- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

RFID training course description This training course focuses on the technologies used in Radio Frequency Identification (RFID). What will you learn Describe the RFID architecture. Design RFID systems. Evaluate tag types. Recognise common RFID problems. RFID training course details Who will benefit: RFID technologists and system engineers. Prerequisites: RF fundamentals. Duration 2 days RFID training course contents What is RFID? Review of RF basics, what is RFID, RFID history, RFID base system architecture, frequency bands used by RFID, comparison with barcodes. RFID applications Supply chain, asset tracking, theft reduction, retail, access control, tolls. Tags Tag features, types of tag, passive and active, chips, read only, read write, affixing tags, selecting location to affix a tag, tag orientation and location, tag stacking, impact of rate of movement, tag data formats. Interrogators/readers Interrogation zones, interrogator types, antennas, read distance tests, multiple interrogators, synchronisation, dense interrogator environment issues. RFID peripherals. Standards and regulations Global regulatory requirements, regional regulatory requirements, ISO, ETSI, FCC, EPC, safety regulations/issues. Testing and troubleshooting Read rate problems, improperly tagged items, tag failure. RFID system design Antenna types, interference, antenna location and spacing, how many antennas? How many interrogators? tag types, grounding considerations, cabling, site diagrams.

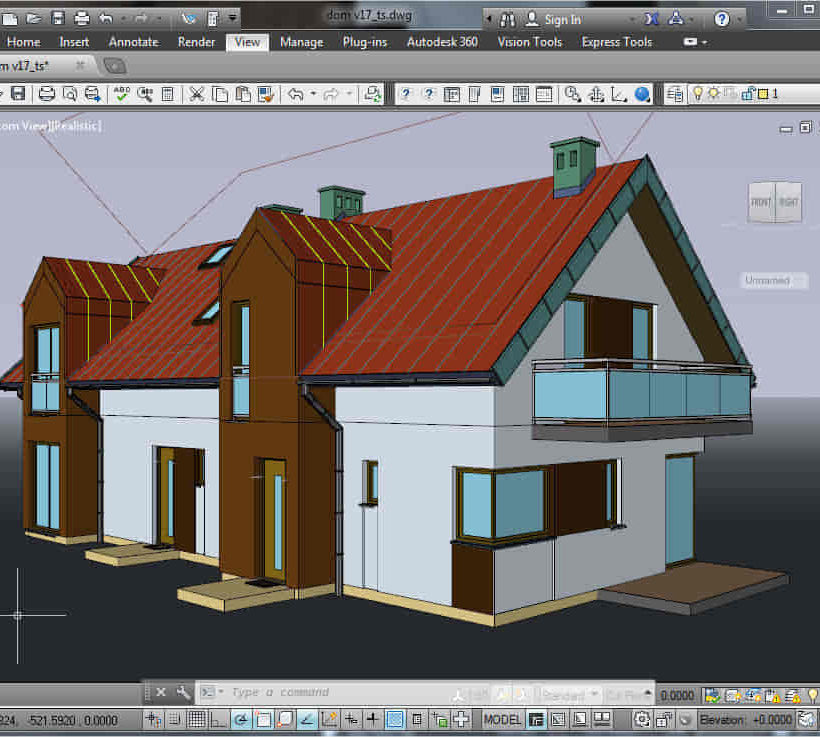

Revit and 3dsMax V-Ray Visualization Basic to Advance Training

By London Design Training Courses

Why Learn Revit and 3dsMax V-Ray Visualization Basic to Advance Training Course? Course info Master architectural visualization and photorealistic renderings. In-person or live online options available. Learn Revit and 3dsMax, V-Ray rendering, and advanced techniques. Hands-on projects for real-world experience. Duration: 40 hrs Method: 1-on-1 - Individual support. Schedule: Tailor your own schedule by pre-booking a convenient hour of your choice, available from Mon to Sat between 9 am and 7 pm. Comprehensive Training: Master Revit, 3dsMax, and advanced visualization techniques for exceptional results. V-Ray Rendering: Explore realistic rendering with V-Ray, including advanced techniques and materials. Real-World Projects: Work on industry-relevant projects for a professional portfolio. Flexible Learning: Choose in-person or live online sessions for an engaging experience. Lesson Recordings: Access recorded classes to reinforce your understanding. Lifetime Email Support: Get guidance and assistance from experienced instructors beyond the course duration. Autodesk Certified Instructors. Comprehensive Training: Master Revit, 3dsMax, and advanced visualization techniques for exceptional results. V-Ray Rendering: Explore realistic rendering with V-Ray, including advanced techniques and materials. Real-World Projects: Work on industry-relevant projects for a professional portfolio. Flexible Learning: Choose in-person or live online sessions for an engaging experience. Lesson Recordings: Access recorded classes to reinforce your understanding. Lifetime Email Support: Get guidance and assistance from experienced instructors beyond the course duration. Autodesk Certified Instructors. Part 1: Revit (16 hours) Module 1: Introduction to Revit Familiarizing with the Revit interface and workspace Embracing the Building Information Modeling (BIM) workflow Creating a fundamental building model as a starting point Module 