- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

682 Courses

Keep your drivers informed, compliant, and confident behind the wheel. Toolbox Talks are designed to improve driver knowledge, reduce risks, and support ongoing transport compliance. Each course tackles real-world challenges with clear, practical guidance drivers can apply immediately. 📲 24/7 online access for 3 months – start anytime, on any device!

Keep your drivers informed, compliant, and confident behind the wheel. Toolbox Talks are designed to improve driver knowledge, reduce risks, and support ongoing transport compliance. Each course tackles real-world challenges with clear, practical guidance drivers can apply immediately. 📲 24/7 online access for 3 months – start anytime, on any device!

NPORS Appointed Person Course or Training NPORS Appointed Person Lifting Operations Training is aimed at anyone who is required to plan safe systems of work using lifting equipment and to gain the NPORS Appointed Person operator card. The aim of the course is to provide candidates with underpinning knowledge to prepare them for the role and responsibility. It is recommended that prior to attending this course individuals should have some experience of working with lifting equipment, especially mobile cranes. It is important that all delegates have a good understanding of spoken and written English for the appointed person course. NPORS is an approved CSCS Partner Card Scheme, firstly providing evidence that individuals working on construction sites have the appropriate training and qualifications but more importantly for the safe operation of the appointed person. Furthermore, training criteria is based on the approved standards of the Construction leadership Council. Experienced Appointed Person Test For experienced Appointed Persons you must complete a 1 day refresher training course. For refresher training you must have held a certificate or card in the past Appointed Person Course Duration: Experienced Worker Test: 1 day refresher training, maximum of 6 candidates Novice: 5 day’s training, maximum of 6 candidates Location*: Tewkesbury or at our clients’ site nationwide Mileage and accommodation charges may apply Certification NPORS Traditional card – lasts for 5 years and is mainly accepted with housebuilders, utilities, port and marine as proof of competence OR NPORS card with CSCS logo – accepted by all major building contractor’s. The initial card is the RED trained operator card which lasts for 2 years and can be upgraded to BLUE competent operator card further to completion of relevant NVQ. CSCS Health & Safety Test If you require the NPORS Appointed Person Red operator card with the CSCS logo on then you must have completed the operatives health and safety test within the last two years. In house certificates: suitable as proof of operator competence accepted for insurance and HSE compliance. The Appointed Person Course Includes: This Appointed Person Course covers essential legislation, crane appreciation, lifting accessories, and planning lifting operations. It culminates in writing a risk assessment and method statement. Legislation LOLER, PUWER, HASAWA. Codes of practice BS7121. Roles and responsibilities of personnel involved with lifting operations. Crane appreciation, crane types, capabilities and limitations. Duty charts. Crane terminology. Documentation and certification for lifting equipment and lifting accessories. Crane stability/ground conditions. Safe Load Indicators (SLI) and Safe Working Loads (SWL). Lifting accessories. Types of accessories and use. Slinging techniques. Down rating of accessories. Sling angles. Communications. Planning a lifting operation. Writing a risk assessment (end test). Writing a method statement (end test). Appointed Person Training Available 7 days a week to suit your business requirements. VPT have a team of friendly and approachable instructors, who have a wealth of knowledge of lifting equipment and the construction industry We have our own training centre conveniently located close to the M5 junction 9, In Tewkesbury. With its own purpose-built practical training area to simulate an actual working environment for the AP Course. Our Appointed Person training and test packages are priced to be competitive. Discounts are available for multiple bookings We can send a fully qualified NPORS Appointed Person Tester to your site nationwide, to reduce the amount of time away from work Frequently Asked Questions 1. What is the NPORS Appointed Person Lifting Operations Training? This training is designed for individuals required to plan safe systems of work using lifting equipment. It provides the knowledge necessary to prepare for the role and responsibilities of an Appointed Person. 2. Who should take this course? Anyone involved in planning and managing lifting operations, especially those with prior experience with lifting equipment, should take this course. 3. What does the course cover? The course covers legislation, codes of practice, roles and responsibilities, types of cranes, duty charts, lifting accessories, risk assessment, and method statement preparation. 4. How long is the course? The course duration is 5 days for novices and 1 day for experienced individuals seeking a refresher. 5. What certification do I receive upon completion? Participants receive an NPORS Appointed Person operator card, valid for 5 years or an NPORS card with CSCS logo. 6. Are there any prerequisites? Candidates should have a good understanding of English. For the NPORS card with CSCS logo, a CSCS Health & Safety test must have been completed within the last two years. Our more courses: Polish your abilities with our dedicated Lift Supervision Training, Slinger Signaller Training, Telehandler Training, Cat & Genny Training, Plant Loader Securer, Ride-On Road Roller, Abrasive Wheel Training, Lorry Loader Training and Scissor Lift Training sessions. Learn the safe and effective operation of these vital machines, crucial for construction and maintenance tasks. Elevate your skills and career prospects by enrolling in our comprehensive courses today.

