- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

213 Gas courses in South Queensferry

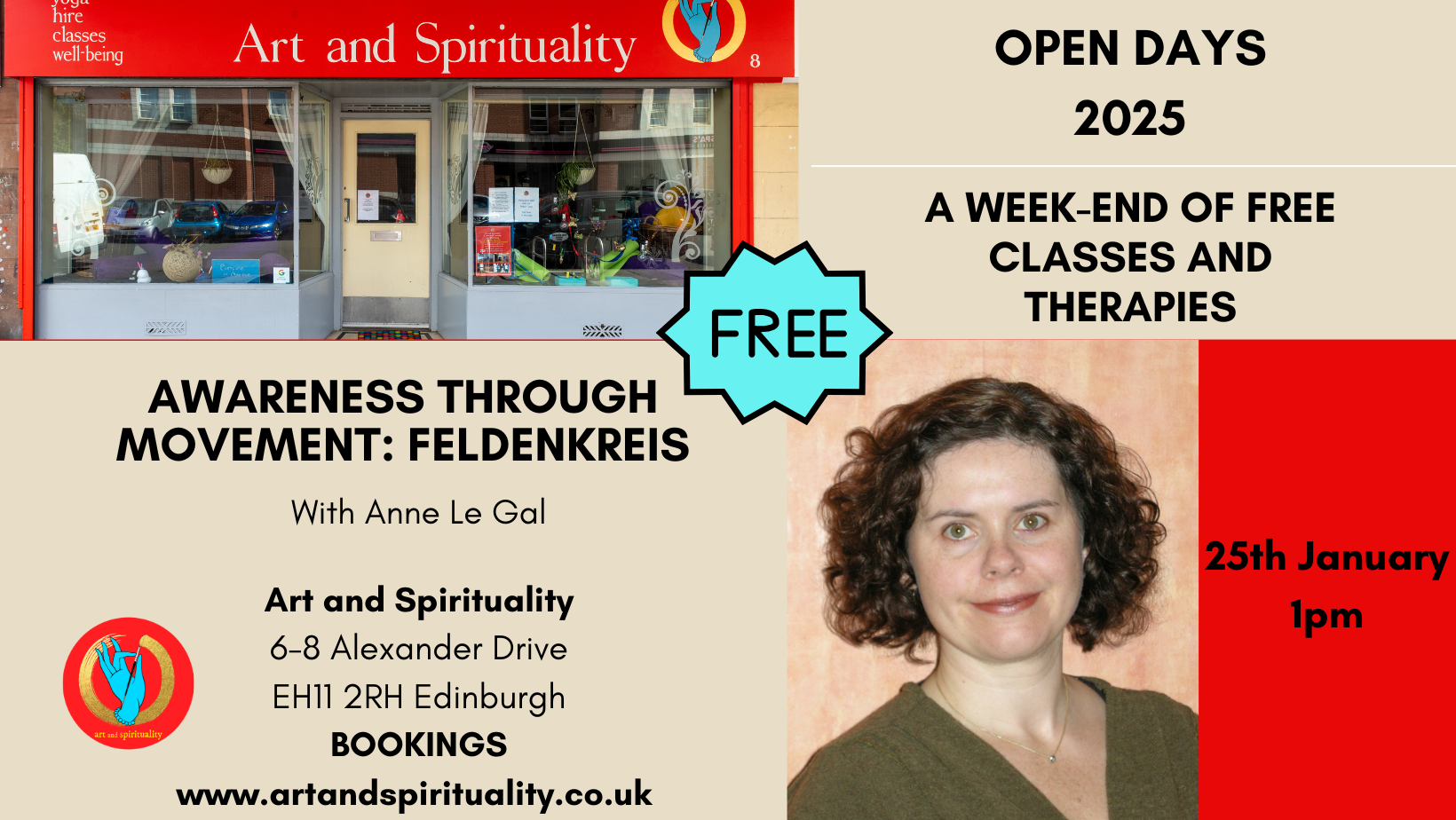

A gentle movement class to take you on a journey of self-discovery. Awaken your curiosity and learn to use your awareness to release chronic patterns of tension and create new movement possibilities. By attending this session you release the teacher, Giada Gaslini and Art and Spirituality Cic, from any liability arising out of any personal injuries, emotional or physical release, death, expectations of results, theft in the venue or damages that may happen to people and objects while attending.