2: Basic Modeling in Revit Working with essential elements such as walls, doors, and windows Constructing floors and roofs to complete the building structure Crafting functional and visually appealing stairs and railings Module 3: Advanced Modeling in Revit Delving into the creation and manipulation of families Utilizing parameters and constraints to enhance modeling efficiency Exploring intricate geometries for complex designs Module 4: Annotation and Documentation in Revit Enhancing project documentation by adding text and dimensions Generating informative schedules for better project management Mastering the printing and exporting processes for professional output Part 2: 3ds Max (16 hours) Module 1: Introduction to 3ds Max Navigating the 3ds Max interface and workspace Understanding the 3D modeling workflow for design visualization Initiating the creation of basic 3D models Module 2: Basic Modeling in 3ds Max Working with primitive shapes to build foundational models Creating and refining splines to form versatile shapes Advancing to complex 3D model development for intricate designs Module 3: Materials and Textures in 3ds Max Exploring the material editor and its functionalities Skillfully applying and adjusting materials for realistic renders Incorporating textures to add depth and detail to the models Module 4: Lighting and Cameras in 3ds Max Mastering the art of lighting creation and manipulation Utilizing the daylight system for enhanced realism Understanding cameras and perspectives for compelling visual storytelling Part 3: V-Ray (8 hours) Module 1: Introduction to V-Ray Getting acquainted with the V-Ray interface and workflow Exploring V-Ray materials and textures for high-quality renders Module 2: Lighting and Rendering in V-Ray Creating and refining lighting setups for stunning renders Utilizing global illumination to enhance the realism of scenes Implementing advanced rendering techniques for professional output Module 3: Materials and Textures in V-Ray Crafting and modifying V-Ray materials for realistic surfaces Applying V-Ray textures to add depth and realism to objects Utilizing V-Ray displacement maps for intricate details For 3ds Max free trial, visit: https://www.autodesk.co.uk/products/free-trial. To access the V-Ray free trial, visit: https://www.chaosgroup.com/. Start your journey to becoming a proficient designer and renderer in the world of 3D modeling and visualization. Download Revit Revit and 3dsMax V-Ray Visualization Basic to Advance Training Course: Proficient Software Skills: Acquire a strong command of Revit and 3dsMax, along with advanced techniques in V-Ray rendering. High-Quality Visualizations: Create realistic and visually stunning architectural visualizations using V-Ray. Architectural Modeling: Master the process of modeling architectural elements with precision and efficiency. Materials and Textures: Understand how to apply realistic materials and textures to enhance visualizations. Lighting Setup: Set up lighting environments to achieve optimal illumination and ambiance in renderings. Rendering Techniques: Explore advanced rendering techniques, including global illumination, caustics, and ambient occlusion. Real-World Projects: Complete industry-relevant projects to build a professional-grade portfolio. Problem-Solving Skills: Develop the ability to troubleshoot and resolve rendering challenges effectively. Efficient Workflows: Learn time-saving workflows and best practices for efficient visualization production. Portfolio Showcase: Showcase your newly acquired skills through a diverse range of visualizations.

