- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

The Powerboat Instructor course aims to provide candidates with the necessary skills and knowledge required to instruct the RYA National Powerboat Scheme in a safe and effective way. The course duration is 3 days and comprises both practical and theoretical training scenarios where candidates are expected to deliver short training sessions. These sessions aim to develop the candidates personal skills and teaching ability in the safety of the training environment. The course does focus on teaching you how to instruct. You will learn effective methods of instructing and coaching, how to debrief, and how to structure the courses. We do revise the skills you will need to teach, but you will need to be proficient on a power boat to do this course. All potential Powerboat Instructors are required to complete a 1 day pre-assessment course to assess your personal boat handling skills. This assessment must be completed within the 3 months prior to the commencement of your Powerboat Instructor course. Course Pre-Requisites To do this course you will need to have completed Pre-Assessment. You will also need the following certificates: Valid First Aid Certificate, RYA Powerboat Level 2, RYA VHF Short Range Certificate. You will need to have 5 years powerboating experiencing (or one season full time). The minimum age of this course is 16 years old. Ideally you will have a familiarity with a range of craft giving you a wide range of knowledge of powerboats. Your theory knowledge should be at RYA Day Skipper Theory level, and we would recommend holding the certificate. RYA Instructor Training At Torbay Sea School we have trained many RYA Instructors who have gone on to instruct with us, other RYA training centres or as freelance instructors. During the course of your general RYA training you will have gained all the skills necessary to sail, motor or power boat with confidence to a high standard. The following courses consolidate all those skills and give you the tools required to instruct others to gain their RYA qualifications. You will be able to utilise our Instructors experience and our boats/equipment to feel at ease with instructing others.

HOW DANCING CAN IMPROVE YOUR MENTAL AND PHYSICAL HEALTH Move your body to your favourite tunes – it’s the ultimate feel-good exercise and has some surprising effects on both the body and mind Music and dance have been fundamental parts of the human experience for thousands of years. No matter what your favourite tune may be, music can have a huge effect on your wellbeing – Charles Darwin even thought that our ability to make and understand rhythmic beats worked as an early form of communication. Whether or not we still share messages through music, we all know that it can change our mood and studies have shown that we share a natural sense of rhythm (no matter how much you might protest). Dance is therefore a natural outlet, and one which can do a lot to make us feel good. Club Azucar offers corporate dance packages for the workplace in order for your organisation (Companies, Institutions & Schools) not only function at its best, but to be happy and healthy in life. These are the expected benefits for the individual employee which have been also confirmed by the participants: Physical Health: Salsa/Zumba or any Latin Dance Classes improves mobility, coordination / motor skills and fitness level.while being a low-impact exercise which includes people of all ages, abilities and fitness levels Mental Health: Dancing requires full concentration so for one hour away from their desk ,participants will experience reduced stress levels, , feel refreshed and more alert and able to concentrate better following the lesson Music in combination with physical exercise has an uplifting effect through the release of endorphins and dopamine in the body & brain Learning a new skill is proven to train your brain, contribute to prevention of dementia and give the confidence to face new tasks and challenges in other areas of work and life The patience and encouragement of the teachers has furthered this new confidence and sense of achievement and contributed to participants’ belief in themselves and their ability to take themselves out of their “comfort zones” and take on new challenges Getting to know each other in a social rather than work context and learning a new skill together, dancing and laughing together, gives participants a sense of belonging and furthers team buildingDo you want more proof? Get involved and hire us!!! Booking Terms & Conditions 1. The above prices are only for Greater London 2. Fees are non refundable 3. Courses are subject to availability from both parties 4. Train, plane. petrol, or any sort of transport fares are to be refunded. 5. Cancellation must be before 24 hours every class