RELAX YIN & CHAKRA MEDITATION is a serene and restorative class designed to harmonize the body, mind, and spirit through gentle Yin Yoga poses and guided meditation focusing on the chakras. Benefits: Promotes deep relaxation and stress reduction. Enhances self-awareness and emotional balance. Improves flexibility and releases physical tension. Supports energy flow and chakra alignment for holistic well-being. This class is ideal for individuals seeking a gentle, introspective practice to unwind and reconnect with their inner selves. No prior experience in yoga or meditation is necessary—everyone is welcome. By attending this class you release the teacher, Giada Gaslini and Art and Spirituality Cic, from any liability arising out of any personal injuries, emotional or physical release, death, expectations of results, theft in the venue or damages that may happen to people and objects while attending.

Industrial Instrumentation and Modern Control Systems

By EnergyEdge - Training for a Sustainable Energy Future

About this training course This 5 full-day course provide a comprehensive understanding of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, HART protocol, control valves, actuators, and smart technology. This course will focus on maximizing the efficiency, reliability, and longevity of these systems and equipment by providing an understanding of the characteristics, selection criteria, common problems and repair techniques, preventive and predictive maintenance. This course is a MUST for anyone who is involved in the selection, applications, or maintenance of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology because it covers how these systems and equipment operate, the latest maintenance techniques, and provides guidelines and rules that ensure their successful operation. In addition, this course will cover in detail the basic design, operating characteristics, specification, selection criteria, advanced fault detection techniques, critical components and all preventive and predictive maintenance methods in order to increase the reliability of these systems andequipment and reduce their operation and maintenance cost This course will provide the following information for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology: Basic Design Specification Selection Criteria Sizing Calculations Enclosures and Sealing Arrangements Codes and Standards Common Operational Problems All Diagnostics, Troubleshooting, Testing, and Maintenance Practical applications of smart instrumentation, SCADA, and Distributed Control Systems, control valves, actuators, etc in the following industries will be discussed in detail: Chemical and petrochemical Power generation Pulp and paper Aerospace Water and sewage treatment Electrical power grids Environmental monitoring and control systems Pharmaceutical plants Training Objectives Equipment Operation: Gain a thorough understanding of the operating characteristics of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Diagnostics and Inspection: Learn in detail all the diagnostic techniques and inspections required of critical components of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Testing: Understand thoroughly all the tests required for the various types of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Maintenance and Troubleshooting: Determine all the maintenance and troubleshooting activities required to minimize the downtime and operating cost of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Repair and Refurbishment: Gain a detailed understanding of the various methods used to repair and refurbish modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Efficiency, Reliability, and Longevity: Learn the various methods used to maximize the efficiency, reliability, and longevity of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Sizing: Gain a detailed understanding of all the calculations and sizing techniques used for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Design Features: Understand all the design features that improve the efficiency and reliability of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Selection: Learn how to select modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology by using the performance characteristics and selection criteria that you will learn in this course Equipment Enclosures and Sealing Methods Learn about the various types of enclosures and sealing arrangements used for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Commissioning: Understand all the commissioning requirements for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Codes and Standards: Learn all the codes and standards applicable for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Causes and Modes of Failure: Understand the causes and modes of failure of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology System Design: Learn all the requirements for designing different types of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: Industrial Instrumentation and Modern Control Systems Practical Manual (400 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

