- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

5142 Operations courses

Legal Secretaries and PAs Mini Bundle

By Compete High

Looking to step into the legal world as a confident support professional? The Legal Secretaries and PAs Mini Bundle is tailored for jobseekers ready to thrive in legal departments, barristers’ chambers, and corporate legal teams. Covering Administrative Assistant, Virtual Assistant, Compliance, Minute Taking, and Tax, this bundle turns your CV into a magnet for interviews. Priced for value, designed for hireability—this is your moment to get in the game. Description Legal employers don’t want generalists—they want specialists who understand the unique nature of legal operations. That’s why this bundle starts strong with Administrative Assistant training, covering the core skills you’ll need in every law office. Virtual Assistant capabilities future-proof your profile, making you ideal for hybrid or remote PA work. Compliance is central to legal workflows, and being well-versed in it sets you apart immediately. Minute Taking might seem minor—until you realise it’s one of the most trusted responsibilities in meetings, negotiations, and legal strategy sessions. Tax, too, makes a strong impact on your CV—whether you’re supporting solicitors dealing with finance or liaising with corporate clients. Together, Administrative Assistant, Virtual Assistant, Compliance, Minute Taking, and Tax create a sharp, credible, and compelling skillset that fits seamlessly into legal support roles. You don’t need a law degree to work in law—you just need this bundle. FAQ Q: Can I get hired as a PA in a law firm with this? A: Absolutely. This bundle is designed for legal PAs and administrative roles. Q: Is Minute Taking really that important? A: Yes. Legal records must be accurate, formal, and legally defensible. Q: What’s the value of Compliance in a legal PA job? A: High. Every law firm must meet strict compliance standards—daily. Q: Will this help with remote legal assistant roles? A: Definitely. Virtual Assistant skills are in demand across legal and admin roles. Q: Where does Tax come into play? A: Tax is essential in legal support roles involving finance, estates, or contracts. Q: Is this bundle suitable for entry-level applicants? A: Yes. It’s perfect for first-time legal jobseekers or career changers. Q: What industries will this help with? A: Legal services, finance law, HR compliance, local government, and corporate law. Q: Is it good value for the price? A: Exceptionally. You get five core legal admin skills—Administrative Assistant, Virtual Assistant, Compliance, Minute Taking, and Tax—in one compact bundle.

Food Health & Safety Consultant Mini Bundle

By Compete High

If you're aiming for consultancy roles in food regulation, catering oversight, or hospitality compliance, the Food Health & Safety Consultant Mini Bundle is your launchpad. Combining core disciplines like Food Safety, Food Science, Hospitality and Catering, First Aid, and Personal Hygiene, this bundle positions you directly where modern food safety careers are growing. Recruiters aren’t looking for “basic awareness”—they want well-rounded professionals who understand every layer of safety and hygiene in food service. This bundle is made for those ready to stand out, stay compliant, and get hired fast. Description The Food Health & Safety Consultant Mini Bundle is built for high-stakes environments where Food Safety, Food Science, and Hospitality and Catering converge with real responsibility. Whether consulting for restaurants, working with schools, or supporting large-scale food chains, success depends on understanding the health and safety standards that shape the sector. This bundle doesn’t stop at Food Safety—it integrates essential topics like First Aid and Personal Hygiene, giving you the rounded profile recruiters seek. The ability to advise on food handling, react in emergencies, and oversee Hospitality and Catering operations with confidence makes you more than employable—you become essential. If you've been waiting to upgrade your value in the food consultancy space, this is it. Every minute counts—enrol now while roles are still open. FAQ Q: Who is this course bundle for? A: Ideal for those pursuing roles in food safety consultancy, hospitality compliance, or advisory positions across catering sectors. Q: Why these specific subjects? A: Because Food Safety, Food Science, Hospitality and Catering, First Aid, and Personal Hygiene are critical across consultancy roles. Q: Will this make me more hireable? A: Absolutely. These are the top-line skills food safety recruiters actively search for. Q: Which industries does this apply to? A: Restaurants, healthcare catering, education, hotel groups, and food manufacturing. Q: Can this help me get a job faster? A: Yes—especially when these subjects are clearly listed on your CV. Q: Is it flexible enough for busy professionals? A: Completely. Learn on your schedule without sacrificing momentum. Q: Will I use all of these in a food safety job? A: Yes. From First Aid to Personal Hygiene—each subject has direct workplace relevance. Q: Is this bundle in high demand? A: Yes. Hiring managers are looking for exactly these competencies—get in before demand surges again.