The RYA Powerboat Instructor Skills Assessment is a mandatory requirement ahead of all Powerboat Instructor courses. Course Duration 1/2 day for each group of 3 attendees. If we have 6 attending then one group will go afloat in the morning and another in the afternoon with an overlap at lunchtime to address the theory element of the assessment. Instructor – student ratio 3 students to 1 Powerboat Trainer per boat. Minimum Age Those over the age of 16 can attend the assessment. Course price For those attending the RYA Powerboat Instructor course with us the cost of the assessment is £150. Course dates You can attend a pre-assessment at any time up to 6 months before your course. Assessments are always scheduled the day before a instructors course for those that can’t get to the centre ahead of the course. We are usually happy to schedule dates for assessments to suit your diary. Candidates for the pre-assessment will be expected to demonstrate competence in Hold off a mark Pick up and secure to a buoy Moor alongside up/downtide Turn using warps Turn in a confined space Recover a man overboard (dummy) Stop and start the engine Planing speed runs including figure 8 and ‘U’ turns Theory including charts, tides, buoyage, colregs and pilotage RYA Instructor Training At Torbay Sea School we have trained many RYA Instructors who have gone on to instruct with us, other RYA training centres or as freelance instructors. During the course of your general RYA training you will have gained all the skills necessary to sail, motor or power boat with confidence to a high standard. The following courses consolidate all those skills and give you the tools required to instruct others to gain their RYA qualifications. You will be able to utilise our Instructors experience and our boats/equipment to feel at ease with instructing others.

Natural Gas Properties & Sulphur Recovery

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Training (VILT) This 5 half-day VILT course will comprehensively cover the technical aspects of gas processing. The scope will be from the wellhead through the typical gas processing plant and discuss gas gathering (pipeline hydraulics), natural gas treating (H2S, CO2 removal), acid gas injection and sulfur recovery. One unique aspect of this training course is the operations and troubleshooting discussions in each module. This VILT course is suited to technical personnel or technical management. Training Objectives After the completion of this VILT course, participants will be able to: Grasp the key specifications of natural gas and liquid products Understand the physical and transport properties of gases and liquids and liquid-vapor phase behavior Explore the various technologies for processing natural gas and to make the specifications Examine the design of the technologies Learn how to diagnose operating problems to keep facilities running reliably Target Audience This VILT course is intended for all surface technical personnel such as process engineers & technologists, facility engineers and production engineers & technologists. This VILT course will greatly benefit but not limited to: Process, petroleum and production engineers Field operators and technicians Personnel involved in gas treatment and processing Managers and Supervisors involved with gas processing operations Course Level Basic or Foundation Intermediate Training Methods The VILT course will be delivered online in 5 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. Course Duration: 5 half-day sessions, 4 hours per session (20 hours in total). The maximum number of participants for this course is 20 persons. Case studies and Exercises: This VILT course will use actual case references throughout its duration in various forms. This will allow the application of the participants' newly-acquired knowledge. Case studies also stimulate independent thinking and discussion among the participants Trainer Your expert course leader has written several papers that have been published in both academic and industry journals. He has over 30 years of industry experience, specializing in gas processing (pipeline hydraulics, separation, dehydration, treating, sulphur recovery and refrigeration processes) and also has experience with crude oil dehydration, stabilization and micro-refining topping plants. He has experience with developing new technology and is recently involved in lithium, waste biomass and used motor oil pyrolysis and geothermal projects. He has recognized expertise in thermodynamics and physical and transport properties of fluids. He has consulted for several EPC and operating companies through his company Chem-Pet Process Tech., and currently holds the role of Director of Technology in an integrated engineering and solutions provider to the energy industry. He is currently involved with a small power-based carbon capture project as well as helping clients determine the best options for utilities decisions. He has been involved with CO2 dehydration and CO2 flood gas treating as well as acid gas injection projects for several years. Highlighted Achievements: Developed ORC geothermal model to determine the available power from wells in Alberta Acting on the Technical Advisory Board for E3 Metals, extracting lithium from formation water. Acted as a Subject Matter Expert for assessing the performance of the Plains Midstream Canada, Empress 1 Deep Cut Straddle Plant in a potential litigation. Acted as an Expert Witness for JL Transportation patent defence of a dense phase technology. Process engineer lead on the addition of the new Orloff gas plant for Deltastream. Also troubleshooted the oil battery shipping pump, plate exchanger and FWKO and treater. Evaluated gas processing and sulphur recovery options for new feeds to the Zhaikmunai Zelenovsky Gas Plant, Kazakhstan (with PM Lucas, Serbia). Completed capacity analysis for hydrocarbon dew point versus liquid recovery of three trains at Birchcliff Pouce Coupe facility including amine unit, refrigerated gas plant and acid gas injection. Completed process design for CO2 flue gas dehydration for Husky Energy Inc (with Status Engineering) Provided simulations of EnCana Foster Creek and Christina Lake and Husky McMullen SAGD facilities (with Vista Projects). Performed process engineering for Cenovus Pelican Lake SAGD pilot (with GRB Engineering) Bear Lake heavy oil polymer injection pilot (with GRB Engineering). Lead process engineer on the design of IEC Kerrobert crude oil micro-refinery (topping plant). Provided engineering support and troubleshooting for Enerchem Slave Lake Crude tower and product blending (with Status Engineering). POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

