable with Objective-C's unique capabilities and Apple's Xcode 5 development environment. Make the most of Objective-C objects and messaging. Work effectively with design patterns, collections, blocks, foundation classes, threading, Git and a whole lot more. Every session builds on what you've already learned, giving a rock-solid foundation for real-world success! What will you learn Use Xcode 5. Declare classes, instance variables, properties, methods, and actions. Use arrays, dictionaries, and sets. Expand and extend classes with protocols, delegates, categories, and extensions. Use Apple's powerful classes and frameworks. Objective-C programming training course details Who will benefit: Developers wanting to learn Objective-C. Prerequisites: Software development fundamentals. Duration 5 days Objective-C programming training course contents PART 1: GETTING STARTED WITH OBJECTIVE-C The Developer Program: Objective-C, enrolling as an Apple Developer, setting up the development environment, Xcode. Your first project. OO programming with Objective-C: OO projects, Frameworks, classes and instances, encapsulation, accessors, Inheritance. OO features in Objective-C: Messages, methods, working with id, nesting messages, method signatures and parameters. allocating and initializing objects. Using Xcode: Xcode, source code control, git and Xcode, Using a Remote Repository. Compiler Directives: Projects, Compiler Directives, Prefix headers, main.m, .h files. PART 2: OBJECTIVE-C BASICS Messaging in a Testbed App: Setting Up the Testbed Apps, Adding a Text Field and Connecting It to Your Code, Sending a Message to the Text Field, Reviewing the Message Syntax. Declaring a Class in an Interface File: Context, Creating an Instance Variable with id, What Happens When Execution Stops, dynamic binding, Creating an Instance Variable for with the Class Name and with a Superclass Name, instance variable visibility. Properties in an Interface File: Interface Variables vs Properties, Declared Properties, Using Attributes. Implementing Properties. @synthesize, @dynamic. Methods in an Interface File: Methods in a Class, class and instance methods, Method declaration, returning complex data structures from Methods. Actions in an Interface File: Actions, Actions in OS X and iOS, disconnecting actions. Routing messages with selectors: Receiver and selector objects in messages, Objective-C Runtime, SEL and @selector (), performSelector, NSInvocation, testing whether an Instance can respond to a selector. Building on the Foundation: The Foundation Framework, Foundation Classes, Foundation Paradigms and Policies; Mutability, class clusters, notifications. Defining a Class in Implementation Files: Projects, dynamic typing, creating a new App, implementing a method, expanding Classses with init Methods. Organizing Data with Collections: Collecting Objects, Property Lists, Runtime, comparing the Collection Classes, Creating a Collection, Objective-C Literal Syntax, Enumerating collections, Testing Membership in a Collection, Accessing an Object in a Collection. Managing Memory and Runtime Objects: Managing objects in memory, managing reference counts manually and with ARC, variable qualifiers, variable autorelease. PART 3: EXPANDING AND EXTENDING CLASSES Protocols and Delegates: Subclassing, Protocols, Delegates, Looking Deeper Inside Protocols. Categories and Extensions: Comparing categories and protocols, categories vs subclasses, working with categories, class extensions, informal protocols. Associative References and Fast Enumeration: Objective-C 2.0 Time-Saving Features, Extending Classes by Adding Instance Variables (Sort of), Using Fast Enumeration. Blocks: Revisiting Blocks, Callbacks, Blocks, Exploring Blocks in Cocoa, Cocoa Blocks and Memory. PART 4: BEYOND THE BASICS Handling Exceptions and Errors: Exception and Error classes: NSException, NSError, Identifying exceptions, throwing exceptions, catching exceptions. Queues and Threading: Getting Started with Concurrency, Introducing Queues, Dispatch Sources, Using Dispatch Queues. Working with the Debugger: Logging Information, Console Logs, NSLog, Smart Breakpoints, enhancing breakpoints with messages. Using Xcode Debug Gauges for Analysis: Debug Gauges, Monitoing CPU and memory utilization, monitoring energy, Using Instruments. PART 5: OPTIONAL TOPICS C Syntax Summary: Data Types, Control Structures. Apps, Packages, and Bundles: Project Bundles, lproj Files, Asset Catalogs, plist Files, Precompiled Header Files (.pch). Archiving and Packaging Apps for Development and Testing: Archiving.

