- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

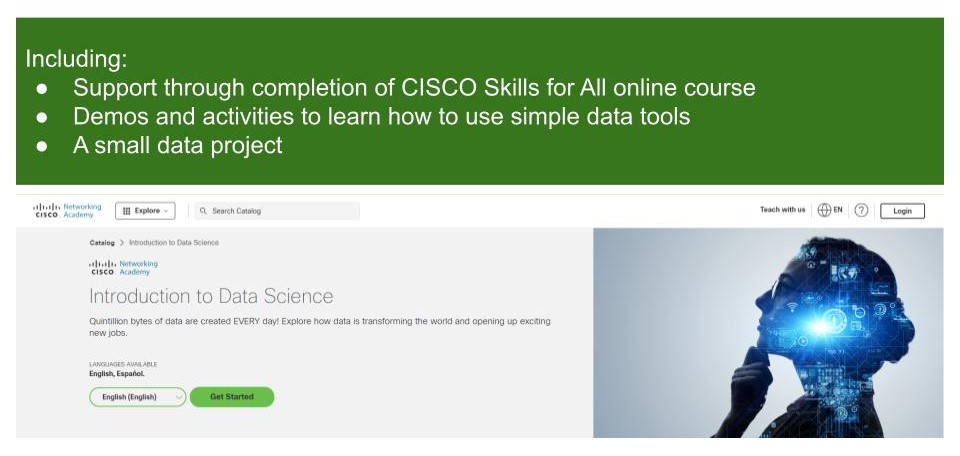

Introduction to Data Science

By futureCoders SE

Learn the basics of Data Science, combining a supported #CISCO Skills for All online course with practical learning and a project to help consolidate the learning.

