- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Abstract landscape painting workshop

By BloomsFair

Creative workshop to challenge your inner artist, relax and have fun

Pivot tables are really very easy to create, but very powerful. By using Excel pivot tables, one can get very interesting and valuable business intelligence from your data in very little time. This short session aims to give you the techniques to use this valuable Excel tool creatively. It is enough time to learn a lot about Excel Pivot Tables, but there is very little time for other questions.

This course will start by giving you an overview of some of the common types and causes of learning disabilities, characteristics and behaviours and how they affect people. We will consider which learning & behavioural strategies are appropriate and how using a person centred approach to care will get the best results and ensure that needs of the individual are effectively met. We also discuss overcoming the stigma attached to learning disabilities

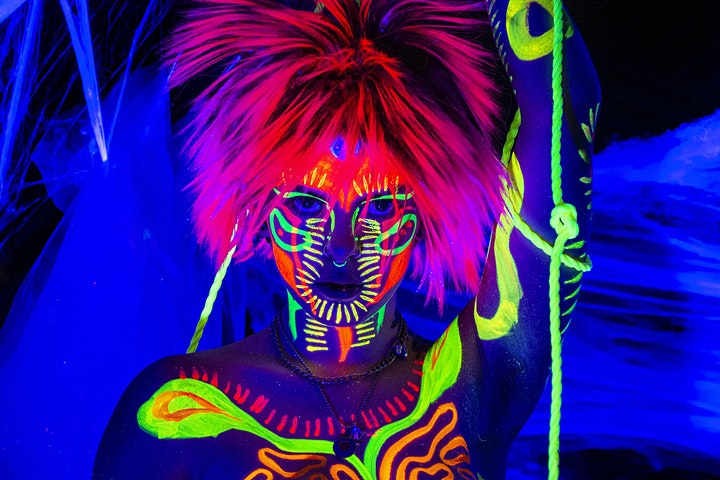

IT'S THAT TIME AGAIN! THE NEON NIGHTMARE HALLOWEEN SCARE SPECIAL DEATH DRAWING CLASS! Join us in Dalston for an evening of spooky artistic fun. Come to a life drawing class like no other using neon reactive arts materials to draw inspiringly colorful life models. Trick or Treat! What will they be dressed as this year...crazy clowns, zealous zombies... or something much worse!

