- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

3220 ARC courses

Screen Acting Essentials

By Actors Studio

Looking refresh and advance your technical screen acting skills? This 5 Day Screen Acting Essentials course held at the World Famous Pinewood Studios has been crafted for those who are committed to improving and developing their knowledge in a practical setting on camera. Over the week you will build camera awareness, understand shot sizes and how they impact performance, hitting marks, script analysis and audition tips. Filming footage throughout the week you will receive immediate feedback from the experienced Directors and see progression to a confidence that can be applied both in self-tapes and on set. Course Outline Screen Acting Essentials Your Week On Camera The course aims to help actors leave feeling prepared and confident in their new skills enabling them to deliver better performances on screen. Day 1: The Technicals Learn and Practice the basic technical skills an actor needs to master to perform successfully in front of the camera. Understand the differences between acting for stage and screen. Topics include: shot sizes, continuity, eye-lines, vocal control, physicality and hitting marks. Day 2: Understanding The Script & Character Development Learn techniques and methods to successfully analyse a script in order to create inspirational and authentic characters. Developing characters you will identify their arc, and find contrast even within a page of script underpinned by voice, diction, physicality and improvisation skills. Day 3: Working on a Film Set To raise your awareness on a film set, you will participate in filming as members of the crew including sound, script supervising and Directing to really understand the challenges of each role and it you should communicate as an actor. You will also film a scene as part of this role-play process. Day 4: Audition Technique Understand how you should prepare for a screen audition. Experience the casting process most commonly in use today and how to avoid the pitfalls of interview ‘overkill’, preparing you for your next audition. Day 5: Lights, Camera, Action Implementing everything you have learned throughout the week, you will film a scene with a crew. Additional Information Features Suitable for anyone (17 yrs+) committed to improving their screen acting skills Learn the art of screen performance Practical and intensive training on camera Attracts a varied age range from 17 yrs + Led by Award-Winning Industry Professionals This course is taught in English so it is important that you have proficient English language skills Learning Outcomes Increase your chances of securing acting roles Improved knowledge and confidence in front of camera Learn rehearsal techniques and processes Develop natural immersive acting skills Experience with a professional crew and Director Course Location Actors Studio, Pinewood Studios, Pinewood Road, Iver Heath, Buckinghamshire, SL0 0NH Free parking available at Pinewood Studios Free frequent shuttle bus service from London Uxbridge Tube Station, Slough & Gerrards Cross. Transfer from station to Pinewood Studios – 10 minutes Canteen & Coffee shops on site