Smart Metering & Power Quality Analytics

By EnergyEdge - Training for a Sustainable Energy Future

About this training course The smart meter or smart grid represents the next-generation electrical power system. This system uses information, data & communication technology within generation, delivery and consumption of electric energy. This 4-day course will equip you with the innovations that are shaping the power generation and distribution systems and will cover topics ranging from Smart Metering Architecture, Cybersecurity, Smart Grid Systems and Power Line Communications. Training Objectives By participating in this course, you will be able to: Comprehend the Smart Grid and Smart Meters architecture Review latest trends and challenges within the Smart Grid Technology Perform analysis on smart electronic meters Comply with regulatory and metering standards Recognize the importance of cybersecurity in smart grids Maximize efficiency, reliability, and longevity of your smart meters and equipment Gain valuable insights into power quality and harmonics Target Audience This course will greatly benefit the following groups but not limited to: Smart Grid managers and engineers Smart Meters managers and engineers Power plant managers Outage managers Maintenance and operations engineers Power regulatory personnel Transmission managers and engineers Distribution managers and engineers IT managers Renewable energy managers and engineers Course Level Basic or Foundation Intermediate Training Methods The training instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught in their own organization. Course Duration: 4 days in total (28 hours). Training Schedule 0830 - Registration 0900 - Start of training 1030 - Morning Break 1045 - Training recommences 1230 - Lunch Break 1330 - Training recommences 1515 - Evening break 1530 - Training recommences 1700 - End of Training The maximum number of participants allowed for this training course is 25. This course is also available through our Virtual Instructor Led Training (VILT) format. Trainer Your expert course leader is a professional engineer with extensive experience in power system studies, substation design field-testing, and EHS programs settings for Mining and Electrical Utilities sectors. He was formally the Engineering Manager at GE Canada in Ontario. He received his M.Sc. in electrical engineering from the University of New Brunswick and his MBA from Laurier School of Business in Waterloo. He has managed and executed more than 150 engineering projects on substation design EMF audits and power system studies and analyses, EMF audits and grounding audits, for major electrical utilities, mines, oil and gas, data centers, industrial and commercial facilities in Canada and the U.S. He is a certified professional engineer in the provinces of Ontario and Alberta. He has various IEEE publications, has served as a technical reviewer for many IEEE journals in power systems and control systems, and is the chair of the Industry Application Chapter (IAS) for IEEE Toronto Section. He remains a very active member for the IEEE substation committee of IEEE Std. 81 ground testing (WGE6) and IEEE Std. 80 ground design (WGD7). A certified electrical safety trainer by GE Corporate and a Canadian Standard Association (CSA) committee member at the mining advisory panel for electrical safety, he also taught many technical courses all over Canada to industrial customers, electrical consultants as well as to electrical utilities customers. Highlighted Projects: Various Power System Studies for 345/230 kV Stations - Nova Scotia Power (EMERA) RF audits for Telecom tower and antennas - Cogeco/Rogers Mobile Power System analysis - Powell Canada Structural/Geotechnical Design and upgrades - Oakville Hydro Underground Cables testing and sizing - Plan Group Relay programming and design optimization - Cenovus Canada Different Arc Flash Analysis and BESS Design - SNC Lavalin Environmental site assessment (ESA) Phase I/II for multiple stations - Ontario Electromagnetic compatibility (EMC) assessment for Toronto LRT expansion - MOSAIC Battery energy storage system (BESS) installation at City of London - Siemens Canada EMF audits for 500 kV Transmission Lines - Hydro One EMF audits for 500 kV Transmission Lines - Hydro Quebec AC interference for 138 kV line modeling and mitigations - HBMS Mine POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