Advanced Junos SP Routing course description This is designed to provide students with detailed coverage of OSPF, IS-IS, BGP, and routing policy. Students will gain experience in configuring, monitoring, and troubleshooting the Junos operating system and in monitoring device and protocol operations. This course uses Juniper Networks vMX Series Routers for the hands-on component, but the lab environment does not preclude the course from being applicable to other Juniper hardware platforms running the Junos OS. What will you learn Describe and configure OSPF area types and operations. Configure and monitor IS-IS. Describe basic BGP operation. Explain the causes for route instability. Describe how to troubleshoot routing policy. Explain the default behaviour of damping on links. Advanced Junos SP Routing course details Who will benefit: Network staff working with Junos at layer 3. Prerequisites: Junos Intermediate Routing Duration 5 days Advanced Junos SP Routing course contents OSPF OSPFv2 Review Link-State Advertisements Protocol Operations OSPF Authentication Lab: OSPF Multi-Area Networks Chapter 3: OSPF Areas Review of OSPF Areas Stub Area Operation and Configuration NSSA Operation and Configuration Route Summarization Lab: OSPF Route Summarization OSPF Case Studies and Solutions Virtual Links OSPF Multiarea Adjacencies External Reachability Lab: Advanced OSPF Options and Routing Policy Troubleshooting OSPF Troubleshooting OSPF Lab: OSPF Troubleshooting IS-IS Overview of IS-IS IS-IS PDUs Neighbors and Adjacencies Configuring and Monitoring IS-IS Lab: IS-IS Configuration and Monitoring Advanced IS-IS Operations and Configuration Options IS-IS Operations IS-IS Configuration Options IS-IS Routing Policy Lab: Advanced IS-IS Configuration Options and Routing Policy Multilevel IS-IS Networks Level 1 and Level 2 Operations Multilevel Configuration Lab: Configuring a Multilevel IS-IS Network Troubleshooting IS-IS Troubleshooting IS-IS Lab: IS-IS Troubleshooting BGP Review of BGP BGP Operations BGP Path Selection Options Configuration Options Lab: BGP and BGP Attributes BGP Attributes and Policy - Part1 BGP Policy Next Hop Origin and MED AS Path Lab: BGP Attributes - Next Hop, Origin, MED, and AS Path Attributes and Policy - Part2 Local Preference Communities Lab: BGP Attributes - Local Preference and Communities Route Reflection and Confederations Route Reflection Operation Configuration and Routing Knowledge BGP Confederations Lab: Scaling BGP BGP Route Damping Route Flap and Damping Overview Route Damping Parameters Configuring and Monitoring Route Damping Lab: BGP Route Damping Troubleshooting BGP Troubleshooting BGP Lab: BGP Troubleshooting Troubleshooting Policy Troubleshooting Policy Lab: Policy Troubleshooting

Advanced Body Shape Package

By Harley Elite Academy (HeLa)

Expert Body Shape Fillers Package includes: Fat-Dissolving injections – Fillers BBL (Brazilian Buttocks Lift ) with Filler – Non Surgical Threads lift injectables for body Entry requirements Registered Medical professional Level – Beauty Therapist Dental Nurse Physiotherapist Holds at least 6 months experience with needles (micro-needling, microblading, tattooing, vaccinations, phlebotomy and more) NOTE! After booking we will contact you for scheduling the exact course date! Courses dates are subject to change due to mentors availability. We will inform you via email if a date becomes available! Additional information ATTENDANCE ONLINE (Theory), IN CLINIC (Practice) EXPERT LEVEL Fat-Dissolving injections – Fillers BBL (Brazilian Buttocks Lift ) with Filler – Non Surgical PDO Threads lift injectables for body PRP/ Mesotherapy Training Course Choose Online Theory or In-Clinic with practice 4 Days Intensive Courses (1 Week)

OOAD training course description A workshop course providing thorough practical knowledge of object oriented analysis and design methods. What will you learn Perform Systems Analysis with Object Oriented methods. Identify key classes and objects. Expand and refine OO problem domain models. Design Class hierarchies using inheritance and polymorphism. Design programs with Object Oriented methods. OOAD training course details Who will benefit: System analysts, designers, programmers and project managers. Prerequisites: It is desirable that delegates have experience of programming in C++/Java or some other OOP language. Duration 5 days OOAD training course contents What is OO? Classes, objects, messages, encapsulation, associations, inheritance, polymorphism, reusability. What is Systems Analysis and design? Data flow diagrams, structure diagrams. The OO approach. OOA The problem domain and object modelling. Identifying classes and objects. Generalisation and inheritance. Defining attributes and methods. OOD Refining the OOA results. Designing the User Interface. Designing the algorithms and data structures using objects. Designing the methods. OOP Prototyping. Implementing OOD with OOPs and OOPLs.