Novel Writing Course For Beginners

By Lead Academy

Quality Guarantee: Promising training excellence, satisfaction gurantee Accredited by: CPD UK & Quality License Scheme Tutor Support: Unlimited support via email, till you complete the course Recognised Certification: Accepted by thousands of professional bodies Start Anytime: With 1 year access to the course materials Online Learning: Learn from anywhere, whenever you want From this immersive course, you will learn the art of crafting compelling characters and captivating plots, empowering yourself with expert guidance on story structure, dialogue and narrative pacing. This will set the foundation for your novel-writing journey. This course at a glance Accredited by CPD UK Endorsed by Quality Licence Scheme Get a comprehensive understanding of novel writing. Get the knowledge about the characterization in the novel. Develop the skills and gain the knowledge required to write a novel. Learn how to introduce various characters in the novel. Understand the elements of a novel and the character's place. Learn how to describe the characters in the novel. Understand the character arc. Get to learn how to bring your novel characters into reality. Why Novel Writing Course For Beginners right for you? This novel writing for beginners course will help you gain all the skills required to become a confident novel writer. This online course will give you a comprehensive understanding of how you can turn your ideas and imagination into reality. This novel writing course will also make you understand the significant elements of novel writing. This online course will help you introduce different characters, write about them in the novel, and make them real in the readers' minds. You will also understand how to transform the characters smoothly throughout the story of the novel after taking this novel writing course. By the end of the course, you will be able to develop a solid foundation in the novel writing industry and will also develop the skills and knowledge required to write a novel efficiently and will also be able to understand. Novel Writing Course For Beginners Details Accredited by CPD certificates are accepted by thousands of professional bodies and government regulators here in the UK and around the world. Many organisations look for employees with CPD requirements, which means, that by doing this course, you would be a potential candidate in your respective field. The Quality Licence Scheme is a brand of the Skills and Education Group, a leading national awarding organisation for providing high-quality vocational qualifications across a wide range of industries. Course Curriculum Lessons How to Write Characters Promotional Introduction - The Elements of a Novel and The Character's Place Creating Your Characters & Making Them Real - The Profile The Character Arc Different Types of Characters Characterization How to Describe Your Characters Introducing Your Characters Who should take this course? This online novel writing for beginners course is particularly useful to those who are interested in writing novels and want to build a strong career in novel writing. Anyone aspiring to accelerate their career in fictional writing can also opt for this comprehensive online course. Entry Requirements There are no academic entry requirements for this Novel Writing For Beginners course, and it is open to students of all academic backgrounds. However, you are required to have a laptop/desktop/tablet or smartphone and a good internet connection. Assessment Method This novel writing For beginners course assesses learners through multiple-choice questions (MCQs). Upon successful completion of the modules, learners must answer MCQs to complete the assessment procedure. Through the MCQs, it is measured how much a learner could grasp from each section. In the assessment pass mark is 60%. Certification Endorsed Certificate from Quality Licence Scheme After successfully passing the MCQ exam you will be eligible to order the Endorsed Certificate by Quality Licence Scheme. The Quality Licence Scheme is a brand of the Skills and Education Group, a leading national awarding organisation for providing high-quality vocational qualifications across a wide range of industries. It will give you a competitive advantage in your career, making you stand out from all other applicants and employees. There is a Quality Licence Scheme endorsement fee to obtain an endorsed certificate which is £65. Certificate of Achievement from Lead Academy After successfully passing the MCQ exam you will be eligible to order your certificate of achievement as proof of your new skill. The certificate of achievement is an official credential that confirms that you successfully finished a course with Lead Academy. Certificate can be obtained in PDF version at a cost of £12, and there is an additional fee to obtain a printed copy certificate which is £35. FAQs Is CPD a recognised qualification in the UK? CPD is globally recognised by employers, professional organisations and academic intuitions, thus a certificate from CPD Certification Service creates value towards your professional goal and achievement. CPD-certified certificates are accepted by thousands of professional bodies and government regulators here in the UK and around the world. Are QLS courses recognised? Although QLS courses are not subject to Ofqual regulation, they must adhere to an extremely high level that is set and regulated independently across the globe. A course that has been approved by the Quality Licence Scheme simply indicates that it has been examined and evaluated in terms of quality and fulfils the predetermined quality standards. When will I receive my certificate? For CPD accredited PDF certificate it will take 24 hours, however for the hardcopy CPD certificate takes 5-7 business days and for the Quality License Scheme certificate it will take 7-9 business days. Can I pay by invoice? Yes, you can pay via Invoice or Purchase Order, please contact us at info@lead-academy.org for invoice payment. Can I pay via instalment? Yes, you can pay via instalments at checkout. How to take online classes from home? Our platform provides easy and comfortable access for all learners; all you need is a stable internet connection and a device such as a laptop, desktop PC, tablet, or mobile phone. The learning site is accessible 24/7, allowing you to take the course at your own pace while relaxing in the privacy of your home or workplace. Does age matter in online learning? No, there is no age limit for online learning. Online learning is accessible to people of all ages and requires no age-specific criteria to pursue a course of interest. As opposed to degrees pursued at university, online courses are designed to break the barriers of age limitation that aim to limit the learner's ability to learn new things, diversify their skills, and expand their horizons. When I will get the login details for my course? After successfully purchasing the course, you will receive an email within 24 hours with the login details of your course. Kindly check your inbox, junk or spam folder, or you can contact our client success team via info@lead-academy.org

Switchgears and Transformers: Selection, Maintenance & Testing

By EnergyEdge - Training for a Sustainable Energy Future

Gain expertise in switchgears and transformers through EnergyEdge's classroom training. Enroll now for a comprehensive learning experience.