Business Growth Academy

By The Power Within Training & Development Ltd

Our team of Construction industry experts provide business management training for leaders and business owners across England and Scotland CONSTRUCTION INDUSTRY SPECIFIC Construction Business Growth Academy The Power Within Training is dedicated to helping construction-based business owners and construction management throughout England, Scotland, and Wales achieve more than they believed possible. Our construction business training is designed to develop owner-managers and help them create the future they want. To ensure business growth, we have a dedicated team of industry professionals to give unique support specific to the skills, traits, and challenges found within Construction. This programme was created to help you push and elevate your business to the next level. Contact us to register for our construction business training. Explore Our Construction Business Growth Course We created the Business Growth Academy for business owners like you to grow and develop their businesses in a more controlled and sustainable way. To ensure growth, our construction business training is a series of six training modules focused on business growth, leadership, and financial management. Most of our participants are business owners looking to get the tools needed to spend more time working on their business while generating more profitability to ensure consistent business growth. The Power Within Training uses the latest business growth strategies, which allow you to identify, modify and quickly implement our easy-to-follow business-building tools and techniques designed around the construction and property development industry. Whether you are a business owner or an aspiring construction and property development entrepreneur, our Construction Management Course will provide the tools and techniques to drive your business forward and achieve sustainable growth. Join us at the Business Growth Academy and unlock your full potential. The Goal of Our Construction Management Training Our goal with this training is to provide you with the tools you need to take control of your business. This allows you to use the latest strategies and ensure the smooth growth of your construction business. The construction management training we offer is a three-month course with new modules available twice monthly, delivered via Zoom or in person. These modules are designed to work around your schedule. After, you’ll have a 39-hour CPD certification thanks to our CITB skills & training courses. Overall, our fully funded construction management training will help you place the proper foundation, allowing you to build a more substantial and focused business that’s centred around constant growth and profits while future-proofing your business. BUSINESS GROWTH ACADEMY The Benefit of Our Business Growth Academy As you go through our training, you’ll delve into each module and the critical steps and tools. These include how to plan, organize, and control construction operations, all designed to provide you with a well-rounded view of your business. Not only will you get the tools you need to ensure your construction business growth, but you’ll also get access to benefits such as lifetime access to your online interactive training portal, entrance into a private social and professional networking group, pro bono coaching, and mentoring from industry experts and leaders. Here are some additional benefits of our construction management training: Register your interest today You’ll build a personalised 12-month business development plan that keeps you focused on high-value activities, ensuring you remain on track to grow. Tools and techniques to not only measure but also increase your profitability within your business. These tools help you ensure that you’re never leaving money on the table again. Learn, develop, and nurture self-management and leadership strategies that you can work on and in your business to help you from chasing your tail or burning out. You’ll develop unshakeable confidence in your business’s ability to grow and become the kind of entrepreneur that chooses the customers they want to work with, meaning customers who are driven by value, not by price. Gain valuable leadership and self-development skills, which encourage learning for life. Lastly, you’ll no longer wonder, “what if?” You’ll have the knowledge and understanding to keep unlocking and growing your business’s true potential. WHAT'S INCLUDED IN THE PROGRAMME Course Overview As we’ve mentioned, our business management course is designed to be completed over three months, with two courses being released monthly. These are designed to be done on Zoom or in person and are flexible around your busy schedule. Our modules were created to be easy to understand while providing the resources needed to elevate your construction business. Here is a more in-depth look at what to expect from our modules: Module 1: The C.O.D.E Breaker: The Business FundamentalsThis module will encourage you to deep dive into your why and break the business C.O.D.E. You’ll be shown the importance of knowing why you started the business, how you can build a business while remaining authentic, and what needs to be done to ensure you create and support a solid foundation moving forward. During this module, you’ll discover how to successfully build a business in the construction industry, from the fundamentals and foundations to the growth. Lastly, we’ll review your vision, values, and purpose, show why these are critical areas, and allow you to establish a real business for you and your customers. Module 2: Your M.E.N.T.A.L Agility: The Entrepreneurial Mindset With this module, we’ll focus on self-leadership and how you should constantly be developing the ‘inner game’ or minder and the ‘outer game’ or action. The inner game consists of intention, self-awareness, self-confidence, and self-efficacy. These must be used to achieve personal mastery, while the outer game consists of influence and impact. M.E.N.T.A.L. agility is your key to all success and failure, meaning that without leading yourself, you’ll never find business success. For us, your M.E.N.T.A.L. agility is made of five key components that enable you to transition from owning a business to thinking and planning like an entrepreneurial business owner. Module 3: The T.I.M.E Multiple: Working ON or Working IN The point of this module is to help you understand that you can’t manage your time; you can only manage your use of time or your self-management skills. It’s vital to have strong self-management skills to be more successful at work. We’ll explore ways to help maximise your time and identify your High Payoff Activities. The T.I.M.E. multiplier is about accepting that you cannot do everything yourself. Instead, it would be best if you focused on your high-payoff activities. Our goal is to teach you to say it’s okay to say no. We’ll show you the importance of recognising the significance of all your decisions. Along with that, we focus on unique planning and defining processes to bring the future into the present. Module 4: The Business P.R.O.B.E: The Numbers Game Understanding your finances is essential as it allows you to make informed decisions that have the potential to make significant impacts on your business, growth, and even your bottom line. We want you never to leave money on the table again. When you know the difference between markup and margin, fixed and variable costs can make the difference between owning a business and the business owning you. Understanding your business numbers will increase your revenue and profitability and even grow your business. Module 5: High-Performance T.E.A.M.S: The Well-Oiled High-performing teams are more than a group that works together. A high-performing team has clear priorities and purposes and shares an understanding of how each team member or subcontractor prefers to approach work. The foundation of a high-performing team or business starts with trust. The development starts with creating an environment where leaders and team members can openly disclose which strengths they feel they bring to a team and what support they need to be their best selves. Truth is that all people’s problems directly reflect the business owner’s leadership and management. When a team doesn’t do things your way, they probably have no idea what your way is. Module 6: G.O.A.L.S: Setting & Defining the Accountability System Everyone works best with clearly defined goals, from completing a refurb on a budget or growing your construction business to over 10M annual profit. Remember the old saying, through a goal with a plan, is just a wish! We’ll teach you our tried and tested process for setting and achieving your objectives by focusing on what matters most. Reviewing your daily, weekly, and monthly goals, we can help you make high performance a habit. Best of all, you’ll create a detailed 12-month business development plan to get your personal and professional goals moving in the right direction. Meet the Construction Business Training Presenters Derrick Matheson: Training and Development Director and Trainer of Business Growth Academy A seasoned business owner, Derrick understands the challenges UK construction and property development professionals face. We have crafted a targeted program that simplifies growth, empowering entrepreneurs with easy-to-implement strategies. Derrick’s mission is simple: to empower and equip ambitious entrepreneurs and professionals with the tools and knowledge necessary to thrive in today’s competitive market. The Business Growth Academy is a testament to his dedication, offering an innovative, step-by-step business-building process that demystifies the complexities of growth and unlocks the full potential of your enterprise. Stuart Mason: BGA’s Bold Training Manager, Lead Trainer, and Author of “How To Wreck Your Business Stuart, the fearless BGA Training Manager and Lead Trainer has turned his business failures into powerful lessons for others. As the author of “How To Wreck Your Business,” Stuart shares his hard-earned wisdom to help business owners avert the same pitfalls that led to the demise of his own company on its 20th anniversary. Stuart’s approach is refreshingly direct and unapologetically abrupt, cutting through the noise to deliver real-world insights that make a difference. Don’t expect a dry lecture on business theory from a dusty textbook; instead, Stuart offers a ‘streetwise’ perspective that is both practical and actionable, pushing you to uncover the answers that will make your business shine in a competitive market.