AutoCAD 3D Basics-Advanced Training

By London Design Training Courses

Why Learn AutoCAD 3D Basics-Advanced Training Course? Course Link Learn 3D modeling, materials, lighting, and rendering, and parametric models. Learn real-world Architecture, products, mechanics. Enroll for in-person or online sessions to master AutoCAD 3D. Duration: 16 hrs Method: 1-on-1 Schedule: Tailor your own schedule by pre-booking a convenient hour of your choice, available from Mon to Sat between 9 am and 7 pm. "Dial 02077202581 or WhatsApp 07970325184 to reserve your preferred dates and times. AutoCAD 3D Basics-Advanced Level 1-2-1 Training Course: Comprehensive coverage from basics to advanced techniques. Suitable for beginners and those advancing their 3D modeling skills. Personalized attention in a private learning environment. Experienced instructors with expertise in 3D modeling. Hands-on practice for confident 3D modeling. Flexible scheduling and lifetime email support. Certificate upon course completion for career advancement AutoCAD 3D Basics-Advanced Level 1-2-1 Training Course: Comprehensive coverage from basics to advanced techniques. Suitable for beginners and those advancing their 3D modeling skills. Personalized attention in a private learning environment. Experienced instructors with expertise in 3D modeling. Hands-on practice for confident 3D modeling. Flexible scheduling and lifetime email support. Certificate upon course completion for career advancement AutoCAD 3D Basics to Advanced Level Training Course Outline (10 hours): Session 1: Introduction to 3D Modeling (2 hours) Understanding 3D modeling concepts Working in the 3D Modeling Workspace Drawing 3D objects with Solid tools Extruding 2D polylines to create 3D objects Session 2: Advanced 3D Features and UCS (2 hours) Setting up AutoCAD for advanced 3D modeling Mastering the User Coordinate System (UCS) Using viewports to aid in 3D drawing Efficient modeling with Array tools Session 3: Rendering and Visualization (2 hours) Testing rendering techniques Creating a quick study rendering Simulating natural lighting and the sun Enhancing 3D models with materials and lights Session 4: Editing 3D Solids and Mesh Modeling (2 hours) Understanding solid modeling principles Creating and editing basic solid forms Editing 3D solids and streamlining 2D drawing process Exploring 3D mesh modeling and editing The AutoCAD 3D training course provides a comprehensive understanding of 3D modeling, visualization, and rendering. Participants will learn to create complex 3D models, render realistic visuals, and efficiently customize the AutoCAD interface for improved productivity. Master 3D Modeling: From basics to advanced techniques. Realistic Rendering: Achieve lifelike visualizations. Professional Presentations: Dynamic walkthroughs and showcases. Enhanced Career Opportunities: Stronger prospects in design fields. Personalized Learning: One-to-one attention for focused training. Practical Hands-On Practice: Building confidence in 3D modeling. Lifetime Email Support: Ongoing assistance beyond the course. Certification: Proof of proficiency in AutoCAD 3D modeling.

Autodesk Maya One to One Basic to Advance Training

By Real Animation Works

Maya face to face training customised and bespoke.

Subsea Production Engineering - Incorporating Subsea Tie-backs - Virtual Instructor Led Training