Virtual Assistant (VA) Diploma Mini Bundle

By Compete High

Take your career to the next level with the Virtual Assistant (VA) Diploma Mini Bundle — a professional, hireability-focused package designed for ambitious individuals ready to enter the remote work world or upskill fast. With core components like Virtual Assistant, MS Word, Administrative Assistant, Report Writing, and Equality and Diversity, this bundle prepares you for versatile roles across corporate, creative, and nonprofit sectors. This is more than a credential — it’s a powerful signal to employers that you’re serious, skilled, and job-ready. Description The Virtual Assistant (VA) Diploma Mini Bundle has one goal: to help you get hired. Inside, you’ll find a mix of real-world relevant skills that employers constantly list in job posts: Virtual Assistant, MS Word, Administrative Assistant, Report Writing, and Equality and Diversity. This isn’t fluff — it’s focused, practical training to make you stand out in a competitive job market. Want to land freelance clients as a Virtual Assistant? Apply for full-time Administrative Assistant roles? Show proficiency in MS Word? Deliver polished Report Writing? Or align with modern workplace values through Equality and Diversity? This bundle helps you do it all. What makes this bundle a must-have is its versatility. It appeals to HR teams, marketing departments, online business owners, and operations managers alike — because every business needs organized, digitally literate, and inclusive-minded support professionals. And with more companies shifting to hybrid and remote models, having a solid Virtual Assistant foundation plus transferable office skills is an undeniable advantage. FAQ Q: Is this diploma bundle suitable for someone with no experience? A: 100%. It’s designed to get you job-ready from scratch — even if you're transitioning careers or returning to work. Q: What’s the difference between this and regular admin training? A: This bundle specifically prepares you for flexible, modern roles — especially in digital, freelance, or hybrid work settings — by combining Virtual Assistant, MS Word, Administrative Assistant, Report Writing, and Equality and Diversity together in one hireable package. Q: What types of companies value these skills? A: Startups, NGOs, law firms, marketing agencies, tech platforms, education providers — just about anyone hiring admin and support staff. Q: Is this a good fit for VA freelancing? A: Definitely. If you’re building a profile or pitching services, this bundle covers essential foundations clients expect — including Report Writing, MS Word, and understanding Equality and Diversity in workplace settings.

Veterinary Assistant Diploma Mini Bundle

By Compete High

Ready to launch a real, respected career in animal care? The Veterinary Assistant Diploma Mini Bundle is your shortcut to getting hired in today’s pet-focused workforce. With in-demand qualifications like Veterinary Assistant, Dog Basics, Animal Care, Dog Grooming, and Health and Safety, this career-focused bundle is packed with employer-relevant skills. Whether you’re aiming to work alongside vets, assist with animal procedures, or support clinic operations, this is the kind of diploma employers love to see on a CV. Description The Veterinary Assistant Diploma Mini Bundle isn’t just a bunch of random courses — it’s a job-readiness powerhouse. Every single course — Veterinary Assistant, Dog Basics, Animal Care, Dog Grooming, and Health and Safety — has been curated to target the core skills needed to start working immediately in clinics, shelters, rescue centres, or mobile pet care services. As the pet industry continues to grow rapidly, so does the demand for reliable, qualified, and passionate assistants who are ready to step into dynamic roles. Employers are searching for people who already speak the language of Animal Care, understand Health and Safety, and have practical exposure to areas like Dog Grooming and Dog Basics. If you’ve got Veterinary Assistant certification to top it off — even better. With this bundle, you’re not just learning — you’re building a strong professional profile that employers instantly recognize. It’s perfect for those who want to get working fast, skip years of debt, and join one of the most emotionally rewarding industries out there. And yes — this is the kind of bundle that gets interviews. FAQ Q: What kinds of jobs can I apply for after this? A: Veterinary assistant, clinic support staff, grooming technician, animal care worker, kennel assistant, shelter assistant — the list goes on. Q: Will employers value this bundle? A: They already do. Veterinary Assistant, Dog Basics, Animal Care, Dog Grooming, and Health and Safety training are all highly transferable across the pet and veterinary care sector. Q: Is this better than doing a long diploma? A: If your goal is to get working fast — absolutely. This bundle focuses on what you actually need to know to become hireable in months, not years. Q: Will I be certified? A: Yes, and your certificates in Veterinary Assistant, Dog Basics, Animal Care, Dog Grooming, and Health and Safety can be presented to employers immediately.

