- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Introduction to Power Systems

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Training (VILT) This course will provide a comprehensive, foundational content for a wide range of topics in power system operation and control. With the growing importance of grid integration of renewables and the interest in smart grid technologies, it is more important than ever to understand the fundamentals that underpin electrical power systems. This course provides a thorough understanding of all basic terminology and concepts of electrical systems, structure of a power system, transmission line parameters, insulators, high-voltage direct current transmission, substation and neutral grounding, distribution system, circuit breakers, relaying and protection, power system stability, economic operation of power systems, load frequency control, voltage and reactive power control, renewable energy sources, restructuring of electrical power systems, and smart grids. This course is a MUST for practitioners, consultants, engineers of all disciplines, managers, technicians and all technical personnel who need to learn about electrical power systems. Training Objectives Basic Terminology and Concepts of Electrical Systems: Gain an understanding of the basic terminology and concepts of electrical systems and the structure of a power system Transmission Line Parameters: Learn in detail all the transmission line parameters including line resistance, line inductance, transposition of transmission lines, and capacitance of transmission lines Insulators: Understand thoroughly all the various types of insulators, pin type insulators, suspension type or disc insulators, strain insulators, and testing of insulators High-Voltage Direct Current Transmission: Determine the advantages and disadvantages of high voltage direct current transmission, and gain an understanding of all the features of high-voltage direct current transmission Substations and Neutral Grounding: Gain a detailed understanding of all substation equipment, factors governing the layout of substations, station transformers, elements to be earthed in a substation, power system earthing, earthing transformers, bus bar arrangements and gas-insulated substations Distribution System: Learn about the effects of voltage on the conductor volume, distributor fed from one end, distributors fed from both ends at the same voltage, distributors fed from both ends at different voltages, and alternating current distribution Circuit Breakers: Learn about the classification of circuit breakers, plain-break oil circuit breakers, air break circuit breaker, air blast circuit breakers, vacuum circuit breakers, SF6 circuit breakers, rating and testing of circuit breakers Relaying and Protection: Learn all the requirements of relaying, zones of protection, primary and backup protection, classification of relays, electromagnetic relays, induction relays, feeder protection, phase fault protection, reactance relay, static overcurrent relay, differential protection, transformer protection, Buchholz relays, alternator protection restricted earth fault protection, rotor earth fault protection, and negative-sequence protection Economic Operation of Power Systems: Gain an understanding of steam power plants, heat rate characteristics and characteristics of hydro plants Load Frequency Control: Learn about speed governing mechanism, speed governor, steady state speed regulations and adjustment of governor characteristics Voltage and Reactive Power Control: Gain an understanding of impedance and reactive power, system voltage and reactive power, voltage regulation and power transfer Renewable Energy Sources: Learn about solar power, wind power, geothermal energy, biomass and tidal power Restructuring of Electrical Power Systems: Gain an understanding of smart grids, smart grid components, smart grid benefits, and open smart grid protocol Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Course Level Basic or Foundation Training Methods The VILT will be delivered online in 5 half-day sessions comprising 4 hours per day, with 2 x 10 minutes break per day, including time for lectures, discussion, quizzes and short classroom exercises. Additionally, some self-study will be requested. Participants are invited but not obliged to bring a short presentation (10 mins max) on a practical problem they encountered in their work. This will then be explained and discussed during the VILT. A short test or quiz will be held at the end the course. The instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all the delegates gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: 'ELECTRICAL EQUIPMENT HANDBOOK' published by McGraw-Hill in 2003 (600 pages) Introduction to Power Systems Manual (500 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

Overview The International English Language Testing System (IELTS) measures the language proficiency of people who want to study or work where English is used as a language of communication. We offer both group and private IELTS preparation courses. Online Trainer led IELTS Coaching. Our method Throughout the course students work on all four modules; listening, reading, writing, and speaking. We also help our students with the grammar and vocabulary knowledge they need to achieve their band score. We believe that the best way to learn exam English is to relate it to real life. Our trainer will show you how your IELTS skills can be used in every day situations and will help to achieve higher bands and fulfil the requirement of the universities and colleges.