Movie Script Writing Course For Beginners

By Lead Academy

Quality Guarantee: Promising training excellence, satisfaction gurantee Accredited by: CPD UK & Quality License Scheme Tutor Support: Unlimited support via email, till you complete the course Recognised Certification: Accepted by thousands of professional bodies Start Anytime: With 1 year access to the course materials Online Learning: Learn from anywhere, whenever you want This movie script writing online course for beginners will provide you with a comprehensive introduction of movie script formatting and directions, movie script characters and setup and pro tips for writing movie tips. This online course will build a solid foundation of tools used for movie analysis and screenplay. This course at a glance Accredited by CPD UK Endorsed by Quality Licence Scheme Gain knowledge of how to write creative and engaging movie scripts Learn the importance of the story arc in screenwriting Strengthen your storytelling skills Understand how to convert your story into a movie script Know how to set up a movie character Get the knowledge of movie script formatting and direction skills Respond successfully to the tools required to write a movie Understand the pro tips for writing a movie script Why Movie Script Writing Course For Beginners right for you? This movie script writing course for beginners is especially for those who want to kickstart their career in writing movie scripts. This course has been designed to provide learners with an understanding of how they can transfer any story to an appealing movie script. This online course will give you knowledge of how you can write creative and engaging movie scripts. By the end of the course, you will have theoretical knowledge in writing a movie script and understand the skills required to become a confident movie script writer. Movie Script Writing Course For Beginners Details Accredited by CPD certificates are accepted by thousands of professional bodies and government regulators here in the UK and around the world. Many organisations look for employees with CPD requirements, which means, that by doing this course, you would be a potential candidate in your respective field. The Quality Licence Scheme is a brand of the Skills and Education Group, a leading national awarding organisation for providing high-quality vocational qualifications across a wide range of industries. Course Curriculum Intro - ' How to Write a Movie Script: Film Scriptwriting ' - Creative Aspects Intro to the Course: ' How to Write a Movie Script: Film Scriptwriting ' Story Telling When Screenwriting The Importance of the Story Arc in Screenwriting Screenwriting - How to Transfer the Story to a Movie Script Movie Script Characters and Setup Movie Script Formatting and Directions Pro Tips for Writing a Movie Script Screenwriting - Movie Script Analysis, Tools and Submission Movie Script Analysis - Die Hard Movie Screenplay Writing Tools - Amazon Storywriter Conclusion to Course and Submitting Your Script Who should take this course? This movie script writing online course for beginners has been designed for those who want to build a strong career in the field of movie script writing. This comprehensive online course will aspire the learners to accelerate their career and enhance job prospects in writing an attractive movie script. Entry Requirements There are no academic entry requirements for this Movie Script Writing Course For Beginners course, and it is open to students of all academic backgrounds. However, you are required to have a laptop/desktop/tablet or smartphone and a good internet connection. Assessment Method This movie script writing course for beginners assesses learners through multiple-choice questions (MCQs). Upon successful completion of the modules, learners must answer MCQs to complete the assessment procedure. Through the MCQs, it is measured how much a learner could grasp from each section. In the assessment pass mark is 60% Certification Endorsed Certificate from Quality Licence Scheme After successfully passing the MCQ exam you will be eligible to order the Endorsed Certificate by Quality Licence Scheme. The Quality Licence Scheme is a brand of the Skills and Education Group, a leading national awarding organisation for providing high-quality vocational qualifications across a wide range of industries. It will give you a competitive advantage in your career, making you stand out from all other applicants and employees. There is a Quality Licence Scheme endorsement fee to obtain an endorsed certificate which is £65. Certificate of Achievement from Lead Academy After successfully passing the MCQ exam you will be eligible to order your certificate of achievement as proof of your new skill. The certificate of achievement is an official credential that confirms that you successfully finished a course with Lead Academy. Certificate can be obtained in PDF version at a cost of £12, and there is an additional fee to obtain a printed copy certificate which is £35. FAQs Is CPD a recognised qualification in the UK? CPD is globally recognised by employers, professional organisations and academic intuitions, thus a certificate from CPD Certification Service creates value towards your professional goal and achievement. CPD-certified certificates are accepted by thousands of professional bodies and government regulators here in the UK and around the world. Are QLS courses recognised? Although QLS courses are not subject to Ofqual regulation, they must adhere to an extremely high level that is set and regulated independently across the globe. A course that has been approved by the Quality Licence Scheme simply indicates that it has been examined and evaluated in terms of quality and fulfils the predetermined quality standards. When will I receive my certificate? For CPD accredited PDF certificate it will take 24 hours, however for the hardcopy CPD certificate takes 5-7 business days and for the Quality License Scheme certificate it will take 7-9 business days. Can I pay by invoice? Yes, you can pay via Invoice or Purchase Order, please contact us at info@lead-academy.org for invoice payment. Can I pay via instalment? Yes, you can pay via instalments at checkout. How to take online classes from home? Our platform provides easy and comfortable access for all learners; all you need is a stable internet connection and a device such as a laptop, desktop PC, tablet, or mobile phone. The learning site is accessible 24/7, allowing you to take the course at your own pace while relaxing in the privacy of your home or workplace. Does age matter in online learning? No, there is no age limit for online learning. Online learning is accessible to people of all ages and requires no age-specific criteria to pursue a course of interest. As opposed to degrees pursued at university, online courses are designed to break the barriers of age limitation that aim to limit the learner's ability to learn new things, diversify their skills, and expand their horizons. When I will get the login details for my course? After successfully purchasing the course, you will receive an email within 24 hours with the login details of your course. Kindly check your inbox, junk or spam folder, or you can contact our client success team via info@lead-academy.org