Level 2 Diploma in JavaScript Course

By One Education

Ready to make JavaScript less of a mystery and more of a skill you actually understand? This Level 2 Diploma in JavaScript is a refreshing take on learning one of the most widely-used programming languages on the internet. Whether you're aiming to build dynamic websites or improve your coding fluency, this course delivers clarity and confidence without overwhelming you with jargon. It takes you through JavaScript’s essential concepts—like variables, functions, objects, loops, and logic—with a rhythm that’s structured for those who enjoy learning with purpose. Written with a modern developer's mindset in mind (but no flashy nonsense), this course avoids empty filler and gets straight to the core of what you need to know. Whether you're enhancing your knowledge or brushing up on what you forgot last Tuesday, each module builds logically on the last, encouraging solid, repeatable understanding. If JavaScript ever felt like an unsolvable puzzle, this diploma gives you the pieces in the right order—so things actually click. Learning outcomes: Upon completing the JavaScript Basics course, learners will be able to: Understand the fundamentals of JavaScript programming, including data types, variables, and functions. Create basic JavaScript programs to perform simple tasks, such as manipulating HTML elements and responding to user interactions. Develop a strong understanding of JavaScript scope and how to work with objects and arrays. Write more complex JavaScript programs using advanced programming concepts such as loops, conditionals, and events. Implement string manipulation and data validation in their JavaScript code. The JavaScript Basics course is designed to provide learners with a foundational understanding of JavaScript programming. This course is perfect for beginners who are interested in learning the basics of JavaScript, as well as developers who want to refresh their knowledge of the language. The course covers everything from the basics of JavaScript syntax to more advanced programming concepts such as events and loops. Learners will also gain practical experience by working on real-world examples and projects. This course is taught by industry experts who have years of experience in JavaScript development. They will provide learners with a comprehensive understanding of JavaScript programming and how it can be used to create interactive and dynamic web applications. The course is designed to be self-paced, allowing learners to work at their own speed and learn at their own convenience. â±â±Level 2 Diploma in JavaScript Course Curriculum Section 01: JavaScript Introduction Section 02: JavaScript Examples Section 03: JavaScript Data Types Section 04: JavaScript Objects and Functions Section 05: Java Script Scope Section 06: JavaScript Events and String How is the course assessed? Upon completing an online module, you will immediately be given access to a specifically crafted MCQ test. For each test, the pass mark will be set to 60%. Exam & Retakes: It is to inform our learners that the initial exam for this online course is provided at no additional cost. In the event of needing a retake, a nominal fee of £9.99 will be applicable. Certification Upon successful completion of the assessment procedure, learners can obtain their certification by placing an order and remitting a fee of __ GBP. £9 for PDF Certificate and £15 for the Hardcopy Certificate within the UK ( An additional £10 postal charge will be applicable for international delivery). CPD 10 CPD hours / points Accredited by CPD Quality Standards Who is this course for? Beginners who want to learn the fundamentals of JavaScript programming. Developers who want to refresh their knowledge of JavaScript. Individuals who want to create dynamic and interactive web applications. Students who want to prepare for a career in web development. Professionals who want to expand their skillset and stay competitive in the job market. Requirements There are no formal entry requirements for the course, with enrollment open to anyone! Career path Web Developer Front-End Developer Full-Stack Developer JavaScript Developer Software Engineer Certificates Certificate of completion Digital certificate - £9 You can apply for a CPD Accredited PDF Certificate at the cost of £9. Certificate of completion Hard copy certificate - £15 Hard copy can be sent to you via post at the expense of £15.

