- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

168 Detailing courses

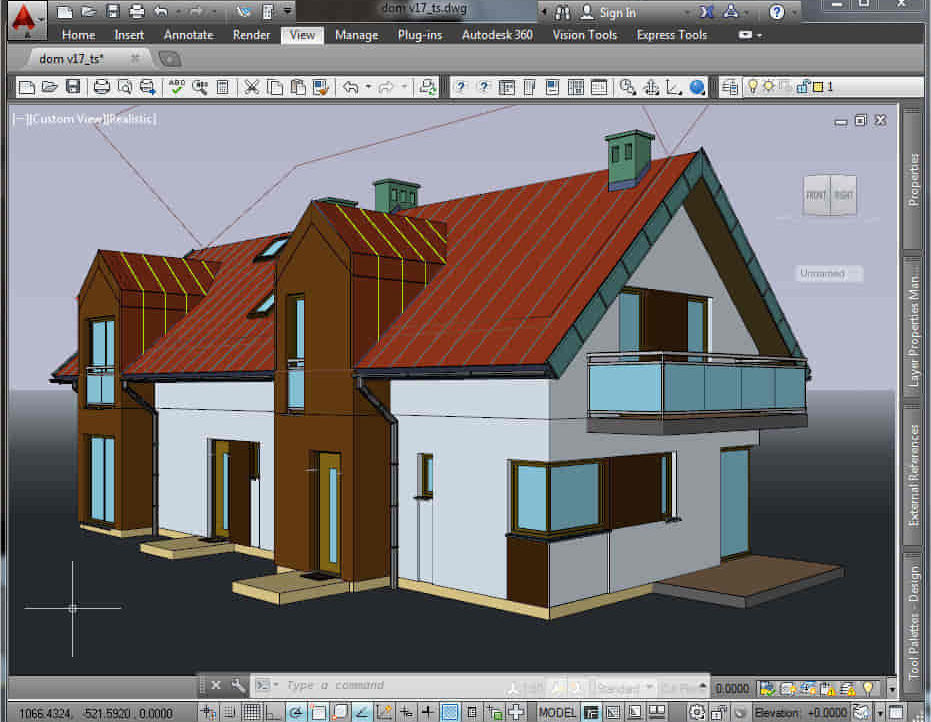

AutoCAD Architecture 1 on 1 Course

By ATL Autocad Training London

Why Choose AutoCAD Architecture 1 on 1 Course? Our courses for AutoCAD and AutoCAD Architecture. AutoCAD conveys design intent through Lines and Circles, AutoCAD Architecture enhances these elements with walls, doors, windows and AEC. Click here for more info: Website When Can I Reserve My Spot? 1 on 1 training and available from Monday to Saturday, 9 am to 7 pm Duration: 16 hours, which you can flexibly book. Training Method: 1-on-1, in-person face-to-face or live online training. AutoCAD Architecture 3D Course Overview: AutoCAD Architecture Introduction Distinguishing AutoCAD Architecture from AutoCAD LT Exploring the User Interface and 3D Viewing Wall Construction and Customization: Adding Walls to the Model Creating Specialized Curtain Walls Modifying Walls for Specific Needs Joining Walls for Complex Structures Incorporating Wall Openings for Doors and Windows Ceiling Plans (Reflected): Establishing Ceiling Grids and Construction Details Customizing Ceiling Grids for Design Consistency Inserting Ceiling Fixtures and Detailed Construction Structural Design and Analysis: Utilizing Structural Elements and Online Resources Constructing Column Grids and Annotating Columns Adjusting Column Grids and Annotations Enhancing Clarity with Column Grid Annotations Stairs: Designing and Customizing Stairs Adding Railings and Detailed Construction Refining Railings and Detailed Construction Floors and Slabs: Creating Floor Slabs with Construction Details Aligning Floor Slabs with Design Specifications Editing Slabs Using Slab Tools and Construction Details Roofs and Roof Detailing: Roof Creation for the Building Designing Roof Slabs for Specific Areas Modifying Roofs and Roof Slabs as Needed Precise Roof Detailing with Roof Slab Tools Annotation: Scaling Detail Drawings and Annotations Incorporating Text, Leaders, and Comments Accurate Dimensioning in AutoCAD Architecture Enhancing Clarity with Various Annotation Tools Equipment and Furnishings: Integrating Interior and Exterior Furnishings Incorporating Blocks and 3D Models for Realism Leveraging Tool Palettes and Autodesk Seek Resources Model Views Ready for Printing PDF: Creating Callouts for Specific Views Designing Elevations, Sections, and Construction Details Modifying Callout Objects for Improved Visualization Implementing Live Sections and Elevations Generating Reports and Managing Project Resources Schedules: Adding Door and Window Labels Editing Label Data for Accuracy Creating Schedules for Efficient Project Management Customizing