- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

282 Metal courses

Breathe: Qigong and Breathwork Day Retreat

By Sunhouse

Breathe A day retreat at The Sunhouse: Relax, Let Go & Be at Peace this Autumn Sunday 24th November 10.30am-5pm Price £70 for the whole day A day of Qigong, Forest Bathing, Breathwork & Meditation (includes delicious vegetarian organic soup, seasonal snacks and herbal drinks) Join me for a day retreat in the beauty of the Sunhouse to embrace the season of Autumn and the METAL Element. A wonderful opportunity to take time out and align yourself with the natural flow of energy of the season. At this time of year we focus on our lungs, our breath and our strong and healthy immune system. Just as the leaves are falling from the trees, nature supports us to let go of that which we no longer need and to appreciate that which is of value in our lives. Breath is life, it is the energy or “Qi” that sustains life within every cell. When we breathe well our entire body receives the energy it needs. When we reconnect with our breath we become calm, aware and in control and we can begin to bring balance to our lives and access places of deep peace within. WHATS INCLUDED: – Qigong exercises to support our lungs and strengthen our Qi. Increasing our flow of energy & improving our immunity – Learn The Bird Form a beautiful Qigong form designed to help “transform grief into love” This form has a light, uplifting, energising quality leaving us bright eyed and full of joy. – Forest Bathing in the beautiful woodland taking time to pause and listen to the forest around us, absorbing the healing energy of the trees. – Guided Conscious Connected Breathwork Journey to open our lungs and increase awareness of our breath. Encouraging detoxification of your body, releasing stuck energy and beliefs and resetting your whole nervous system. Giving you the tools to transform and to let go of whatever may be holding you back from living the life you truly want to live. In the morning we will practice some simple qigong exercises, movements and meditations to access the deeper energies within us. Then its time to enter the woods together to connect with the living Earth. As we walk through the woods, we will take time to pause and play with our Qigong moving meditations, listening to the forest around us, waking up our the wild within us. After a delicious lunch, we will lie down and relax into the support of the ground to receive a deep healing Breathwork Session. We will use conscious connected breathing to encourage detoxification of your body, releasing stuck energy and beliefs and resetting your whole nervous system. Giving you the tools to transform and to let go of whatever may be holding you back from living the life you truly want to live. Come and join me and nourish yourself in the beauty of life. Relax, Let Go & Be at Peace this Autumn Price includes a delicious vegetarian soup, herbal teas and delicious seasonal treats If you are interested but have more questions please contact me. I would love to hear from you. Contact me for more details Tel: 07779151916 emma@bringingbalance.co.uk