Profitable Ecommerce Management Mini Bundle

By Compete High

Want to stand out in ecommerce hiring pipelines or build a money-making online business from scratch? The Profitable eCommerce Management Mini Bundle was created for professionals ready to compete—and win—with expertise in Online Business, Viral Marketing, Online Entrepreneurship, Traffic Generation, and Finance. This isn’t just a skill pack. It’s your gateway to profitability in a digital-first economy. Every course inside—Online Business, Viral Marketing, Online Entrepreneurship, Traffic Generation, and Finance—directly boosts your hireability and earnings potential. Description eCommerce today is more competitive than ever, and businesses need professionals with a toolkit that combines reach, revenue, and reliability. That’s exactly what this bundle delivers: Online Business insight, Viral Marketing creativity, Online Entrepreneurship vision, Traffic Generation strategy, and Finance fluency. Employers and clients alike are looking for candidates who can launch, scale, and manage digital projects that actually convert. And they specifically want team members who understand Online Business, Viral Marketing, Online Entrepreneurship, Traffic Generation, and Finance. That’s why this bundle is more than relevant—it’s essential. Whether you're planning to grow a digital brand, work with ecommerce clients, or secure a full-time position in online retail or marketing, having credentials in Online Business, Viral Marketing, Online Entrepreneurship, Traffic Generation, and Finance is how you get noticed—and hired. Thousands of applicants won’t even make it past the screening stage because they lack the combination of Online Business, Viral Marketing, Online Entrepreneurship, Traffic Generation, and Finance. You won’t be one of them. FAQ Q: Who’s this bundle best suited for? A: Anyone pursuing careers in digital marketing, ecommerce, startup operations, or financial management. Every role that mentions Online Business, Viral Marketing, Online Entrepreneurship, Traffic Generation, or Finance will value this bundle. Q: Can I use this to start my own ecommerce business? A: Definitely. You’ll gain strategic insight into Online Business, Viral Marketing, Online Entrepreneurship, Traffic Generation, and Finance—the pillars of profitable ventures. Q: Will these topics still be relevant in a few years? A: Yes. Online Business, Viral Marketing, Online Entrepreneurship, Traffic Generation, and Finance are not passing trends—they’re fundamental to the ecommerce landscape long-term. Q: What makes this a “profitable” bundle? A: It trains you in skills that generate ROI. With Online Business, Viral Marketing, Online Entrepreneurship, Traffic Generation, and Finance, you're prepared to make money, not just spend it.

Excel Courses - Build Excel Skills Mini Bundle

By Compete High

Boost your career prospects with the Excel Courses - Build Excel Skills Mini Bundle, tailored to make you highly hireable in industries relying on data, finance, administration, and HR. Master MS Excel, streamline workflows with Data Entry, sharpen your analytical edge through Mathematics, understand payroll essentials with Payroll, and enhance database skills using MS Access. This bundle delivers exactly what employers seek in candidates ready for operational and office-based roles. Whether you're aiming for roles in finance, administration, or HR, the combination of MS Excel, Data Entry, Mathematics, Payroll, and MS Access makes your profile stand out in a competitive job market. Don’t miss the chance to skill up and secure the position you deserve. Description The workplace demands professionals who can navigate spreadsheets, databases, and payroll systems efficiently. This bundle’s focus on MS Excel guarantees your ability to handle complex data, while Data Entry sharpens your speed and accuracy—skills recruiters value immensely. Employers look for candidates with strong foundations in Mathematics to ensure precise calculations, and with Payroll knowledge, you show readiness for HR or finance administration. Additionally, MS Access adds a critical edge for managing and querying databases, rounding out your technical toolkit. This is more than just learning tools—it’s about becoming a candidate employers actively pursue. Excel, Data Entry, Mathematics, Payroll, and MS Access are the must-have skills in today’s office jobs. Seize this bundle before your competition does. FAQ Q: What job roles does this bundle target? A: Roles in administration, finance support, HR assistant, data entry clerk, and office operations where MS Excel, Data Entry, Mathematics, Payroll, and MS Access are essential. Q: Can this bundle help with payroll processing jobs? A: Yes, the inclusion of Payroll ensures you're equipped for finance and HR roles involving salary and benefits management. Q: Why is Mathematics important here? A: Precise calculations and numerical confidence are crucial across all data and payroll-related tasks. Q: Does MS Access really add value? A: Absolutely. MS Access skills set you apart for roles that require database management beyond spreadsheets. Q: Will this help me get hired faster? A: Yes, hiring managers specifically look for candidates proficient in MS Excel, Data Entry, Mathematics, Payroll, and MS Access. Q: Is this bundle better than buying courses separately? A: Definitely. You get all five skills—MS Excel, Data Entry, Mathematics, Payroll, and MS Access—in one streamlined, affordable package.

