- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Product Design Training Courses 1-2-1

By Real Animation Works

PRODUCT DESIGN face to face training customised and bespoke.

Marine Warranty Surveying

By International Maritime Training

Marine operations are still of higher risk to underwriters, who, not having this expertise, need appropriate technical support to assess the risks. This involves the services of an additional independent third-party specialist. The MWS is the eyes and ears of the underwriter and claims adjuster. His role is to assess risk by reviewing the technical and operational aspects of a marine project on their behalf, the ultimate aim being the issue of a certificate of approval. The course deals with the various types of warranty survey and the role of the MWS, including: •The various types of warranty and legal aspects. •The London market joint committees. •Codes of practice and Scope of Work. •Required outcomes. •Surveyors’ liability. •Port risk surveys. •Lay-up and reactivation surveys. •Tow approvals. •Stowage of deck and project cargoes. •Port and terminal surveys. •Shipyard risk assessments. •Warranties in the offshore sector including mooring, anchor spreads, rig lay-ups and wind farm operations. This training program will be a tool for training and a reference source for the new and experienced Marine Warranty Surveyor.

Rhino 3d and V-Ray for Rhino Basic to Intermediate Training Course

By Real Animation Works

Rhino Basic to Intermediate Training Course

Practical MySQL Course Intermediate, to leave you fully conversant with queries, DML and DDL statements. Hands-on, Practical MySQL Course Intermediate. PCWorkshops MySQL Course Intermediate Certificate. Max 4 people per course, we keep it personalised.

NVQ Level 2 Diploma in Building Maintenance Multi-trade Repair and Refurbishment Operations (Construction)

5.0(29)By Site Competence

Blue CSCS Card NVQ Level 2 Craft This qualification provides you with the opportunity to showcase their knowledge, skills and understanding in their chosen craft. You will have the relevant experience in one of the trade specific areas. You will work in one of the following areas: Trowel Occupations (Bricklayer) Building Maintenance Painting and Decorating Wall and Floor Tiling Stone Masonry Wood Occupations (site Carpentry) Plastering Roofing Induction - As soon as you register you will be given a dedicated assessor. They will arrange an induction and together with your assessor, you will get to decide on the pathway which best proves your competency. The induction is used to plan out how you will gather the relevant evidence to complete the course. During the course - The assessor will work with you to build a portfolio of evidence that allows you to showcase your knowledge, skills and experience. The assessor will also regularly review and provide you with feedback. This will allow you to keep on track to progress quickly. You will be assessed through various methods such as observations, written questions, evidence generated from the workplace, professional discussion, and witness testimonials. On completion - Once all feedback has been agreed, the Internal Quality Assurer will review your portfolio and in agreement with your assessor the certificate will be applied for. To download our PDF for this course then please click here.