Electrical Substation: Design, Construction & Commissioning

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your knowledge with EnergyEdge course on electrical substation design, construction, and commissioning. Join us today!

Register on the ETAP Power System Analysis For Electrical Engineers today and build the experience, skills and knowledge you need to enhance your professional development and work towards your dream job. Study this course through online learning and take the first steps towards a long-term career. The course consists of a number of easy to digest, in-depth modules, designed to provide you with a detailed, expert level of knowledge. Learn through a mixture of instructional video lessons and online study materials. Receive online tutor support as you study the course, to ensure you are supported every step of the way. Get an e-certificate as proof of your course completion. The ETAP Power System Analysis For Electrical Engineers is incredibly great value and allows you to study at your own pace. Access the course modules from any internet-enabled device, including computers, tablet, and smartphones. The course is designed to increase your employability and equip you with everything you need to be a success. Enrol on the now and start learning instantly! What You Get With The ETAP Power System Analysis For Electrical Engineers Receive a e-certificate upon successful completion of the course Get taught by experienced, professional instructors Study at a time and pace that suits your learning style Get instant feedback on assessments 24/7 help and advice via email or live chat Get full tutor support on weekdays (Monday to Friday) Course Design The course is delivered through our online learning platform, accessible through any internet-connected device. There are no formal deadlines or teaching schedules, meaning you are free to study the course at your own pace. You are taught through a combination of Video lessons Online study materials Certification Upon successful completion of the course, you will be able to obtain your course completion e-certificate free of cost. Print copy by post is also available at an additional cost of £9.99 and PDF Certificate at £4.99. Who Is This Course For: The course is ideal for those who already work in this sector or are an aspiring professional. This course is designed to enhance your expertise and boost your CV. Learn key skills and gain a professional qualification to prove your newly-acquired knowledge. Requirements: The online training is open to all students and has no formal entry requirements. To study the ETAP Power System Analysis For Electrical Engineers, all your need is a passion for learning, a good understanding of English, numeracy, and IT skills. You must also be over the age of 16. Course Content ETAP Power System Analysis For Electrical Engineers Lesson 1 - Introduction to ETAP Course 00:07:00 Lesson 2 - Why To Use Power System Analysis Software 00:07:00 Lesson 3 - Creating New Project In ETAP 00:06:00 Lesson 4 - ETAP Software Overview 00:11:00 Lesson 5 - How To Create Single Line Diagram in ETAP 00:09:00 Lesson 6 - Load Flow Analysis Fundamentals 00:21:00 Lesson 7 - Load Flow Hand Calculations and Comparing With ETAP software 00:19:00 Lesson 8 - Load Flow Analysis Example 00:32:00 Lesson 9 - Transformer XbyR Ratio Calculation 00:04:00 Lesson 10 - Generator Load Sharing 00:09:00 Lesson 11 - Cable Ampacity & Sizing 00:22:00 Lesson 12 - Transformer MVA Sizing 00:15:00 Lesson 13 - Short Circuit Analysis Fundamentals 00:24:00 Lesson 14 - Short Circuit Hand Calculations and Comparing With ETAP software 00:09:00 Lesson 15 - Short Circuit Analysis Example 00:35:00 Lesson 16 - Protection & Coordination Analysis Fundamentals 00:23:00 Lesson 17 - Protection & Coordination Analysis Example 00:52:00 Lesson 18 - Arc Flash Analysis Fundamentals 00:24:00 Lesson 19 - Arc Flash Analysis Example 00:21:00 Lesson 20 - Motor Starting Analysis Fundamentals 00:11:00 Lesson 21 - Motor Starting Analysis Example - Part 1 00:26:00 Lesson 22 - Motor Starting Analysis Example - Part 2 00:08:00 Lesson 23 - Transient Stability Analysis Fundamentals 00:29:00 Lesson 24 - Transient Stability Analysis - Example 1 00:19:00 Lesson 25 - Transient Stability Analysis - Example 2 00:14:00 Lesson 26 - Transient Stability Analysis - Example 3 00:08:00 Lesson 27 - Harmonic Analysis Fundamentals 00:24:00 Lesson 28 - Harmonic Analysis Example 00:34:00 Lesson 29 - Ground Grid Study 00:16:00 Resource - ETAP Power System Analysis For Electrical Engineers 00:00:00 Frequently Asked Questions Are there any prerequisites for taking the course? There are no specific prerequisites for this course, nor are there any formal entry requirements. All you need is an internet connection, a good understanding of English and a passion for learning for this course. Can I access the course at any time, or is there a set schedule? You have the flexibility to access the course at any time that suits your schedule. Our courses are self-paced, allowing you to study at your own pace and convenience. How long will I have access to the course? For this course, you will have access to the course materials for 1 year only. This means you can review the content as often as you like within the year, even after you've completed the course. However, if you buy Lifetime Access for the course, you will be able to access the course for a lifetime. Is there a certificate of completion provided after completing the course? Yes, upon successfully completing the course, you will receive a certificate of completion. This certificate can be a valuable addition to your professional portfolio and can be shared on your various social networks. Can I switch courses or get a refund if I'm not satisfied with the course? We want you to have a positive learning experience. If you're not satisfied with the course, you can request a course transfer or refund within 14 days of the initial purchase. How do I track my progress in the course? Our platform provides tracking tools and progress indicators for each course. You can monitor your progress, completed lessons, and assessments through your learner dashboard for the course. What if I have technical issues or difficulties with the course? If you encounter technical issues or content-related difficulties with the course, our support team is available to assist you. You can reach out to them for prompt resolution.