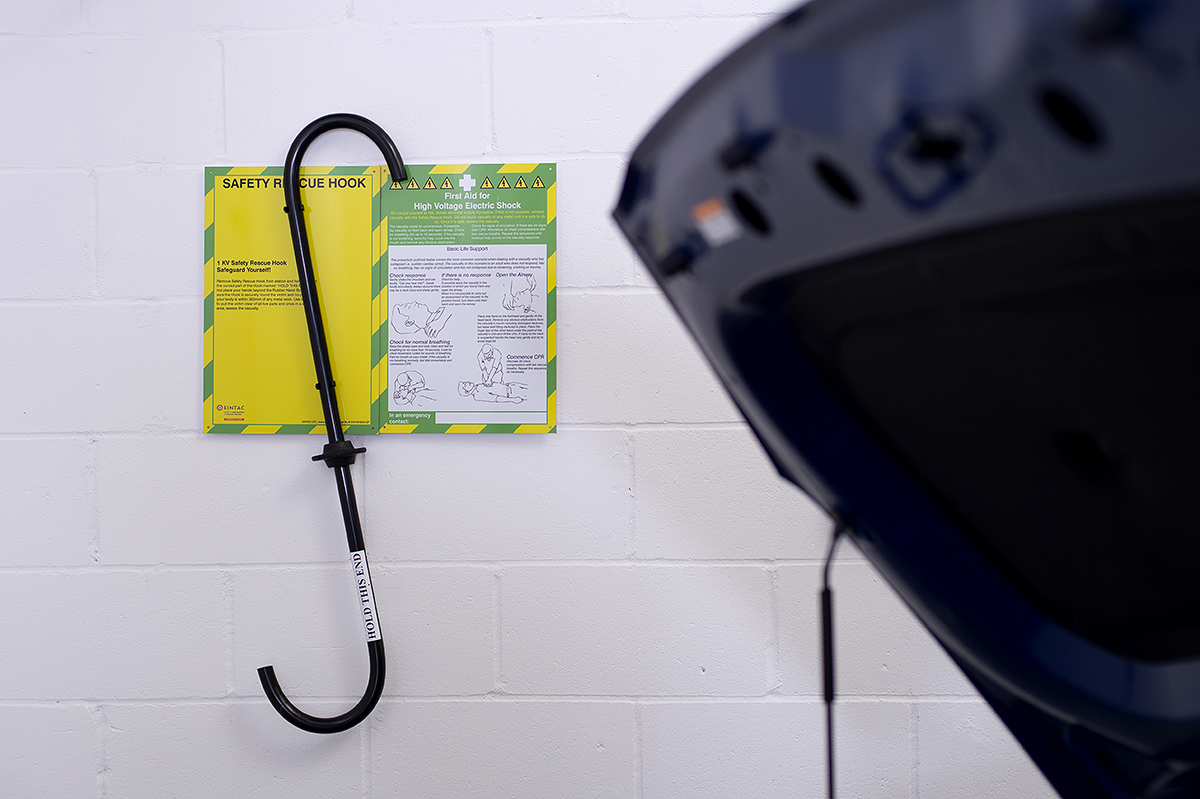

EINTAC IMI Level 2 Award In Electric/Hybrid Vehicle Hazard Management For Emergency And Recovery Personnel

By EINTAC Ltd

This IMI qualification is designed for those personnel who in the course of their daily work may encounter damaged electric/hybrid vehicles. It contains the knowledge required to work safely around the electric/hybrid vehicles high and low voltage electrical system and electric drive train systems. On completing this qualification those personnel will have gained knowledge of both low and high voltage technologies and an understanding of their dangers. The content of this qualification has been designed to give learners the knowledge and skills required to work safely around Electric/Hybrid vehicles during emergency and recovery situations.