Telephone Training - Live On-Site and Remote Training Sessions

By Telephone Trainers Ltd

Our telephone training takes place in your normal working situation, using the actual telephones and software, and the programming software clients that trainees will use when fully trained. Our trainers will travel anywhere in the world to train you face to face, or if you prefer, we can offer our whole training catalogue remotely using Teams or Zoom. On-site and live remote telecoms training sessions have a general reputation as most effective for trainees to continue to efficiently carry out their telecoms usage, programming and own in-house training of future new employees. On-site training involves employees training at their place of work while they are doing their actual job, or in pre-organised classroom training sessions, based around hands-on interaction, trainer Q&A and all carried out using your own site telephone system. Our telephone trainers also offer consultations on your new or current telephone systems: looking into how you currently use your system, making suggestions on how programming could be tweaked and changed to improve your current usage, how to improve on call handling methods, and informing you of additional products which may be available on your system that you may not be aware of. This could help improve the level of communication across your company and interactions with your customers. We believe telephone handset and voicemail training sessions are essential to the smooth and efficient running of your company, making sure your staff are aware of all the features and benefits that the telephone handsets can offer, and ensuring calls are dealt with quickly and effectively. System administration training is available to teach new administrators how to manage and control a variety of system features. This type of training is especially important when new administrators have little or no previous telecom knowledge or experience, but it is equally important at all levels to ensure the new system is utilised to its maximum capability. Administration days or Call Centre Software training days take one full day to complete. Full Day Example: 9:30 - 16:00 Day Structure 09:30 - 10:45 Handset & VM session for up to 8 people 10:45 - 12:00 Handset & VM session for up to 8 people 12:00 - 12:45 Lunch 12:45 - 14:00 Handset & VM session for up to 8 people 14:00 - 15:15 Handset & VM session for up to 8 people 15:15 - 16:30 Handset & VM session for up to 8 people Half Day Example: 9:30 - 13:00 Switchboard training takes half a day (3-4 hours for up to 3 people). If you want to train more than 3 people, you may need to extend the day to a full day, to ensure everyone gets to have hands-on training on the switchboard. Super Users and Train the Trainer Sessions Super User sessions can also be organised to show advanced system features in order to provide an ongoing training service to their colleagues, once the trainers have left the site.

Sales superheros (In-House)

