- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

This foundational course will help all managers better understand what a procurement function does, including the processes, tools and techniques it employs to reach its goals and how it measures its business performance. PARTICIPANTS WILL LEARN HOW TO: Explain the contribution of procurement to the overall business objectives. Explain the added value that can be obtained by a business when it manages its procurement activities efficiently and effectively. Understand the complex activity of procurement and the challenges it presents for risk management. Develop good quality procurement practices that will manage the expectations of all stakeholders Identify methods by which a procurement function can be measured and performance monitored. Perform contract management activities. Understand ways in which improvements might be identified and implemented. COURSE TOPICS INCLUDE: Procurement and business objectives Stakeholder Management Commercial Specifications Whole Life Costing Targeted procurement Procurement planning Supplier Appraisal and selection RFQ & ITT & Evaluation Contract Management

Forklift Truck Training The aim of the NPORS Forklift Truck Training is to provide both theoretical and practical training to ensure the safe usage of the FLT Counter Balance Forklifts. As a result of the forklift truck training you will receive the red trained operator card or the Traditional Card. Call to book your forklift course today Experienced operator – NPORS Forklift Truck Test Book with Confidence at Vally Plant Training At Vally Plant Training, we guarantee unbeatable value with our Forklift Experienced Test Price Match Promise. When you choose us, you can book with confidence, knowing that we will not be beaten on price. If you find a lower price for the same NPORS Forklift Experienced Worker Test, we’ll match it—ensuring you receive top-quality training at the best possible rate. Click for our terms and conditions Your skills, our commitment—always at the best price. NPORS Forklift Truck Test is for operators who have received some form of forklift training in the past or alternatively has been operating Forklift trucks for a period of time. If you are unsure if you qualify to go down the forklift truck test route please contact us to discuss this in more detail. There are two parts to the forklift truck course, a theory section comprised of 25 questions and a practical session. Forklift Truck Training Course: Navigating Safety and Efficiency Forklift trucks, also known as lift trucks or forklifts, are indispensable tools in various industries, facilitating the movement and handling of materials with precision and ease. However, operating a forklift requires specialised skills and knowledge to ensure safety, efficiency, and compliance with regulations. In this comprehensive course outline, we will delve into the essential content covered in a forklift truck training course, designed to equip participants with the expertise needed to operate forklifts safely and effectively in the work place. 1. Introduction to Forklift Trucks: Overview of forklift types: counterbalance, reach, pallet trucks, etc. Understanding the components and controls of a forklift Different configurations and attachments for specific tasks All health and safety regulations covered 2. Forklift Safety Procedures: Importance of safety in forklift operation Pre-operational checks and inspections Understanding load capacity and load centre Personal protective equipment (PPE) requirements Emergency procedures: evacuation, fire, and accident response 3. Forklift Operation Basics: Starting, stopping, and manoeuvring the forklift safely around obstacles Steering techniques: forward, reverse, and turning Operating on various surfaces: smooth floors, ramps, and inclines Lifting, lowering, side shifting and tilting loads using hydraulic controls 4. Load Handling Techniques: Proper load assessment: weight, size, and stability Positioning the forklift for efficient loading and unloading Securing loads