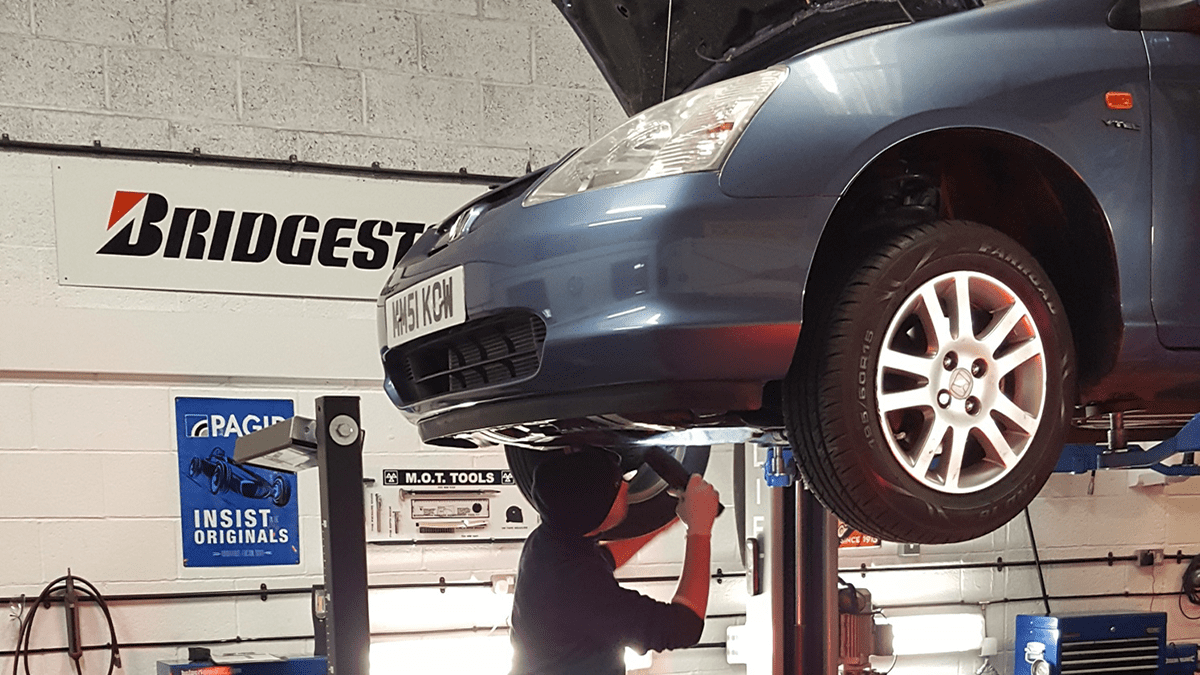

Light Vehicle Inspection Technician Accreditation

By PFTP Ltd

The IMI Light Vehicle Inspection Technician Accreditation is for experienced mechanics who would like to gain recognition for their skills and knowledge. It is also accepted by the Driver and Vehicle Standards Agency (DVSA) as the stage 1 entry qualification for mechanics and technicians who wish to train to become an MOT Tester for class 4 and 7 vehicles (cars and vans) It is normally valid for 3 years and successful candidates, as well as receiving a certifcate, photo card and pin badge, will also be entered on to the IMI Professional Register. This is a public-facing register to showcase individuals working in the motor industry, who have been recognised for their experience, professionalism and commitment to ethical working practices. However, there will be no requirement for you to re-accredit if you go on to complete your IMI Level 2 Award in MOT testing (classes 4 & 7) within the 3 year period. As an Inspection Technician you must be able to work unsupervised – ideally, you should be in full time employment with at least 3 years experience (4 years if you wish to become an MOT tester) to ensure you are familiar with the techniques for vehicle servicing, inspection and system(s) diagnosis. There are 5 practical assessments for this route and two online exams, one containing 30 questions and a second containing 10 questions. Please click on the links below to get an overview of the contents of each assessment. AOM – 071 – Emissions System – Inspection AOM – 072 – Electrical System – Inspection AOM – 073 – Braking Systems – Inspection AOM – 074 – Steering and Suspension Systems – Inspection AOM – 075 – Vehicle Structure – Inspection AOM – 076 – Vehicle Appraisal – Inspection 5 Day Training and Assessment. This training is aimed at experienced technicians who might need some training input prior to assessment. The assessments will take place over a 5 day period with the online assessment taking place mid week to allow for any re-sits that may be necessary. You will receive a copy of Tom Denton’s 4th edition Advanced Automotive Fault Diagnosis book which you can use in the intervening period to study and practice your knowledge and skills prior to attending the course. PLEASE NOTE THESE ASSESSMENTS ARE TO A LEVEL 3 STANDARD AND ARE DESIGNED TO BE TOUGH. THEY CONCENTRATE ON FAULT FINDING WITHIN A GIVEN TIMESCALE. SUCCESSFUL CANDIDATES WILL FIND ALL OF THE FAULTS WITHIN 1 HOUR. The next step If this accreditation is of interest to you, particularly if you wish to become an MOT tester, have a go at our initial assessment test. Our administrator will be in touch with you once we receive your result so that we can best advise you on the way forward.