By The In House Training Company

Are your sales people too stressed, running on adrenalin, perhaps driving towards burnout, struggling to reach targets? Wouldn't you rather they delivered consistently good performance, sustainable over longer periods of time, with less stress (for both them and you)? This uniquely empowering workshop will help your team develop naturally high levels of focus, energy and motivation. They will attain a sense of grounded euphoria, giving them a very distinct and ethical edge in selling. A one-day programme, it gives salespeople an introduction to the 'Natural Superheroes' concepts and resources, tools and techniques, to help them improve their sales performance - realising greater sales potential, developing deeper and more profitable client relationships, winning more business. Through this experience, sales teams gain: Information about profiling clients to instantly understand more about their deepest drives and true needs so they can be genuinely met and, where possible, exceeded Insights into deep, honest and very 'real' reasons for sales procrastination - participants are given specific workable strategies they can easily apply to overcome sales resistance, by tapping their natural motivational styles An understanding of communicating at the very highest levels with different people so they truly understand your sales message and have a significantly more positive sales experience A realisation of their very specific natural sales talents as individuals and as a team A deeper level of experience and understanding of what specifically drives their own behaviour and the behaviour of their clients - these unique insights explain not only how but exactly why people behave the way they do An experience of what it takes to be unshakeable under pressure and manage the sales processes and relationships to a positive outcome for all Brand-new insights into working with and handling difficult people across all levels of authority An understanding of the pitfalls and the psychological traps we set ourselves which cause unnecessary stress, anxiety and frustration on a daily basis and, in turn, limit our sales performance Access to very simple and practical tools that massively increase self-awareness, engender accountability and responsibility and develop emotional sales mastery 1 Introducing 'Natural Superheroes' for sales What is a 'Natural Superhero'? Defining emotional intelligence in the context of sales and why it is so important Knowing yourself - why most people don't know themselves at all and how we can understand exactly what drives our behaviour for the purpose of improving sales performance specifically Knowing exactly why others, and specifically clients and team members, behave the way they do - understanding the real motives behind people's good and bad behaviour in a sales meeting Simple steps to freeing yourself of any anxiety, pressure and false sense of limitation when selling Being yourself in sales - why this is not as easy as it sounds but how you can make it effortless How to take control of achieving the sales performance you really need and want for yourself and others Strategies that raise your self-awareness, increase an authentic and sustainable sense of self-confidence, in difficult situations and in moments of crisis 2 Understanding yourself, your team members and your customers - using the Enneagram Introducing the Enneagram and why it is so valuable to sales people and their clients Exploring the 9 types of motivational drives and why people have different reasons for buying from you Core types and wings - understanding the influence of other motivations either side of the core Enneagram type How to confirm the profile of your client - using celebrities from the world of politics, cinema, sports - we explore how to identify each type - what are their core drives, why have they arisen and how can we use these insights to help you in improving your sales performance The 3 levels of behaviour within your personal profile and that of your clients Lookalike Enneagram types - mistaken identities - how to avoid these traps when profiling your clients and your team How to communicate effectively in a sales environment with each of the different Enneagram types - communication strategies for positive impact on morale, performance and, ultimately, sales results How to interpret and make use of the results of your online personal profile - participants complete an online profile before the event and have the opportunity to analyse their results with a view to improving their sales performance How sales teams sabotage their own performance and that of other people within the team - and how to stop it Uncovering your particular edge in a sales role - what unconsciously trips you up as a sales person? How the Enneagram helps us in sustaining a truly great sales performance over time 3 Why positive thinking alone doesn't work in sales Why 'PMA' does not stand for positive mental attitude when selling - learn its alternative meaning that can serve you even more effectively in a sales role 3 steps and exercises that naturally increase PMA The value of making unconscious thinking conscious and how to do this without any pain or discomfort in a sales meeting Why each Enneagram type has a different experience of PMA in terms of their outward behaviour and how to know when you are maximising your sales performance 4 Measuring success How to measure the development of your individual profile as a sales person Development planning and review Into the future - how to continue your Natural Superhero development

Body Piercing Training Course 1 or 2 Days-choose your own dates .

By Sassthetics Training Academy

One -2- One Body Piercing Training Course . 1 or 2 days depending on the level of mentorship you require. Blackpool based

Advanced sales negotiation skills (In-House)