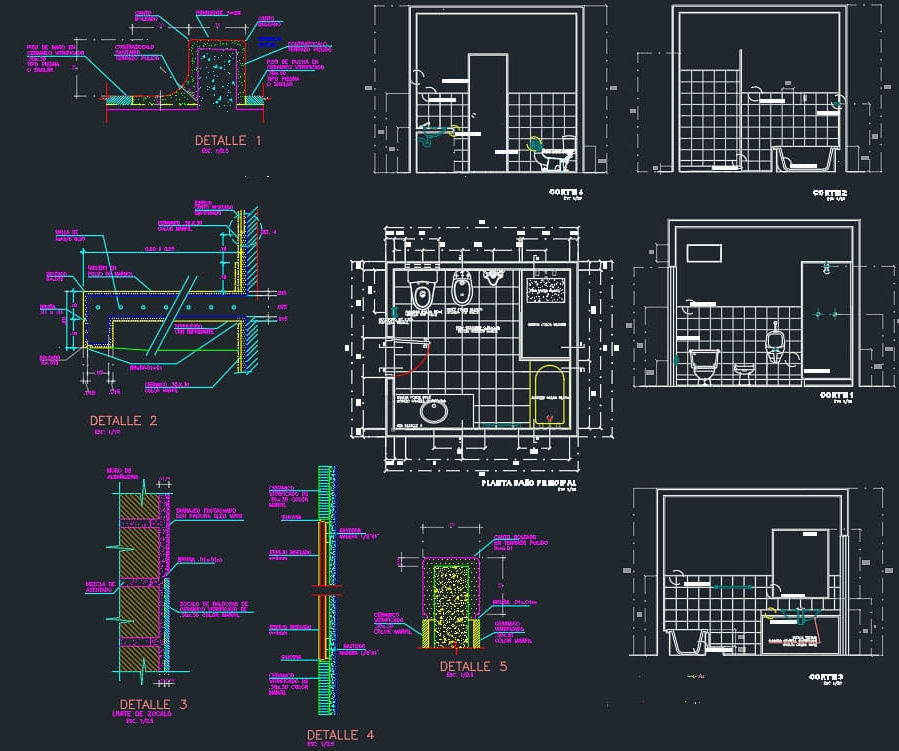

AutoCAD Basics-Advanced Training Classes

By London Design Training Courses

Why AutoCAD Basics-Advanced Training Classes? Click here for more info AutoCAD Basics to Advanced Level Training Master drawing, editing, and advanced techniques. Optimize productivity and customize workspace. Create precise 2D drawings for various industries. Access recorded lessons and lifetime email support. Duration: 16 hrs Method: 1-on-1, Personalized attention. Schedule: Tailor your own schedule by pre-booking a convenient hour of your choice, available from Mon to Sat between 9 am and 7 pm. The AutoCAD from Basics leading to Advanced Training Course offers a comprehensive learning experience for participants to become proficient in AutoCAD. Whether you're a beginner or an experienced user, this progressive program covers the full spectrum of AutoCAD functionality. Participants will learn core features like drawing, editing, annotations, and dimensioning, progressing to advanced topics such as object manipulation, workspace customization, and workflow optimization. Upon completion, participants will create precise 2D drawings and designs. Interactive learning experiences with experienced instructors are available in-person or through live online sessions. AutoCAD 2D Course Outline: Session 1: Introduction to AutoCAD interface, commands, and tools Managing drawings and drawing basic shapes Basic modification techniques (erase, move, rotate, scale) Session 2: Working with layers and properties Creating and modifying text and dimensions Introduction to blocks and attributes Session 3: Advanced object modification techniques (fillet, chamfer, trim, extend) Using grips to modify objects Creating and modifying polylines and splines Session 4: Creating and editing tables Working with layouts and viewports Printing and exporting drawings Construction detailing and Detailed sections Course Highlights: Engaging exercises and projects