- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

226 Solar Energy courses

CE520: Introduction to SketchUp PV System Modeling

By Solar Energy International (SEI)

There are three lessons in this course. In lesson one, we start with modeling the roof based on site evaluation drawings. There is a roof geometry quiz at the end of this lesson that must be successfully completed before you can access lesson two. In lesson two, vents and other shading features and obstructions will be added to the roof. The opportunity for doing additional modeling will be provided in this lesson for those that want to learn how to add other features to enhance the roof and make it into a house. This additional modeling is entirely optional. This lesson also has a vent placement quiz that must be successfully completed before you can access lesson three. In lesson three, PV modules will be added to the roof. Also fire code roof access pathways and setbacks will be discussed, analyzed, and used when placing the PV modules. Additionally, other setbacks that are part of good design practice will also be used to determine where to place PV modules. The lesson, and course, will conclude with doing shading analysis to refine PV module placement and system size

CE540: 2023 National Electrical Code ® Updates: Solar and Storage Systems

By Solar Energy International (SEI)

Join SEI for this on-demand online solar training session. Online registration provides 60 days of access to the training. Once you have viewed and completed the online on-demand training session, you can print a Record of Completion that reflects the NABCEP CE Hours. Questions? call 970-527-7657 option 1

CE522: 2017 National Electrical Code⢠and PV Systems

By Solar Energy International (SEI)

Updates to rapid shutdown requirements for PV systems on buildings. Updates to grounding requirements for PV systems. Introduction to 4 entirely new articles: Energy Storage, Stand-alone Systems, DC Microgrids, and Large-Scale PV Electric Power Production Facilities. Updates to system disconnects and associated labeling New requirements for battery-based PV systems, both stand-alone and interactive. Additional changes in Articles 690 and 705, as well as other relevant Articles.

