- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

56 Cleaning courses in Porth delivered Live Online

One of the most powerful ways to tap into intrinsic motivation is by cleaning up your mindset. The way you talk to yourself, visualise and manage your emotions is directly related to your ability to stay motivated and focused. This session will introduce you to a menu of mind hacks to help you Free your Mind?

Certified Network Cabling Design Professional (CNCDP)

By Nexus Human

Duration 2 Days 12 CPD hours This course is intended for The primary audience for this course is any IT, facilities or data centre professional, consultant and/or those who work in network cabling system design, implementation and operation. Overview With few exceptions, enterprises today rely on IT for the delivery of business-critical services - often directly to the end consumer. It is therefore vital that the mission-critical data centre is designed, maintained and operated with high-availability and efficiency in mind. Among all the facilities, network cabling is the foundation for the network and one of the major contributors to the availability of the data center.CNCDP© is a 2-day course designed to expose participants to in-depth knowledge in designing and installing the data network cabling system which includes key subject matters such as; technical standards, designing of different cabling sub-systems, calculation of material requirements, architecture, installation, testing and acceptance. Introduction to Structured Cabling System (SCS) Brief history of SCS Basic copper and fibre transmission Copper and fibre cabling Single and multimode fibre Step/graded index multimode fibre Difference between Commercial Wiring and data centre cabling Development of standards Role of standards ANSI/TIA 568 standard Common standards The new usage of cabling to support Smart building Horizontal and Administration - Commercial Building Standard diagram recap: ANSI/TIA-568 Functional elements and example Scenario A: Determine the number of work areas Scenario B: Determine the number of user locations Zone wiring Administration: Interconnect and cross-connect Angled and flat panels Creating a cabling schematic design Convert schematic into physical layout Calculating the material list Horizontal and Administration - Data Centre Standard diagram recap: TIA-942 Basic/Reduced/Typical data centre setup Traditional 3 layers network design/ Spine and Leaf network design Select termination hardware Administration design ToR/EoR/Spine & Leaf cabling design Network and cabling resiliency Create cabling schematic design for ToR/EoR Convert into patch panel/rack layout Calculate the material list for ToR/EoR Building Backbone - Commercial Building Backbone diagram Calculate the copper backbone requirements per Telecom Room (TR) Calculate the fibre backbone requirements per Telecom Room Summarize the building backbone requirements Recognised cables Backbone Patch panels The maximum backbone distances Create cabling schematic design Converting the schematic design into patch panel/ rack layout Building Backbone - Data Centre TIA-942 based backbone topology TIA-942 backbone requirements Recognised backbone cable ToR/EoR/Spine and Leaf Backbone distance estimation Resiliency of backbone cable routes Creating cabling schematic design Converting the schematic design into patch panel/ rack layout Field and Fusion Termination for fibre connectors Pre-terminated fibre trunk and copper cables Architectural Considerations ANSI/TIA569-D Cable pathway and spaces Common requirements for the rooms Definition of the rooms Entrance Room/Demarcation Ceiling and floor pathways types Cable trays/basket/ladder/conduit Inner duct/sleeve/slot Calculating of pathway size Cable run best practices Cable management/AIM Grounding and bonding Separation distance requirements for copper cabling to power cabling Fire stopping Fire rated barrier Fire rated jacket cable Campus / Outdoor Backbone Common campus cable installation and cable types : Aerial cable / Direct-buried / Underground in-conduit Outdoor cable installation planning Lightning / surge protection Approved ground for surge protector Creating a schematic diagram Converting a schematic into a physical layout Site Inspection and Testing Visual site inspection notes Installation common issues Copper testing standard Permanent link / Channel / Patch cord / MPTL testing configuration Fibre connectors Fibre testing standard Tier 1 & 2 certification Fibre link definition Fibre testing steps Fibre inspection and cleaning Calibrating the test sets - 3 methods Setting up mandrel for testing Fibre loss budget calculation G.657 Bend insensitive fibre Optical Time-Domain Reflectometer (OTDR) Exam - Certified Network Cabling Design Professional (CNCDP©) The exam is a 60-minute closed book exam, with 40 multiple-choice questions. The candidate requires a minimum of 27 correct answers to pass the exam. Additional course details: Nexus Humans Certified Network Cabling Design Professional (CNCDP) training program is a workshop that presents an invigorating mix of sessions, lessons, and masterclasses meticulously crafted to propel your learning expedition forward. This immersive bootcamp-style experience boasts interactive lectures, hands-on labs, and collaborative hackathons, all strategically designed to fortify fundamental concepts. Guided by seasoned coaches, each session offers priceless insights and practical skills crucial for honing your expertise. Whether you're stepping into the realm of professional skills or a seasoned professional, this comprehensive course ensures you're equipped with the knowledge and prowess necessary for success. While we feel this is the best course for the Certified Network Cabling Design Professional (CNCDP) course and one of our Top 10 we encourage you to read the course outline to make sure it is the right content for you. Additionally, private sessions, closed classes or dedicated events are available both live online and at our training centres in Dublin and London, as well as at your offices anywhere in the UK, Ireland or across EMEA.