Schedules to Meet Specific Requirements This comprehensive AutoCAD Architecture 3D course equips participants with the skills needed to create intricate 3D architectural models, implement construction details, and efficiently manage project resources. It empowers participants to produce professional-grade architectural designs using AutoCAD Architecture software." Upon completion of the AutoCAD Architecture 1-on-1 Course, participants will demonstrate proficiency in architectural design using the application. They will have mastered essential techniques, gained expertise in drawing management, refined their model visualization skills, and earned an accredited certificate. This tailored learning experience, coupled with post-course support and practical exercises, will significantly boost career prospects in the field. Download Autocad Architecture Training Choices: Personalized in-person or Live online courses. Tailored courses designed to meet your specific knowledge and project needs. Customized Learning: Adapt the course to match your existing skills and project requirements. Certifications: Instructors certified by Autodesk. AutoCAD Architecture training Certificate of Attendance. Expert Guidance: Learn from Autodesk Certified Instructors with extensive professional experience. Interactive Learning: Engage in practical, hands-on training. Follow step-by-step demonstrations and practice in real-time. Keep your course-created files for future reference. Comprehensive Resources: Receive a detailed training guide for ongoing reference. Earn an e-certificate upon successful course completion. Post-Course Assistance: Access lifetime email support from your instructor. Prerequisites: Basic familiarity with standard AutoCAD or equivalent knowledge. Version Versatility: Training available for any AutoCAD Architecture version to suit your requirements." Thorough Learning Experience: Establish a robust 3ds Max foundation and master vital skills for crafting impressive 3D models and visualizations. Customized Instruction: Benefit from one-on-one guidance provided by seasoned instructors, ensuring focused and tailored learning. Flexible Learning Paths: Select between in-person or live online sessions, granting you the flexibility to learn from any location. Lesson Recordings: Gain access to recorded lessons for future reference, facilitating self-paced review of course content. Ongoing Email Assistance: Access continuous email support from our experts to address any queries or seek clarifications. Complimentary Career Guidance: Receive valuable career advice from industry professionals, assisting you in charting a successful course in the realm of 3D modeling and visualization."