with proper attachments: forks, clamps, and attachments Stacking and de-stacking loads safely and efficiently 5. Site Safety and Hazard Awareness: Identifying potential hazards in the workplace Working safely around pedestrians, other forklifts, and obstacles Recognising environmental hazards: narrow aisles, confined spaces, and overhead obstructions Understanding site-specific safety rules and regulations 6. Maintenance and Inspections: Importance of regular maintenance for forklift performance and longevity Daily, pre-shift, and post-shift inspection procedures Lubrication points and maintenance schedules Identifying and reporting mechanical issues and defects 7. Practical Hands-On Training: Practical exercises in forklift operation under supervision Manoeuvring through obstacle courses and tight spaces Load handling exercises: stacking, de-stacking, and transporting loads Emergency response drills: simulated scenarios to test response and decision-making skills 8. Assessment and Certification: Written examination to assess theoretical knowledge Practical assessment of forklift operation skills Certification upon successful completion of the course Conclusion: A forklift truck training course equips participants with the essential knowledge, skills, and confidence to operate forklifts safely and efficiently in various work environments. By covering topics such as safety procedures, operation techniques, load handling, site awareness, maintenance practices, and practical hands-on training, participants can enhance their proficiency and contribute to a safer and more productive workplace. Whether you’re a novice operator or an experienced professional, investing in forklift training is essential for ensuring compliance, reducing risks, and promoting excellence in material handling operations. Frequently Asked Questions 1. What types of forklifts are covered in the training? The training covers various forklift types, including counterbalance, reach trucks, and pallet trucks. 2. What are the course components? The course includes theoretical training, practical sessions, safety procedures, load handling techniques, site safety, maintenance, and inspections. 3. Who is the training suitable for? The training is suitable for both novice operators and experienced operators who need certification or recertification. 4. What certification will I receive? Participants will receive an NPORS card, either a red trained operator card or a traditional card, valid for 2-5 years depending on the type. 5. What are the prerequisites for the course? There are no prerequisites for novice operators, but experienced operators should have prior forklift operation experience. Forklift Truck Training Available 7 days a week to suit your business requirements. VPT have a team of friendly and approachable instructors, who have a wealth of knowledge of Forklifts and the construction industry We have our own training centre conveniently located close to the M5 junction 9, In Tewkesbury. With its own purpose-built practical training area to simulate an actual working environment. However, this training can only be conducted on your sites Our forklift training and test packages are priced to be competitive. Discounts are available for multiple bookings We can send a fully qualified NPORS forklift Tester to your site nationwide, to reduce the amount of time away from work Our more courses: Polish your abilities with our dedicated Lift Supervision Training, Slinger Signaller Training, Telehandler Training, Cat & Genny Training, Plant Loader Securer, Ride-On Road Roller, Abrasive Wheel Training, Lorry Loader Training and Scissor Lift Training sessions. Learn the safe and effective operation of these vital machines, crucial for construction and maintenance tasks. Elevate your skills and career prospects by enrolling in our comprehensive courses today. For those looking for a “NPORS Forklift Training near me,” our widespread operations make it convenient for you to access Vally Plant Trainings top-quality training no matter where you are in the UK

