- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

65272 Courses

A-Level Economics Distance Learning Course by Oxbridge

By Oxbridge

In today's media-flooded world, economic insights fill our screens. This A-Level Economics course allows you to grasp a deeper understanding of these discussions, becoming an ever-popular choice for those with aspirations in various sectors. This A-Level Economics course immerses you in dissecting economic issues, evaluating economic data, and articulating coherent ideas and judgements. Your learning journey culminates in an invaluable foundation for future endeavours in finance, banking, or governance. Our Economics A-Level deepens your understanding of the global impact of Economics and the market economy's role in shaping policy, both domestically and internationally. A comprehensive exploration of the European Union will further prepare A-Level Economics learners for a plethora of career opportunities. A-Levels are UK education's golden standard 🥇, recognised by universities and employers alike as a testament to notable accomplishment. Your A-Level demonstrates a thorough understanding of a subject, boosting your career prospects and unlocking new opportunities. Our A-Level Economics course, mapped to the latest specifications, offers you the best chance of success. The course package equips you with everything needed for success: a clear induction, well-structured assignments, and the following benefits: A brand new course, written to the latest specification with dynamic and engaging content Fast track option for exams in 2022 🏎️ Access to a network of partnership exam centres (guaranteed exam venue) 📍 Unlimited tutor support throughout the course 🎓 Exam pass guarantee 🎖️ About the awarding body Awarding body: AQA Our course code: X914 Qualification code: 7136 Awarding body: AQA, recognised globally, taught in 30 countries, and highly esteemed by employers and universities. ⏱ Study Hours Anticipate between 250 and 300 hours of study time, plus additional time for completing assignments. 👩🏫 Study Method Delivered via our online learning platform, the course offers dynamic and engaging materials. If you prefer, you can print your own learning materials. Resources come in various formats including videos, quizzes, and interactive activities. 📆 Course Duration Enjoy unlimited tutor support for up to 24 months post-enrolment. You'll receive login details for MyOxbridge, housing all your learning materials. 📚 Assessment Registration is currently open for summer 2022 examinations. The assessment involves three standard written exams: Standardised Exams - Each lasting for 2 hours, each contributing to 33.3% of your final score. We ensure a hassle-free examination experience by providing guaranteed exam spaces in various centres across the nation. Explore the nearest exam centre to you. 📋 Assignments Throughout the course, you'll need to complete assignments marked by your tutor (TMAs). Though these assignments don't contribute to your final grade, they offer an excellent opportunity to get feedback and monitor your progress as you traverse the course. 🎓 Course Outcomes Upon successful completion of this self-paced learning course, you will earn an A-Level in Economics, certified by AQA. We've opted for this specific syllabus due to its suitability for distance learning. Rest assured, your certificate holds the same credibility as those issued by any other educational institution. ℹ️ Further Information Level of Difficulty - Level 3 Entrance prerequisites - A GCSE or an equivalent qualification in economics or mathematics is advisable for this course. UCAS Points - 56 Course Contents 1. Individuals, Firms, Markets, and Market Failure In the initial phase of the course, delve into the dynamics of markets and market failure. Explore price determination in a competitive marketplace, aspects impacting production, costs, and revenue, and get a glimpse of the national economy from a global perspective. Investigate competitive and concentrated markets, governmental interventions, and the management of macroeconomic performance. 2. The National and International Economy The latter part of the course focuses on economic methodology, the economic dilemma, and the impact of individual economic decisions. Examine the labour market, the uneven distribution of wealth leading to issues like poverty and inequality. Furthermore, study the national and international economy, the circular flow of income, AD/AS analysis, financial markets, and monetary policy. Lastly, delve into fiscal policy and supply-side policies.