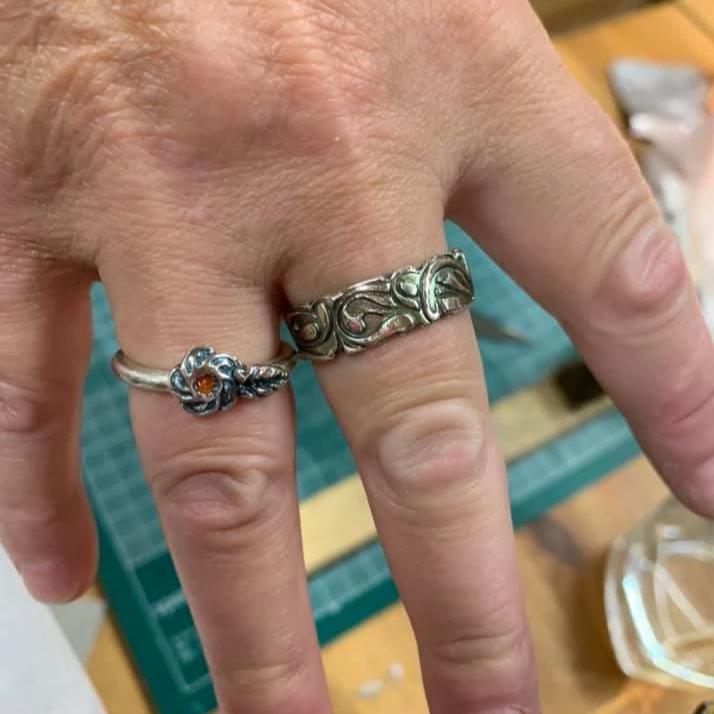

Silver Ring Making Course

By Louise Anne Designs

Come and learn to make your own unique solid silver ring from the amazing material that is silver clay incorporating a stone. I will show you how to size, design, make and fire your ring into a beautiful solid silver piece ready to wear home. You will make a patterned ring band and a ring with a stone setting. Our instructor, Louise, is fully qualified as a senior tutor and holds an Art Clay Higher Diploma and has been teaching jewellery making for over ten years.

This class is about getting to grips with Tube Setting. You will have to option to create a pendant or ring – maybe even two pieces if time allows. Krista will guide you through the process of tube setting where you will be using the Foredom Pendant Motor to cut a seat for your facetted brilliant cut stone. From here you can design and make your pendant or ring, solder your setting in place and then learn the techniques to set your stone. WHEN: Sunday 15th September 10-5pm WHERE: Workshop 925 based at The Mayford Centre, just outside of Woking and very close to Guildford. Unit F9 The Mayford Centre, Mayford Green Woking, Surrey GU22 0PP TUTOR: Krista Thomson WHAT DOES THE DAY INVOLVE? This class is about getting to grips with Tube Setting. You will have to option to create a pendant or ring – maybe even two pieces if time allows. Krista will guide you through the process of tube setting where you will be using the Foredom Pendant Motor to cut a seat for your facetted brilliant cut stone. From here you can design and make your pendant or ring, solder your setting in place and then learn the techniques to set your stone. Krista will guide you through each stage and there is time to practice settings so your can really understand the process correctly. We will be working with 4mm round facetted brilliant cut stones. If you would like to bring along your own stones, that is not a problem, Krista can advise if they are suitable on the day. We will work with Cubic zirconias as they are affordable, strong and perfect while you practice. Each student has their own fully equipped bench with its own Foredom Pendant Motor. We have put together a Pinterest Board to show how tube setting can be used within jewellery making. EXPERIENCE REQUIRED: It will help to have some experience with basic making skills. CLASS SIZE: 6 WHAT IS INCLUDED? All tools and consumables are supplied YOU WILL BE PROVIDED WITH: 0.8mm silver sheet – 0.5cm wide x 9cm length – for a band ring or pendant design. 2mm silver round wire – 15cm Length – for a pendant or 2 rings 4.5mm silver tube – 7cm 4mm Cubic Zirconias x 3 WHAT TO BRING: For safety reasons, during each class, you are required to wear appropriate footwear, we request that no open toed shoes are worn within Workshop 925. Long hair should also be tied back when working with the equipment. You may also wish to bring a notebook. We have handouts for many demonstrations, but there are always many tips and tricks given verbally by the tutor, which some might like to keep note of. Also pack your own lunch, snacks and drinks for the session. We regret we can’t offer tea and coffee at the moment due to Coronavirus so make sure you bring enough refreshments and supplies to keep you going during the day. PAYMENT OPTIONS: You can pay via our website or in our workshop in person using our card machine. If you prefer to pay directly, you can email us on hello@workshop925.com and we can invoice you manually to arrange a bank transfer. For classes over £80, instalment options are also available. Please email us on hello@workshop925.com to arrange. Gift Voucher – if you have a voucher to redeem, please email us before booking on hello@workshop925.com Please check your dates carefully before booking a class as we are unable to offer refunds. See our Terms & Conditions for full details.