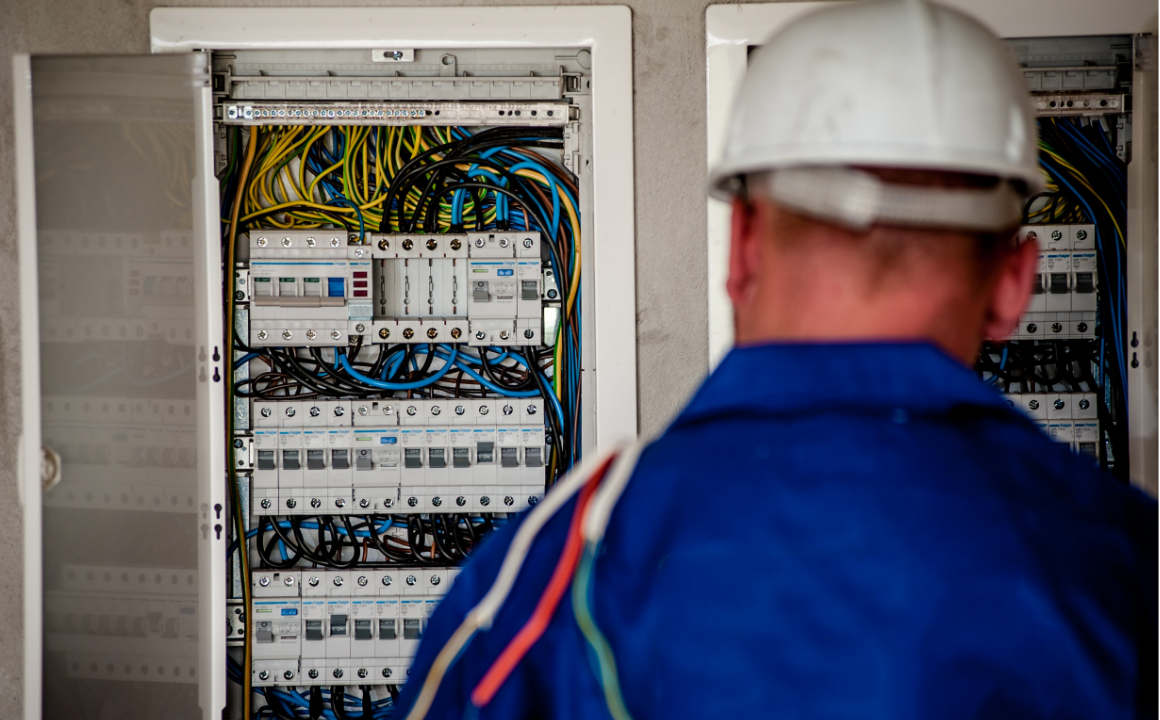

Electrical safety remains a critical concern across numerous industries and workplaces. This Advanced Electrical Safety course offers an in-depth exploration of essential concepts such as direct and alternating current, voltage, resistance, and capacitance. Designed to enhance understanding of the technical principles underpinning electrical systems, the course also highlights crucial safety precautions and procedures to minimise risk when working with electrical equipment. With a strong focus on identifying potential hazards and the steps needed to prevent incidents, learners will gain valuable knowledge to support safer environments. The course further delves into the practical aspects of risk assessment, detailing how to effectively reduce and control electrical risks through structured inspection and testing methods. By mastering these principles, individuals can contribute significantly to safer operations and reduce the likelihood of electrical incidents. Fully CPD accredited, this course is ideal for professionals seeking to deepen their understanding of electrical safety without the need for physical attendance, combining technical theory with essential safety guidelines in a convenient online format. Learning Outcomes: Demonstrate in-depth knowledge of electricity safety precautions Understand the key detail of direct current Learn how to conduct risk assessments Understand the process of development and training in the hospitality management industry Learn key detail on voltage and resistance Learn key strategies and techniques of combined inspection and testing It's your chance to start with our Engineering & Technology course and give your resume the stamp of approval that employers are looking for. So, pick up your card now and fill up your virtual basket with this highly-rated Advanced Electrical Safety - CPD Accredited online training program from Training Express Still not convinced? Take a glimpse of the key benefits you'll get with - Lessons prepared in collaboration with Professionals User-friendly Learner Management System (LMS) Syllabus designed in line with the standards of the UK Education System Updated Study Materials focusing both on Knowledge and Skill based training Guidance to expand in 'a' territory and move forward with Electrician profession Free Assessment to test learners' knowledge and skills Course Curriculum: Module 01: Safety Precautions Module 02: Direct Current Module 03: Alternating Current Basics Module 04: Voltage and Resistance Module 05: Capacitance and Capacitors Module 06: Working Safely with Electrical Equipment Module 07: Electrical Incidents Module 08: Risk Assessment Module 09: Reducing and Controlling Risks Module 10: Combined Inspection and Testing Course Assessment You will immediately be given access to a specifically crafted MCQ test upon completing the Advanced Electrical Safety - CPD Accredited course. For each test, the pass mark will be set to 60%. Accredited Certificate After successfully completing this Advanced Electrical Safety - CPD Accredited course, you will qualify for the CPD Quality Standards (CPD QS) certified certificate from Training Express. CPD 10 CPD hours / points Accredited by The CPD Quality Standards (CPD QS) Who is this course for? The Advanced Electrical Safety - CPD Accredited training is ideal for highly motivated individuals or teams who want to enhance their skills and efficiently skilled employees. Requirements There are no formal entry requirements for the course, with enrollment open to anyone! Career path Learn the essential skills and knowledge you need to excel in your professional life with the help & guidance from our Advanced Electrical Safety - CPD Accredited training.