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual instructor Led Training (VILT) The Subsea Production Engineering Virtual instructor Led Training (VILT) course provides an overview of all of the functionalities and key interfaces of subsea equipment. The VILT course will refer to relevant industry engineering standards for subsea equipment, subsea tie-backs and critical operational requirements. The sessions will cover challenges associated with equipment design and installability, as well as a new module on subsea tie-backs. The primary learning objectives for this VILT course are met through a combination of interactive presentations, discussion and exercises. Training Objectives By the end of this VILT course, participants will be able to: Apply the requirements of related industry standards (API 6A/ 17D, API 17A etc.) engineering standards Understand the barrier and qualification requirements Identify the barriers in place given a specific mode of operation Evaluate and select which tree alternatives are valid based on the key design drivers Identify and describe the key design drivers Explain the importance of well kill rate Describe which tree alternatives are valid for certain scenarios based on an evaluation of the key tree design requirements Examine what effects subsurface requirements may have on tree design Understand the challenges associated with designing equipment for manufacturability and installability Recognise the implications of design changes to specific components and the effects on transportation and installation (such as what type of vessels, lifting equipment, and tools to use and the logistical requirements) Recognise the implication of design changes on manufacturability of subsea equipment Target Audience This VILT course provides a comprehensive understanding of the equipment used in subsea production systems. It is designed for petroleum engineers, production engineers, subsea project engineers and is also highly suitable for cost, planning, offshore installation and offshore operations engineers. Anyone directly or indirectly involved with subsea equipment will benefit from attending this VILT course - from engineers installing the equipment to procurement staff looking to understand more. Training Methods The VILT course will be delivered online in 4 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. Course Duration: 4 half-day sessions, 4 hours per session (16 hours in total). Trainer Most of his working life, your expert course leader has been in a role that has enabled him to pass on skills and knowledge to others. A full-time role in Training and Development came about in 1996 with the offer to take up a full-time teaching post at Aberdeen College. In 1998, he was recruited by Kvaerner Oilfield Products, an Oil & Gas industry company, specialising in Subsea Control Systems, to develop and implement a Training & Competence program acceptable for its staff of over 600 and their client companies - a challenge he could not resist. In 2003, he broadened his horizons and became an independent Training & Development consultant. Building a reputation for delivering training and development to the Oil & Gas industry to the highest standards, he later joined Jee Ltd, a leading subsea engineering and training company based in Aberdeen. He was tasked with a wide portfolio of training, coaching & mentoring to achieve high levels of competence for the client's staff and customers. He is also a Science and Engineering Ambassador (Scotland), promoting the need for engineers and technicians for Scotland's industries, a frequent consultant to the European Economic & Social Committee for standardising Vocational Skills training and competence throughout the EU. He holds memberships in the Society of Operations Engineers, Chartered Institute of Personnel & Development and Society of Underwater Technologies. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

Vray for Sketchup Training

By London Design Training Courses

Why choose Vray for Sketchup Training Course? Course info Our in-person or live online sessions led by certified tutors. Learn advanced rendering techniques, practical hands-on experience, recorded lessons, lifetime email support, and an industry-recognized certification. Enroll now to elevate your Sketchup renderings. Duration: 6 hrs Method: 1-on-1, Personalized attention Schedule: Tailor your own schedule by pre-booking a convenient hour of your choice, available from Monday to Saturday between 9 am and 7 pm Experience V-Ray training, where you'll master the art of creating stunningly realistic 3D architectural and interior design scenes from your SketchUp models. V-Ray for SketchUp is a user-friendly rendering solution, offering faster rendering, enhanced lighting tools, and the ability to visualize intricate scenes effortlessly. Our SketchUp - Rendering with V-Ray course empowers you to seamlessly integrate SketchUp with V-Ray, allowing you to craft scenes with captivating features, including: Various lighting techniques (daylight, sunlight, and skylight). Reflective surfaces for added depth. Dynamic moving cameras for captivating visualizations. This hands-on course is highly practical, ensuring you gain real-world skills and expertise. You have the flexibility to arrange this course on-request, either as one-to-one training or as a 'closed course' for your group. The training can be tailored to accommodate your existing knowledge and specific project requirements. Choose from in-class sessions available at six centers or participate in live online classes. V-Ray works seamlessly on both Windows and Mac platforms, and our centers provide computers for delegates to use, ensuring a familiar environment for all. Upon successful completion, you'll receive an e-certificate to validate your V-Ray training. Following the training, you'll enjoy lifetime email support from your trainer to address any post-course queries or concerns. Prerequisites for this course include familiarity with the fundamentals of SketchUp, such as attending our Introduction to SketchUp course or possessing equivalent knowledge. Our training can accommodate any recent version of SketchUp Pro and V-Ray, ensuring compatibility with your preferred Windows or Mac platform. Experience the transformative power of V-Ray and elevate your SketchUp projects to new heights. Experience V-Ray training, where you'll master the art of creating stunningly realistic 3D architectural and interior design scenes from your SketchUp models. V-Ray for SketchUp is a user-friendly rendering solution, offering faster rendering, enhanced lighting tools, and the ability to visualize intricate scenes effortlessly. Module 1: Introduction to Vray for SketchUp Gain insights into Vray's benefits for SketchUp Install and set up Vray for SketchUp Familiarize with the Vray interface and workflow Explore Vray materials and their properties Module 2: Lighting and Environment Master effective lighting techniques in Vray Understand different Vray light types and settings Create realistic outdoor lighting with Vray sun and sky Utilize Vray dome lighting for interior scenes Introduce IES lights and their usage in Vray Module 3: Camera and Composition Learn Vray camera settings and their impact on the final image Control exposure and adjust camera settings in Vray Create depth of field effects with Vray camera Animate the Vray camera for dynamic shots Explore the Vray frame buffer and its functionalities Module 4: Vray Materials and Textures Gain an in-depth understanding of Vray materials and their properties Create realistic materials using Vray's material editor Save and organize custom Vray material libraries Apply Vray material overrides for quick changes Module 5: Rendering and Post-Production Explore Vray rendering settings and optimization techniques Render high-quality images and animations with Vray Enhance Vray renders using post-production techniques in Photoshop Fine-tune the final output with the Vray frame buffer Compose Vray render elements in Photoshop for added control For those interested in trying Vray for SketchUp, a free trial can be accessed through the following link: https://www.chaosgroup.com/vray/sketchup/free-trial. Additionally, provided material and texture resources (https://www.vray-materials.de/ and https://textures.com/) can enhance the quality of renders by providing access to a variety of materials and textures for use in Vray.