to reinforce skills. Q&A and troubleshooting support. Solid understanding of AutoCAD 2D for basic to intermediate drawings. List of Topics Covered: Drawing: Line, Polyline, Circle, Arc, Rectangle, Ellipse, Spline, Polygon, Ray, Hatching, Gradient. Inquiry: Measure and Select All. Modify: Move, Copy, Rotate, Mirror, Fillet, Trim, Extend, Erase, Offset, Explode, Array, Stretch, Break, Polyline Edit, Hatch Edit, Scale. Layers: Creating, Managing, Changing, Line Type, Line Weights. Annotation: Dimensions, Text, Dimension Style, Text Style, Leaders. Properties: Colors, Line weights, Line Types, Line Type Scaling. Blocks: Create, Insert, Edit, Explode, Export. Insert: Insert, Attach. View: Navigate, View, Windows. Plot/Print: Model Space, Layouts/Workspaces, Viewports, Layout Scaling, Paper Setup, What To Plot, Plot Scale, Plot Offset, Plot Options. Final Project: Create a Plan, Section, and Elevation drawing. Option for a personal project. Free Trial - Download AutoCAD Software & Toolsets: Participants can download a free trial of AutoCAD and industry-specific toolsets from Autodesk's official website: (https://www.autodesk.co.uk). Master AutoCAD Basics: Understand the interface, commands, and drawing tools. Create and Modify Drawings: Proficiently manage drawings and apply various modification techniques. Work with Layers and Annotations: Effectively use layers, text, and dimensions. Utilize Advanced Drawing Techniques: Apply advanced object modifications and work with polylines. Navigate Layouts and Viewports: Manage layouts, viewports, and printing/exporting. Hands-On Project Experience: Practice skills through exercises and a final project. Personalized Learning: Receive focused one-to-one attention. Convenient Options: Choose in-person or live online sessions. Lesson Recordings and Support: Access recorded lessons and receive ongoing email assistance. Enhance Career Opportunities: Develop valuable 2D drawing skills for career advancement.