A team of stars or a star Team?- Team Effectiveness workshop

By Verax International

Team development to improve business performance. Quantifiable results. Change measured. &0+% of teams are measured as more effective after 6 months.

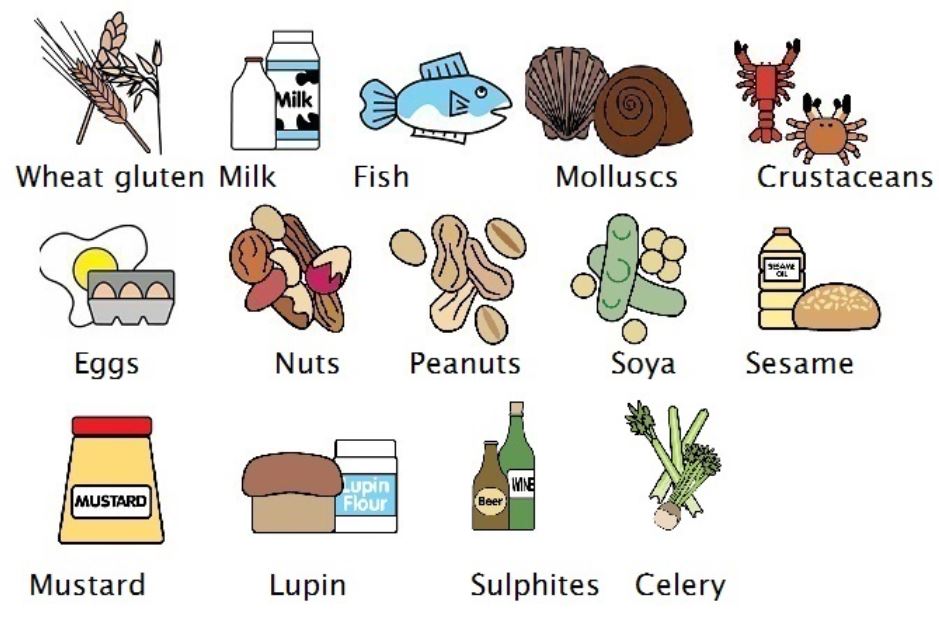

RSPH level 2 Identifying and Controlling Food Allergy Risks Training Course

By Kitchen Tonic Training Company and Food Safety Consultants

RSPH level 2 Identifying and Controlling Food Allergy Risks Training Course Do you need an allergy trainer to come to your food business and teach your staff face to face about food and drink allergens, their dangers and how to control them? Our allergy trainer can come to your business and deliver this course at your business premises. Although we are based in London, we are happy to travel and deliver this course at your business location. (Trainer travel fees may be applicable depending on your location). Staff will receive interactive training and coaching on allergens and intolerances with an experienced trainer. We can also tweak the training to include issues you would like to cover. See our website for more details. Special offer for on-site allergy training. £250 plus £20pp includes RSPH exam fees (usually £350 plus £30pp) This course is suitable for any catering business such as restaurants, pubs, hotels, cafes, catering companies, cooks, self employed, artisans, event caterers and more. This course is also important for staff who are Front of House, who take customer orders and relay the orders to cooks and chefs and other people who are preparing food for customers who have allergies and or intolerances. This is a short one day training course, typically 9am-3pm. Topics covered include- Allergens, Allergen Identification, Cross contact, Cross Contamination, Allergic Reactions, Food Intolerances, Coeliac, Anaphylaxis, Natasha's Law, UK Food Safety Regulations, Allergy Controls, Substituting ingredients, Customer Communication and what to do in an Emergency. Contact us to book training.

Overview In this competitive era no matter how much hard work and solid efforts are contributed still, too many projects end up creating unneeded and unsellable products. There is a significant risk that the outcome of the project may not be relevant to the client/user requirements or become outdated when needs change. Here is where Design Thinking and Agile Management play their role. The combination of Agile and Design Thinking should be used in order to achieve impactful outcomes. Agile and design thinking together works well and gives an effective approach to product development, one that results in efficient resolutions to significant problems. In this course, you'll learn how to define and determine what's important to a user primary in the process, to frontload value, by directing your team on testable narratives about the user and generating an effectively shared perspective. For more dates and Venue, Please email sales@gbacorporate.co.uk

Power BI - dashboards (1 day) (In-House)

By The In House Training Company

Power BI is a powerful data visualisation program that allows businesses to monitor data, analyse trends, and make decisions. This course is designed to provide a solid understanding of the reporting side of Power BI, the dashboards, where administrators, and end users can interact with dynamic visuals that communicates information. This course focuses entirely on the creation and design of visualisations in dashboards, including a range of chart types, engaging maps, and different types of tables. Designing dashboards with KPI's (key performance indicators), heatmaps, flowcharts, sparklines, and compare multiple variables with trendlines. This one-day programme focuses entirely on creating dashboards, by using the many visualisation tools available in Power BI. You will learn to build dynamic, user-friendly interfaces in both Power BI Desktop and Power BI Service. 1 Introduction Power BI ecosystem Things to keep in mind Selecting dashboard colours Importing visuals into Power BI Data sources for your analysis Joining tables in Power BI 2 Working with data Utilising a report theme Table visuals Matrix visuals Drilling into hierarchies Applying static filters Group numbers with lists Group numbers with bins 3 Creating visuals Heatmaps in Power BI Visualising time-intelligence trends Ranking categorical totals Comparing proportions View trends with sparklines 4 Comparing variables Insert key performance indicators (KPI) Visualising trendlines as KPI Forecasting with trendlines Visualising flows with Sankey diagrams Creating a scatter plot 5 Mapping options Map visuals Using a filled map Mapping with latitude and longitude Mapping with ArcGIS or ESRI 6 Creating dashboards High-level dashboard Migration analysis dashboard Adding slicers for filtering Promote interaction with nudge prompts Searching the dashboard with a slicer Creating dynamic labels Highlighting key points on the dashboard Customised visualisation tooltips Syncing slicers across pages 7 Sharing dashboards Setting up and formatting phone views Exporting data Creating PDF files Uploading to the cloud Share dashboards in SharePoint online