Four-Wheel Alignment Course

By PFTP Ltd

The IMI Four Wheel Alignment course is 2 1/2 days in duration and is aimed at Technicians involved with carrying out light vehicle wheel alignment. It is advised that candidates should have a minimum of 3 months practical wheel alignment experience but courses of longer duration can be arranged for those people requiring it. Successful candidates will receive an IMI Quality Approved Award in Steering & Wheel alignment. As well as being recognised throughout the Motor Industry, this qualification will also count towards the NTDA tyre Technician Professional Development Scheme’s Licenced Retail Tyre Technician licence. PLEASE NOTE THIS COURSE FOCUSES ON THE FUNDAMENTALS OF WHEEL ALIGNMENT AND NOT ON ANY PARTICULAR TYPE OF WHEEL ALIGNMENT EQUIPMENT. Course Details: Classroom based theory session Workshop practice session Examination and assessment Course Fees £545 + VAT Per Candidate *Please contact us for group rates and onsite training Course Content Theoretical Health & Safety Components, functions & Layout of vehicle steering systems Steering angles and how they work together Common faults associated with steering systems 4 wheel alignment Practical Pre-alignment vehicle inspection. Carry out 4 wheel alignment. Carry ou a thrust angle alignment IMI assessment and test A multi-choice theory question paper Two practical assessments, observed by an IMI approved assessor. What’s included Fully qualified and experienced trainer Course booklet Examinations Fees and Certification One year IMI membership To find out more, please use the live chat function, visit our contact page or call us on 024 76325880

EINTAC IMI Level 1 Award In Electric / Hybrid Vehicle Awareness

By EINTAC Ltd

This IMI qualification is an introduction to electric/hybrid vehicle technology and is intended to provide learners with an awareness of electric/hybrid vehicle operation. This programme is particularly useful for people involved in the automotive retail industry as the growth in electric/hybrid vehicle market continue to increase. The content of this qualification has been designed to give learners the knowledge required to work safely around Electric/Hybrid vehicles.

Wrigglers Baby Yoga Cubs is a colourful, bright and lively baby yoga based class suitable from approx. 3-4 months until crawling. A unique class, perfect for baby AND grown up – both are equally important! Each class centres around baby yoga routines, helping baby to improve co-ordination to aid their physical development, body awareness and brain development.