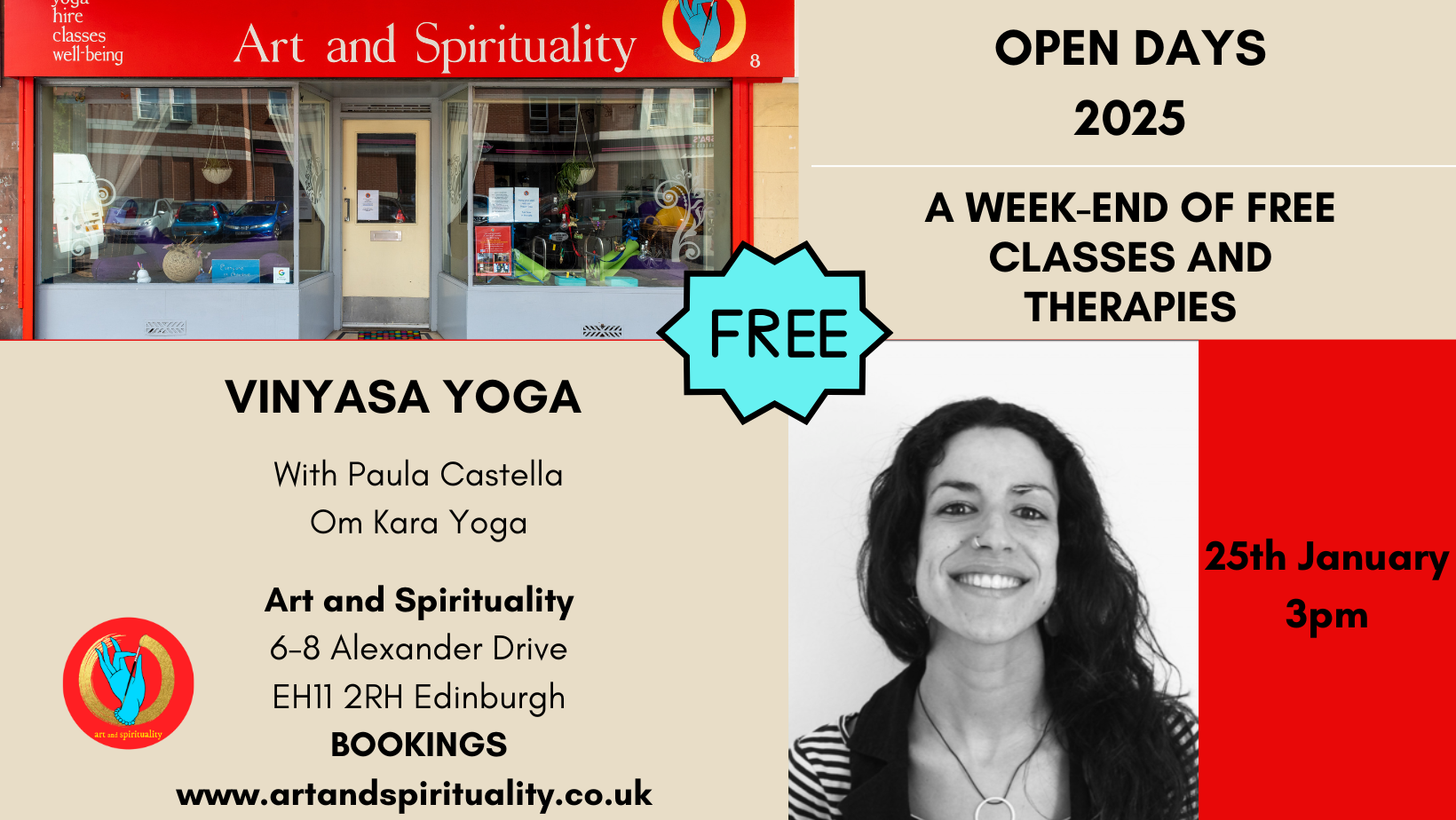

Vinyasa flow is an evolving form of traditional Hatha yoga that focuses on integrating breath, movement, awareness, aligment, strength and flexibility. Originating withing the yogic teachings of Sri T. Krishnamacharya it is likened to a dynamic dance. Asanas are connected through breath for a transformative and balancing effect. Suitable for most levels. Adjustments and options will be given so students of all levels can chose their own challenge as well as relaxation. By attending this session you release the teacher, Giada Gaslini and Art and Spirituality Cic, from any liability arising out of any personal injuries, emotional or physical release, death, expectations of results, theft in the venue or damages that may happen to people and objects while attending.

This 45-minute class combines elements of Ashtanga and Vinyasa in a slow-flow style. We’ll begin with a warm-up and standing sequence to energize the body, moving into deeper bends and stretches before ending in a calming relaxation. Throughout, we’ll synchronize movement with breath, creating a dynamic meditation in motion that revitalises and grounds both body and mind. Perfect for anyone seeking a balanced and mindful practice. By attending this session you release the teacher, Giada Gaslini and Art and Spirituality Cic, from any liability arising out of any personal injuries, emotional or physical release, death, expectations of results, theft in the venue or damages that may happen to people and objects while attending.