Advanced DNS training course description This two-day hands on DNS training course studies both the UNIX BIND and the Microsoft (MS DNS) implementations. The course follows on from our Definitive DNS for engineers course starting with best practices. The majority of the course is spent on securing DNS and in particular DNSSEC. Some parts are specific to BIND. Students choose whether to use Windows or UNIX for the hands on sessions. What will you learn Implement DNS best practices. Harden DNS servers. Install, configure, maintain and troubleshoot DNSSEC. Advanced DNS training course details Who will benefit: Technical staff wanting to learn DNS including: Network personnel. System administrators. Prerequisites: Total DNS for engineers Duration 2 days Advanced DNS training course contents Best practices MX and PTR records, lame delegations, disallowing recursion, TTLs, online testing. Hands on Review of your DNS servers. Split DNS Partitioning internal and external DNS, views. Hands on Implementing split DNS. Hardening DNS ACLs, recursion, queries, trusted sources, chroot jail, secure BIND template. Hands on Securing the DNS server. DNSSEC What is DNSSEC? DNSSEC benefits, DNSSEC RRs. DNSKEY, RRSIG, NSEC, DS. Hands on Creating DNSSEC keys. Securing zone transfers TSIG, shared secret. Securing DDNS. Hands on Secure file transfers. Zone integrity Trusted anchors, Chains of trust, Zone status, Zone signing, Keys. ZSK, KSK, adding keys to a zone file. Secure delegations. Hands on Zone signing Maintaining Signed zones Key rollover, pre publish, double signing, rollover cache.

Lubricants Blending and Quality Assurance (Accredited by the United Kingdom Lubricants Association (UKLA))

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Training (VILT) Accredited by the United Kingdom Lubricants Association (UKLA), this 4 half-day Virtual Instructor Led Training (VILT) course will provide an in-depth understanding of the principles, economics and flexibility of lubricant blending plants and how to operate a lubricants blending plant efficiently and economically. The latest developments and trends in lubricant blending and the advantages and disadvantages of lubricant blending equipment, facilities and operations will be discussed. The importance of testing components and products for each blend, lubricant blend quality control and product quality management will also be explained. The VILT course will also clarify the importance of lubricant product filling, packaging and warehouse storage, strategies for optimising existing lubricant blending plant facilities and how to avoid or minimise problems with lubricant blending and product quality. The VILT course is recognised under the UKLA Continuing Professional Development (CPD) scheme for Registered Lubricant Professional. *There will be an examination for this VILT. Training Objectives This VILT course will enable you to: Learn about Mineral Oil Base Oils; API Groups I, II and III: Properties and Characteristics Acquire the knowledge about Synthetic Base Oils; API Groups IV and V: Properties and Characteristics Learn about Lubricant Additives: Properties and Characteristics Know the Lubricant Formulation and Ease of Blending Explore the Blending Plant Design: Grassroots Plants and Upgrading Existing Plants Learn about Blending Plant Equipment and Facilities and Their Operation Understand the Lubricant Blending Issues: Avoiding Problems Test and Analyse Base Oils and Additives Test and Analyse Blended Lubricants Explore the importance of Product Quality Control Understand the process of Lubricant Packaging and Filling Understand the process of Lubricant Storage Learn about Product Quality Management Target Audience This VILT course will be useful and applicable for: Middle and Senior managers to understand how and why to design and operate an efficient and profitable lubricant blending plant. Blending plant operators and specialists to improve and optimise current blending plant operations. Manufacturers of lubricants will understand how and why high quality components and effective testing during the entire blending process are important to final lubricant product quality and performance. Lubricant formulators will understand the importance of close communication and co-operation with blending plant managers and operators to minimise blending costs and to thereby maximise product profitability. Course Level Intermediate Training Methods The VILT course will be delivered online in 4 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. Course Duration: 4 half-day sessions, 4 hours per session (16 hours in total). Trainer Your expert course leader (CChem, MRC) has worked as Sales, Technical Marketing Manager and Company Director with over 50 years of broad experience in the lubricants, fuels, petroleum additives, with four leading companies Chevron, Ethyl Petroleum Additives Ltd, Texaco Limited and Kuwait Petroleum (GB) Ltd. His major recent responsibilities have been concerned with leading the Oil Industry Association United Kingdom Lubricants Association, and acting in an advisory capacity as Technical Director to the Association. He has acquired a wide experience in technical, marketing and sales within the oil industry. The related experience gained with the oil additives industry has provided him with special additional insights. He has also led the Certificate of Lubricant Competence course for the United Kingdom Lubricants Association (UKLA) for 11 years. He is a Chartered Chemist and a Member of the Royal Society of Chemistry. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