Working in confined spaces presents a unique set of challenges that demand a thorough understanding of safety principles and legal responsibilities. This CPD accredited course delivers essential knowledge about confined space environments, focusing on the relevant laws and regulations to ensure awareness and preparedness. Participants will explore the importance of identifying potential hazards and understanding the legal framework that governs safe operations in these restricted areas. The course also covers vital topics such as risk assessment, effective control measures, and emergency procedures designed to reduce risks and protect individuals working in such conditions. Delivered in a fully online format, this training offers a flexible way to gain important theoretical knowledge without the need for physical attendance. It is ideal for professionals who seek to enhance their understanding of confined space safety with clear, precise information tailored to promote safe practices across various industries. Learning Outcomes: By the end of the course learners will be able to demonstrate that they can: Identify the legislation in place in the UK for workers in confined spaces. Perform advanced risk assessment for a confined space (lack of oxygen, fire risk, etc.) Put measures in place to protect themselves and others in a confined space. Perform the necessary emergency procedures. Show an awareness of the available safety equipment and apparatus needed to wok safely. It's your chance to start with our Construction course and give your resume the stamp of approval that employers are looking for. So, pick up your card now and fill up your virtual basket with this highly-rated Working in Confined Spaces Training - CPD Accredited online training program from Training Express Still not convinced? Take a glimpse of the key benefits you'll get with - Lessons prepared in collaboration with Professionals User-friendly Learner Management System (LMS) Syllabus designed in line with the standards of the UK Education System Updated Study Materials focusing both on Knowledge and Skill based training Guidance to expand in 'a' territory and move forward with Construction Worker profession Free Assessment to test learners' knowledge and skills Course Curriculum: Module 01: Working in Confined Spaces and the Laws Module 02: Risk Assessment Module 03: Control Measures Module 04: Emergency Procedures Course Assessment You will immediately be given access to a specifically crafted MCQ test upon completing the Working in Confined Spaces Training - CPD Accredited course. For each test, the pass mark will be set to 60%. Accredited Certificate After successfully completing this Working in Confined Spaces Training - CPD Accredited course, you will qualify for the CPD Quality Standards (CPD QS) certified certificate from Training Express. CPD 10 CPD hours / points Accredited by The CPD Quality Standards (CPD QS) Who is this course for? The Working in Confined Spaces Training - CPD Accredited training is ideal for highly motivated individuals or teams who want to enhance their skills and efficiently skilled employees. Requirements There are no formal entry requirements for the course, with enrollment open to anyone! Career path Learn the essential skills and knowledge you need to excel in your professional life with the help & guidance from our Working in Confined Spaces Training - CPD Accredited training.

Learn Automation Testing with Java and Selenium Webdriver

By Packt

In this course, you will learn how to write great automation tests with Selenium WebDriver and Java, and start building automation testing frameworks!

Search By Location

- Operations Courses in London

- Operations Courses in Birmingham

- Operations Courses in Glasgow

- Operations Courses in Liverpool

- Operations Courses in Bristol

- Operations Courses in Manchester

- Operations Courses in Sheffield

- Operations Courses in Leeds

- Operations Courses in Edinburgh

- Operations Courses in Leicester

- Operations Courses in Coventry

- Operations Courses in Bradford

- Operations Courses in Cardiff

- Operations Courses in Belfast

- Operations Courses in Nottingham