Rhino Introduction to Intermediate Training Course

By ATL Autocad Training London

Why Choose Rhino Introduction to Intermediate Training Course? Learn: 3D NURBS models. Master: Surfacing modeling. Interface: Rhino's navigation. Rendering Skills: Enhance presentations with Rhino renderings. Check our Website Flexible Scheduling: 1-on-1 training sessions according to your convenience. Choose any hour between 9 a.m. and 7 p.m., Mon to Sat. You can call us at 02077202581 to book over the phone. Duration: 10 hours. Methods: Personalized training either in-person, or live online. Introduction and Navigation Become acquainted with Rhino's interface, menus, and screen layout. Efficiently traverse through Rhino models, ensuring precision in 2D lines, polylines, and NURBS curves. Utilize modeling setup features, incorporating constraints like snap, ortho, and planar for accuracy. Leverage object snaps and Smart Track functionality to enhance precision. Solid and Surface Modeling Develop rapid 3D solids and surfaces, employing Rhino's organized layering system. Utilize coordinates and constraints for meticulous modeling, exploring 3D space and elevations. Create diverse shapes, such as rectangles, circles, arcs, ellipses, and polygon curves. Elevate models with Rhino render and render color, incorporating free-form curves, helix, and spiral curves. Efficiently handle model views with pan, zoom, and view management tools. Implement various editing commands for curve manipulation and transform curves into surfaces and solids. Utilize history tracking for advanced editing and execute general editing actions: move, copy, rotate, mirror, and scale. Create arrays with both polar and rectangular arrangements and employ boolean operations like union, difference, and intersection. Offset curves and surfaces effectively, ensuring meticulous detailing. Intermediate Edit and Surfacing Introduce key NURBS modeling concepts and terminologies. Edit curves and surfaces via control point manipulation and rebuild them for optimal refinement. Employ the nudge modeling aid for precise adjustments and generate deformable shapes. Create curves through projection techniques and split surfaces using curves and surfaces. Blend surfaces seamlessly, utilizing symmetry tools, lighting, and rendering effects. Convert intricate 3D objects into detailed 2D drawings, expertly crafting page layouts. Advanced Surfacing and Solid Modeling Construct model primitives and solid text, employing techniques such as pipe and extrusion. Modify solids efficiently using Boolean tools, expanding your surface modeling capabilities. Employ techniques like extrusion, lofting, and revolving for intricate surfaces. Create sweeps using 1 and 2 rail curves, mastering surface network techniques for complex shapes. Upon completion, you will: Master Rhino Tools: Navigate interfaces, utilize advanced tools for precise modeling, and employ features like object snaps and Smart Track. Expert Solid and Surface Modeling: Develop intricate 3D solids and surfaces, create diverse shapes, and use Rhino render effectively. Advanced Editing Skills: Apply intermediate and advanced editing techniques, including symmetry tools and realistic rendering. Precision Modeling: Utilize coordinates, constraints, and advanced aids for accurate detailing and problem-solving. Professional Project Execution: Create high-quality renderings, 2D drawings, and polished 3D models for real-world design scenarios. Upon completion, you'll be adept at 3D modeling, product design, and architecture, positioning you as a valuable asset in the design industry. Why Choose Our Rhino Courses? Rhino, also known as Rhinoceros, stands as a robust 3D computer graphics and computer-aided design software, utilized extensively in domains like architecture, industrial design, and multimedia. Our Rhino courses are meticulously crafted to empower you in mastering this software. Led by seasoned instructors, our courses provide a comprehensive understanding of Rhino, enabling you to create exceptional designs. Rhino 3D Training: Our Rhino 3D training caters to beginners and those seeking advanced techniques. Course Highlights: Precise 3D Modeling: Master free-form 3D NURBS models with precision. Advanced Functionality: Explore Rhino's features, including advanced surfacing commands. User Interface Mastery: Navigate Rhino's interface and hone skills in curves, surfaces, and solids. Expert Guidance: Acquire expertise in Rhino's modeling environment under expert guidance. Modeling Techniques: Learn free-form and precision modeling techniques. Modeling Aids: Utilize tools for accurate modeling and create basic Rhino renderings. Benefits of our Courses: Expert Guidance: Receive instruction from experienced architects and designers, providing practical, real-world insights for comprehensive learning. Comprehensive Resources: Access bespoke video tutorials for additional learning and reference, enhancing your understanding of the course materials. Digital Reference Material: Receive a digital reference book to support your revision efforts, providing a comprehensive resource for your studies. Ongoing Support: Enjoy free after-support through phone or email even after course completion, ensuring continuous assistance and guidance. Tailored Learning Experience: Customize your learning journey by adapting the syllabus and projects to align with your specific needs and interests, fostering a personalized educational experience. Certificate: Upon completion, earn a certificate from us, validating your achievement and recognizing your expertise in the field.

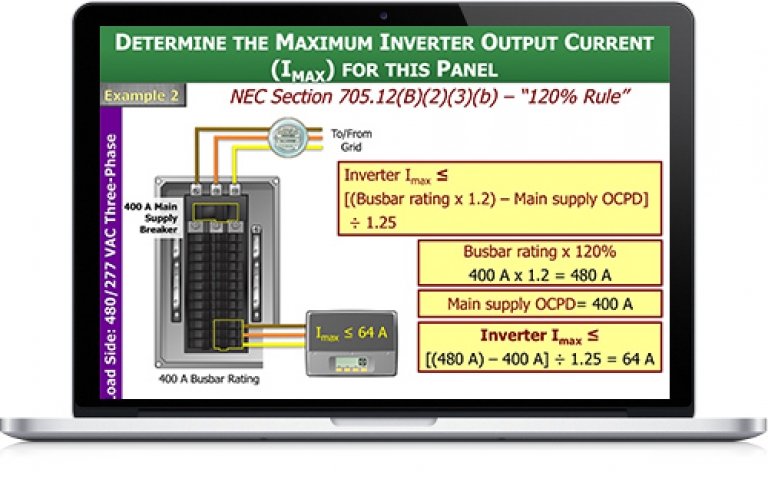

PV202: Solar Training - Advanced PV System Design and the NEC (Grid-Direct)

By Solar Energy International (SEI)