By The In House Training Company

The 'golden rule' of negotiation is simple - don't! But life's rarely that simple and very often we do have to negotiate, particularly if we want to win the business and especially if we want to win it on our terms. Such negotiations are crucial. We need to prepare for them. We need a strategy, and the skills to execute it. Does your team have a structured approach? Is it flawlessly executed, every time? Or is there room for improvement? This programme will help them master the six fundamentals of closing better business: Manage all these elements well and you will win more business, more profitably. This course will help participants: Negotiate from a position of partnership, not competition Deal more effectively and profitably with price objections Identify and practise successful sales negotiating skills Identify strengths and weaknesses as a sales negotiator Understand different types of buyer behaviour Learn to recognise negotiating tactics and stances Apply a new and proven structure to their business negotiations Identify and adapt for different behavioural styles Be alert to unconscious (non-verbal) communication Prepare and present a proposal at a final business negotiation stage Project confidence and exercise assertiveness in all sales negotiations 1 Planning for successful business negotiations This session introduces the concept of business negotiation and looks at its importance in the context of the participants' roles and activities. It briefly examines why we negotiate and the dynamics involved. Session highlights: What kind of a negotiator are you? Negotiation skills self-assessment and best practice How to establish roles and responsibilities for both parties How to identify and set objectives for both buyer and seller How to research and establish the other person's position (business negotiation stance) 2 How to structure your negotiations This module presents an eight-step framework or structure for use in negotiations and considers how best to prepare and plan your negotiations within the context of a supplier/customer relationship or business cycle. It also includes a brief review of legal responsibilities and what constitutes a 'deal'. Session highlights: Learn and apply a formal structure to use when negotiating How to establish short- and longer-term objectives and opportunities How best to plan, prepare and co-ordinate a major business negotiation meeting, or on-going negotiations Understanding of basic legal and organisational requirements 3 Verbal negotiation skills This session examines the human and communication dynamics inherent in any negotiation situation. It emphasises the importance of professional skills in preparing for a negotiation by identifying needs, wants and requirements accurately and by qualifying the competitive and organisational influences present. Session highlights: How to fully 'qualify' the other party's needs, requirements and constraints during the negotiation process by using advanced questioning and listening skills How to pre-empt negotiation objections by promoting and gaining commitment to options, benefits, value and solutions How best to propose and suggest ideas, using drawing-out skills 4 Non-verbal negotiation skills This module highlights how different personal styles, corporate cultures and organisation positions can influence events, and demonstrates practical methods for dealing with and controlling these factors. It also examines key principles of body language and non-verbal communication in a practical way. Session highlights: Gaining rapport and influencing unconsciously Understanding the importance of non-verbal communication; reading other people's meaning and communicating effectively as a result Ensure that non-verbal behaviour is fully utilised and observed to create maximum impact and monitor progress (eg, buying signals) Recognising that business negotiations are precisely structured and agreements gained incrementally 5 Proposing and 'packaging' This session highlights how best to present and package your proposal. It looks at how to pre-empt the need for negotiating by creating minor-options and 'bargaining' points, as well as how to manage the expectations and perceptions of the customer or buyer. Session highlights: How to identify the key variables that can be negotiated The power and use of 'authority' within your negotiations How to structure and present your proposal, ideas or quotation to best effect The importance of when and how to identify and influence buyer's objections 6 Dealing with price This module highlights how to best present and package price within your proposal or negotiation. In most cases, price has more to do with psychology than affordability and preparation and careful handling are essential. Session highlights: The three reasons that people will pay your asking price How to set price in a competitive market The key differences between selling and negotiating Ten ways to present price more effectively and persuasively 7 Getting to 'Yes': tactics and strategies There are many different tactics and strategies common to successful negotiators. This session looks at those that are most appropriate to the participants' own personal styles and situations. The importance of 'follow-through' is also explained and how to deal with protracted or 'stale-mate' business negotiations. Session highlights: How to negotiate price and reduce discounting early in the process How to recognise negotiating tactics and strategies in your customer or supplier Key strategies, techniques and tactics to use in negotiation The importance of follow-through and watching the details How to deal with stalled business negotiations or competitor 'lock-out' 8 Case studies and review This session examines a number of different situations and participants discuss ways to approach each. This will allow learning to be consolidated and applied in a very practical way. There will also be a chance to have individual points raised in a question and answer session. Session highlights: Case studies Question and answer Planning worksheet Negotiation 'toolkit' and check-list 9 Personal action plans Session highlights: Identify the most important personal learning points from the programme Highlight specific actions and goals Flag topics for future personal development and improvement

Bespoke Management Training

By Dickson Training Ltd

One of our greatest strengths is our ability to tailor any of our open management courses to the needs and requirements of different businesses in different industries. We understand that whilst our open management training courses provide a wealth of knowledge in their particular area of focus, not all of it may be relevant for your business and the particular industry you operate in.Rather than making delegates sit through management training that is irrelevant to their job role, we offer bespoke management training where we tailor the course to cover the specific needs of your organisation, ultimately relieving the inevitable boredom and "switching off" that would come with having to sit through training that a person knew they would not need. Why choose us for your bespoke management training needs? We have provided tailored, bespoke management training courses to some of the largest organisations in the UK. Using our acquired experience and knowledge of running these courses, we will be able to work with you to create a bepoke management training programme that delivers a significant return on investment, both in terms of tangible and intangible results. ILM accredited management training courses Because we charge a daily training rate rather than a per delegate fee, if you have a number of delegates requiring management training, a bespoke management training course can often be less expensive than putting them all on an open course. A number of courses have been accredited by the ILM, which means you can be assured as to the standard of the course content and delivery. For more information on these, please see our page on ILM Management Training. All of our ILM Programmes are provided in partnership with BCF Group Limited, which is the ILM Approved Centre we deliver under. Interested in finding out more about bespoke management training? Between us, we can come up with a training plan which will provide relevant, bespoke management training for your delegates which will maximise the return on both your time and cost. We are happy to come to your premises or arrange training facilities nearer to your location if this would be more convenient. Feedback Below is a small selection of past feedback for our management training and development courses and programmes: "Excellent instructor. I looked forward to our monthly lectures knowing that I would have a good laugh but also that I would learn more about the subject and myself. He has been very helpful to me and the rest of the students, not just during the lectures but often in his own time. His enthusiasm for all of the subjects covered during the course was evident throughout, which again helped me to enjoy and understand the subjects and lectures. If I get the chance in future to attend a further course with you, I would jump at the chance."Senior Acquisitions SurveyorGalliford Try "A very accomplished trainer and someone who I would very much like to be involved in our business training going forward. The feedback I have had from all levels of our team structure is excellent."Group HR OperationsEADS Personnel Services UK "Phil has a lot of energy which he throws into the course. This visably broke down resistance and attendees entered into the exercises wholeheartedly."Senior QSBullock Construction Scheduled Courses Unfortunately this course is not one that is currently scheduled as an open course, and is only available on an in-house basis. Please contact us for more information.