MI Skills Club for Educational Psychologists (MISC)

By The Ed Psych Coach

If you have already undertaken some training in Motivational Interviewing (at least half a day)*, you are welcome to join our MI Skills Club (MISC), which is a free community group for Educational Psychologists wishing to practise their MI skills within a small and friendly group. Because MI is a conversational style, rather than a discrete skill, it is not something that can be mastered by attending a one-off training session. While MI is a learnable approach, it takes practice, reflection and supervision to improve. Learning MI on your own is hard, and receiving objective feedback and expert feedback are helpful in developing and maintaining competence in MI (Miller & Rollnick, 2023). Cathy Atkinson and Fi Coley, who are both members of the Motivational Interviewing Network of Trainers (MINT), are collaborating to build an MI Learning Community for EPs. MINT (2019) defines a learning community as a network of practitioners interested in the same topic, and the community can serve as both a resource and a forum for developing practice. In each 90-minute online session we will focus on one small aspect of MI (micro-skills practice) and use breakout rooms with small groups to practice skills and give /receive supportive feedback. This event is open to Educational Psychologists, Trainee Educational Psychologists, and Assistant Psychologists. We are unable to accommodate aspiring EPs at this event. *If you are just starting out on your MI journey, or you would like to refresh your skills, you can join our one-day Introduction and Refresher training on Friday 27th September 2024 - Motivational Interviewing for Ed Psychs: Introduction and Refresher Tickets, Fri 27 Sep 2024 at 09:00 | Eventbrite

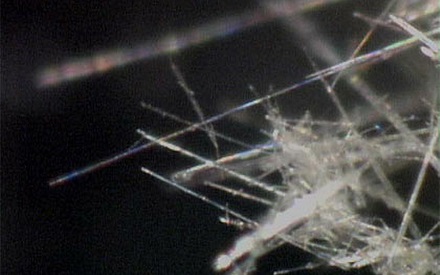

BOHS/OHTA W504 - Asbestos and other fibres

By Airborne Environmental Consultants Ltd

P404 Air Sampling of Asbestos and MMMF and Requirements for a Certificate of Reoccupation Following Clearance of Asbestos is the industry standard qualification for those whose work involves air sampling and clearance testing, such as asbestos analysts. In addition to holding the qualification, they are required to undertake and provide evidence of annual refresher training. RP404 Refresher is a new course, specifically designed to meet this requirement. RP404 Refresher enables candidates to revise and update their knowledge on air sampling and clearance testing techniques, and to receive a certificate of course completion by passing a written examination, which covers both the theory and practice of air sampling and clearance testing.

WordPress Academy: Learn WordPress Step by Step

By Packt

This course will help you to master all the skills you require to become a successful web designer using WordPress.

Search By Location

- Refresher Courses in London

- Refresher Courses in Birmingham

- Refresher Courses in Glasgow

- Refresher Courses in Liverpool

- Refresher Courses in Bristol

- Refresher Courses in Manchester

- Refresher Courses in Sheffield

- Refresher Courses in Leeds

- Refresher Courses in Edinburgh

- Refresher Courses in Leicester

- Refresher Courses in Coventry

- Refresher Courses in Bradford

- Refresher Courses in Cardiff

- Refresher Courses in Belfast

- Refresher Courses in Nottingham