Shamanism is a spiritual practice that goes beyond every beliefs and culture and is about trying to reach your full potential as you walk on planet earth, so connecting yourselves to the whole. Shamans were described as the first physicians, magicians, artists, storytellers, spiritual beings. But shamans are healers that make changes in invisible realms to help healing in the ordinary reality of the community. Shamans see in the darkness while connecting with the divine outside the time in an altered state of consciousness. I will explain to you how to go on a shamanic journey. Some powerful benefits from Shamanic drumming: Reduce stress Improves concentration opens up acceptance of self it encourages the body to desire a healthier lifestyle beneficial to your cardiovascular health boosts your immune system induces a deeper self-awareness by prompting synchronus brain activity and alpha waves helps releasing negative feelings and emotional trauma If you suffer from particular mental health conditions, please contact me via e-mail before booking. Giada's Journey Creative explorer of the human well-being with twenty years’ experience running events, workshops and retreats. Co-author of a non-profit book with other 33 Italian women about their stories in different countries. She has been learning to heal herself supporting a Holistic connection between mind, body and spirit. She has been studying and practicing Buddhist teachings, meditation and the Five Tibetan Rites Yoga in Nepal, India and Italy. Approached the imaginal world and dreams with the psychologist Elio Occhipinti and a regressive hypnosis journey with the vision of the psychiatrist Brian Weiss. Her studies and practice have helped her become: Shamanic Practitioner and Teacher with the two years formal training at Anam Cara and Teacher Training in Wales Shamanic and Integral Yoga Teacher, Ikigai Coach, Forest Therapy Guide qualified with Selene Calloni Williams at the Imaginal Academy and part of the Italian-Swiss Association for Counselling and Coaching, Aiscon. Professional Esoteric Numerologist graduated at The Connaissance School of Numerology Corporate Mental Health Coach achieved with WeFocus Founder of Drink In Art exhibitions of local artists in private flats Founder of School of Shamanism creative and spiritual workshops, classes and therapies Founder of the Art and Spirituality Centre centre for creativity and well-being in Edinburgh By attending this session you release the teacher, Giada Gaslini and Art and Spirituality Cic, from any liability arising out of any personal injuries, emotional or physical release, death, expectations of results, theft in the venue or damages that may happen to people and objects while attending.

Commissioning of Combined Cycle Power Plants

By EnergyEdge - Training for a Sustainable Energy Future

About this Course This 5 full-day course provides a comprehensive understanding of all the commissioning procedures for combined cycle power plants. The Commissioning Management System (CMS) of combined cycle power plants is covered in detail in this course. This includes all the commissioning procedures and documents, purpose of commissioning, responsibilities, system description, organization, working parties, test teams, documentation, testing and commissioning schedules, test reports, safety, plant certification, and plant completion report. The course provides also a thorough understanding of all the commissioning requirements for gas turbines, steam turbines and auxiliaries, generator and auxiliaries, electrical equipment, switchgear equipment, switchgear and transformers. All the stages of the commissioning procedure are covered in-depth in this course. This includes preparation - planning various activities, pre-commissioning checks and tests, typical commissioning schedule, detailed tests and commissioning procedures and instructions for every component in a combined cycle power plant, instrumentation, trial run of the equipment, safety and precautions, commissioning of combined cycle power plant systems, safety rules clearance certificates, procedure for the control and handling of defects, commissioning reports, operational testing, first fire, generator synchronization, performance testing, heat rate testing, emission testing, contract testing, CO2 concentration tests, electrical full-load rejection test, duct burner testing, partial load stability test, and reliability test. This course is a MUST for anyone who is involved in the pre-commissioning or commissioning of any combined cycle power plant equipment because it provides detailed pre-commissioning checks and tests, and detailed tests and commissioning procedures and instructions for every component in a combined cycle power plant. In addition, the seminar provides an in-depth coverage of all preparation, planning activities, commissioning schedules, trial run of each combined cycle power plant equipment, safety and precautions, safety rules clearance certificates, procedures for handling defects, and commissioning reports. Training Objectives Pre-commissioning Checks and Tests, Detailed Tests and Commissioning Procedures and Instructions for Every Equipment in Combined Cycle Power Plants: Gain a thorough understanding of all pre-commissioning checks and tests, and all commissioning procedures and instructions for every equipment in combined cycle power plants Commissioning Management System (CMS) of Combined Cycle Power Plants: Discover the benefits of the CMS of combined cycle power plants including all commissioning procedures and documents, purpose of commissioning, responsibilities, system description, organization, working parties, test teams, documentation, testing and commissioning schedules, test reports, safety, plant certification, and plant completion report Commissioning Procedures and Instructions for Heat Recovery Steam Generators, Air Blow and Steam Blow of Steam and Gas Piping in Combined Cycle Power Plants: Learn about the commissioning procedures and instructions for heat recovery steam generators, chemical cleaning of heat recovery steam generators, air blow and gas blow of steam and gas piping in combined cycle power plants, safety valve setting and soot blowers Commissioning Procedures and Instructions for Gas Turbines and Steam Turbines: Gain a thorough understanding of all the commissioning procedures and instructions for gas and steam turbines and auxiliaries including acid cleaning of oil pipelines, lubrication and governing system (oil flushing and hydraulic testing), jacking oil system, governing system, regenerative system, barring gear, vacuum tightness test, first rolling of turbine and data logging Commissioning Procedures and Instructions for Generator and Auxiliaries: Discover all the commissioning procedures and instructions for generator and auxiliaries including generator, seal oil system, hydrogen gas system, stator water system, rolling and start-up of generators Commissioning Procedures and Instructions for Electrical Equipment: Learn about all the commissioning procedures and instructions for electrical equipment including switchyard equipment, switchgear, transformers and motors Operational Testing, Performance Testing, Heat Rate Testing, Emission Testing of Combine Cycle Power Plants: Gain a thorough understanding of operational testing, first fire, generator synchronization, performance testing, heat rate testing, emission testing, contract testing, CO2 concentration tests, electrical full-load rejection test, duct burner testing, partial load stability test, and reliability test of combined cycle power plants Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Training Methods The instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all the delegates gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Are you feeling stressed, overwhelmed, or out of balance? Reiki can help restore harmony to your mind, body, and spirit. In this 1-1 session, you’ll experience the gentle yet powerful energy of Reiki, a Japanese healing technique that promotes relaxation, reduces stress, and encourages self-healing. During the session, the therapist will channel universal energy to clear blockages and balance your energy flow, leaving you feeling refreshed, grounded, and at peace. ✨ Benefits of Reiki: Reduces stress and anxiety Enhances emotional well-being Boosts energy and vitality Supports physical healing and relaxation Promotes mental clarity and focus By attending this session you release the teacher, Giada Gaslini and Art and Spirituality Cic, from any liability arising out of any personal injuries, emotional or physical release, death, expectations of results, theft in the venue or damages that may happen to people and objects while attending.