Data Analytics Workflows for Artificial Lift, Production and Facility Engineers

By EnergyEdge - Training for a Sustainable Energy Future

About this training course Business Impact: The main aim is to provide insight and understanding of data analytics and machine learning principles through applications. Field data is used to explain data-analysis workflows. Using easy to follow solution scripts, the participants will assess and extract value from the data sets. Hands-on solution approach will give them confidence to try out applicable techniques on data from their field assets. Data analysis means cleaning, inspecting, transforming, and modeling data with the goal of discovering new, useful information and supporting decision-making. In this hands-on 2-day training course, the participants learn some data analysis and data science techniques and workflows applied to petroleum production (specifically artificial lift) while reviewing code and practicing. The focus is on developing data-driven models while keeping our feet closer to the underlying oil and gas production principles. Unique Features: Eight business use cases covering their business impact, code walkthroughs for most all and solution approach. Industry data sets for participants to practice on and take home. No software or complicated Python frameworks required. Training Objectives After the completion of this training course, participants will be able to: Understand digital oil field transformation and its impact on business Examine machine learning methods Review workflows and code implementations After completing the course, participants will have a set of tools and some pathways to model and analyze their data in the cloud, find trends, and develop data-driven models Target Audience This training course is suitable and will greatly benefit the following specific groups: Artificial lift, production and facilities engineers and students to enhance their knowledge base, increase technology awareness, and improve the facility with different data analysis techniques applied on large data sets Course Level Intermediate Advanced Training Methods The course discusses several business use-cases that are amenable to data-driven workflows. For each use case, the instructor will show the solution using a data analysis technique with Python code deployed in the Google cloud. Trainees will solve a problem and tweak their solution. Course Duration: 2 days in total (14 hours). Training Schedule 0830 - Registration 0900 - Start of training 1030 - Morning Break 1045 - Training recommences 1230 - Lunch Break 1330 - Training recommences 1515 - Evening break 1530 - Training recommences 1700 - End of Training The maximum number of participants allowed for this training course is 20. This course is also available through our Virtual Instructor Led Training (VILT) format. Prerequisites: Understanding of petroleum production concepts Knowledge of Python is not a must but preferred to get the full benefit. The training will use the Google Collaboratory environment available in Google-Cloud for hands-on exercises Trainees will need to bring a computer with a Google Chrome browser and a Google email account (available for free) Trainer Your expert course leader has over 35 years' work-experience in multiphase flow, artificial lift, real-time production optimization and software development/management. His current work is focused on a variety of use cases like failure prediction, virtual flow rate determination, wellhead integrity surveillance, corrosion, equipment maintenance, DTS/DAS interpretation. He has worked for national oil companies, majors, independents, and service providers globally. He has multiple patents and has delivered a multitude of industry presentations. Twice selected as an SPE distinguished lecturer, he also volunteers on SPE committees. He holds a Bachelor's and Master's in chemical engineering from the Gujarat University and IIT-Kanpur, India; and a Ph.D. in Petroleum Engineering from the University of Tulsa, USA. Highlighted Work Experience: At Weatherford, consulted with clients as well as directed teams on digital oilfield solutions including LOWIS - a solution that was underneath the production operations of Chevron and Occidental Petroleum across the globe. Worked with and consulted on equipment's like field controllers, VSDs, downhole permanent gauges, multiphase flow meters, fibre optics-based measurements. Shepherded an enterprise-class solution that is being deployed at a major oil and gas producer for production management including artificial lift optimization using real time data and deep-learning data analytics. Developed a workshop on digital oilfield approaches for production engineers. Patents: Principal inventor: 'Smarter Slug Flow Conditioning and Control' Co-inventor: 'Technique for Production Enhancement with Downhole Monitoring of Artificially Lifted Wells' Co-inventor: 'Wellbore real-time monitoring and analysis of fracture contribution' Worldwide Experience in Training / Seminar / Workshop Deliveries: Besides delivering several SPE webinars, ALRDC and SPE trainings globally, he has taught artificial lift at Texas Tech, Missouri S&T, Louisiana State, U of Southern California, and U of Houston. He has conducted seminars, bespoke trainings / workshops globally for practicing professionals: Companies: Basra Oil Company, ConocoPhillips, Chevron, EcoPetrol, Equinor, KOC, ONGC, LukOil, PDO, PDVSA, PEMEX, Petronas, Repsol, , Saudi Aramco, Shell, Sonatrech, QP, Tatneft, YPF, and others. Countries: USA, Algeria, Argentina, Bahrain, Brazil, Canada, China, Croatia, Congo, Ghana, India, Indonesia, Iraq, Kazakhstan, Kenya, Kuwait, Libya, Malaysia, Oman, Mexico, Norway, Qatar, Romania, Russia, Serbia, Saudi Arabia, S Korea, Tanzania, Thailand, Tunisia, Turkmenistan, UAE, Ukraine, Uzbekistan, Venezuela. Virtual training provided for PetroEdge, ALRDC, School of Mines, Repsol, UEP-Pakistan, and others since pandemic. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Food Hygiene Awareness