Database Design and Data Normalization Course Summary Relational Databases & Data Normalisation Overview Training Courses London. Learn how to decide which tables and columns are required for a database, plan relationships, how to decide on data types and how to relate tables. Database Design and Data Normalization Course Description Session 1: Introduction to Relational Databases The Database Approach Database Management Systems The function of a Database Management System The Processing Architecture The Schema Architecture The Storage Architecture An overview of Database System Development An overview of general database principles Session 2: Conceptual Data Models Overview of Entity Models Entities and how to identify them Attributes and how to identify them Relationships and their qualities Building an Entity Relationship Diagram Resolving many-to-many relationships Sub-type and Super-type Relationships Arc Relationships Recursive Relationships Constraints and Assumptions Normalization to the First Normal Form (1NF) Normalization to the Second Normal Form (2NF) Normalization to the Third Normal Form (3NF) Exercises: Analyzing a specification Creating an Entity Relationship Diagram from it Session 3: The Relational Model Relational Structure Relational Terminology Domains A Relational schema Candidate keys and Primary Keys Foreign Keys Key Constraints Attribute Constraints Implementing Sub-type/Super-type Relationships Views Denormalization using Pre-joined Tables Denormalization using Derived Data An Introduction to Structured Query Language (SQL) Simple Queries Simple Updates of the Data Included in the Database Design and Data Normalization Courses: Database Design and Data Normalization Course Certificate on completion Database Design and Data Normalization Course Manual Practical Database Design and Data Normalization Course exercises, Database Course Homework / Database Course Revision work After the course, 1 free session for questions online Database Course via Gotomeeting.com. Max group size, online and in classroom, on this Database Course is 4.