An Understanding of Respiratory Care

By Guardian Angels Training

Enhance your respiratory care skills with our comprehensive course. Learn to assess, diagnose, and manage respiratory conditions for better patient outcomes.

Pipeline Integrity Management - Incorporating API 1160 / 1173 and ASME B31.8S

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This 3 full-day course provides a sound review of Pipeline Integrity Management strategies, in compliance with regulatory requirements, including self-assessment. The course is highly interactive and takes the form of lectures and case studies. On completion of the course, the participants will have a solid understanding of the procedures, strengths, limitations, and applicability of the main issues that comprise a Pipeline Integrity Management Program. The course incorporates API 1160 / 1173 and ASME B31.8S, and explains in detail the pipeline integrity requirements described in these standards. This course can also be offered through Virtual Instructor Led Training (VILT) format. Training Objectives Objectives of this course: Explore the latest techniques used to develop a comprehensive integrity management program covering both pipelines and their associated facilities Determine the necessary elements of such a program described in detail with examples of typical program content including an overarching view of where detailed risk analysis and defect assessment fits in the program Understand the scopes and contents of pipeline integrity standards i.e. API 1160 / 1173 and ASME B31.8S On completion of this course, the participants will be able to understand: Codes used in developing Integrity Management Plans, API 1160 / 1173 and ASME B31.8S, others The elements of an Integrity Management Plan Threat assessment Critical aspects of risk assessment Prevention and mitigation measures Characteristics and limitations of different inspection methods A risk-based approach to maintenance Target Audience The course is intended for supervisors, engineers and technicians responsible for ensuring the adequate protection of pipeline assets. In addition, maintenance planners, regulators and service providers to the pipeline industry will also benefit from attending this course. Course Level Basic or Foundation Trainer Your expert course leader is a Ph.D. Metallurgical Engineer with advanced expertise in asset integrity management of oil & gas production facilities, corrosion control, materials selection, chemical treatments, pipeline pigging, inspections, fitness-for-service evaluations, failure analysis and related consulting. He has 40 years of experience working for BP in Asia and South America, Amoco in the US, Intertek, and four years with Applus-Velosi in Southeast Asia. Practical Work Experience: AIM consultant with focus on Southeast Asia operations and clients Direct technical interface with clients on Velosi services Technical consultant for ongoing regional contracts and lead roles as auditor, instructor or facilitator Main clients have included the following organisations: BP and Vico Indonesia, Pertamina Offshore Northwest Java and West Madura Offshore (Indonesia), NCSP (Vietnam), ADCO-OPCO (Abu Dhabi), Thang Long (Vietnam), Exxon-Mobil (Malaysia) and Mubadala Petroleum (Indonesia). POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable

Search By Location

- Gas Courses in London

- Gas Courses in Birmingham

- Gas Courses in Glasgow

- Gas Courses in Liverpool

- Gas Courses in Bristol

- Gas Courses in Manchester

- Gas Courses in Sheffield

- Gas Courses in Leeds

- Gas Courses in Edinburgh

- Gas Courses in Leicester

- Gas Courses in Coventry

- Gas Courses in Bradford

- Gas Courses in Cardiff

- Gas Courses in Belfast

- Gas Courses in Nottingham