- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Educators providing Vehicle Maintenance courses in Coventry

We couldn't find any listings for your search.

Know someone teaching this? Help them become an Educator on Cademy.

Courses matching "Vehicle Maintenance"

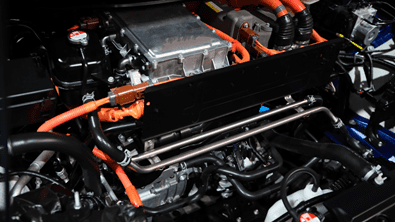

Show all 4Hybrid & Electric Vehicle Training

By PFTP Ltd

Course Details: The level 1, 2 & 3 hybrid and electric vehicle mechanic courses include; Classroom based theory session Workshop practice session Examination and assessment Course Fees: Level 1 £160 + VAT per candidate Level 2 £396 + VAT per candidate Level 3 £659 + VAT per candidate Electric & Hybrid Course Information: IMI LEVEL 1 AWARD IN EV AWARENESS This programme is designed for individuals who may encounter electric/hybrid (all variations) vehicles and require safety awareness. It is suitable for non-technical people working in roles such as: Valeters Parts Sales and aftersales It is also suitable for individuals working in roles such as: Vehicle recovery Vehicle dismantlers Vehicle damage assessors Electric/hybrid professional vehicle drivers. LEVEL 2 AWARD IN ELECTRIC/HYBRID VEHICLE ROUTINE MAINTENANCE ACTIVITIES This award is designed for technicians who maintain and repair electric/hybrid vehicles. It contains the skills and knowledge required to work safely around a vehicle’s high & low voltage electrical system and electric drive train system, whilst carrying out repairs or maintenance. As a result, learners successfully completing this qualification will acquire significant core knowledge and skills and the ability to work safely around and maintain Electric/Hybrid vehicles. LEVEL 3 AWARD IN ELECTRIC/HYBRID VEHICLE REPAIR AND REPLACEMENT The content of this qualification has been designed to give the learners the knowledge and skills required to work safely on Electric/Hybrid vehicles whilst carrying out diagnostic, testing and repair activities. This may include vehicles that may have or had damage to their high energy/electrical system. As a result, learners successfully completing this qualification will acquire significant core knowledge and skills, and the ability to remove and replace Electric/Hybrid vehicle high voltage components Entry Requirements The selection criteria for entry should take into account each applicants existing academic/vocational qualifications and experience. Level 1 EV awareness There is no eligibility requirement. Level 2 electric & hybrid vehicle training course Individuals will already have vehicle maintenance and repair knowledge and skills at level 2. Level 3 electric & hybrid vehicle training course Individuals will already have vehicle maintenance and repair knowledge and skills at level 3. Candidates who already hold the EV Level 2 qualification can do a one-day Level 3 Assessment In order to pass these qualifications, learners must demonstrate its learning outcomes by following and achieving its assessment components: a. IMI External Testing (online) b. IMI Practical Assessment What’s included: Support from fully qualified and experienced trainers Course training material Registration with the awarding body Examinations Fees and Certification To find out more, please use the live chat function, visit our contact page or call us on 024 76325880 Get up to speed with industry changes The automotive industry is constantly changing, but more so than ever before. The shift to electric vehicles is only going to continue to grow as environmental and consumer needs change. As hybrid and electric vehicles become more and more mainstream, mechanics/technicians must have the right skills and knowledge to keep up with new technologies and the demand for their maintenance and repair. This course is designed to teach you how to safely and effectively work on hybrid and electric vehicles as well as keep up with the constantly evolving technology. Upon completion of this electric vehicle training course, technicians will be able to demonstrate they have the skills and knowledge needed for repairing vehicles with high voltage hybrid and electrical technologies. Future-proofed skills As more consumers make the shift to hybrid and electric vehicles, the demand for knowledgeable mechanics is increasing exponentially. This new market is ideal to expand your customer base and grow your business. Safety is always the number one priority for any vehicle technician, this course will teach you how to approach an electric vehicle and work on it safely. Our experienced instructors will teach you invaluable skills such as disengaging battery cells and the different hazards associated with high-energy electricals. Electric vehicles are quickly becoming a common sight on UK roads and will soon be the new normal, ensuring you get ahead of the trend with our electric car mechanic course means you will be ready for when the vast majority of your customers are in these types of cars.