A-Level Spanish Distance Learning Course by Oxbridge

By Oxbridge

Uncover the richness of the Spanish language, spoken officially in twenty-one countries by over 400 million natives. It's a language born from a myriad of Latin dialects and holds a prominent position in the global business realm. Mastery of a foreign language is a distinct asset highly esteemed by academic institutions and employers alike, opening doors in various professions such as teaching, law, sales, medicine, translation, and more! Our A-Level Spanish course lets you broaden the language skills you have accrued at GCSE, with a strong emphasis on culture and societal themes. Immerse yourself in authentic spoken and written sources, and study Spanish within the framework of the social currents and trends that have moulded multicultural Hispanic societies. You'll also delve into how history has impacted the present-day Hispanic art, political climate, and Spanish identity. Plus, conduct independent research on texts and films of your preference, ranging from Pan’s Labyrinth (2006) to works by Gabriel García Márquez. With unlimited tutor support guiding you at each stage, you’ll refine your ability to converse in grammatically correct Spanish, comprehend spoken Spanish, and express your thoughts, ideas, and opinions creatively. Our AQA A-Level Spanish course is meticulously designed for online, self-paced study, with your tutor available to aid your learning journey and provide assignment feedback. You'll receive a comprehensive course induction and structured assignments to cultivate the skills and knowledge needed to excel in your exams. You stand to gain from: A recently developed course, tailored to the latest specification with engaging and dynamic content Fast track option on this course (for 2022 exams) Complimentary e-textbook to facilitate your learning Access to a network of partnered exam centres (guaranteed exam venue) Unlimited tutor support – Your tutor will aid in crafting a study plan and provide ongoing support. Exam pass guarantee (We’ll provide support for your next exam if you don’t pass the first time) Acquire the skill to converse in grammatically correct Spanish, comprehend spoken Spanish, and express your thoughts, ideas, and opinions creatively! About the awarding body Awarding body: AQA Our course code: X912 Qualification code: 7692 The AQA qualifications are globally recognised and taught in 30 countries, esteemed by employers and universities, and assist young people to progress to the subsequent stage of their lives. AQA qualifications accommodate a range of abilities and comprise GCSEs, IGCSEs, and A-levels. ⏱ Study Hours Allocate between 250 and 300 hours for study time, plus additional time for completing assignments. 👩🏫 Study Method Our course is offered via our interactive online learning platform, providing learners with an engaging experience. If you prefer, you can print the learning materials. The resources come in various media, including videos, quizzes, and interactive activities. 📆 Course Duration Upon enrolment, you’ll have up to two years to study and sit your exams, with ongoing unlimited tutor support during this period. 📋 Assessment Enrolment for examinations from Summer 2022 is now open. Assessment tasks will vary, encompassing listening, speaking, reading, and writing skills. You’ll need to complete three standard A-Level written exams and one speaking assessment. Exams Paper 1: Written exam lasting 2 hours, 30 minutes, 50% of A-Level, 100 marks. Paper 2: Written exam lasting 2 hours, 20% of A-Level, 80 marks. Paper 3: Speaking exam lasting 21-23 minutes, 30% of A-Level, 60 marks. We provide a guaranteed exam space in one of our exam centres across the UK to simplify your exam process. Find your nearest exam centre. Assignments Throughout your course, various assignments need to be completed. While they don't contribute to your final grade, they serve as an opportunity to submit work for your tutor’s marking and feedback, helping monitor your progress and generate predicted grades, if necessary. 👩🎓 Course Outcomes Upon successful completion of this home study course, you will receive an A-Level in Spanish, issued by AQA. This syllabus (7692) has been chosen particularly as it is best suited to online learning, and we believe it offers the best chance of success. ℹ️ Additional Information Difficulty - Level 3 Entry requirements - GCSE Spanish or equivalent is required for this course. UCAS Points - 56 Course Content Spanish Identity Unpack Spain as a multicultural nation in unit one, exploring its languages, dialects, and regional disparities economically, socially, and culturally. Cultural Heritage Discuss pre-Hispanic civilisations in Spain and South America, the impact of Spanish colonisation on culture and identity, and world heritage sites in Spanish-speaking nations. Modern Times Examine attitudes towards marriage, divorce, families, sexism, homophobia, feminism, and LGBTQ+ groups in Spanish culture. Politics Focus on Spanish language skills to discuss politics, including monarchy in Spain, South American dictatorships, corruption scandals, social protests, and youth unemployment. Multiculturalism and Racism Investigate immigration and its perceived benefits and challenges in Spanish-speaking countries. Media Study the role of media in Spanish-speaking countries, including the cultural awakening post-Franco dictatorship and contemporary issues such as social media and streaming platforms. Customs and Celebrations Confidently discuss national celebrations and culinary traditions in Spain, Latin America, and South America. Comparing Life in Hispanic Communities Expand your vocabulary and grammar to discuss the present political scenario and future prospects in the Spanish-speaking world. Exam Preparation Recap all the topics studied and prepare for your final exams.