Pumps, Compressors, Turbines & Troubleshooting

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This intermediate to advanced level 3 full-day training course has been designed to provide participants with a detailed and up-to-date overview of the fluid mechanic fundamentals and operating practice of pumps, compressors and gas and steam turbines. Upon the successful completion of this course, participants will have acquired the practical knowledge to enable them not only to choose the correct device for a particular application but also be in a position to resolve many commonly occurring operating problems. Troubleshooting is an important part of this course and will cover the important topics of Machinery Root Cause Failure Analysis (RCFA) together with Vibration Analysis. This course is ideal for those personnel in the oil, gas, petrochemical, chemical, power and other process industries who require a wider and deeper appreciation of pumps, compressors and turbines, including their design, performance and operation. The participants will be taken through an intensive primer of turbo-machinery principles, using the minimum of mathematics, and will learn how to solve the many and varied practical industrial problems that are encountered. The course makes use of an extensive collection of VIDEO material together with case studies and numerical exercises. Training Objectives Upon the successful completion of this course, each participant will be able to: Apply a comprehensive knowledge of pumps, compressors & turbines and troubleshoot rotating equipment in a professional manner Identify the different types of turbomachinery including basic design aspects and highlighted problem areas Minimise compressor work by understanding the processes involved and identifying their efficiency Understand the flow through turbomachines and the corresponding velocity triangles including torque and power calculations Analyse the different types of centrifugal machines including their design, installation, operation, maintenance, re-rate/retrofit, troubleshooting and control Recognise the various beneficial design aspects of turbomachines and understand the crucial process of cavitation Carry out proper methods of device installation, operation, maintenance and troubleshooting Understand and apply the powerful methods of Machinery Root Cause Failure Analysis Understand the various methods of vibration analysis applied to device diagnostics Target Audience This course provides an overview of all significant aspects and considerations of pumps, compressors and turbines for those who are involved in the design, selection, maintenance or troubleshooting of such equipment. This includes maintenance, reliability, integrity, engineering, production and operations managers, engineers and other technical staff. Course Level Intermediate Advanced Trainer Your expert course leader is a Senior Mechanical & Instrumentation Engineer (UK, B. Sc., M.Eng., Ph D) with over 45 years of industrial experience in Process Control & Instrumentation, Pumps, Compressors, Turbines and Control Valve Technology. He is currently a Senior Independent Consultant to various petrochemical industries in the UK, USA, Oman, Kuwait and KSA where he provides consultancy services on both the application and operational constraints of process equipment in the oil & gas industries. During his early career, he held key positions in Rolls Royce (UK) where he was involved in the design of turbine blading for jet engines, subject to pre-specified distributions of pressure. During this period and since, he has also been closely involved in various aspects of Turbomachinery, Thermodynamics and Fluid Mechanics where he has become a recognised authority in these areas. Later, he joined the academic staff of University of Liverpool in the UK as a Professor in Mechanical Engineering Courses. A substantial part of his work has been concerned with detailed aspects of Flowmetering - both of single & multiphase flows. He has supervised doctoral research students in this area in collaboration with various European flowmeter manufacturers. He joined Haward Technology Middle East in 2002 and was later appointed as European Manager (a post which has since lapsed) and has delivered over 150 training courses in Flowmeasurement (single- and multi-phase), Control, Heat Exchangers, Pumps, Turbines, Compressors, Valve and Valve Selection as well as other topics throughout the UK, USA, Oman and Kuwait. During the last two years, he has delivered courses with other training companies operating in the Far and Middle East. He has published about 150 papers in various Engineering Journals and International Conferences and has contributed to textbooks on the topics listed above. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

