- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

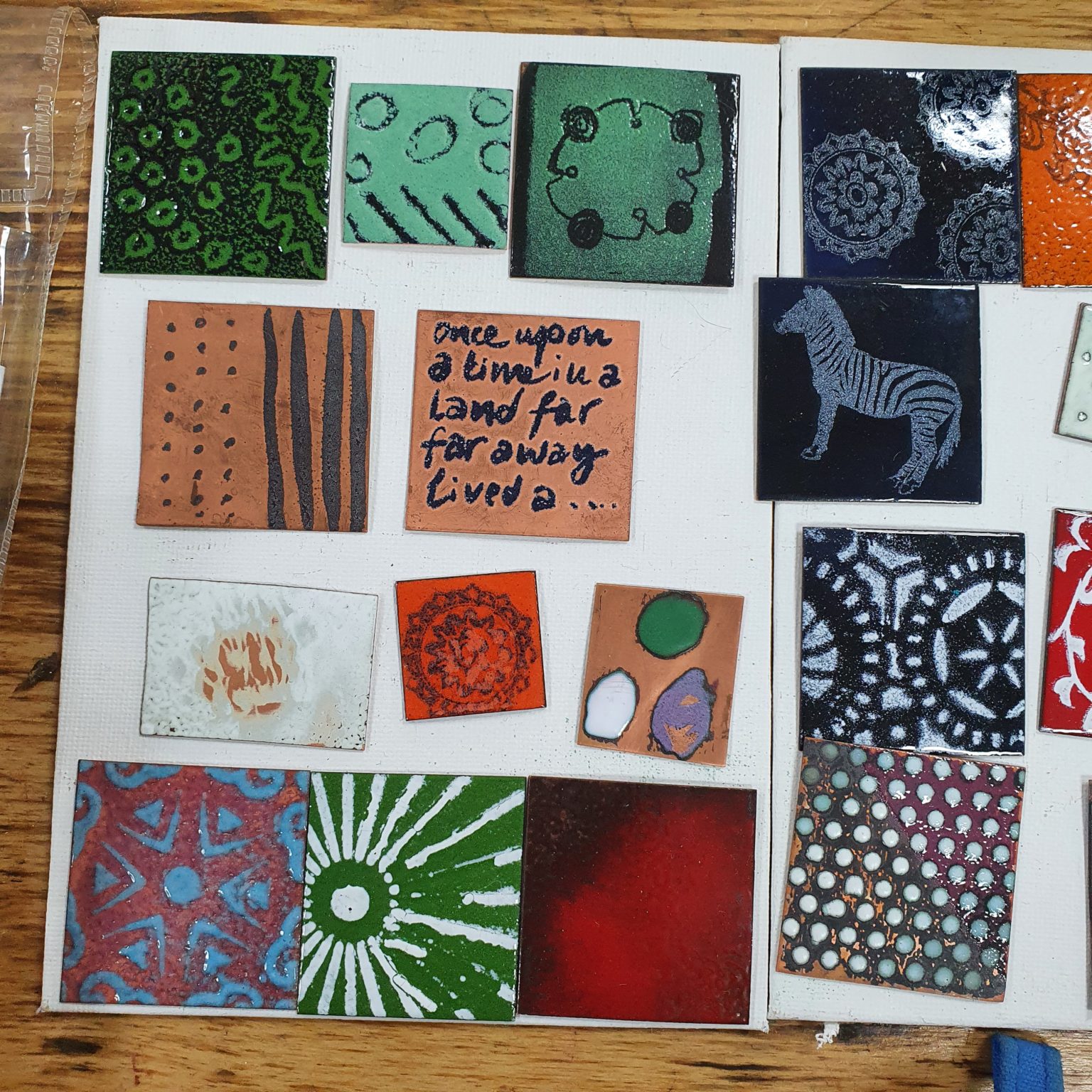

Join our expert enamelling and jewellery tutor Sally Lees to learn introductory enamelling techniques in this exciting one-day course. You will learn a wide range of enamelling techniques for copper and make samples to refine your skills and technique. You will explore techniques including sifting; sgraffito; stenciling; drawing on enamelled surfaces with graphite pencils; using wet pens and painting with wet enamels. This course is ideal for students with no experience of enamelling. However, more experienced students can join the course and use the time to further experiment with these techniques or try them for the first time. WHEN: Saturday 13th July 10-5pm WHERE: Workshop 925 based at The Mayford Centre, just outside of Woking and very close to Guildford. Unit F9 The Mayford Centre, Mayford Green Woking, Surrey GU22 0PP TUTOR: Sally Lees WHAT DOES THE DAY INVOLVE? Join our expert enamelling and jewellery tutor Sally Lees to learn introductory enamelling techniques in this exciting one-day course. You will learn a wide range of enamelling techniques for copper and make samples to refine your skills and technique. You will explore techniques including sifting; sgraffito; stenciling; drawing on enamelled surfaces with graphite pencils; using wet pens and painting with wet enamels. This course is ideal for students with no experience of enamelling. However, more experienced students can join the course and use the time to further experiment with these techniques or try them for the first time. To see the day in action see our Instagram post here DURING THIS DAY SESSION YOU WILL… Learn how to prepare copper before enamelling. Understand how to fire enamels to the right temperatures to create attractive results. Practice how to sift onto copper to create an even surface to be able to decorate it. Explore and practice sgrafitto and stenciling enamelling techniques. Learn how to draw onto enamelled surfaces using graphite pencils. Learn how to wash enamels and use them to paint patterns onto enamelled surfaces. Understand the principles decorating metal with enamels and the processes of firing enamels at the correct temperatures to achieve specific effects. You will be shown a series of demonstrations throughout the day and can try all of the techniques demonstrated or you can decide to concentrate on a particular technique – this is your ay to explore enamelling and the vast potential it offers. Please note, this day is not focussed on working on finished designs or working with silver. Enamelling