A-Level Biology Distance Learning Course by Oxbridge

By Oxbridge

Immerse yourself in the intricate exploration of life with our A-Level Biology distance learning course. Engage with the intricate processes that create and sustain life, from cellular functions to expansive ecosystems, unified by the energy that fuels life itself. Feel you have a grip on DNA and evolutionary theory? Prepare to dig deeper. This course offers an in-depth journey into the workings of cells and how they intertwine to create the vast biodiversity observed on our planet. Choosing to study A-Level Biology remotely is an excellent decision if you value the liberty of studying at your own pace and have aspirations to pursue a university education in science, medicine, physiotherapy, or related fields. Not only will you cultivate robust analytical and evaluative skills by interpreting, manipulating, and presenting data, but also enhance your comprehension of life in its entirety. This course is an excellent stepping stone for those keen on a career in healthcare, research, or the social, environmental, and forensic science sectors. This home-based course adheres to the latest AQA A-Level Biology syllabus and is specifically designed for online study at your own convenience. It offers unrestricted tutor support, a clear induction, and well-organised assignments to aid in the acquisition of the necessary skills and knowledge for the exam. You are assured of an examination slot at one of our centres if you plan to take your final A-Level examinations in the UK. Benefits of undertaking this A-Level Biology course include: - A freshly minted course, drafted in accordance with the most recent specifications for a dynamic and engaging learning experience - Fast track option for the 2022 exams - Access to a network of partner exam centres (guaranteed exam venue) - Unrestricted tutor support- assistance with devising a study plan and throughout the course - Exam pass guarantee (Resit support provided if the initial attempt is unsuccessful) This course will enhance your awareness and critical understanding of social and environmental matters, fostering an appreciation for living beings. Awarding body: AQA Our course code: X910 Qualification code: 7402 Official Qualification Title: A-Level Biology AQA qualifications, taught in 30 countries worldwide, are globally recognised, highly esteemed by employers and universities, and empower individuals to progress to their next life phase. ⏱ Estimated study hours range between 250 and 300 hours. 👩🏫 Our dynamic online learning platform delivers the course, including a variety of learning resources in different formats such as videos, quizzes, and interactive activities. 📆 The course duration is up to 24 months from the enrolment date. You will receive login details for the MyOxbridge portal where your learning materials will be accessible. 📋 Assessment details: The course culminates in three standard A-Level written exams, each requiring a blend of short and long answer responses and extended response questions. Our network of UK-based exam centres guarantees a venue for your exams. We also offer an exam pass guarantee, offering free resit support if needed. Assignments will be a part of the course for practice and feedback, and if required, for predicted grades. A practical endorsement may be necessary for students planning to study medicine at university. This can be arranged through our examination partners, Tutors & Exams. 👩🎓 Successful completion of this home learning course will earn you an A-Level in Biology, issued by AQA. The 7402 syllabus has been chosen by Oxbridge as it is best suited to online learning and offers the best chance of success. ℹ️ Additional Information Official Qualification Title - A-Level Biology Difficulty - Level 3 Entry requirements - A GCSE or equivalent in Biology and Chemistry, or Double or Triple Science, and Maths is strongly recommended for this course. UCAS Points - 56 The course content includes exploration of biological molecules, cells, organism-environment interaction, genetic information, energy transfers in organisms, organism response to changes, genetics, evolution, ecosystems, and control of gene expression. Course Content: Biological molecules: This unit delves into the common compounds that comprise all living cells, like carbohydrates, enzymes, and proteins. It unravels the interactions and roles of these biological molecules in sustaining life. Cells: Discover the common features shared by all life forms, such as cell origin, composition, and intercellular communication. This module also addresses the role of cellular interaction in diseases and the immune system response. Organisms exchange substances with their environment: This section explores how cells exchange substances across plasma membranes and transport them within the body or their environment. Genetic information, variation, and relationships between organisms: Gain insights into biological diversity and its genetic and environmental causes. Learn about DNA sequences, genetic variation, and the role of natural selection. Energy transfers in and between organisms: This module delves into energy transfer processes, including respiration and photosynthesis, in a variety of organisms like plants, animals, bacteria, and fungi. Organisms respond to changes in their internal and external environments: Understand how organisms respond to stimuli through electrical impulses in nerve cells and the release of chemical messengers. Genetics, populations, evolution, and ecosystems: This unit addresses the theory of evolution, explaining the emergence of new species from existing ones due to genetic and environmental factors like natural selection. The control of gene expression: Learn about the factors influencing gene expression, including external environmental factors, and explore the ongoing research in altering gene expression for medical purposes. Enrol in our A-Level Biology distance learning course today, to deepen your understanding of the complex web of life. Whether your ambitions lie in healthcare, research, or environmental sectors, this course is the perfect foundation to set you on your path to success.