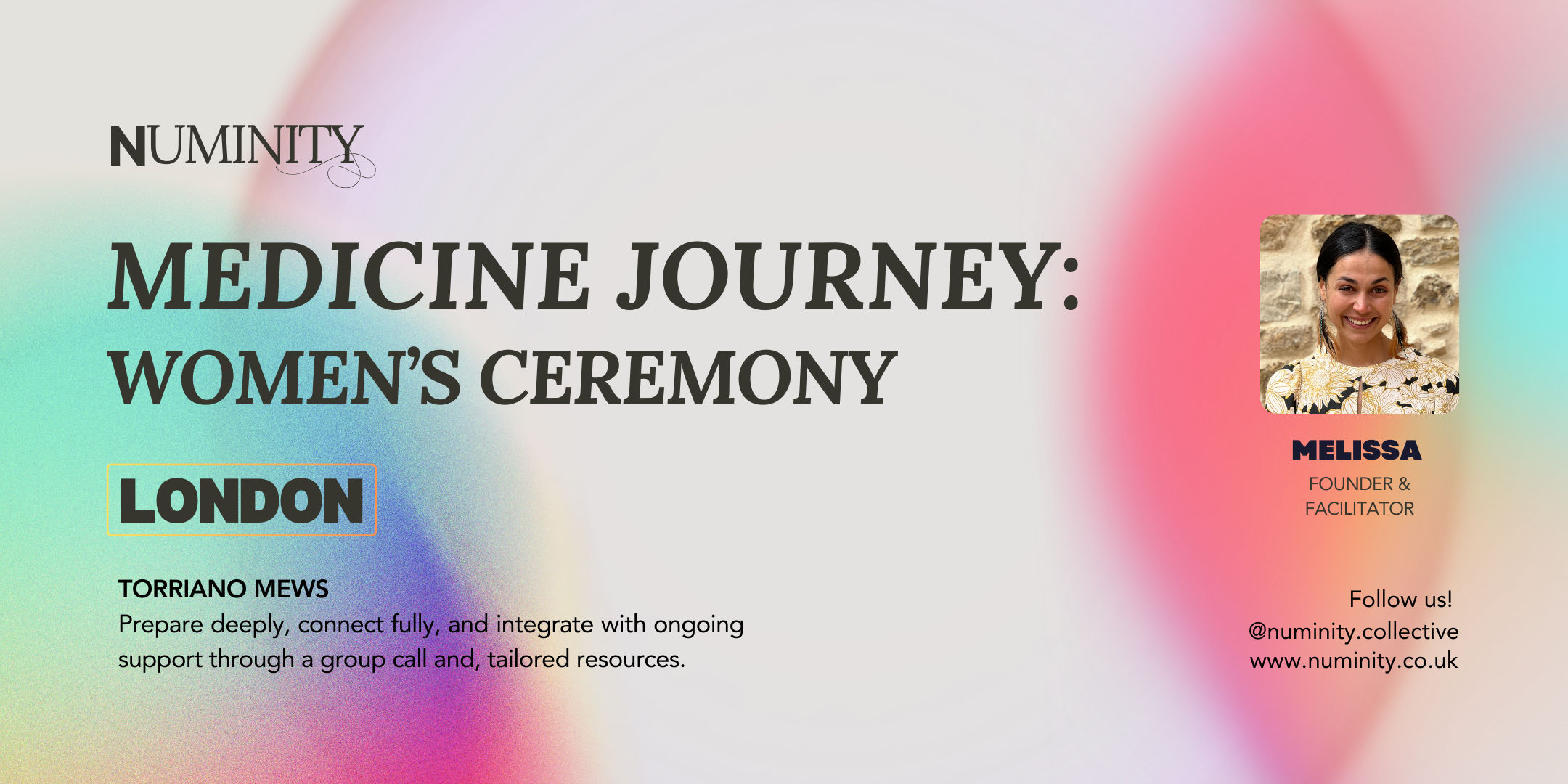

Medicine Journey: Women's Ceremony There is something powerful that happens when women gather together to heal. We live in a world that constantly asks us to speed up, toughen up, and disconnect from ourselves and from each other. This ceremony is a chance to slow down and come back to who you were before a lifetime of conditioning. Through a guided inner journey with the medicine, you’ll reconnect with your body’s wisdom, your own rhythm, and the deeper truth that’s been there all along. What Makes This Different: Harness the Power of the Feminine: By journeying as part of a small group, you’ll discover how connection and mutual support amplify the transformative potential of your journey. This ceremony is designed for women, by a woman. The space holds what we’re often not given room for in daily life: emotional truth, embodied wisdom, and the depth that comes from being fully met. Empower Yourself: By becoming your own healer. We will give you the tools, insights, and confidence to navigate your healing path long after the ceremony itself. Be Part of a Framework for Growth: You’ll connect with other women from the community and find support that extends beyond the ceremony, offering support, accountability, and resources to keep you grounded, inspired and moving forward. What’s Included: Pre-Ceremony Guidance You’ll receive a clear, practical guide to help you prepare physically, emotionally, and mentally. From setting your intention to creating the right environment around you, we'll help you arrive feeling ready. Personalised Dose Consultation Before the ceremony, Melissa will speak with you to determine the right dose for your body and where you are in your journey. The Ceremony This is a quiet, powerful space where you can focus on your intention and go inwards. Melissa will guide the day with care and clarity, creating the conditions for you to meet yourself fully. Integration Support After the ceremony, you’ll receive a written guide to help you process and apply what’s come through. You’ll also be invited to an online integration call to reflect, share, and take your next steps with intention. Booking Details: Total cost: £300 (balance payable two weeks before the ceremony). £30 non-refundable deposit to reserve your spot. Upcoming Ceremony Dates: Sunday 18th May, 12–6pm (max group 5 - 2 spots left) Group Call Dates:* Integration - Tuesday 27th May, 7-8.30pm *Please note, if you are unable to make the call, you can still join, and will still have access to the same resources. Spaces are intentionally limited to keep the group intimate. If you’re ready, you can book your spot today.