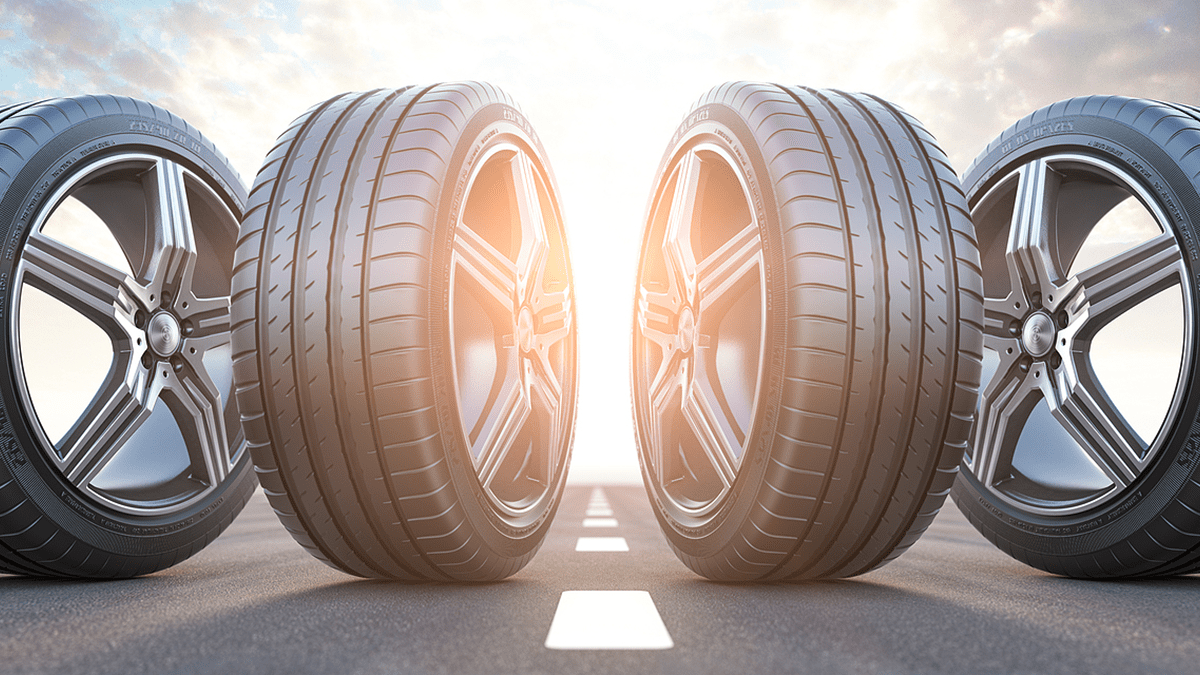

High-Performance Car Tyre Fitting Course

By PFTP Ltd

The IMI PAC course in High Performance Light Vehicle Tyre Fitting is 3 days in duration and is aimed at light vehicle tyre fitters wishing to update their skills and knowledge for today’s modern tyre types and designs. A minimum of 3 months practical light vehicle tyre fitting experience is required as this is not an introductory course. We also run a 1 day basic, non certificated course if for those without the tyre fitting experience, please contact for further details. Successful candidates will receive an IMI Professional Achievement Certificate in High Performance Light Vehicle Tyre Fitting. As well as being recognised throughout the Motor Industry, this qualification will also count towards the NTDA tyre Technician Professional development Scheme’s Licenced Retail Tyre Technician licence (LRTT). / Course Details: One day classroom based theory session One day workshop practice session One day examination and assessment Course Fees £475.00 + VAT. per person Please contact us for group rates Course Content Theoretical Health & Safety Light Vehicle Tyre construction identification Run-flat technologies Light Vehicle Wheel rim identification Light Vehicle Tyre sidewall markings (including lyre labeling) Construction & Use regulations Limits of wear and serviceability Fault identification methods Tyre & Inner tube repairs conforming to BSAU159g Practical Tyre inspection and fault reporting Safe vehicle jacking Safe removal and replacement of road wheels Safe wheel balancing Safe tyre removal and replacement (High Performance & Run Flat) Safe tubeless tyre and inner tube repair IMI assessment and test A multi-choice theory question paper Four practical assessments, observed by an IMI approved assessor. What’s included Fully qualified and experienced trainers Course booklet Examinations Fees and Certification One year IMI membership To find out more, please use the live chat function, visit our contact page or call us on 024 76325880

Search By Location

- Motor Courses in London

- Motor Courses in Birmingham

- Motor Courses in Glasgow

- Motor Courses in Liverpool

- Motor Courses in Bristol

- Motor Courses in Manchester

- Motor Courses in Sheffield

- Motor Courses in Leeds

- Motor Courses in Edinburgh

- Motor Courses in Leicester

- Motor Courses in Coventry

- Motor Courses in Bradford

- Motor Courses in Cardiff

- Motor Courses in Belfast

- Motor Courses in Nottingham