Renewable Energy Course Online

By Lead Academy

Quality Guarantee: Promising training excellence, satisfaction gurantee Accredited by CPD UK & Quality License Scheme Tutor Support Unlimited support via email, till you complete the course Recognised Certification: Accepted by thousands of professional bodies Start Anytime With 1 year access to the course materials Online Learning Learn from anywhere, whenever you want Why Renewable Energy Course right for you? Whether you are self-taught and you want to fill in the gaps for better efficiency and productivity, this Renewable Energy course will set you up with a solid foundation to become a confident renewable energy engineer and develop more advanced skills. This comprehensive course is the perfect way to kickstart your career in the field of renewable energy. This course will give you a competitive advantage in your career, making you stand out from all other applicants and employees. As one of the leading course providers and most renowned e-learning specialists online, we're dedicated to giving you the best educational experience possible. This course is crafted by industry expert, to enable you to learn quickly and efficiently, and at your own pace and convenience. Renewable Energy Course Details Accredited by CPD certificates are accepted by thousands of professional bodies and government regulators here in the UK and around the world. Many organisations look for employees with CPD requirements, which means, that by doing this course, you would be a potential candidate in your respective field. The Quality Licence Scheme is a brand of the Skills and Education Group, a leading national awarding organisation for providing high-quality vocational qualifications across a wide range of industries. Course Curriculum Renewable Energy Introduction Current status and trends solar energy Wind energy Bioenergy Geothermal energy Hydro Energy Who should take this course? This comprehensive course is suitable for anyone looking to improve their job prospects or aspiring to accelerate their career in this sector and want to gain in-depth knowledge of renewable energy. Entry Requirements There are no academic entry requirements for this course, and it is open to students of all academic backgrounds. As long as you are aged seventeen or over and have a basic grasp of English, numeracy and ICT, you will be eligible to enrol. Assessment Method On successful completion of the course, you will be required to sit an online multiple-choice assessment. The assessment will be evaluated automatically and the results will be given to you immediately. Certification Endorsed Certificate from Quality Licence Scheme After successfully passing the MCQ exam you will be eligible to order the Endorsed Certificate by Quality Licence Scheme. The Quality Licence Scheme is a brand of the Skills and Education Group, a leading national awarding organisation for providing high-quality vocational qualifications across a wide range of industries. It will give you a competitive advantage in your career, making you stand out from all other applicants and employees. There is a Quality Licence Scheme endorsement fee to obtain an endorsed certificate which is £65. Certificate of Achievement from Lead Academy After successfully passing the MCQ exam you will be eligible to order your certificate of achievement as proof of your new skill. The certificate of achievement is an official credential that confirms that you successfully finished a course with Lead Academy. Certificate can be obtained in PDF version at a cost of £12, and there is an additional fee to obtain a printed copy certificate which is £35. FAQs Is CPD a recognised qualification in the UK? CPD is globally recognised by employers, professional organisations and academic intuitions, thus a certificate from CPD Certification Service creates value towards your professional goal and achievement. CPD-certified certificates are accepted by thousands of professional bodies and government regulators here in the UK and around the world. Are QLS courses recognised? Although QLS courses are not subject to Ofqual regulation, they must adhere to an extremely high level that is set and regulated independently across the globe. A course that has been approved by the Quality Licence Scheme simply indicates that it has been examined and evaluated in terms of quality and fulfils the predetermined quality standards. When will I receive my certificate? For CPD accredited PDF certificate it will take 24 hours, however for the hardcopy CPD certificate takes 5-7 business days and for the Quality License Scheme certificate it will take 7-9 business days. Can I pay by invoice? Yes, you can pay via Invoice or Purchase Order, please contact us at info@lead-academy.org for invoice payment. Can I pay via instalment? Yes, you can pay via instalments at checkout. How to take online classes from home? Our platform provides easy and comfortable access for all learners; all you need is a stable internet connection and a device such as a laptop, desktop PC, tablet, or mobile phone. The learning site is accessible 24/7, allowing you to take the course at your own pace while relaxing in the privacy of your home or workplace. Does age matter in online learning? No, there is no age limit for online learning. Online learning is accessible to people of all ages and requires no age-specific criteria to pursue a course of interest. As opposed to degrees pursued at university, online courses are designed to break the barriers of age limitation that aim to limit the learner's ability to learn new things, diversify their skills, and expand their horizons. When I will get the login details for my course? After successfully purchasing the course, you will receive an email within 24 hours with the login details of your course. Kindly check your inbox, junk or spam folder, or you can contact our client success team via info@lead-academy.org

CE538: NFPA 855 And Fire Codes For Energy Storage Systems

By Solar Energy International (SEI)

This course covers National Fire Protection Association (NFPA) 855 and UL9540 standards as they relate to design and installation considerations, as well as their intersection with the International Fire Code (IFC), International Residential Code (IRC)and NFPA 1 Fire Code. Overview of applicable fire codes Why fire codes matter ESS fire codes evolution over time (1997-2021) Fire code cycles across the U.S. Fire code requirements by cycle (IRC, IFC, NFPA 1) NFPA 855 requirements for ESS (residential and commercial) UL 9540 listing and UL 9540A testing Summary and wrap-up

CE537: 2017 and 2020 NEC Roadmap for Solar Plus Storage Systems

By Solar Energy International (SEI)

This course covers important solar-plus-storage design and installation requirements for the most recent iterations of the National Electrical Code (NEC 2017 and 2020). The course is intended for industry professionals who are already familiar with grid-interactive systems but want to understand NEC requirements specific to solar-plus-storage systems as demand for energy storage continues to rise. Introduction to interactive solar and solar+storage systems AC- and DC-coupled energy storage systems Introduction to PV and ESS NEC Articles NEC Article 690 (Sections: 690.12, 690.15, 690.55, 690.56, 690.71) NEC Article 706 NEC Article 705 (Sections: 705.1, 705.13, 705.2, 705.5, 705.6, 705.65, 705.7) NEC Article 480 and Article 710 Common design issues and wrap-up

CE533: Comparing Battery Technologies

By Solar Energy International (SEI)

In this class, we'll review basic PV system types that use battery storage, the various use cases, and we'll take an in-depth look at what metrics are used to compare technologies. We'll discuss features of the most common battery chemistries currently used with PV systems and compare them. We'll look at how battery chemistry impacts battery bank sizing by reviewing a couple of design examples. Finally, we'll use a design example as the basis for a cost comparison of different battery technologies looking at both upfront and life cycle costs.