Broadband access training course description ADSL is a broadband technology providing fast Internet access (amongst other applications) over existing telephone lines. This course covers an overview of the DSL family, what ADSL is through to how ADSL works. What will you learn Describe what ADSL is. Describe how ADSL works. Describe the ADSL architecture. Recognise the limitations of ADSL. List the elements required for an ADSL installation. Broadband access training course details Who will benefit: Network engineers and anyone who will be working with ADSL. Prerequisites: Intro to data communications & networking Duration 2 days Broadband access training course contents What is ADSL? Broadband definitions, OSI layer 1, ADSL services, WANS. ADSL features: always on, point to point, Asymmetric, speeds. ADSL benefits, xDSL family, standards, history, example DSL forum documents. ADSL architecture The big picture, The PSTN and telephones, Digital and analogue, PSTN and modems, ADSL vs. modem speeds, Block 1: Customer premises, Block 2: The last mile, Block 3: The exchange, Block 4: the core network. Customer premises Splitters, micro filters, splitter architectures, Splitterless ADSL, ADSL modems, USB, ADSL routers. The local loop ADSL PHY, Some basics, ADSL margins, speed implications, distances, RADSL, Line testing, whoosh tests, line coding, multiple channels, FDM, echo cancellation, Modulation: AM, FM, PM, QAM, QAM constellations, DMT, CAP, Framing, Superframes, fast data mode, interleaved mode, RADSL revisited. The exchange Local exchange ADSL items, DSLAMs, ADSL racks, Contention. The core network The role of the core network, ATM, ATM VPI/VCI, ATM cells, ATM layers, AAL5, RAS, Home gateways. ADSL and the higher layers Layer 2 choices, PPPoA, PPP, CHAP, Layer 4 and above, ADSL and ATM. Installing and configuring ADSL Choosing providers, line activation, hardware requirements, Configuring layer 1 and layer 2, Configuring IP. Summary ITU ADSL standards

Apache training course description A hands on training course covering installation, configuration and management of the Apache web server. What will you learn Install Apache. Configure Apache. Manage Apache. Build static and dynamic web sites with Apache. Secure Apache. Apache training course details Who will benefit: Technical staff working with Apache. Prerequisites: TCP/IP foundation for engineers. UNIX fundamentals Duration 3 days Apache training course contents Installing Apache What is Apache? Apache versions, history, downloading Apache, source distribution, compilation, binary distribution, installation, platform considerations. Hands on Downloading and installing Apache. Controlling the Apache server Running Apache, automatic Apache start, starting, stopping, restarting Apache. Checking Apache status. Hands on Server control. Configuration Serving webpages, setting the document root, applying configuration changes, Configuration files, httpd.conf, syntax, directives, modules, utilities, turning features on/off. Hands on basic Apache configuration. More configuration MIME, URL mapping, content negotiation, indexing, performance tuning. Logging log file content, configuration, log file locations, error logging, browser errors, error page configuration, forbidden index pages. Hands on Log files. Security File permissions, .htaccess, protecting files with passwords, password files, authentication, restricting access by IP address. Secure HTTP HTTPS, installing mod_ssl, certificates, configuring mod_ssl, http and https coexistence Virtual hosts Multiple sites on one server, separate configuration files, IP based, name based, port based, virtual host names, enabling, defining, configuring, aliases, testing, https virtual hosts. Hands on Virtual hosts. Dynamic sites Dynamic sites, CGI, PHP, PERL, CGI programs, example CGI scripts, Apache and CGI, CGI parameters, CGI issues, PHP, mod_php, Perl and Apache, mod_perl, installing mod_perl. Hands on CGI, PHP and Perl with Apache. Modules What are modules, standard modules, loading modules, mod_speling, mod_rewrite, other special purpose modules, URL rewriting, redirection, URL transformation, browser dependent pages. Hands on Working with modules.