A-Level Chemistry Distance Learning Course by Oxbridge

By Oxbridge

🔬 Chemistry isn't just in the lab; it's all around us! From the medicines we take, the fuels that power our vehicles, to the food we eat, chemistry is at the heart of everything. Through our A-Level Chemistry Distance Learning Course, we bring this captivating science to your doorstep! Learn about elements on the Periodic Table, the creation of new compounds, and the profound interactions of chemistry with our world. This course equips you not only with a solid grounding in Chemistry but also develops critical skills such as data analysis, problem-solving, and creative thinking, making it an invaluable stepping-stone for careers in health, teaching, research, and beyond. 🎓 Our A-Level Chemistry course, respected in academic circles, aligns with the new AQA A-Level Chemistry syllabus and is structured for optimal online learning. With unlimited tutor support, well-structured assignments, and guaranteed exam centre access for UK students, we ensure a seamless learning experience. This flexible, self-paced course is enriched with dynamic and engaging content, alongside a network of partnership exam centres, and a promise to support you until you pass the exam. 📝 Enrol to reap benefits such as: - Engaging and up-to-date course content - Fast-track option available for 2022 exams - A dedicated study plan with constant support - An exam pass guarantee About the awarding body Awarding body: AQA Our course code: X909 Qualification code: 7405 📜 The AQA qualifications we offer are internationally recognised, taught in 30+ countries, and highly valued by employers and universities. With an AQA A-Level in Chemistry, you open doors to an array of opportunities worldwide. ⏱ Study Hours: Plan for between 250-300 hours of study time, plus time for assignments. 👩🏫 Study Method: Our course is delivered via our engaging online learning platform with a mix of videos, quizzes, and interactive activities. You can also opt to print the learning materials. 📆 Course Duration: The course spans up to 24 months from enrolment, accessible via our MyOxbridge portal. 📋 Assessment: Enrol now for exams from Summer 2022. There will be three standard A-Level written exams. We provide a guaranteed exam space in one of our UK exam centres, alongside an exam pass guarantee. Three standard A-Level written exams form the core of the assessment: - Paper 1: 2 hours, 35% of A-Level, 105 marks. - Paper 2: 2 hours, 35% of A-Level, 105 marks. - Paper 3: 2 hours, 30% of A-Level, 90 marks. These exams mix short and long answer questions and extended response questions. We provide a guaranteed exam space in one of our UK centres, and if you don't pass at the first attempt, our exam pass guarantee offers you free support until you succeed. You'll also complete various assignments throughout the course for feedback from your tutor. 🔬 Practical Endorsements: If your university course or career path requires it, you may need to complete a practical endorsement as part of your qualification. We can arrange this through our examination partners, Tutors & Exams. Unravel the magic of Chemistry at your own pace and convenience with Oxbridge. Enrol today to get started on your scientific journey! 🚀 👩🎓 Course Outcomes: Upon successful completion, you receive an AQA-issued A-Level in Chemistry, identical to that received by on-campus students. ℹ️ Additional Information: Difficulty: Level 3 Entry requirements: GCSE Science (double award) or GCSE Chemistry (min grade 4) and GCSE Maths (or equivalent) UCAS Points: 56 Course Content includes Atomic Structure, Chemical Reactions, Energy Changes, Equilibria, Electrochemical Cells, Inorganic Chemistry, and more. 🔍 Course Details: Our curriculum is carefully curated to give you a comprehensive understanding of chemistry and its various facets: 1. Structure of the Atom and Bonding: Start your journey by learning about the evolution of atomic structure, supported by evidence from advances in science and technology. 2. Chemical Reactions and Calculations: Understand key terms like relative atomic mass and relative molecular mass and discover the importance of the mole in measuring amounts of substances. 3. Rate of Reaction and Energy Changes in Chemical Reactions: Delve into the collision theory and how changes in conditions can impact the speed of a chemical reaction. 4. Chemical Reactions in Equilibria: Learn about the factors influencing reaction progression, and how Le Chatelier’s principle can be used to predict the effects of changes in conditions. 5. Redox Reactions and Electrochemical Cells: Explore the changes during redox reactions, deduce whether oxidation or reduction has occurred, and construct half-equations for these processes. 6. Inorganic Chemistry: Uncover how elements are classified based on their position in the periodic table and understand trends in atomic radius. 7. Inorganic Chemistry Part One: Familiarise yourself with the IUPAC system for naming organic compounds, their reactions, and different types of isomerism. 8. Inorganic Chemistry Part Two: Finish with a comprehensive look at optical isomerism, aldehydes, ketones, carboxylic acids, aromatic chemistry, amines, polymers, amino acids, organic synthesis, and chromatography.