By Prima Cura Training

The Food Hygiene Regulations 2006 are considered to be the most important food safety and hygiene regulations in the UK. These regulations go one step further than the Food Safety Act 1990 as they specify that ALL food businesses have a legal obligation to make sure that food they prepare and serve to the public is safe and hygienic.

This Python Machine Learning online instructor led course is an excellent introduction to popular machine learning algorithms. Python Machine Learning 2-day Course Prerequisites: Basic knowledge of Python coding is a pre-requisite. Who Should Attend? This course is an overview of machine learning and machine learning algorithms in Python SciKitLearn. Practical: We cover the below listed algorithms, which is only a small collection of what is available. However, it will give you a good understanding, to plan your Machine Learning project We create, experiment and run machine learning sample code to implement a short selected but representative list of available the algorithms. Course Outline: Supervised Machine Learning: Classification Algorithms: Naive Bayes, Decision Tree, Logistic Regression, K-Nearest Neighbors, Support Vector Machine Regression Algorithms: Linear, Polynomial Unsupervised Machine Learning: Clustering Algorithms: K-means clustering, Hierarchical Clustering Dimension Reduction Algorithms: Principal Component Analysis Latent Dirichlet allocation (LDA) Association Machine Learning Algorithms: Apriori, Euclat Other machine learning Algorithms: Ensemble Methods ( Stacking, bagging, boosting ) Algorithms: Random Forest, Gradient Boosting Reinforcement learning Algorithms: Q-Learning Neural Networks and Deep Leaning Algorithms: Convolutional Network (CNN) Data Exploration and Preprocessing: The first part of a Machine Learning project understands the data and the problem at hand. Data cleaning, data transformation and data pre-processing are covered using Python functions to make data exploration and preprocessing relatively easy. What is included in this Python Machine Learning: Python Machine Learning Certificate on completion Python Machine Learning notes Practical Python Machine Learning exercises and code examples After the course, 1 free, online session for questions or revision Python Machine Learning. Max group size on this Python Machine Learning is 4. Refund Policy No Refunds

Introduction to watercolour | 2-day course

By Elena Blanco artist

Introduction to watercolour Artist-taught watercolour course that will get you inspired and confident to practise with this wonderful medium!

Adobe After Effects Basic Level Training course 1-2-1

By Real Animation Works

Aftereffects face to face training customised and bespoke.

