- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Definitive Ethernet switching course description A hands on comprehensive look at Ethernet switches with extensive coverage of VLANs. The course focuses on the technology and not any one manufacturers product enabling delegates to configure switches from any manufacturer. What will you learn Configure and troubleshoot switches using: Console port telnet HTTP TFTP Configure and troubleshoot switch features such as: Duplex/speed Port based MAC security Spanning Tree Link aggregation Tagged ports Configure and troubleshoot VLANs. Definitive Ethernet switching course details Who will benefit: Technical staff. Prerequisites: Intro to data communications & networking. Duration 3 days Definitive Ethernet switching course contents What is Ethernet? LANs, network cards and cables, CSMA/CD, Ethernet frames, Ethernet evolution, 802.3. Hands on: ping, Ethernet speeds, CSMA/CD. Ethernet layer 2 Layer 2 functions, NICs, MAC addresses, unicasts, multicasts and broadcasts, frame formats. Hands on: Configuring NICs, Analysing MAC addresses with Wireshark IP and Ethernet Relationship Hands on: ARP. What is a switch? Switches connect multiple devices, switches versus hubs, simultaneous conversations, switches work at layer 2, the forwarding database, how the forwarding database is built, broadcast and collision domains Hands on: Difference between hubs and switches. Switch configuration Switch configuration Managed/unmanaged switches, configuration methods, reasons to configure switches. Console ports, HyperTerminal (and alternatives). Hands on: Using the console port to troubleshoot and configure switches. Switches in more detail Latency, forwarding mechanisms, switch fabrics. Hands on: Using telnet and HTTP to switches. Ethernet extensions Auto negotiation, Power over Ethernet. Hands on:Configuring and troubleshooting switch ports: Speed, duplex and security. Redundant links Loops, broadcast storms, STP, BPDU format, STP convergence. Hands on: Tracking blocked ports. STP convergence. Backbone links Architectures, link aggregation, LACP, load sharing, resilience. Hands on: fail over times. VLANs Virtual versus physical LANs, Why have VLANs? Broadcast domains, Creating VLANs, Assigning ports to VLANs. Hands on: Analysing the effect of VLANs on traffic. Enterprise VLANs VLANS are internal, multiple VLANs, Load balancing, Default VLAN, VLAN registration protocols: VTP, GVRP, MVRP. Hands on: VLANs on multiple switches. Tagging/Trunking Reason for tagging, terminology, tagging process, 802.1Q, Tag format, VLAN stacking. Hands on: Configuring and troubleshooting tags. STP variants RSTP, Common STP, Multiple STP, PVST, ring alternatives. Hands on: RSTP. Inter VLANs Layer 3 switching, IP addressing rules, Interconnecting VLANs. Hands on: Routing between VLANs. Troubleshooting Ethernet Methods, tools, locating faults, layer 1 issues, layer 2 issues Hands on: Fixing the network.