OSPF training course description A detailed hands on examination of OSPF. Hands on sessions are used to reinforce the theory rather than teach specific manufacturer equipment. The course starts with a recap of reading routing tables and then jumps straight in with simple OSPF configuration. OSPF features are then studied and configured before moving onto how OSPF works within an area. Multi area OSPF is then studied before looking at OSPF operation in detail by analysing OSPF packets. Finally areas are covered again in more detail followed by troubleshooting. What will you learn Design OSPF networks. Design IP addressing schemes suitable for route summarisation. Troubleshoot OSPF networks. Describe the operation of OSPF. OSPF training course details Who will benefit: Technical staff working with OSPF. Prerequisites: TCP/IP Foundation for engineers Duration 3 days OSPF training course contents Basic routing and OSPF Reading routing tables, routing protocols, What is OSPF? Process IDs, passive interfaces. Hands on Simple OSPF configuration. OSPF History of OSPF, metrics, costs, convergence, Distance Vector vs. Link state routing protocols, IGPs, classless, OSPF features, load sharing, per packet/destination, OSPF authentication. Hands on Configuring OSPF features. OSPF within an area How OSPF works, LSDB, LSDB benefits and disadvantages, LSA types, Type 1 and 2, LSA propagation, router IDs, hellos, configuring hellos, the exchange protocol. Hands on Investigating OSPF structures. Areas Scalability, why areas? Area IDs, area 0, ABRs, ABR resilience, areas & LSDBs, areas & LSAs, Type 3 LSAs, virtual links. Hands on Multi area OSPF. Redistribution Multiple routing protocols, common scenarios, routing distance, External LSAs, E1 and E2. Type 4 LSAs. OSPF and default routes. Hands on Configuring static route redistribution. Route aggregation Route summarisation. How to aggregate, ABR summarisation, ASBR summarisation. Hands on OSPF address summarisation. OSPF packet formats OSPF packets, protocol stack, OSPF stages, packet flows, packet types, the OSPF header, multicasts, Hello, DDB, LS request, LS update, LS ACK, LSA header, LSA formats, neighbours, neighbour states, DRs, adjacencies, BDRs, DR election. Hands on Analysing OSPF packets, troubleshooting. OSPF network types BMA, NBMA, Point to point links. Hands on Configuring OSPF over Frame Relay. OSPF stub areas LSA types, area types, area architecture, stub areas, default routes, benefits and disadvantages of stub areas, TSSAs, NSSAs, Type 7 LSAs. Hands on Stub and TSSA configuration. The OSPF MIB SNMP overview, MIB 2, the OSPF MIB, OSPF MIB groups, useful objects, OSPF traps. Hands on the OSPF MIB. troubleshooting. Summary RFCs, OSPF design guidelines. OSPF variants (appendix) OSPF on demand, MOSPF, multicast overview, Type 6 LSAs, OSPF for IPv6 (OSPFv3).