takes time to learn and explore. You will be working with a series of copper blanks – some of which have holes so you are able to slot them onto earring hooks or place a jump ring on them for a pendant if you are pleased with your sample. The aim of the course is to introduce you to the techniques and processes and for you to experiment and put into practice what you have been shown, not to create finished designs at this stage, this will be something you can work towards once you have gained some experience. EXPERIENCE REQUIRED: None, all abilities are welcomed. We support you throughout the session and provide demonstrations to show you the techniques and steps needed to create your project. CLASS SIZE: 6 WHAT IS INCLUDED? All tools and consumables are supplied. We will supply copper sheet for your samples, but please feel free to bring along any pierced designs you might have of your own or anything you would like to experiment with. YOU WILL BE PROVIDED WITH: Copper sheet is supplied. WHAT TO BRING: A sketch book – to note your practices throughout the day, especially important for those who would like to recreate their samples again at home or on future occasions. If you want to bring along any silver to experiment with, you are welcome to do so. Please wear closed toe shoes – no sandals or flip flops as you will be working with hot metal and tools. Please bring along any lunch, snacks and drinks for the session. We have tea and coffee supplies you are welcome to help yourself to but make sure you bring enough refreshments and supplies to keep you going during the day. We have a fridge, microwave and kettle which you are welcome to use. PAYMENT OPTIONS: You can pay via our website or in our workshop in person using our card machine. If you prefer to pay directly, you can email us on hello@workshop925.com and we can invoice you manually to arrange a bank transfer. For classes over £80, instalment options are also available. Please email us on hello@workshop925.com to arrange. Gift Voucher – if you have a voucher to redeem, please email us before booking on hello@workshop925.com

EUSR Category 1 Locate Utility Services (HSG47)

By Vp ESS Training

EUSR Category 1 Locate Utility Services (HSG47) - This course is designed for personnel who are involved in excavating and/or other activities involving breaking ground. This course is often referred to Cat and Genny Training, Cable Avoidance Training or HSG47. Book via our website @ https://www.vp-ess.com/training/utility-detection/eusr-category-1-locate-utility-services-(hsg47)/ or via email at: esstrainingsales@vpplc.com or phone on: 0800 000 346

