- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

45 Surf courses in Manchester

Level 2 NVQ Certificate in Highways Maintenance - Excavation and Reinstatement Operations

By Dynamic Training and Assessments Ltd

Level 2 NVQ Certificate in Highways Maintenance - Excavation and Reinstatement Operations

Level 2 NVQ Certificate in Highways Maintenance - Kerbs and Channels

By Dynamic Training and Assessments Ltd

Level 2 NVQ Certificate in Highways Maintenance - Kerbs and Channels

PORTRAITS, PET PORTRAITS AND COMMISSIONS

By Wyllie Fox Tuition

Commission an original, traditional and quirky Portrait in oils, acrylics or digital sketches

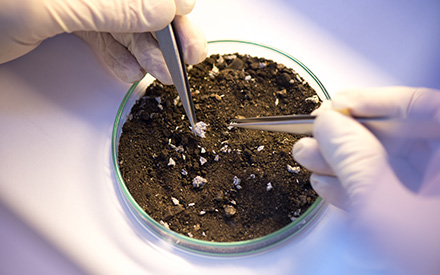

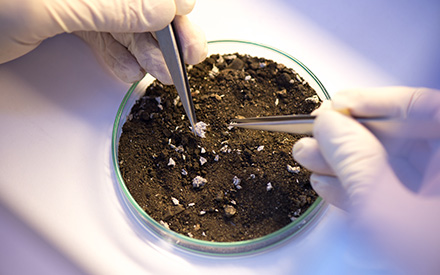

Non-licensed training for land remediation contractors

By Airborne Environmental Consultants Ltd

We have developed the non-licensed training to cover work for land remediation contractors working on asbestos-contaminated sites. Including: Interpretation of CAR Regulations to asbestos-contaminated land. This will include 'litter-picking' surface contamination and form contaminated soil. Site segregation, decontamination procedures and air monitoring expectations.

NVQ DIPLOMA IN DECORATIVE FINISHING – PAINTING AND DECORATING (CONSTRUCTION)

By Oscar Onsite

REFERENCE CODE 610/0054/0 COURSE LEVEL NVQ Level 3 THIS COURSE IS AVAILABLE IN Course Overview Who is this qualification for? This qualification is aimed at those who are involved in setting out and erecting masonry structures onsite working from drawings and specifications. The structures could be brick and blockwork or local materials. It is not expected that candidates working in this industry all do the same activities, so the qualification is structured to ensure that there is a high degree of flexibility within the units available and will allow employees from companies of all sizes and specialisms equal opportunity to complete. To provide this opportunity in addition to the mandatory units’ candidates will also be able to select optional units recognising specific skills What is required from candidates? Qualifications are now required to indicate the total qualification time (TQT), this is to show the typical time it will take someone to attain the required skills and knowledge to meet the qualification criteria, this qualification has a TQT of 610 hours. Qualifications are also required to indicate the number of hours of teaching someone would normally need to receive in order to achieve the qualification. These are referred to as Guided Learning Hours (GLH). The GLH for this qualification is 334. Group A MANDATORY UNITS Level Credit Confirming Work Activities and Resources for an Occupational Work Area in the Workplace Developing and Maintaining Good Occupational Working Relationships in the Workplace Confirming the Occupational Method of Work in the Workplace Conforming to General Health, Safety and Welfare in the Workplace Erecting and Dismantling Access/Working Platforms in the Workplace Preparing surfaces for painting and/or decorating in the workplace Applying surface coatings by brush and roller in the workplace Optional units Group A – Minimum of 1 unit must be achieved from this group Hang wallcoverings (standard and foundation papers) in the workplace Hanging non-standard width wallcoverings in the workplace 3 20 Optional units Group B-Minimum of 1 unit must be achieved from this group Applying coatings by the airless spray method in the workplace Summary of the: LEVEL 3 NVQ DIPLOMA IN DECORATIVE FINISHING-PAINTING AND DECORATING (CONSTRUCTION) Producing and applying complex stencils in the workplace 3 21 Hanging wallcoverings to complex surfaces in the workplace 3 32 Hanging wallcoverings (specialised paper) in the workplace 4 30 Assessment Guidance: Evidence should show that you can complete all of the learning outcomes for each unit being taken. Types of evidence: Evidence of performance and knowledge is required. Evidence of performance should be demonstrated by activities and outcomes, and should be generated in the workplace only, unless indicated under potential sources of evidence (see below). Evidence of knowledge can be demonstrated though performance or by responding to questions. Quantity of evidence: Evidence should show that you can meet the requirements of the units in a way that demonstrates that the standards can be achieved consistently over an appropriate period of time. Potential sources of evidence: The main source of evidence for each unit will be observation of the candidate’s performance and knowledge demonstrated during the completion of the unit. This can be supplemented by the following types of physical or documentary evidence: Accident book/reporting systems Photo/video evidence Safety records Work diaries Training records Timesheets Audio records Telephone Logs Job specifications and documentation Meeting records Delivery Records Records of toolbox talks Witness testimonies Equipment Correspondence with customers Prepared materials and sites Notes and memos Completed work Please Note that photocopied or downloaded documents such as manufacturers or industry guidance, H&S policies, Risk Assessments etc, are not normally acceptable evidence for these qualifications unless accompanied by a record of a professional discussion or Assessor statement confirming candidate knowledge of the subject. If you are in any doubt about the validity of evidence, please contact Oscar Onsite Academy