Sketchup Artificial Intelligence Training Course

By ATL Autocad Training London

Who is this course for? Sketchup Artificial Intelligence Training Course. Mastering SketchUp Artificial Intelligence (AI) is essential for designers, offering automation, efficiency, and innovative solutions. It saves time, enhances visualizations, fosters collaboration, and future-proofs skills, ensuring a competitive edge in the design industry. Click here for more info: Website How to Book? 1-on-1 training. Customize your schedule from Mon to Sat from 9 am to 7 pm Call to book Duration: 16 hours. Method: In-person or Live Online Sketchup and (Artificial Intelligence) Stable Diffusion Rendering Course (16 hours) Module 1: Sketchup Fundamentals (2 hours) Sketchup software overview and interface navigation Introduction to basic drawing tools and fundamental geometry creation techniques Module 2: Texturing and Material Mastery (2 hours) Application of textures and customization of materials Exploration of texture mapping and comprehensive material libraries Module 3: Illumination and Shadows (2 hours) Comprehending lighting principles and strategic light placement Crafting realistic shadows and reflections Module 4: Advanced Modeling Techniques (3 hours) Creating intricate shapes and harnessing advanced modeling tools Efficiently managing groups, components, and modifiers Module 5: Stable Diffusion Rendering (2 hours) Initiating stable diffusion rendering Optimizing rendering settings for superior outcomes Module 6: Scene Composition and Camera Configuration (2 hours) Exploring composition principles and camera perspectives Scene management and creation of captivating walkthrough animations Module 7: Rendering Optimization Strategies (2 hours) Techniques for optimizing models to expedite rendering Application of render passes and post-processing methods Module 8: Real-World Projects and Portfolio Building (1 hour) Application of acquired skills in completing authentic projects Professional portfolio presentation techniques Optional: Stable Diffusion and Python Installation (Additional 10 hours) Module 1: Introduction to Stable Diffusion and Python Comprehensive understanding of Stable Diffusion and Python's significance Module 2: System Prerequisites Hardware and software requirements for successful installation Module 3: Python Installation Guide Step-by-step installation process for various operating systems Module 4: Configuring Python Environment Configuration of environment variables and package managers Module 5: Stable Diffusion Installation Downloading and installing the Stable Diffusion package Module 6: Setting Up the Development Environment Configuration of integrated development environments (IDEs) for Python and Stable Diffusion Module 7: Troubleshooting and Common Issues Identification and resolution of common installation errors Module 8: Best Practices and Recommendations Effective management of Python and Stable Diffusion installations Module 9: Practical Applications and Projects Hands-on exercises exemplifying the practical usage of Stable Diffusion and Python Module 10: Advanced Topics (Optional) Exploration of advanced features and techniques Stable Diffusion https://stablediffusionweb.com https://stable-diffusion-ui.github.io https://stability.ai/stable-diffusion Upon successful completion of the Sketchup and Stable Diffusion Rendering Course with a focus on AI image rendering, participants will achieve the following: 1. Mastery of AI Image Rendering: Attain expertise in employing AI-powered rendering techniques to produce realistic and top-quality visualizations. 2. Proficiency in Sketchup for 3D Modeling: Navigate the software adeptly, utilize drawing tools with proficiency, and craft intricate 3D models. 3. Enhanced Rendering Optimization: Implement AI-based rendering to enhance model visuals, resulting in faster rendering times and superior image quality. 4. Application of AI-driven Lighting and Shadows: Employ AI algorithms for precise lighting placement, shadows, and reflections, elevating the realism of renderings. 5. Development of a Professional Portfolio: Present AI-rendered projects within a polished professional portfolio, highlighting advanced image rendering capabilities. 1. Mastering Sketchup: Attain proficiency in Sketchup, a renowned and user-friendly 3D modeling software, equipping you with the skills needed to adeptly create and manipulate 3D models. 2. Advanced Rendering Expertise: Explore stable diffusion rendering, an avant-garde technique that simplifies the creation of realistic and high-quality renderings. Broaden your rendering capabilities, producing visually stunning representations of your designs. 3. Practical Industry Applications: Cultivate practical skills relevant to diverse industries, encompassing architecture, interior design, product development, and visualization. Elevate your professional portfolio with captivating renderings that showcase your design prowess. 4. Interactive Learning: Participate in hands-on exercises and projects that promote active learning and the practical application of concepts. Benefit from personalized feedback and expert guidance, ensuring your continuous progress throughout the course. 5. Career Advancement: Elevate your career prospects by adding valuable skills to your toolkit. Proficiency in crafting detailed 3D models and impressive renderings through stable diffusion techniques opens doors to diverse job opportunities within the design and visualization sector. 6. Flexibility and Convenience: Access course materials online and learn at your own pace. Enjoy the flexibility of tailoring the coursework to your schedule, allowing you to harmonize your learning journey with other commitments. Course Advantages: Tailored Learning: Enjoy personalized 1-on-1 sessions, accommodating your schedule from Monday to Saturday, 9 am to 7 pm. Mastery of Sketchup: Develop proficiency in the widely-used and user-friendly 3D modeling software, enabling efficient creation and manipulation of 3D models. Advanced Rendering Proficiency: Acquire expertise in stable diffusion rendering for producing realistic, high-quality renderings that enhance the visual appeal of your designs. Practical Applicability: Develop practical skills applicable across diverse domains, including architecture, interior design, product development, and visualization, enriching your professional portfolio. Interactive Practical Experience: Engage in hands-on exercises with personalized guidance from seasoned instructors, ensuring consistent progress in your skillset. Career Progression: Boost your career opportunities by gaining valuable skills in 3D modeling and generating impressive renderings through stable diffusion techniques. Comprehensive Support: Benefit from free portfolio reviews, mock interviews, and career advice, providing additional resources to enhance your professional journey.