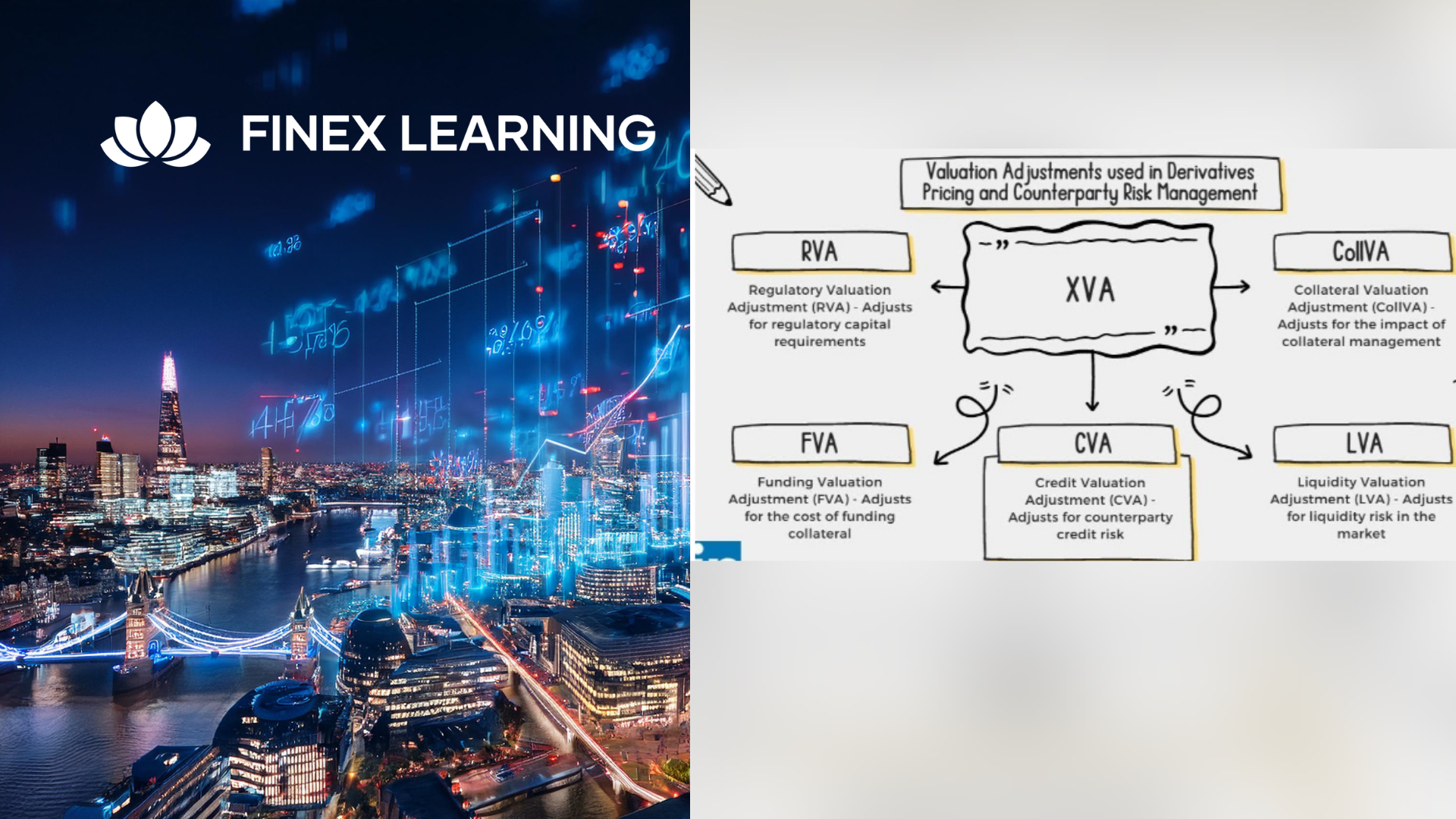

Overview This is a 2 day applied course on XVA for anyone interested in going beyond merely a conceptual understanding of XVA and wants practical examples of Monte Carlo simulation of market risk factors to create exposure distributions and profiles for derivatives used for XVA pricing Learn how to do Monte Carlo simulation of key market risk factors across major asset classes to create exposure distributions and profiles (with and without collateral) for derivatives used for XVA pricing. Learn how to calculate each XVA. Learn sensitivities of each XVA and how XVA desks manage these. Learn regulatory capital treatment of counterparty credit risk (both for CCR and CVA volatility) and how to stress test this within ICAAP or system-wide external, supervisor-led capital stress test. Who the course is for Anyone involved in OTC derivatives XVA traders XVA quants Derivatives traders and salespeople Risk management Treasury staff Internal audit and finance Course Content To learn more about the day by day course content please click here To learn more about schedule, pricing & delivery options, book a meeting with a course specialist now

HACCP Trainer - On site Level 3 HACCP Training - Nationwide

By Kitchen Tonic Training Company and Food Safety Consultants

HACCP Trainer. on site delivery nationwide

Search By Location

- Business Courses in London

- Business Courses in Birmingham

- Business Courses in Glasgow

- Business Courses in Liverpool

- Business Courses in Bristol

- Business Courses in Manchester

- Business Courses in Sheffield

- Business Courses in Leeds

- Business Courses in Edinburgh

- Business Courses in Leicester

- Business Courses in Coventry

- Business Courses in Bradford

- Business Courses in Cardiff

- Business Courses in Belfast

- Business Courses in Nottingham