HPHT Planning and Well Control

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course In our pursuit to discover oil & gas in deeper horizons, wells are often drilled in a HPHT environment. To be considered a HPHT well, the downhole conditions will have pressures in excess of 10,000 psi (69 MPa) and 300° F (150° C). To drill these usually expensive wells successfully, the planning and execution phase has to be of an exceptionally high standard. Therefore, both operator and drilling/service contractor staff must be seamlessly aligned and work as a coherent team to reach and then harness the well objectives. This is particularly important when speciality services such as Managed Pressure Drilling (MPD) are being applied with crews and/or supervisors who are not intricately familiar with complicated well control incidents. As we seek to prevent costly non-productive time, attention will also be paid to enabling technologies like expandable solid tubulars, mud coolers and specialty mud. The 3 full-day course will explain the key characteristics and challenges of HPHT Planning and Well Control. This includes: Differences between HPHT and standard (conventional) wells and what this entails for well design. The challenges unique to HPHT and the impact of Pore Pressure Prediction (PPP). Static and Dynamic Equivalent Mud Density and the factors that influence the ultimate Bottom Hole Pressure (BHP). Control practices such as 'fingerprinting' to identify what's happening downhole. HPHT shut-in procedures and practices. Specific HPHT equipment and drilling tool requirements and advantages of Managed Pressure Drilling (MPD). Well control on/off bottom, bull-heading and dealing with kick-loss situations. Mud management, tolerance on mud properties and challenges in cementing. Case history on emergency control. Drills, team effort, checklists, human factor and 'getting everybody on board'. Training Objectives By the end of this course, participants will be able to: Recognize the main differences in planning/design between HPHT and standard (conventional) wells as well as the challenges that will have to be faced. Explain drilling and tripping operational challenges and practices as well as how to manage these effectively. Identify wellbore breathing (a.k.a. ballooning) and how to safely deal with this within the narrow window for mud density selection. Apply practices of consistent fingerprinting and how to develop procedures for this to benefit the rig team. Measure and understand bottom hole pressure and the effect of influencing factors such as temperature, rotation and flow rate. Understand the critical mud properties to alleviate barite sag, general mud density control techniques and specify the essentials in cementing. Manage losses and low fracture gradients with well bore strengthening methods. Execute sound HPHT shut-in procedures. Understand how MPD can assist in the safe and efficient drilling and hole cleaning of HPHT wells. Understand the use of MPD Influx Management Envelopes. Identify critical Early Kick Detection Systems (EKDS) and HPHT well control equipment. Execute safe secondary well control practices in a H2S environment, bull-heading, on and off bottom and handling of gas at surface, using MGS and hydrate mitigation measures. Target Audience The course is intended for: Office-based staff engaged in HPHT well planning and day-to-day operations Field-based rig staff working as front-line supervisors - from Assistant Drillers to Senior Toolpushers Field-based rig staff working for service companies supporting the execution of HPHT wells (MPD, mud and mudlogging services etc.) Trainer Your expert course leader has over 45 years of experience in the Oil & Gas industry. During that time, he has worked exclusively in the well engineering domain. After being employed in 1974 by Shell, one of the major oil & gas producing operators, he worked as an apprentice on drilling rigs in the Netherlands. After a year, he was sent for his first international assignment to the Sultanate of Oman where he climbed up the career ladder from Assistant Driller, to Driller, to wellsite Petroleum Engineer and eventually on-site Drilling Supervisor, actively engaged in the drilling of development and exploration wells in almost every corner of this vast desert area. At that time, drilling techniques were fairly basic and safety was just a buzz word, but such a situation propels learning and the fruits of 'doing-the-basics' are still reaped today when standing in front of a class. After some seven years in the Middle East, a series of other international assignments followed in places like the United Kingdom, Indonesia, Turkey, Denmark, China, Malaysia, and Russia. Apart from on-site drilling supervisory jobs on various types of drilling rigs (such as helicopter rigs) and working environments (such as jungle and artic), he was also assigned to research, to projects and to the company's learning centre. In research, he was responsible for promoting directional drilling and surveying and advised on the first horizontal wells being drilled, in projects, he was responsible for a high pressure drilling campaign in Nigeria while in the learning centre, he looked after the development of new engineers joining the company after graduating from university. He was also involved in international well control certification and served as chairman for a period of three years. In the last years of his active career, he worked again in China as a staff development manager, a position he nurtured because he was able to pass on his knowledge to a vast number of new employees once again. After retiring in 2015, he has delivered well engineering related courses in Australia, Indonesia, Brunei, Malaysia, China, South Korea, Thailand, India, Dubai, Qatar, Kuwait, The Netherlands, and the United States. The training he provides includes well control to obtain certification in drilling and well intervention, extended reach drilling, high pressure-high temperature drilling, stuck pipe prevention and a number of other ad-hoc courses. He thoroughly enjoys training and is keen to continue taking classes as an instructor for some time to come. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Directional, Horizontal and Multilateral Drilling – Simulator Assisted

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your drilling skills with our Directional, Horizontal, and Multilateral Drilling Simulator Assisted course. Join EnergyEdge for comprehensive training.