Commissioning of Combined Cycle Power Plants

By EnergyEdge - Training for a Sustainable Energy Future

About this Course This 5 full-day course provides a comprehensive understanding of all the commissioning procedures for combined cycle power plants. The Commissioning Management System (CMS) of combined cycle power plants is covered in detail in this course. This includes all the commissioning procedures and documents, purpose of commissioning, responsibilities, system description, organization, working parties, test teams, documentation, testing and commissioning schedules, test reports, safety, plant certification, and plant completion report. The course provides also a thorough understanding of all the commissioning requirements for gas turbines, steam turbines and auxiliaries, generator and auxiliaries, electrical equipment, switchgear equipment, switchgear and transformers. All the stages of the commissioning procedure are covered in-depth in this course. This includes preparation - planning various activities, pre-commissioning checks and tests, typical commissioning schedule, detailed tests and commissioning procedures and instructions for every component in a combined cycle power plant, instrumentation, trial run of the equipment, safety and precautions, commissioning of combined cycle power plant systems, safety rules clearance certificates, procedure for the control and handling of defects, commissioning reports, operational testing, first fire, generator synchronization, performance testing, heat rate testing, emission testing, contract testing, CO2 concentration tests, electrical full-load rejection test, duct burner testing, partial load stability test, and reliability test. This course is a MUST for anyone who is involved in the pre-commissioning or commissioning of any combined cycle power plant equipment because it provides detailed pre-commissioning checks and tests, and detailed tests and commissioning procedures and instructions for every component in a combined cycle power plant. In addition, the seminar provides an in-depth coverage of all preparation, planning activities, commissioning schedules, trial run of each combined cycle power plant equipment, safety and precautions, safety rules clearance certificates, procedures for handling defects, and commissioning reports. Training Objectives Pre-commissioning Checks and Tests, Detailed Tests and Commissioning Procedures and Instructions for Every Equipment in Combined Cycle Power Plants: Gain a thorough understanding of all pre-commissioning checks and tests, and all commissioning procedures and instructions for every equipment in combined cycle power plants Commissioning Management System (CMS) of Combined Cycle Power Plants: Discover the benefits of the CMS of combined cycle power plants including all commissioning procedures and documents, purpose of commissioning, responsibilities, system description, organization, working parties, test teams, documentation, testing and commissioning schedules, test reports, safety, plant certification, and plant completion report Commissioning Procedures and Instructions for Heat Recovery Steam Generators, Air Blow and Steam Blow of Steam and Gas Piping in Combined Cycle Power Plants: Learn about the commissioning procedures and instructions for heat recovery steam generators, chemical cleaning of heat recovery steam generators, air blow and gas blow of steam and gas piping in combined cycle power plants, safety valve setting and soot blowers Commissioning Procedures and Instructions for Gas Turbines and Steam Turbines: Gain a thorough understanding of all the commissioning procedures and instructions for gas and steam turbines and auxiliaries including acid cleaning of oil pipelines, lubrication and governing system (oil flushing and hydraulic testing), jacking oil system, governing system, regenerative system, barring gear, vacuum tightness test, first rolling of turbine and data logging Commissioning Procedures and Instructions for Generator and Auxiliaries: Discover all the commissioning procedures and instructions for generator and auxiliaries including generator, seal oil system, hydrogen gas system, stator water system, rolling and start-up of generators Commissioning Procedures and Instructions for Electrical Equipment: Learn about all the commissioning procedures and instructions for electrical equipment including switchyard equipment, switchgear, transformers and motors Operational Testing, Performance Testing, Heat Rate Testing, Emission Testing of Combine Cycle Power Plants: Gain a thorough understanding of operational testing, first fire, generator synchronization, performance testing, heat rate testing, emission testing, contract testing, CO2 concentration tests, electrical full-load rejection test, duct burner testing, partial load stability test, and reliability test of combined cycle power plants Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Training Methods The instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all the delegates gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

This course is specifically designed and delivered by Emergency Medicine Doctors, Specialist Paramedics and Specialist Nurses. The Paediatric Minor Illness course is designed for those working in emergency and urgent care settings. Children are often seen as a challenge to clinicians. The Paediatric Minor Illness course exists to look at common minor medical presentations of children and how these can be managed appropriately. Utilising tools to support decision making, the Paediatric Minor Illness course expands knowledge around history taking and examination, red flags and safety netting along with appropriate referral and management options.

Breaking Bad News

By M&K Update Ltd

This workshop is designed to give those who have to give bad news and broach difficult conversations increased confidence. Participants will leave the workshop with the tools and techniques to prepare for a difficult conversation and ensure that they are supporting patients and relatives through a stressful time in their lives.

Non Medical Prescribing Update

By M&K Update Ltd

This 1 day update course is designed for all non-medical prescribers to develop and maintain safe and effective prescribing practice.

Dermatology for HCAs

By M&K Update Ltd

A course for Healthcare Assistants, designed to give a broader understanding of anatomy and physiology of the skin and giving ability in recognising lesions, lumps and bumps.

Project Management in Healthcare

By M&K Update Ltd

This two day programme is designed to support participants to work through the technical steps and stages as well as the more practical realities of project management.

Search By Location

- Design Courses in London

- Design Courses in Birmingham

- Design Courses in Glasgow

- Design Courses in Liverpool

- Design Courses in Bristol

- Design Courses in Manchester

- Design Courses in Sheffield

- Design Courses in Leeds

- Design Courses in Edinburgh

- Design Courses in Leicester

- Design Courses in Coventry

- Design Courses in Bradford

- Design Courses in Cardiff

- Design Courses in Belfast

- Design Courses in Nottingham