DIPLOMA IN FLOORCOVERING OCCUPATIONS (CONSTRUCTION)

By Oscar Onsite

REFERENCE CODE 603/5285/1 COURSE LEVEL NVQ Level 2 THIS COURSE IS AVAILABLE IN Course Overview Who is this qualification for? This is a work-based learning qualification for those involved in laying floorcoverings in a Construction related working environment. Although many of the skills and knowledge across floorcovering occupations are generic, not all those employed to fit floorcoverings will be fitting the same product. The group of optional units will allow specialisms of timber based, textile and resilient floorcoverings. What is required from candidates? To achieve this pathway unit the survey work must be carried out in ways that will minimise the risk of damage to the work and surrounding area and using and maintaining equipment effectively. This qualification is made up of 9 mandatory units and a group of optional units. The minimum credit value of this qualification is 127 credits. Qualifications are now required to indicate the total qualification time (TQT), this is to show the typical time it will take someone to attain the required skills and knowledge to meet the qualification criteria, this qualification has a TQT of 1,270 hours. Qualifications are also required to indicate the number of hours of teaching someone would normally need to gain the skills and knowledge to achieve the qualification. These are referred to as Guided Learning Hours (GLH). The GLH for this qualification is 543 Mandatory units Level Credit Conforming to General Health, Safety and Welfare in the Workplace Conforming to Productive Working Practices in the Workplace Moving, Handling and Storing Resources in the Workplace Surface preparation to receive floorcoverings in the workplace Setting out for laying floorcoverings in the workplace Preparing and fitting underlays for floorcoverings in the workplace Develop customer relationships Assessing and preparing background surfaces for floor-covering in the workplace Assessing and evaluating conditions for floorcoverings in the workplace Optional Units (Minimum of 18 credits) Installing timber–based floorcoverings in the workplace Summary of the: GQA NVQ LEVEL 2 DIPLOMA IN FLOORCOVERING OCCUPATIONS (CONSTRUCTION) Installing textile floorcoverings in the workplace Installing resilient floorcoverings in the workplace Types of evidence: Evidence of knowledge is required. Evidence of knowledge through performance can contribute and if applicable should be demonstrated by completing projects and reports, by responding to questions or through Professional/Guided Discussions. Quantity of evidence: Evidence should show that you can meet the requirements of the units consistently over an appropriate period of time. Potential sources of evidence: Suggested sources of evidence are shown above, these can be supplemented by physical or documentary evidence, e.g.: Accident book/reporting system Notes and memos Safety record Telephone/e-mail records Training record Customer and colleague feedback Audio evidence Records of equipment and materials Witness testimonies Work records Photographic/ video evidence Please Note that photocopied or downloaded documents such as manufacturers or industry guidance, H&S policies, Risk Assessments etc, are not normally acceptable evidence for GQA qualifications unless accompanied by a record of a professional discussion or assessor statement confirming candidate knowledge of the subject. If you are in any doubt about the validity of evidence, please contact Oscar Onsite Academy