MPLS training course description A hands-on introduction to MPLS covering the basics of what MPLS is and how to configure it, through to more advanced concepts such as MPLS VPNs and traffic engineering with MPLS. What will you learn Describe MPLS Explain how MPLS works Describe the interaction between OSPF/IS-IS/BGP and MPLS Describe MPLS traffic engineering MPLS training course details Who will benefit: Anyone working with MPLS. Prerequisites: IP Routing BGP Duration 3 days MPLS training course contents What is MPLS? What does MPLS stand for? What is MPLS? Core MPLS, MPLS and the 7 layer model, MPLS is a protocol, MPLS is a standard, MPLS runs on routers, MPLS history, Why MPLS? For service providers, For enterprises. MPLS Architecture Label Switch Routers, two types of LSR, PE and P router roles, FEC, swapping labels, MPLS packet format, Loops, TTL control. Hands on: Building the base network. Enabling MPLS. Simple testing and troubleshooting of MPLS. Label distribution Label review, label switch path, label distribution methods, piggybacking, Label distribution Protocols, LDP, LDP operation, LDP packets, discovery messages, session messages, advertisement messages, notification message, Label Information Base, routing tables, the LFIB, MPLS forwarding, penultimate hop popping, handling labels, LSP control modes, when to distribute labels, how long to keep labels, aggregation, label merging. Hands on: LDP traffic analysis. MPLS TE and QoS What is MPLS TE? Why TE? TE versus shorted path, how MPLS TE works, CR-LDP, OSPF-TE, IS-IS-TE, TE with BGP, RSVP-TE, MPLS Fast reroute, MPLS QoS. Hands on: Enabling MPLS-TE. BFD BFD, hello the BFD protocol. MPLS VPN What is a VPN? MPLS VPN types, MPLS VPN comparison, MPLS L3 VPN, VRFs, MBGP, MPLS VPN architecture, VRF RD, VRF RT, the label stack, L2 VPNs, VPWS, AToM, VPLS. Hands on: MPLS L3 VPN setup, troubleshooting.