Maintenance and operation (M&O) of engineering plant and services (In-House)

By The In House Training Company

M&O of engineering plant and services is becoming more important to the success of the core business. To select the right M&O technique for specific plant and equipment it is necessary to know what options are available, what they deliver and how they should be implemented. This course will help you consider options and techniques that provide best value based on that thorough understanding of the business need. M&O will increasingly be required to demonstrate it is delivering the optimum of cost and value and the main purpose of the course is to show how this can be achieved. Note: this is a purely indicative list of topics that can be covered. The content, duration, objectives and material used would all be adapted to match your specific requirements. This course will help you: Determine what the business needs from the M&O service Determine the cost and value of the various M&O options Prepare and present the business case for the selected M&O strategy Introduce meaningful KPIs based on performance-based service by the M&O provider Undertake a review of current M&O and make recommendations for improvement Introduce energy and carbon management performance criteria in M&O Better deal with project risk and uncertainties Motivate others to deliver a reliable and cost effective M&O service Note: this is a purely indicative list of topics that can be covered. The content, duration, objectives and material used would all be adapted to match your specific requirements. 1 What is maintenance and what is operation? - their relative importance to the business 2 Comparison of the various maintenance options and techniques, including: Planned preventative Run to failure Condition monitoring Business focused Business critical Total productive Reliability centred maintenance 3 Forms of contracts and service, including: Comprehensive Input driven Output driven Limited replacement Performance based M&O 4 Selecting the right options and making the business case 5 Continuous commissioning as a tool for delivering best value 6 Case studies

Reliability centred maintenance (In-House)

By The In House Training Company

Reliability Centred Maintenance (RCM) is commonly used to help establish safe minimum levels of maintenance, determine changes to operating procedures and help establish maintenance regimes and plans. Successful implementation can result in cost savings, machine uptime and improved risk management. But the devil's in the detail - how can you achieve these benefits and successfully implement RCM in your organisation? This programme will help you do just that. Note: this is a purely indicative outline. The content, duration, objectives and material used can all be adapted to match your specific requirements. To provide a better understanding of RCM, particularly: What, why, how and who? Opportunities and benefits Risks Cost effectiveness Note: this is a purely indicative outline. The content, duration, objectives and material used can all be adapted to match your specific requirements. 1 What is maintenance? Why maintain? Traditional maintenance methods Common current practices and trends 2 What is Reliability Centred Maintenance? Its history Its development Current usage Where can it be cost-effective? 3 How does it work? Basic features Key criteria Maintenance options Key outcomes 4 Making the business case and preparing the strategy Identifying and quantifying current risks Identifying and quantifying current costs Motivating decision-makers Identifying and empowering those who have to deliver the results Educating / gaining buy-in from interested parties 5 Implementation Identify business functions Prioritise functions Verify correct usage Identify failure modes Identify the consequences of failure Understand the failure process Specify the appropriate maintenance action(s) 6 Ongoing requirements Monitoring Recording Analysis Continuous re-evaluation 7 Open discussion Sharing experience and addressing specific issues of interest to participants Course review Close

Search By Location

- Vehicle Maintenance Courses in London

- Vehicle Maintenance Courses in Birmingham

- Vehicle Maintenance Courses in Glasgow

- Vehicle Maintenance Courses in Liverpool

- Vehicle Maintenance Courses in Bristol

- Vehicle Maintenance Courses in Manchester

- Vehicle Maintenance Courses in Sheffield

- Vehicle Maintenance Courses in Leeds

- Vehicle Maintenance Courses in Edinburgh

- Vehicle Maintenance Courses in Leicester

- Vehicle Maintenance Courses in Coventry

- Vehicle Maintenance Courses in Bradford

- Vehicle Maintenance Courses in Cardiff

- Vehicle Maintenance Courses in Belfast

- Vehicle Maintenance Courses in Nottingham