DIPLOMA IN INSULATION AND BUILDING TREATMENTS

By Oscar Onsite

REFERENCE CODE 601/3040/4 COURSE LEVEL NVQ Level 3 THIS COURSE IS AVAILABLE IN Course Overview Who is this qualification for? This qualification is aimed at those who are involved in carrying out insulation or associated treatments to buildings; the qualification is at Level 3 and should be by those who are experienced and capable of dealing with a wide range of problems and situations and working with installations that have complex requirements. Candidates may take a technical or supervisory role, particularly in relation to less-experienced colleagues. They will also work closely with customers/clients and have well-developed customer service skills. The qualification is designed to ensure that there is a high degree of flexibility to complete by having pathways for a wide range of occupational roles and specialisms. All work must be carried out in accordance with Building Regulations and Industry recognised safe working practices, including the disposal of waste. What is required from candidates? GQA qualifications are made up of a number of units that have a credit value or credits. This qualification consists of 5 mandatory units and 6 pathways to cover occupational roles in External Wall Insulation, Cavity Wall Insulation, Loft insulation, Draught Proofing, Internal insulation and insulation to Framed Sections of Buildings. Candidates must complete all 5 mandatory units which have a total credit value of 23 credits and the required credits from the selected pathway. Dependent on the pathway selected the qualification has a total credit value ranging from 59 credits to 91 credits The units are made up of the things those working in these job roles need to know to be able to do to carry out the work safely and correctly. These are called Learning Outcomes, and all must be met to achieve the unit. Mandatory units Level Credit Maintain, promote and monitor Health and Safety in the Insulation and Building Treatments working environment Environmental Issues in the Insulation and Building Treatments working environment Identify and confirm requirements, resources and methods of work to carry out workplace activity Communication and teamwork in Insulation and Building Treatment activities Understanding Building Regulations and Legislation that apply to the Insulation and Building Treatments working environment Pathway 1 External Wall Insulation D/503/3042 Applying Surface Finishes to External Wall Insulation in the Workplace 2 19 Installing External Wall Insulation in the Workplace 2 19 Setting Out and Installing External Wall Insulation and Applying Surface Finishes to Buildings with Non-Routine or Complex Features Pathway 2 Cavity Wall Insulation Installing Cavity Wall Insulation in the Workplace 2 18 Setting Out and Installing Cavity Wall Insulation to Buildings with Non-Routine or Complex Features 3 24 Pathway 3 Loft Insulation Installing Loft Insulation in the Workplace Setting Out and Installing Loft Insulation to Buildings with Non-Routine or Complex Features Pathway 4 Draught Proofing Installing Draught-proofing to Openings in the Workplace 2 12 Setting Out and Installing Draught-Proofing to Openings with Non-Routine or Complex Features 3 30 Pathway 5 Internal Insulation to Walls, Floors or Ceilings Installing Internal Insulation to Walls, Floors or Ceilings in the Workplace Setting Out and Installing Internal Insulations to Walls, Floors or Ceilings to Buildings with Non-Routine or Complex Features Pathway 6 Insulation to Framed Sections of Buildings Installing Insulation to Framed Sections of Buildings in the Workplace 2 19 Setting Out and Installing Insulation to Framed Sections of Buildings with Complex or Non-Routine Features in the Workplace Assessment Guidance Evidence should show that you can complete all of the learning outcomes for each unit being taken. Types of evidence: Evidence of performance and knowledge is required. Evidence of performance should be demonstrated by activities and outcomes, and should be generated in the workplace only, unless indicated under potential sources of evidence (see below). Evidence of knowledge can be demonstrated though performance or by responding to questions. Quantity of evidence: Evidence should show that you can meet the requirements of the units in a way that demonstrates that the standards can be achieved consistently over an appropriate period of time. Potential sources of evidence: The main source of evidence for each unit will be observation of the candidate’s performance and knowledge demonstrated during the completion of the unit. This can be supplemented by the following types of physical or documentary evidence: Accident book/reporting system Photo/video evidence Safety records Work diaries Training records Timesheets Audio evidence Telephone logs Job specifications and documentations Delivery records Witness testimonies Equipment Correspondence with customers Prepared sites and structures Notes and memos Completed sites and structures Please Note that photocopied or downloaded documents such as manufacturers or industry guidance, H&S policies, Risk Assessments etc, are not normally acceptable evidence for GQA qualifications unless accompanied by a record of a professional discussion or Assessor statement confirming candidate knowledge of the subject. If you are in any doubt about the validity of evidence, please contact Oscar Onsite Academy

Asbestos in soils and contaminated land

By Airborne Environmental Consultants Ltd

The course covers investigation and risk assessment of asbestos-contaminated soils and sites, including waste classification and land remediation. It will cover the current HSE and EA legislation and guidance, assessing risk to health from asbestos in soils and how to assess the land, analysis types and interpretation, and remedial actions.

Asbestos in soils and contaminated land Online

By Airborne Environmental Consultants Ltd

The course covers investigation and risk assessment of asbestos-contaminated soils and sites, including waste classification and land remediation. It will cover the current HSE and EA legislation and guidance, assessing risk to health from asbestos in soils and how to assess the land, analysis types and interpretation, and remedial actions.

NVQ CERTIFICATE IN INSULATION AND BUILDING TREATMENTS (CONSTRUCTION)

By Oscar Onsite

REFERENCE CODE 600/8370/0 COURSE LEVEL NVQ Level 2 THIS COURSE IS AVAILABLE IN Course Overview This qualification is aimed at those who are involved in carrying out insulation or associated treatments to buildings; this could be on internal or external surfaces or structures. The qualification is designed to ensure that there is a high degree of flexibility within the units available that will allow employees from companies of all sizes and specialisms equal opportunity to complete. All work completed must be done in accordance with Building Regulations and Industry recognised safe working practices, including the disposal of waste. The standards cover the most important aspects of the job. This qualification is at Level 2, although some units may be at different levels and should be taken by those who are fully trained to deal with routine assignments. Candidates should require minimum supervision in undertaking the job.

Search By Location

- Surf Courses in London

- Surf Courses in Birmingham

- Surf Courses in Glasgow

- Surf Courses in Liverpool

- Surf Courses in Bristol

- Surf Courses in Manchester

- Surf Courses in Sheffield

- Surf Courses in Leeds

- Surf Courses in Edinburgh

- Surf Courses in Leicester

- Surf Courses in Coventry

- Surf Courses in Bradford

- Surf Courses in Cardiff

- Surf Courses in Belfast

- Surf Courses in Nottingham