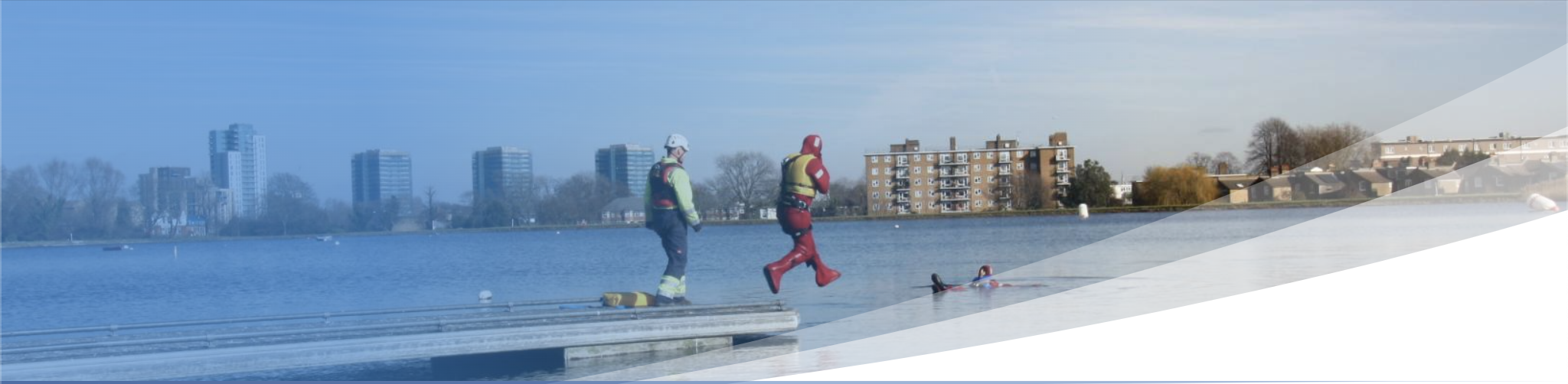

Trainer to Candidate Ratio: Working at Height Theory: 12 Students to 1 instructor; Practical: 6 Students to 1 instructor Frist Aid Theory: 12 Students to 1 instructor; Practical: 6 Students to 1 instructor Manual Handling Theory: 12 Students to 1 instructor; Practical: 12 Students to 1 instructor Fire Awareness: Theory: 12 Students to 1 instructor; Practical: 6 Students to 1 instructor Sea Survival: Theory: 12 Students to 1 instructor; Practical: 6 Students to 1 instructor Enhanced First Aid: Theory: 12 Students to 1 instructor; Practical: 6 Students to 1 instructor Advanced Rescue Training: Theory: 12 Students to 1 instructor; Practical: 4 Students to 1 instructor

TEMA & HTRI Heat Exchanger Design & Cost Saving Management – Virtual Instructor Led Training (VILT)

By EnergyEdge - Training for a Sustainable Energy Future

Acquire in-depth knowledge of heat exchanger design and cost-saving management with EnergyEdge's TEM & HTRI course. Join our virtual instructor-led training to stay ahead in the industry.

We offer fully accredited IRATA Level 1, Level 2 and Level 3 plus refresher training courses in established, fully equipped facilities at CATCH (Centre for the Assessment of Technical Competence Humber). This facility, based in the industrially rich region of the Humber, provides a safe and authentic site environment with full-scale equipment for experiential learning and development. From these world-class training facilities MCL deliver practical, onsite-based training to members of the oil, gas and renewable industries, construction, stage and theatre rigging, theme parks and many more. Classrooms and simulated industrial environments make for the perfect setting in which to undertake accredited qualifications.

This course is intended to introduce the concepts of rigging and lifting, rigging equipment and basic lifting techniques for personnel new to the role. This course provides the information and skills for learners to understand the use of lifting equipment and how it is applied in a practical setting.

The aim of this module is to enable delegates to perform entry-type injured person rescue operations, in a Wind Turbine Generator, using industry standard rescue equipment, rescue methods and techniques, exceeding those of GWO Working at Heights. Valid GWO BST Module Working at Heights, GWO First aid and GWO Manual Handling certificates are prerequisites for participation.

The delegates are able to demonstrate: The participants are able to demonstrate knowledge of hazards and risks associated with working at height specific to a wind turbine generator (WTG) (L2 – Knowledge) The participants are able to demonstrate understanding of current national and regional legislation regarding working at height (L2 – Knowledge) The participants are able to demonstrate correct identification of PPE, including identification of Global and regional standard markings e.g. harness, hard hat, lanyards, etc. (L3 – Skills) The participants are able to demonstrate the knowledge and skills to correctly perform pre-use inspection, service, store and correctly fit relevant PPE, e.g. harness, fall arrest lanyards, guided type fall arrest lanyards and work positioning lanyards (L2 – Knowledge & L3 – Skills) The participants are able to demonstrate correct use of the relevant PPE, e.g. harnesses fall arrest lanyards, guided type fall arresters and work positioning lanyards. This includes correct identification of anchor points and correct conduct on ladder (L3 – Skills) The participants are able to demonstrate correct use of evacuation devices (L3 – Skills) The participants are able to demonstrate how to approach rescue situations in WTGs and use rescue equipment efficiently (L3 – Skills & Ability)

Course Objectives The delegates are able to demonstrate: knowledge of hazards and risks associated with working at heights, specific to WTG (Wind Turbine Generator). understanding of current national legislation regarding working at heights. correct identification of PPE, including identification of European/Global standard markings e.g. harness, hard hat, lanyards, etc. knowledge and skills to correctly inspect, service, store and don the relevant PPE, e.g. harness, lanyards, fall arresters and work positioning equipment. correct use of the relevant PPE, e.g.harness lanyards, fall arresters and work positioning equipment. This includes correct identification of anchor points and correct ladder conduct. correct use of evacuation devices. how to approach rescue situations in WTGs and use rescue equipment efficiently.

The aim of this module is to enable delegates to support and care for others working in the industry by processing the knowledge, skills and attitude of Enhanced First Aid. Valid GWO BST Module First Aid certificate is a prerequisite for participation.

Search By Location

- Fabric Courses in London

- Fabric Courses in Birmingham

- Fabric Courses in Glasgow

- Fabric Courses in Liverpool

- Fabric Courses in Bristol

- Fabric Courses in Manchester

- Fabric Courses in Sheffield

- Fabric Courses in Leeds

- Fabric Courses in Edinburgh

- Fabric Courses in Leicester

- Fabric Courses in Coventry

- Fabric Courses in Bradford

- Fabric Courses in Cardiff

- Fabric Courses in Belfast

- Fabric Courses in Nottingham