Women in Construction Management Course

By The Power Within Training & Development Ltd

Supporting Women in Leadership Throughout The UK Our women in leadership course is specifically designed to target challenges and support women in developing their leadership and management careers. AWARD WINNING LEADERSHIP DEVELOPMENT PROGRAMME Discover Our Women in Construction Management Course The Power Within is dedicated to helping women in construction across England and Scotland achieve business success through our Motivational Intelligence framework. Motivational Intelligence is the third level of intelligence, and the science behind it has won a Nobel Prize. Our women leadership in construction course supports women by improving their motivation, self-belief, decision-making, and leadership skills. This programme is designed to help female business leaders adapt more quickly to their environment, handle adversity more effectively, take productive action, and thrive during times of change. Each is a vital skill needed in today’s ever-changing business environment. When completed, you’ll have the skills needed to make decisions more effectively that help your business grow, become more resilient, and take opportunities when others are stuck. "This course has completely changed my outlook on my responsibilities as a manager/leader. In 26 years with Pfizer, I have never participated in a programme that has as profoundly changed my perspective on my role, my responsibilities and my ability to positively impact my team." FEMALE DIRECTOR OF BUSINESS SERVICES, PFIZER LEADING WITH MOTIVATIONAL INTELLIGENCE What is our Women in Construction Course? In the past five years, we’ve supported thousands of business leaders and managers in nurturing the skills and mindset needed to achieve and exceed their business goals. The Power Within knows women are incredibly effective and consistent at applying our Motivational Intelligence techniques to their lives and business. Our women in construction management course is designed to give you the skills you need to take charge of your business and ensure constant growth while future-proofing your business. The training is perfect for women in construction who are managers or leaders looking to: Quickly Adapt Their Team to Change Effectively Mentor Every Team Member Improve Communication and Collaboration Gain More Buy-In to New Goals or Strategies Transform Their Team Culture Increase Initiative and Self-Motivation Across Their Team How We Help Women in the Construction Industry Our course focuses on imparting fundamental skills, tactical best practices, and powerful insights into the human side of the business. You’ll be provided with valuable knowledge needed to be successful leaders and managers of all levels. We’ll focus on addressing the challenges new businesses around the world face, like leading teams and developing businesses in turbulent and transitional times as well as overcoming the challenges of being women in the construction industry. Throughout the course, particular emphasis is given to helping leaders raise motivational intelligence and foster a growth mindset within their team. LEADING WITH MOTIVATIONAL INTELLIGENCE Our Leading with Motivational Intelligence (MQ) Executive Diploma Programme is specifically designed to help participants create the “complete game” of leadership and management. Leveraged by more than 40% of the largest Fortune 500 companies and implemented around the world, the Leading with Motivational Intelligence (MQ) consistently receives a participant buy-in rate in excess of 97%. However, the most important statistic is: 12 months after completing the course more than 93% of participants continue to use the skills and techniques taught on a daily basis. SQA APPROVED EXECUTIVE DIPLOMA What Skills Do We Help Women in Construction Develop? The skills we teach through our women in construction management courses are delivered through seven modularised sessions, each between three and three-and-a-half hours per session, with all sessions starting at 9:30 am via Zoom. An additional two hours per week is spent working on the online training assignments and leadership development plan. Each session will provide the education and information needed to establish yourself in your business. Here is more information regarding each session and the skills taught: SESSION 1: SELF-LEADERSHIP & THE SECRET TO PERSONAL SUCCESS Our first module is focused on setting course expectations and creating the right environment for learning. We’ll introduce the format and logistics, then discuss leading through turbulent times and how we can take control of ourselves, our thoughts, and our actions to lead growth. There is also a discussion on adult learning techniques and how leaders can leverage them to improve the effectiveness of their teams. We’ll also explore how turbulence and transition have changed how we manage and lead our teams. SESSION 2: THE ROLE OF INTELLIGENCE WHEN LEADING In this session, we’ll discuss the three levels of human intelligence and show how they each play in an individual’s performance and behaviors. Through two distinct mindsets, you’ll be shown how an individual’s motivational intelligence ultimately influences their emotional intelligence and intelligence quotient (IQ). Depending on which mindset a person operates under ultimately dictates their view of themselves, opportunities, and the work at which they will allow themselves to succeed. Finally, we’ll discuss switching your team to a growth mindset. SESSION 3: THE PILLARS OF HUMAN PERFORMANCE Completing this session will allow you to deconstruct the components that create