Medicine Journey: Healing in Community Healing is not a solo journey - all of us require connection, support and accountability to keep us moving in the right direction. Ceremonies open deep doors, but without the right preparation and integration, those openings can feel overwhelming, incomplete and at worst, harmful. This framework is designed to teach and empower you to harness the power of community as an essential vessel for your ongoing healing and growth. What Makes This Different: Harness the Power of Community: By preparing and integrating as part of a small group, you’ll discover how connection and mutual support amplify the transformative potential of your journey. Empower Yourself: By becoming your own healer. We will give you the tools, insights, and confidence to navigate your healing path long after the ceremony itself. Be Part of a Framework for Growth: You’ll join a micro-community that extends beyond the ceremony, offering support, accountability, and resources to keep you grounded, inspired and moving forward. What’s Included: Pre-Ceremony Preparation: Participate in a group call to set intentions, open up, and connect with your fellow participants. Learn how to prepare to get the most out of your medicine journey. Receive a comprehensive guide on how to prepare. 1-1 Consultation: A private consultation with Diego to discuss and decide on the right dose for your journey. You will receive a link to book this call upon booking. The Ceremony: Step into a safe, sacred space for healing in a small group ceremony, where you’ll be supported yet empowered to work by taking your intention directly to the medicine. Integration and Ongoing Support: After the ceremony, you’ll receive a comprehensive guide, join a follow-up call, and continue to thrive as part of a micro-community hub designed to keep you on track. This is a chance to experience a framework of support that can transform one journey into long-lasting growth. Booking Details: Total cost: £300 (balance payable two weeks before the ceremony). £30 non-refundable deposit to reserve your spot. Upcoming Ceremony Dates: Sunday 25th May, 12–6pm (max group 5) Group Call Dates:* Preparation - Monday 19th May, 7-8.30pm Integration - Monday 2nd June, 7-8.30pm *Please note, if you are unable to make a call, you can still join the hub, and will still have access to the same resources. Please take the time to introduce yourself and connect with the rest of the group once you join the hub. Spaces are intentionally limited to keep the group intimate. If you’re ready, you can book your spot today.

Painting Pottery & Glazing Workshop

By Art Craft Studios

Painting & 'glazing' means to add colour & patterns to your pottery. Kicking off with a practical demonstration, we will take you on a step-by-step journey of the fundamental ceramic techniques of glazing (surprisingly there are a few). Each step requires practice but you'll be hands-on in no time learning each step of the journey as we go. We have pre-made pots to choose from, inlcuding cups, bowls and planters. With your newly learned skills, you'll have what it takes to paint pottery and you can collect your finished works a few weeks later. We'll discuss when you can collect at the end of the workshop. All you need to do now is start thinking about your favourite colours and designs!

This course aims to give the learner the understanding of what autism is and how it affects a child or adults daily life, we will discuss the typical behaviours and how to offer support. We will identify a range of interventions and approaches improve the quality and daily lives of individuals with these conditions

Taster Day at Camden Theatre & Film School for Children 4-18 Years Old

By Anna Fiorentini Theatre & Film School

Our students follow a weekly timetable of acting, film, singing and dance lessons all taught by leading industry professionals that have a wonderful rapport with young people.

Search By Location

- Disc Courses in London

- Disc Courses in Birmingham

- Disc Courses in Glasgow

- Disc Courses in Liverpool

- Disc Courses in Bristol

- Disc Courses in Manchester

- Disc Courses in Sheffield

- Disc Courses in Leeds

- Disc Courses in Edinburgh

- Disc Courses in Leicester

- Disc Courses in Coventry

- Disc Courses in Bradford

- Disc Courses in Cardiff

- Disc Courses in Belfast

- Disc Courses in Nottingham