Lean Six Sigma Black Belt Certification Program: In-House Training

By IIL Europe Ltd

Lean Six Sigma Black Belt Certification Program: In-House Training This course is specifically for people wanting to become Lean Six Sigma Black Belts, who are already Lean Six Sigma practitioners. If advanced statistical analysis is needed to identify root causes and optimal process improvements, (Lean) Six Sigma Green Belts typically ask Black Belts or Master Black Belts to conduct these analyses. This course will change that. Green Belts wanting to advance their statistical abilities will have a considerable amount of hands-on practice in techniques such as Statistical Process Control, MSA, Hypothesis Testing, Correlation and Regression, Design of Experiments, and many others. Participants will also work throughout the course on a real-world improvement project from their own business environment. This provides participants with hands-on learning and provides the organization with an immediate ROI once the project is completed. IIL instructors will provide free project coaching throughout the course. What you Will Learn At the end of this program, you will be able to: Use Minitab for advanced data analysis Develop appropriate sampling strategies Analyze differences between samples using Hypothesis Tests Apply Statistical Process Control to differentiate common cause and special cause variation Explain and apply various process capability metrics Conduct Measurement System Analysis and Gage R&R studies for both discrete and continuous data Conduct and analyze simple and multiple regression analysis Plan, execute, and analyze designed experiments Drive sustainable change efforts through leadership, change management, and stakeholder management Successfully incorporate advanced analysis techniques while moving projects through the DMAIC steps Explain the main concepts of Design for Six Sigma including QFD Introduction: DMAIC Review IIL Black Belt Certification Requirements Review Project Selection Review Define Review Measure Review Analyze Review Improve Review Control Introduction: Minitab Tool Introduction to Minitab Minitab basic statistics and graphs Special features Overview of Minitab menus Introduction: Sampling The Central Limit Theorem Confidence Interval of the mean Sample size for continuous data (mean) Confidence Interval for proportions Sample size for discrete data (proportions) Sampling strategies (review) Appendix: CI and sample size for confidence levels other than 95% Hypothesis Testing: Introduction Why use advanced stat tools? What are hypothesis tests? The seven steps of hypothesis tests P value errors and hypothesis tests Hypothesis Testing: Tests for Averages 1 factor ANOVA and ANOM Main Effect Plots, Interaction Plots, and Multi-Vari Charts 2 factor ANOVA and ANOM Hypothesis Testing: Tests for Standard Deviations Testing for equal variance Testing for normality Choosing the right hypothesis test Hypothesis Testing: Chi Square and Other Hypothesis Test Chi-square test for 1 factor ANOM test for 1 factor Chi-square test for 2 factors Exercise hypothesis tests - shipping Non-parametric tests Analysis: Advanced Control Charts Review of Common Cause and Special Cause Variation Review of the Individuals Control Charts How to calculate Control Limits Four additional tests for Special Causes Control Limits after Process Change Discrete Data Control Charts Control Charts for Discrete Proportion Data Control Charts for Discrete Count Data Control Charts for High Volume Processes with Continuous Data Analysis: Non-Normal Data Test for normal distribution Box-Cox Transformation Box-Cox Transformation for Individuals Control Charts Analysis: Time Series Analysis Introduction to Time Series Analysis Decomposition Smoothing: Moving Average Smoothing: EWMA Analysis: Process Capability Process capability Discrete Data: Defect metrics Discrete Data: Yield metrics Process Capability for Continuous Data: Sigma Value Short- and long-term capabilities Cp, Cpk, Pp, Ppk capability indices Analysis: Measurement System Analysis What is Measurement System Analysis? What defines a good measurement system? Gage R&R Studies Attribute / Discrete Gage R&R Continuous Gage R&R Regression Analysis: Simple Correlation Correlation Coefficient Simple linear regression Checking the fit of the Regression Model Leverage and influence analysis Correlation and regression pitfalls Regression Analysis: Multiple Regression Analysis Introduction to Multiple Regression Multicollinearity Multiple Regression vs. Simple Linear Regression Regression Analysis: Multiple Regression Analysis with Discrete Xs Introduction Creating indicator variables Method 1: Going straight to the intercepts Method 2: Testing for differences in intercepts Logistic Regression: Logistic Regression Introduction to Logistic Regression Logistic Regression - Adding a Discrete X Design of Experiments: Introduction Design of Experiment OFAT experimentation Full factorial design Fractional factorial design DOE road map, hints, and suggestions Design of Experiments: Full Factorial Designs Creating 2k Full Factorial designs in Minitab Randomization Replicates and repetitions Analysis of results: Factorial plots Analysis of results: Factorial design Analysis of results: Fits and Residuals Analysis of results: Response Optimizer Analysis of results: Review Design of Experiments: Pragmatic Approaches Designs with no replication Fractional factorial designs Screening Design of Experiment Case Study Repair Time Blocking Closing: Organizational Change Management Organizational change management Assuring project sponsorship Emphasizing shared need for change Mobilizing stakeholder commitment Closing: Project Management for Lean Six Sigma Introduction to project management Project management for Lean Six Sigma The project baseline plan Work Breakdown Structure (WBS) Resource planning Project budget Project risk Project schedule Project executing Project monitoring and controlling and Closing Closing: Design for Lean Six Sigma Introduction to Design for Lean Six Sigma (DMADV) Introduction to Quality Function Deployment (QFD) Summary and Next Steps IIL's Lean Six Sigma Black Belt Certification Program also prepares you to pass the IASSC Certified Black Belt Exam (optional)