a motivational intelligence growth mindset. Through discussion, you’ll see how most organizational challenges can be directly tied back to lapses in these components. We’ll review the leaders who’ve had the most significant influence on the meeting participants and shows the commonalities that make these leaders stand out. Lastly, we’ll introduce terminology, tools, and techniques that leaders can leverage to better coach and mentor their team. SESSION 4: MANAGEMENT VERSUS LEADERSHIP: THE TWO CRITICAL AND CO-DEPENDENT SKILLSETS FOR CREATING TEAM SUCCESS We’ll discuss the difference between a manager’s and a leader’s focus. The discussion focuses on the two most common management mistakes and how they undermine team culture and individual performance. The final debate focuses on the five critical best practices of excellent management, including clearly defining and communicating goals, creating alignment and buy-in, setting proper expectations, monitoring performance, and recognizing and rewarding performance. Our final portion will work to define what management is. Session 5: Exploring and Defining Leadership: Dispelling the Myths that Surround It Session 5 strives to define leadership. Building on this definition is a follow-up discussion regarding how people develop their leadership abilities. We’ll explore the underpinnings of what creates a successful leader. It also includes the importance of asking questions and active listening. We’ll review the five behavioral characteristics associated with motivational intelligence and how leaders can assess the relative strengths or weaknesses of the characteristics within their team. Lastly, we’ll explore great leaders’ five critical best practices, including communicating a compelling vision, modeling the correct behaviors, establishing a team culture anchored in responsibility, consistently building team confidence and self-esteem, and proactively coaching and mentoring. SESSION 6: BUILDING A LEADERSHIP TOOLBOX FOSTERING ADAPTABILITY, RESILIENCE, AND COURAGE We’ll provide information regarding tools and techniques that leaders can utilize to foster greater accountability and ownership win their teams. The Power Within will explore self-esteem’s critical role in the relative strength or weakness of a person’s motivational intelligence and adaptability in life. We’ll discuss how self-esteem has formed and how it will influence how a person interprets feedback in life. Lastly, we’ll explore levels of self-esteem and the associated behaviors of each. SESSION 7: HELPING EMPLOYEES DEVELOP A HEALTHY PERSPECTIVE AND RESILIENT ATTITUDE During the final session, we’ll explore self-esteem’s critical role in the relative strength or weakness of a person’s motivational intelligence and adaptability in life. We’ll talk about how self-esteem is formed and how it influences how a person interprets feedback. Finally, we’ll explore levels of self-esteem and the behaviors of each and the influence of comfort zones, and the tools that leaders can use to help people escape the fear of change. Our Course Leaders The Power Within was founded by husband and wife team James and Enas Fleming, to inspire people worldwide to think bigger, be better, and achieve more. They both work on a personal level with individuals, businesses, and organisations to help them create leaders and build environments where they can thrive. James and Enas challenge the limits with the Motivational Intelligence formula to help you broaden your perspective and create a future on your terms. Here is more about your course instructors: James Fleming James Fleming – James Fleming, the co-creator of The Power Within. He wanted to inspire people around the world to think better, be better, and achieve more. James believes everyone can do whatever they set their minds to. Founding The Power Within allowed James to turn that deep knowledge into a business that helps others think bigger, better, and achieve more daily. He strives to give leaders the tools and knowledge to achieve their full potential while increasing their self-confidence and self-belief through the Motivational Intelligence Revolution. James wants to support today’s businesses to become tomorrow’s leaders. Mari Steyn Mari is the go-to person for building self-esteem, offering new perspectives and stepping up in Life. With an endless abundance of excitement and love for all people, combined with degrees in Psychology, Knowledge and Information Management and is a Master NLP and Transformation Coach and International NLP and Coaching Trainer and Executive Coach, Mari offers an attractive, fresh, expert approach to Emotional Freedom, Motivational Intelligence, Leadership Development and ReWriting your Story. We undoubtedly have the power within to alchemize ourselves and any situation! Seeing the light go on in someone’s eyes is my ultimate joy. Take Charge with Our Women in Construction Course The Power Within is a Motivational Intelligence company dedicated to helping businesses and leaders become more accountable, resilient, adaptable, and capable of handling all challenges, regardless of the complexity. Our women in construction management course build upon best practices, strategic insights, and lessons learned over three decades of building leadership universities for Fortune 500 companies. Throughout the course, emphasis is given to helping leaders raise their motivational intelligence and foster a growth mindset within their team. You’ll gain the skills you need to successfully lead your team and overcome adversity while ensuring your company is profitable. To learn more about our course or to register, reach out today.