Students who complete PV202 will be able to: Define the purpose of the National Electrical Code (NEC®) and NEC® terminology for PV equipment Determine procedures for proper installation of equipment and conductors, including minimum requirements for working space Examine methods for PV wire management and determine where expansion fittings are required Describe and identify electrical services, including split-phase and three-phase Wye (Y) and Delta (â) Evaluate electrical service details to collect and record during solar site evaluation Identify options for NEC®-compliant PV system interconnection to the utility grid and determine whether a supply side, load side, or additional service connection is appropriate Identify code-compliant methods for connecting an inverter to an existing AC feeder Calculate PV module voltage based on temperature to ensure compatibility with system components and NEC® Section 690.7, and explore other options for maximum PV system DC voltage calculations Identify NEC® requirements and sizing of disconnects and overcurrent protection devices (OCPDs) in grid-direct PV systems Define inverter grounding configurations Evaluate inverter choices and system configurations, including string inverters, central inverters, and module level power electronics (MLPE) Identify requirements for equipment grounding, equipment grounding conductors (EGC), and grounding electrode conductors (GEC), and size the conductors according to the NEC® Identify common causes of ground-faults and arc-faults Describe ground-fault and arc-fault protection devices Describe benefits and appropriate locations of surge protection devices (SPD) Demonstrate the use of sun charts and perform calculations to determine row spacing and minimize inter-row shading Identify how Codes detailing access for first responders impact PV array roof layout Examine fire classifications that affect racking and module selection Detail NEC rapid shutdown requirements and options for implementation Identify load and structural considerations for low- and steep-slope roof-mounted PV systems Calculate wind uplift force and select appropriate lag bolts Review issues related to planning, design, and installation of ground-mount PV arrays Review PV system circuit terminology, definitions, and conductor types Calculate minimum overcurrent protection device (OCPD) size and conductor ampacity using appropriate adjustment and correction factors Calculate voltage drop and verify system operation within acceptable limits Examine requirements for PV system labeling Calculate the maximum and minimum number of modules per PV source circuit, and number of PV source circuits per inverter Determine size of residential grid-direct PV system based on site and customer-specific considerations including the number and wiring layout of modules, conductor and OCPD sizes, and the AC interconnections Determine the size of a large, multiple inverter, grid-direct PV system based on site and customer-specific considerations, including the quantity and layout of modules and inverters and the AC interconnection Define large-scale PV and review associated NEC® allowances and requirements Describe importance of Data Acquisition Systems (DAS) Identify common DAS equipment and hardware Review DAS design, installation, and commissioning processes and common problems associated with DAS Show how reports can be generated and utilized to remotely assess health of system

PVOL202: Solar Training - Advanced PV System Design and the NEC (Grid-Direct) - Online

By Solar Energy International (SEI)

Students who complete PVOL202 will be able to: Define the purpose of the National Electrical Code (NEC®) and NEC® terminology for PV equipment Determine procedures for proper installation of equipment and conductors, including minimum requirements for working space Examine methods for PV wire management and determine where expansion fittings are required Describe and identify electrical services, including split-phase and three-phase Wye (Y) and Delta (â) Evaluate electrical service details to collect and record during solar site evaluation Identify options for NEC®-compliant PV system interconnection to the utility grid and determine whether a supply side, load side, or additional service connection is appropriate Identify code-compliant methods for connecting an inverter to an existing AC feeder Calculate PV module voltage based on temperature to ensure compatibility with system components and NEC® Section 690.7, and explore other options for maximum PV system DC voltage calculations Identify NEC® requirements and sizing of disconnects and overcurrent protection devices (OCPDs) in grid-direct PV systems Define inverter grounding configurations Evaluate inverter choices and system configurations, including string inverters, central inverters, and module level power electronics (MLPE) Identify requirements for equipment grounding, equipment grounding conductors (EGC), and grounding electrode conductors (GEC), and size the conductors according to the NEC® Identify common causes of ground-faults and arc-faults Describe ground-fault and arc-fault protection devices Describe benefits and appropriate locations of surge protection devices (SPD) Demonstrate the use of sun charts and perform calculations to determine row spacing and minimize inter-row shading Identify how Codes detailing access for first responders impact PV array roof layout Examine fire classifications that affect racking and module selection Detail NEC rapid shutdown requirements and options for implementation Identify load and structural considerations for low- and steep-slope roof-mounted PV systems Calculate wind uplift force and select appropriate lag bolts Review issues related to planning, design, and installation of ground-mount PV arrays Review PV system circuit terminology, definitions, and conductor types Calculate minimum overcurrent protection device (OCPD) size and conductor ampacity using appropriate adjustment and correction factors Calculate voltage drop and verify system operation within acceptable limits Examine requirements for PV system labeling Calculate the maximum and minimum number of modules per PV source circuit, and number of PV source circuits per inverter Determine size of residential grid-direct PV system based on site and customer-specific considerations including the number and wiring layout of modules, conductor and OCPD sizes, and the AC interconnections Determine the size of a large, multiple inverter, grid-direct PV system based on site and customer-specific considerations, including the quantity and layout of modules and inverters and the AC interconnection Define large-scale PV and review associated NEC® allowances and requirements Describe importance of Data Acquisition Systems (DAS) Identify common DAS equipment and hardware Review DAS design, installation, and commissioning processes and common problems associated with DAS Show how reports can be generated and utilized to remotely assess health of system