Network automation training course description This course concentrates on the technical side of tools and languages for network DevOps rather than the soft skills. These tools include Python, Ansible, Git and NAPALM By the end of the course delegates should be able to recognise the tools that they can use to automate their networks and be able to use the knowledge gained to feel confident approaching network automation. What will you learn Describe network DevOps. Choose network automation tools. Explain the role of various network automation technologies including: Python Ansible Git NAPALM Network automation training course details Who will benefit: Those wishing to learn about the tools of network automation. Prerequisites: Introduction to data communications. Duration 1 day Network automation training course contents What is DevOps and network automation Programming and automating networks, networks and clouds, AWS, OpenStack, SDN, DevOps for network operations. Unit testing. Hype vs reality. Benefits and features. Network monitoring and troubleshooting Traditional methods, SNMP. Netflow and xflow. Traditional automation. Streaming telemetry. Event driven automation. gRPC, Protocol buffers. Configuration management Catch 22 and initial configuration. ZTP, POAP. Traditional automation. TFTP. Ansible vs the rest (chef, salt, puppet). Jinja2 and templating. How ansible works. Network programmability Programming languages. Linux, shell scripting. Python vs the rest. Off box vs on box automation. Python network libraries Sockets pysnmp, ncclient, paramiko, netmiko, pyez, NAPALM. APIs Proprietary APIs, CLI, NETCONF, RETCONF. YANG, XML, YAML, JSON. Other tools Git, GitHub, Jenkins, JIRA and others.

Sketchup One to One Basic to Intermediate Level

By Real Animation Works

Sketchup face to face training customised and bespoke.

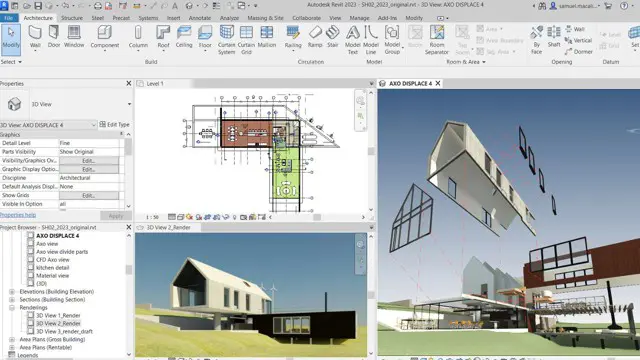

Revit One to One Basic to Advance Weekends Online or Face to Face

By Real Animation Works

Revit face to face training customised and bespoke. Online or Face to Face

Search By Location

- Opera Courses in London

- Opera Courses in Birmingham

- Opera Courses in Glasgow

- Opera Courses in Liverpool

- Opera Courses in Bristol

- Opera Courses in Manchester

- Opera Courses in Sheffield

- Opera Courses in Leeds

- Opera Courses in Edinburgh

- Opera Courses in Leicester

- Opera Courses in Coventry

- Opera Courses in Bradford

- Opera Courses in Cardiff

- Opera Courses in Belfast

- Opera Courses in Nottingham