Process Hazard Assessment using the HAZOP Technique and HAZOP Team Leader Training

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course Process Hazard Assessment using the HAZOP Technique is an intensely participative course that will both explain the key facets of the HAZOP technique as well as provide ample opportunities for participants to practice and become familiar with the technique using generic and real-life examples. HAZOP Team Leader Training is an intensely participative course that will develop participants already familiar with the HAZOP technique, the skills, knowledge and attributes of a HAZOP Team Leader. An in-depth syndicate exercise will provide the opportunity to lead a HAZOP team (consisting of other participants) and to be observed performing the role for constructive feedback. This 5 full-day course has been reviewed and approved by the Institution of Chemical Engineers (IChemE). IChemE is the global professional membership organisation for chemical, biochemical and process engineers and other professionals involved in the chemical, process and bioprocess industries. Their knowledge of professional standards, close involvement with industry, education and regulators, and their expertise as a leading global training provider, means they are uniquely positioned to independently assess and approve training courses and professional development programmes across the world. Training Objectives Process Hazard Assessment using the HAZOP Technique By the end of this course, participants will be able to: Understand the basic HAZOP Technique Fulfill roles as competent HAZOP Team Members Understand the role of HAZOP in risk management Understand how Hazard Identification can predict accidents and incidents Understand how HAZOP complements other hazard identification tool HAZOP Team Leader Training By the end of this course, participants will be able to: Understand the role of the HAZOP Team Leader Practise the role in a classroom environment Provide feedback to participants on their performance as HAZOP Team Leaders Appreciate the leadership skills required as HAZOP Team Leader Plan, organise, manage and successfully undertake a Hazard and Operability study Target Audience This course will benefit: All key persons in the organisation, who by their discipline and/or position, are likely to be called on to initiate, participate or review a HAZOP study. All who have responsibility for the management and supervision of process & safety including but not limited to Senior Management, Plant Managers, Process and Maintenance Engineers (all disciplines), Line Supervisors, Team Leaders, Safety Specialists, and Process Training Instructors. Course Level Basic or Foundation Trainer Your expert course leader has 50 years' experience in chemical and process safety engineering. His early career included 20 years in design and project engineering with various fine chemical and pharmaceutical companies where he designed chemical processes, specified plant equipment and selected materials for highly corrosive and toxic processes, often where textbook data was not available. This was followed by 10 years in offshore oil and gas design projects where he was responsible for setting up a Technical Safety group to change design safety practices in the aftermath of the 1988 Piper Alpha disaster. In recent years, he has been called upon to conduct various offshore and onshore incident investigations. His career has given him experience in project engineering, project management, process design and operations, safety engineering and risk management. He is a Fellow of the UK Institution of Chemical Engineers. He served on the Scottish Branch committee, and was elected chairman for a two-year term in 1991. He has also been chairman of the Safety and Reliability Society - North of Scotland Branch. He has delivered training courses in Process Hazard Analysis (HAZOP and HAZID), Process Safety Management, Hazard Awareness, Risk Assessment, Root Cause Analysis, Failure Modes & Effect Analysis and has lectured on Reliability Analysis to the M.Sc. course in Process Safety and Loss Prevention at Sheffield University. In addition to delivering training courses, he currently facilitates HAZOP / HAZID / LOPA studies and undertakes expert witness roles advising lawyers engaged in contractual disputes, usually involving the design or construction of chemical plants or Oil & Gas production facilities, or criminal prosecutions. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Search By Location

- Design Courses in London

- Design Courses in Birmingham

- Design Courses in Glasgow

- Design Courses in Liverpool

- Design Courses in Bristol

- Design Courses in Manchester

- Design Courses in Sheffield

- Design Courses in Leeds

- Design Courses in Edinburgh

- Design Courses in Leicester

- Design Courses in Coventry

- Design Courses in Bradford

- Design Courses in Cardiff

- Design Courses in Belfast

- Design Courses in Nottingham