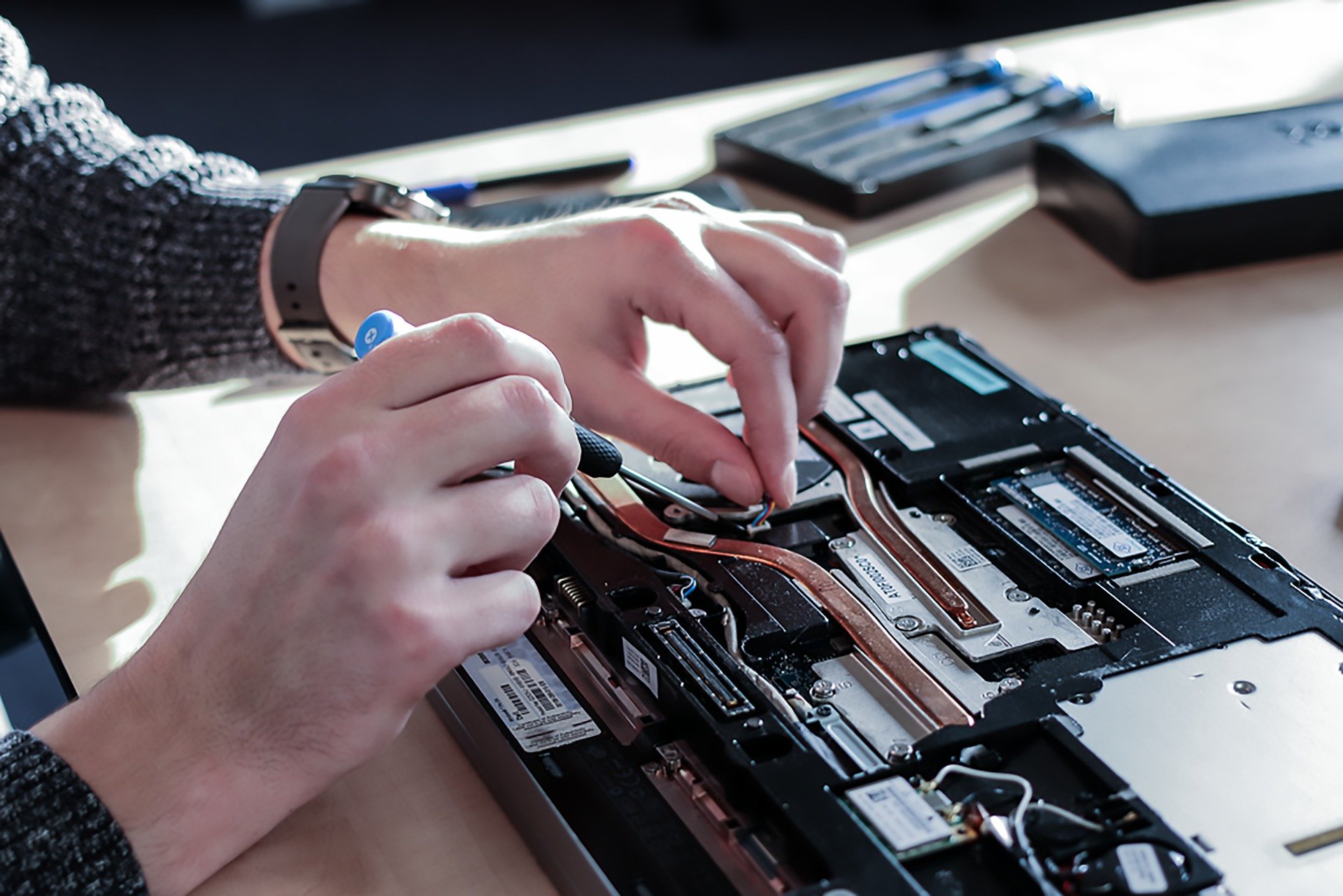

Computer Maintenance and Repair Course

By Hi-Tech Training

The Computer Maintenance & Repair Technician course aims to enable participants to diagnose and repair system level faults in computer-based systems at the foundation level.