ILM Level 2 Award in Leadership and Team Skills

By Dickson Training Ltd

An accredited qualification to prepare supervisors and team leaders for a future management role. This programme gives Team Leaders & Managers the skills, disciplines and confidence to manage their team effectively and add a great deal more value to the organisation - where they have to apply their learning in order to achieve the highly coveted ILM qualification. In order for a business to obtain maximum results, it is important that employees are motivated and supported in their job roles. It is the responsibility of the team leader or supervisor to lead their team effectively and present feedback to management. This 3-day programme will guarantee to boost your performance as a team leader and help you make the transition from working in a team to leading a team. We use a combination of theory and practical to help you develop yourself, and a toolkit of resources to use in the workplace. This is an internationally accredited course which not only carries kudos but it ensures you apply the learning back into the workplace for an immediate impact. All of our ILM Programmes are provided in partnership with BCF Group Limited, which is the ILM Approved Centre we deliver under. Course Syllabus The syllabus of the ILM Level 2 Award in Leadership and Team Skills course is split into three main modules, covering the following: Module One Developing Yourself as a Team Leader Learning the various roles, functions and responsibilities of a team leader - depending on workplace Recognising limits of authority and accountability, and how these are defined Developing personal skills and abilities for effective team leading Using reflective learning skills to improve performance Identifying areas of strength and possible improvement Finding ways of obtaining feedback from others Receiving and responding positively to feedback Module Two Workplace Communications Learning stages in the communication process Consideration of the recipient's needs Spotting barriers to communication and how to overcome them Establishing a range of direct communication methods relevant to the team Collating a range of direct communication methods relevant to people outside own area of responsibility. This includes written, telephone, e-mail and face-to-face Recognising the aspects of face-to-face communication, including appearance, impact, body language Realising the importance of succinct and accurate records of one-to-one oral communication Reasons for maintaining records of one-to-one communication (e.g. potential disciplinary or legal issues) Module Three Managing Yourself Setting SMART objectives and using them to prioritise own actions Learning simple time management techniques Developing an awareness of own skills and abilities Giving yourself personal objectives in relation to team objectives Developing flexibility and responding to daily changing circumstances Diagnosing the causes and impacts of stress at work Identifying symptoms of stress in yourself Knowing the implications of stress for workplace and non-work activities/relationships Developing simple stress management techniques Available sources of support Action planning and review techniques Accreditation As with all ILM accredited programmes, participants will need to complete the post-programme activity in order to achieve their full ILM Level 2 Award in Team Leading. This element is designed to show to ILM that you are able to apply what you have learned in the workplace. Who Is It For? This programme is ideal for practising or aspiring team leaders, in any industry sector, who is looking to gain a solid foundation or develop their existing skills as a team leader. This internationally recognised course will give you a solid understanding of what is needed to be a successful team leader, how to delegate, motivate and how to implement these skills in to your work place. What Will I Learn? At the end of the course, successful candidates will: Have a good understanding of the team leader role Apply a range of effective communication skills to overcome barriers Know how to motivate, build confidence and gain the best from their teams Identify, build and encourage effective team behaviours Apply practical skills and knowledge to be transferred to the workplace Gain an internationally recognised qualification What Is Required? There are no formal entry requirements, but participants will normally be either practising or aspiring team leaders, with the opportunity to meet the assessment demands and have a background that will enable them to benefit from the programme. Scheduled Courses Unfortunately this course is not one that is currently scheduled as an open course, and is only available on an in-house basis. For more information about running this course in-house at your premises, please contact us for more information.

FORENSIC ACCOUNTING FOR INSTITUTIONAL INVESTORS

By Behind The Balance Sheet

Our Forensic Accounting Course is designed to help investment analysts detect earnings manipulation. It focuses on creative accounting rather than conducting detailed forensic analysis but we explain the tools short sellers employ to detect fraud and some of the techniques we used at hedge funds to identify short opportunities.

Search By Location

- future Courses in London

- future Courses in Birmingham

- future Courses in Glasgow

- future Courses in Liverpool

- future Courses in Bristol

- future Courses in Manchester

- future Courses in Sheffield

- future Courses in Leeds

- future Courses in Edinburgh

- future Courses in Leicester

- future Courses in Coventry

- future Courses in Bradford

- future Courses in Cardiff

- future Courses in Belfast

- future Courses in Nottingham