Organisation Programme - How to identify and mitigate procurement fraud and corruption

By Global Risk Alliance Ltd

Our training programme will provide those involved at any stage of the process for procuring goods and/or services within their organisations with the knowledge and skillset to identify and mitigate the threat posed by the breadth and multi-layered complexity of procurement fraud and corruption.

Enhance your valeting team's skills for high-quality results. Valeting for Business Stage 2 follows on from Stage 1 by going into deeper levels of preparation and decontamination and introducing machine polisher enhancement and minor correction to their skillset. perfect for attending to used and re-sale vehicles, maintenance of higher use fleets, and new cars which arrive in need of a little extra work prior to handover. Get your valeting team to a standard to deal with minor paint defects, interior issues, and machine polishing work in-house - both hyper-efficiently and safely. Enhance your team's skills for high-quality results your customers will love. Valeting for Employees Stage 2 follows on from Stage 1 by going into deeper levels of preparation and decontamination and introduces machine polisher enhancement and minor correction to their skillset. Perfect for those attending to used and re-sale vehicles, maintenance of higher use fleets, and dealerships delivering new cars which can arrive in need of a little extra work prior to handover. Get your valeting team to a professional standard to deal with minor paint defects, interior issues, and machine polishing work in-house - both hyper-efficiently and safely. The course day includes; Health and safety discussion and a run-through of vital inspections and checks prior to work. Advanced chemical and decontamination skills and knowledge. Pre-polishing preparation - clay bars, solvent cleaners and mechanical decontamination. Machine polishing skills, and the health and safety requirements for their usage. Interior odour removal and deep cleaning techniques. Stone chip and small area scratch removal and refinement. Please note: Stage 1 must be completed before Stage 2, though they can be booked on consecutive days. With the combined Stage 1 and 2 certification, attendees will be able to address various valeting requirements and can complete quite complex jobs efficiently, and satisfactorily in-house. This will reduce the need to call in specialists, and enhance vehicle turnaround times through greater workflow and competence. Claim back your costs! Students will hold a UKDA accredited certificate in Stage 2 Valeting for Business, and as we are a Government Registered Learning Provider, you can be assured of the highest quality of training. As, in most cases, HMRC considers vocational training to be for the benefit of the business and a legitimate business expense, course costs can usually be recouped against company taxes, and a full VAT invoice is provided for reclamation. Course Length 1 Day (0930-1600) Location UK Detailing Academy, 2 Purlieus Barn, Ewen, Cirencester, GL7 6BY Experience / Qualification Completion of Level 1 Certification UKDA Certified

Architecture Tutor One to One

By Real Animation Works

Face to Face customised and bespoke.

Myers-Briggs Theory and Test

By OnlineCoursesLearning.com

Myers-Briggs Theory and Test With regards to the complexities of people, one considers character being the greatest separation. It is intuition to sort our environmental factors to more readily get things. Clinician for quite a long time have been endeavoring to do exactly that with characters and their numerous characteristics. Be that as it may, how would they figure out how to precisely figure out who has what characteristics? This is the place where hypotheses and testing techniques, for example, the Myers-Briggs proves to be useful. The individuals who set aside the effort to comprehend what they Myers-Briggs test and hypothesis are acquire a more profound comprehension of individuals, themselves and how tests can be utilized as a solid mental instrument. In the event that you are keen on digging into the profundity of your own character, at that point it never damages to begin with the most effortless test - the Myers-Briggs test. In this course you will find out about every part of the Myers-Briggs test and other related tests. What You Will Learn with This Course: The Myers-Briggs hypothesis and test, just as different kinds of psychometric tests The psychometric test announcing techniques The character consequences of the Myers-Briggs test and how they can be applied The polarities utilized in the Myers-Briggs test and hypothesis and the impediments of this test/hypothesis The Benefits of Taking This Course: You will study psychometric testing and how these tests are utilized as mental evaluation instruments You will get familiar with your own character type and how to precisely do your own self-detailing You will actually want to acquire trust in yourself by understanding your qualities and shortcomings You will actually want to accomplish a more profound comprehension of individuals and their various characters