M.D.D DATING ADVICE FOR WOMEN WITH VERY LOW CONFIDENCE PACKAGE (DATING ADVICE FOR WOMEN)

4.9(27)By Miss Date Doctor Dating Coach London, Couples Therapy

Introspective test Emotional regulation and emotional intelligence training Help in addressing pain points areas Full Makeover and beauty treatments 10 V.I.P confidence building sessions Personality test Addressing trauma issues Personal life coach available daily Behavioural pattern training Relationships analysation Happiness test Dating advice for low confidence and insecurity triggers Eradication of negative patterns Cognitive behavioural therapy https://relationshipsmdd.com/product/dating-advice-for-women-with-very-low-confidence-package/

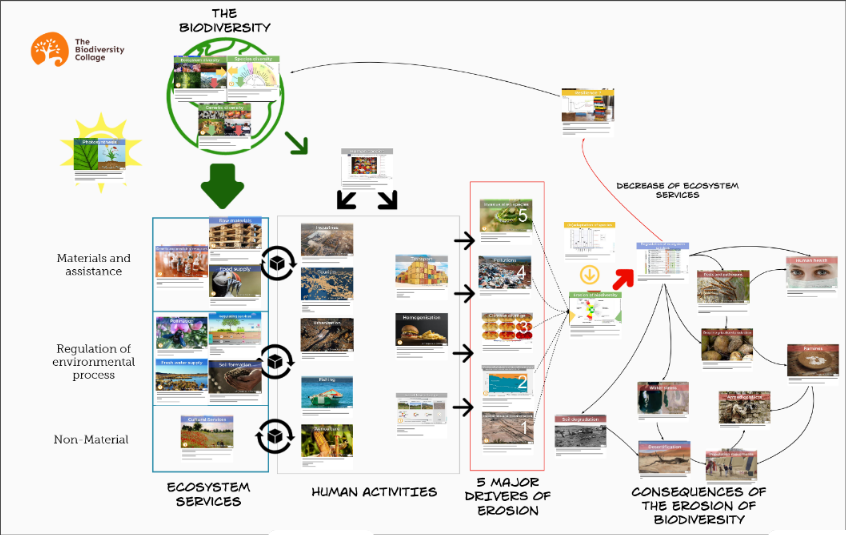

Biodiversity training - Biodiversity collage workshop

By The C Collective

Join a Biodiversity collage workshop to learn about the biodiversity crisis and how to tackle it.

Search By Location

- Courses in London

- Courses in Birmingham

- Courses in Glasgow

- Courses in Liverpool

- Courses in Bristol

- Courses in Manchester

- Courses in Sheffield

- Courses in Leeds

- Courses in Edinburgh

- Courses in Leicester

- Courses in Coventry

- Courses in Bradford

- Courses in Cardiff

- Courses in Belfast

- Courses in Nottingham