A lively night of hot Swing music and dancing including beginners and intermediate Lindy Hop classes brought to you by SwingdanceUK featuring live music! Where history is made! Kick off the evening with a Lindy Hop Swing dance class then dance to live music and DJs Simon 'Mr Kicks' Selmon and guests!

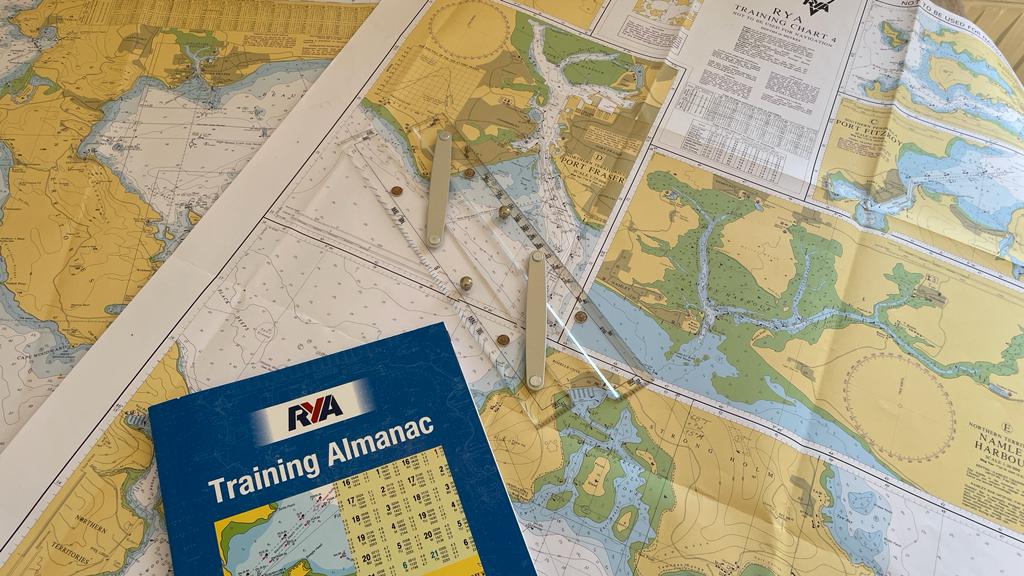

The RYA Coastal Skipper and Yachtmaster Offshore Shorebased course is for experienced sailors. The course builds on the theory learnt on the Day Skipper course, which is the knowledge level required at the outset of this course. It will give you the experience and confidence to plan and achieve your passage in offshore and coastal routes. Unlike the Day Skipper course, it includes precision tidal calculations. The course will increase your theory knowledge to the required standard for the Yachtmaster Coastal and Yachtmaster Offshore exams, concentrating on advanced navigation, IRPCS and meteorology subjects. This is an intense six day course, from 0900 hrs to 1700 hrs every day (1 hr for lunch plus 2 x 15 min breaks), that will teach you advanced navigation techniques. The syllabus contains: position fixing course shaping and plotting tidal knowledge use of almanacs and admiralty publications electronic position finding equipment taking and interpreting forecasts plotting weather systems weather predictions using a barometer and by observation collision regulations customs and excise regulations for cruising abroad

The Day Skipper shore based course sits in the RYA Syllabus as preamble to the Day Skipper practical course and will give the aspiring skipper the knowledge that is needed to navigate familiar water. The course also provides an introduction to lights to help you on your way with sailing in the dark. The course will give you the confidence to be able to plan your passage on inshore and coastal routes, and ensure that you and your crew are safe. The course includes: Basics of seamanship Essentials of inshore navigation and pilotage Chartwork (plotting tidal streams, estimated positions and courses to steer) Electronic charts Position fixing Passage planning Weather forecasting and meteorology Tidal height calculations Collision regulations Construction, parts and equipment of a cruising boat Emergency and safety procedures including distress calls, the use of flares, safety harnesses, lifejackets and liferafts

Charisma is a rare quality – we know when we see charisma because we feel compelled to listen to those who have it. There is a magic about them. We notice them as soon as they walk into a room. We are so inspired by what they say that we find ourselves almost as enthusiastic as they are about the thing they are speaking about. They have a way of communicating that brings us alive and makes us feel good.

Search By Location

- Courses in London

- Courses in Birmingham

- Courses in Glasgow

- Courses in Liverpool

- Courses in Bristol

- Courses in Manchester

- Courses in Sheffield

- Courses in Leeds

- Courses in Edinburgh

- Courses in Leicester

- Courses in Coventry

- Courses in Bradford

- Courses in Cardiff

- Courses in Belfast

- Courses in Nottingham