Overview Reach your full potential, be an efficient welder and climb the career ladder of your choice. In this detailed Welding Training Level 3 (British Standard) course, you'll learn various theoretical and practical welding techniques for various metals. It'll cover everything about how to weld different types of metal for the fabrication industry. Become quickly skilled in welding by enrolling in this course and impress your future employer. How will I get my certificate? At the end of the course there will be a written assignment test which you can take either during or after the course. After successfully completing the test you will be able to order your certificate, these are included in the price. Who is this course for? There is no experience or previous qualifications required for enrolment on this Welding Training Level 3 (British Standard). It is available to all students, of all academic backgrounds. Requirements Our Welding Training Level 3 (British Standard) is fully compatible with PC's, Mac's, Laptop, Tablet and Smartphone devices. This course has been designed to be fully compatible on tablets and smartphones so you can access your course on wifi, 3G or 4G. There is no time limit for completing this course, it can be studied in your own time at your own pace. Career path Having these various qualifications will increase the value in your CV and open you up to multiple sectors such as Business & Management , Admin, Accountancy & Finance, Secretarial & PA, Teaching & Mentoring etc. Course Curriculum 20 sections • 17 lectures • 07:00:00 total length •Module 1: Introduction to Welding: 00:15:00 •Module 2: Getting Familiar with Metals: 00:20:00 •Module 3: Exploring Welding Methods: 00:20:00 •Module 4: Knowing the Welding Metals: 00:30:00 •Module 5: Preparing Steel for Welding: 00:15:00 •Module 6: Working with Stainless Steel: 00:15:00 •Module 7: Working with Aluminium and Other Metals: 00:20:00 •Module 8: MIG Welding Tutorial: 00:30:00 •Module 9: TIG Welding Tutorial: 00:30:00 •Module 10: Arc Welding Tutorial: 00:45:00 •Module 11: Illness Caused by Welding Fume and Gases: 00:15:00 •Module 12: Welding Fume - Reducing the Risk: 00:30:00 •Module 13: Hearing Loss and Vibration White Finger: 00:30:00 •Module 14: Other Safety Issues: 00:30:00 •Module 15: Protection during Welding: 00:45:00 •Module 16: Safety in Gas Welding: 00:30:00 •Assignment - Welding Training Level 3 (British Standard): 00:00:00

Welding Training & MIG Welding Course - CPD Accredited

By Compliance Central

Welding is the most incredible craft in the world. It's what makes us able to make anything out of metal, from buildings to cars to food. Welders are some hardest-working people on Earth and deserve recognition for their skills and hard work. If you want to become a welder, start creating your own parts, or just show off your skills, this course is for you! This course can take your welding and metalworking skills to the next level by incorporating the more technical elements of your career. You'll be a seasoned expert after completing this reputable welding course. Learning Outcomes of Welding: A Summary of the Major Welding Processes. Explanation of Joint Types and Terminology in Depth. Welding Symbol Components. An Introduction to Plug, Slot, and Stud Welds. Welding Fume and Gases Caused Illness. Welding Fume Risk Reduction. Vibration White Finger and Hearing Loss. Why would you choose the Welding Training & MIG Welding course from Compliance Central: Lifetime access to Welding course materals Full tutor support is available from Monday to Friday with the Welding course Learn Welding skills at your own pace from the comfort of your home Gain a complete understanding of Welding course Accessible, informative Welding learning modules designed by expert instructors Get 24/7 help or advice from our email and live chat teams with the Welding course Study Welding in your own time through your computer, tablet or mobile device A 100% learning satisfaction guarantee with your Welding Training course Improve your chance of gaining in demand skills and better earning potential by completing the Welding course Course Curriculum Basics Introduction Getting Familiar with Metals Exploring Welding Methods Knowing the Welding Metals Preparing Steel Working with Stainless Steel Working with Aluminium and Other Metals Tutorials MIG Tutorial TIG Tutorial Arc Tutorial Hazards and Safety Illness Caused by Welding Fume and Gases Welding Fume - Reducing the Risk Hearing Loss and Vibration White Finger Other Safety Issues And many more... CPD 10 CPD hours / points Accredited by CPD Quality Standards Who is this course for? Anyone from any background can enrol in this course. Requirements To enrol in this course, all you need is a basic understanding of the English Language and an internet connection. Career path The course will enable you to get hired in course related Trendy and Demanding jobs. Certificates CDP Accerdited PDF Certificate Digital certificate - Included Free CPD Accredited PDF Certificate. CPD Accredited Hardcopy Certificate Hard copy certificate - £10.79 Delivery Charge: Inside the UK: Free Outside the UK: 9.99

Search By Location

- ARC Courses in London

- ARC Courses in Birmingham

- ARC Courses in Glasgow

- ARC Courses in Liverpool

- ARC Courses in Bristol

- ARC Courses in Manchester

- ARC Courses in Sheffield

- ARC Courses in Leeds

- ARC Courses in Edinburgh

- ARC Courses in Leicester

- ARC Courses in Coventry

- ARC Courses in Bradford

- ARC Courses in Cardiff

- ARC Courses in Belfast

- ARC Courses in Nottingham