Introduction to RIDDOR

By OnlineCoursesLearning.com

Prologue to RIDDOR Certification Detailing mishaps, wounds and word related sickness in the working environment permits associations and specialists to figure out how to recognize and deal with hazards. Reports can advise future strategy at both a nearby and public level. In the UK, the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013 (RIDDOR) declares how and when individuals should report indicated "reportable cases" to the Health and Safety Executive (HSE) and nearby government specialists. This course gives an outline of RIDDOR from both a hypothetical and down to earth point of view. You Will Learn What RIDDOR is, its degree and the overall standards that decide if an occurrence is reportable. The sorts of wounds you should report under RIDDOR including consumes, removals and "more than seven-day" wounds The word related sicknesses and threats you should report, including carpal passage condition, RSI and "close misses" Who should make a RIDDOR report, how to document a report and the time period in which you should present the report Advantages of Taking This Course On the off chance that you are a business, you will profit by obtaining a foundation information on RIDDOR on the grounds that it covers all organizations and work exercises On the off chance that you are liable for wellbeing and security related issue at work, realizing the central issues contained inside RIDDOR will give you the certainty to decide whether an occurrence is reportable On the off chance that you are keen on word related wellbeing, this course will give you a helpful understanding into how UK specialists research mishaps, wounds and close misses in the working environment This course will help you complete ideal, valuable reports if a reportable occurrence happens in your working environment

Our 201 Enthusiast day was created for the hyper-enthusiast who wants to correct and enhance their own vehicle, rather than just care for it. If you've attended our 101 Enthusiast, you're all covered skills-wise for the prior knowledge element, but for all others to benefit from this event you will need a solid knowledge of preparation work and wash procedure, as this is mostly focussed on what comes after - namely paint correction. Refreshments are included on this intensive one-day group course, and there is time allotted at the end of the session to inspect your own vehicles if you need advice on particular issues. Availability If no dates are showing as available in the calendar, you can sign up for updates to find out when new dates are released and new course developments. Our 201 Enthusiast day was created for the hyper-enthusiast who wants to correct and enhance their own vehicle, rather than just care for it. If you've attended our 101 Enthusiast, you're all covered skills wise for the prior knowledge element, but for all others to benefit from this event you will need a solid knowledge of preparation work and wash procedure, as this is mostly focussed on what comes after - namely paint correction. During the day we will be covering: Compound types and chemistry. Paint types and how to approach them. Pre-work decon wash, including clay and clay pads, decon pros/cons. Masking and surface protection tips. Lighting and inspection technique. Machine work, including Dual Action and Forced Rotation polishers, to correct and enhance the paint surface. Deeper defect removal, scratch hand sanding. Coatings, including ceramic and polymer, and their application. The day concludes with a Q&A session with a walk around your vehicles to advise on any issues. This is quite an intense day as we are trying to fit so much in, so we will be running from 9.30am until 16:00, with a break for lunch. You will have hands-on experience all day and will be working your way through all steps of a full correction, it will then be up to you to build on the knowledge you have gained by practising on your own vehicle, with ongoing support if needed. The course is run from our fully equipped studio in the heart of Gloucestershire, with easy access to the M4/M5, and under an hour and a half to the M25. Course Length 1 Day (0930-1600) Group Size Up to 6 people Location UK Detailing Academy, 2 Purlieus Barn, Ewen, Cirencester, GL7 6BY Refreshments or Lunch Lunch Included, Refreshments included

Search By Location

- Detailing Courses in London

- Detailing Courses in Birmingham

- Detailing Courses in Glasgow

- Detailing Courses in Liverpool

- Detailing Courses in Bristol

- Detailing Courses in Manchester

- Detailing Courses in Sheffield

- Detailing Courses in Leeds

- Detailing Courses in Edinburgh

- Detailing Courses in Leicester

- Detailing Courses in Coventry

- Detailing Courses in Bradford

- Detailing Courses in Cardiff

- Detailing Courses in Belfast

- Detailing Courses in Nottingham