CE529: Hazards of Electrochemical Energy Storage in Solar + Storage Applications

By Solar Energy International (SEI)

Common chemistries, including lead acid, lithium ion, and nickel iron, each have different installation, maintenance, storage, and transportation requirements that can lead to fatal consequences if not conducted properly. This 8-hr online course, produced under an OSHA Susan Harwood Training Grant, provides training on the hazards associated with each energy storage technology and the control measures to eliminate or mitigate those hazards. This training includes five lessons for a total of 4 contact training hours. Lessons includes presentations, field videos, interactive exercises, and quizzes. Lesson content includes Lesson 1: Introduction to the Course and OSHA requirements Lesson 2: Energy Storage Technologies- Energy storage basics, lead-acid energy storage systems, lithium-ion energy storage, other types of electrochemical energy storage systems Lesson 3: Energy Storage Safety Regulations- OSHA safety regulations, NFPA 70 (the National Electrical Code) and NFPA 70E (Standard for Electrical Safety in the Workplace) NFPA 855 (Installation of Stationary Energy Storage Systems), the International Residential Code (IRC) and the International Fire Code (IFC) Lesson 4: Electrical Hazards- Electrical shock hazards, electrical arc flash hazards, electrical PPE, electrical connection hazards Lesson 5: Other Hazards- Chemical hazards, fire hazards, gas hazards, physical hazards, storage and transportation hazards, temperature effects on batteries, working space and clean installations

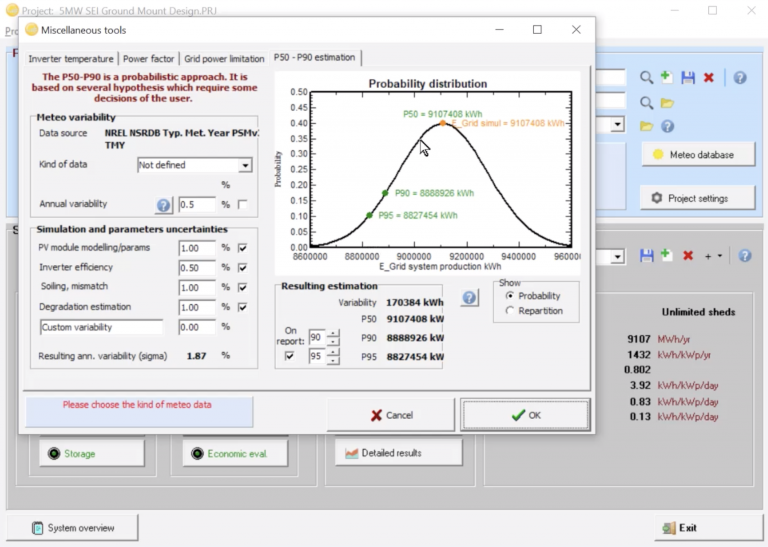

CE524: PVsyst for PV System Production Modeling

By Solar Energy International (SEI)

This short course is targeted towards beginning users, and will show you in detail how to get started creating accurate production estimates for any size PV system, from residential to large-scale. Learn how to find and import the correct meteorological data, create system variants for any size system, and accurately define the orientation, shading scene, and detailed system losses. By the end of this course you will be confidently simulating production and printing reports to share.

Search By Location

- Solar Energy Courses in London

- Solar Energy Courses in Birmingham

- Solar Energy Courses in Glasgow

- Solar Energy Courses in Liverpool

- Solar Energy Courses in Bristol

- Solar Energy Courses in Manchester

- Solar Energy Courses in Sheffield

- Solar Energy Courses in Leeds

- Solar Energy Courses in Edinburgh

- Solar Energy Courses in Leicester

- Solar Energy Courses in Coventry

- Solar Energy Courses in Bradford

- Solar Energy Courses in Cardiff

- Solar Energy Courses in Belfast

- Solar Energy Courses in Nottingham