Industrial Instrumentation and Modern Control Systems

By EnergyEdge - Training for a Sustainable Energy Future

About this training course This 5 full-day course provide a comprehensive understanding of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, HART protocol, control valves, actuators, and smart technology. This course will focus on maximizing the efficiency, reliability, and longevity of these systems and equipment by providing an understanding of the characteristics, selection criteria, common problems and repair techniques, preventive and predictive maintenance. This course is a MUST for anyone who is involved in the selection, applications, or maintenance of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology because it covers how these systems and equipment operate, the latest maintenance techniques, and provides guidelines and rules that ensure their successful operation. In addition, this course will cover in detail the basic design, operating characteristics, specification, selection criteria, advanced fault detection techniques, critical components and all preventive and predictive maintenance methods in order to increase the reliability of these systems andequipment and reduce their operation and maintenance cost This course will provide the following information for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology: Basic Design Specification Selection Criteria Sizing Calculations Enclosures and Sealing Arrangements Codes and Standards Common Operational Problems All Diagnostics, Troubleshooting, Testing, and Maintenance Practical applications of smart instrumentation, SCADA, and Distributed Control Systems, control valves, actuators, etc in the following industries will be discussed in detail: Chemical and petrochemical Power generation Pulp and paper Aerospace Water and sewage treatment Electrical power grids Environmental monitoring and control systems Pharmaceutical plants Training Objectives Equipment Operation: Gain a thorough understanding of the operating characteristics of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Diagnostics and Inspection: Learn in detail all the diagnostic techniques and inspections required of critical components of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Testing: Understand thoroughly all the tests required for the various types of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Maintenance and Troubleshooting: Determine all the maintenance and troubleshooting activities required to minimize the downtime and operating cost of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Repair and Refurbishment: Gain a detailed understanding of the various methods used to repair and refurbish modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Efficiency, Reliability, and Longevity: Learn the various methods used to maximize the efficiency, reliability, and longevity of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Sizing: Gain a detailed understanding of all the calculations and sizing techniques used for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Design Features: Understand all the design features that improve the efficiency and reliability of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Selection: Learn how to select modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology by using the performance characteristics and selection criteria that you will learn in this course Equipment Enclosures and Sealing Methods Learn about the various types of enclosures and sealing arrangements used for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Commissioning: Understand all the commissioning requirements for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Codes and Standards: Learn all the codes and standards applicable for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Causes and Modes of Failure: Understand the causes and modes of failure of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology System Design: Learn all the requirements for designing different types of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: Industrial Instrumentation and Modern Control Systems Practical Manual (400 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

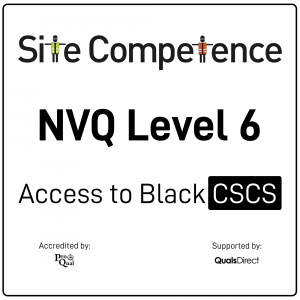

Black CSCS Card NVQ Level 6 Diploma in Construction Contracting Operations Management This qualification is designed for technical learners working in a wide range of job roles, for example estimator, quantity surveyor, buyer or planner. You will have responsibility for other people in their area of occupation. You could be site-based and have responsibility for functions such as dimensional control, surveys, physical testing and work planning. You may work across one or more of the following pathways: Estimating Buying Planning Surveying General Furthermore, this NVQ provides your recognition as a Construction Site Manager and offers you a route to professional memberships such as MCIOB. Induction - As soon as you register you will be given a dedicated assessor. They will arrange an induction and together with your assessor, you will decide on the pathway which best proves your competency. The induction is used to plan out how you will gather the relevant evidence to complete the course. During the course - The assessor will work with you to build a portfolio of evidence that allows you to showcase your knowledge, skills and experience. The assessor will also regularly review and provide you with feedback. This will allow you to keep on track to progress quickly. You will be assessed through various methods such as observations, written questions, evidence generated from the workplace, professional discussion and witness testimonials. On completion - Once all feedback has been agreed, the Internal Quality Assurer will review your portfolio and in agreement with your assessor the certificate will be claimed. To download our PDF for this course then please click here.

This Level 4 City and Guilds 2396-01 Design and Verification of Electrical Installations course has been designed to help develop the skills and up date the knowledge of the requirements to enable you to professionally design, erect and then verify an electrical installation. This course is aimed at those who will have responsibility for designing, supervising, installing and testing electrical installations. Further information can be found here: C&G 2396 Electrical Design Course — Optima Electrical Training (optima-ect.com)

Search By Location

- Testing Courses in London

- Testing Courses in Birmingham

- Testing Courses in Glasgow

- Testing Courses in Liverpool

- Testing Courses in Bristol

- Testing Courses in Manchester

- Testing Courses in Sheffield

- Testing Courses in Leeds

- Testing Courses in Edinburgh

- Testing Courses in Leicester

- Testing Courses in Coventry

- Testing Courses in Bradford

- Testing Courses in Cardiff

- Testing Courses in Belfast

- Testing Courses in Nottingham