Raku, Saggar, Barrel & Horsehair Firing Workshop - 2025 BOOK NOW TO SECURE A PLACE

5.0(9)By Alison and Abi Firing Workshops

RAKU, SAGGAR & BARREL FIRING WORKSHOPS POTTERY WORKSHOPS RAKU FIRING NAKED RAKU SAGGAR FIRING HORSEHAIR FIRING BARREL FIRING

ISO 3834:2021 (Quality requirements for fusion welding of metallic materials) Lead Auditor” course provides comprehensive training for participants to be able to understand and audit each and every ISO 3834:2021 guidelines in ensuring orgnaisation compliance and continual improvement in the welding industry

Introduction to Artistic welding,

By High Definition wire sculpture

This is a one day welding course for two people wishing to learn to arc weld, and make a basic 3 dimensional welded steel sculpture ,Cost £300 We are limited to what we can do in one day (6 hour course ) . Your teacher for the day will be award wing sculpture artist Roger Russell . In one day you will learn to weld with confidence and accuracy, a range of welds sizes . You will make a steel dragon fly to take home ,like the one in the picture. You will also be taught how to cut and bend metal using Metalcraft XL5 and mini bending machines, to make the parts of your dragon fly . Anyone completing a welding course with me can can have access to my supervised workshop and equipment on a £100 per day rate, and or for a 2 hour evening session , booked in advance is £20.

Silver Bangle Course

By Louise Anne Designs

Come and have a fun filled day creating your own beautiful bangle. You will get to create a bangle from sterling silver. Then using silver clay you will design and make a lovely, unique charm to adorn your bracelet. You will get to take these away at the end of the course to wear and treasure, or as a gift for a loved one.

Pipeline Integrity Management - Incorporating API 1160 / 1173 and ASME B31.8S

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This 3 full-day course provides a sound review of Pipeline Integrity Management strategies, in compliance with regulatory requirements, including self-assessment. The course is highly interactive and takes the form of lectures and case studies. On completion of the course, the participants will have a solid understanding of the procedures, strengths, limitations, and applicability of the main issues that comprise a Pipeline Integrity Management Program. The course incorporates API 1160 / 1173 and ASME B31.8S, and explains in detail the pipeline integrity requirements described in these standards. This course can also be offered through Virtual Instructor Led Training (VILT) format. Training Objectives Objectives of this course: Explore the latest techniques used to develop a comprehensive integrity management program covering both pipelines and their associated facilities Determine the necessary elements of such a program described in detail with examples of typical program content including an overarching view of where detailed risk analysis and defect assessment fits in the program Understand the scopes and contents of pipeline integrity standards i.e. API 1160 / 1173 and ASME B31.8S On completion of this course, the participants will be able to understand: Codes used in developing Integrity Management Plans, API 1160 / 1173 and ASME B31.8S, others The elements of an Integrity Management Plan Threat assessment Critical aspects of risk assessment Prevention and mitigation measures Characteristics and limitations of different inspection methods A risk-based approach to maintenance Target Audience The course is intended for supervisors, engineers and technicians responsible for ensuring the adequate protection of pipeline assets. In addition, maintenance planners, regulators and service providers to the pipeline industry will also benefit from attending this course. Course Level Basic or Foundation Trainer Your expert course leader is a Ph.D. Metallurgical Engineer with advanced expertise in asset integrity management of oil & gas production facilities, corrosion control, materials selection, chemical treatments, pipeline pigging, inspections, fitness-for-service evaluations, failure analysis and related consulting. He has 40 years of experience working for BP in Asia and South America, Amoco in the US, Intertek, and four years with Applus-Velosi in Southeast Asia. Practical Work Experience: AIM consultant with focus on Southeast Asia operations and clients Direct technical interface with clients on Velosi services Technical consultant for ongoing regional contracts and lead roles as auditor, instructor or facilitator Main clients have included the following organisations: BP and Vico Indonesia, Pertamina Offshore Northwest Java and West Madura Offshore (Indonesia), NCSP (Vietnam), ADCO-OPCO (Abu Dhabi), Thang Long (Vietnam), Exxon-Mobil (Malaysia) and Mubadala Petroleum (Indonesia). POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable

Dive into the world of crochet with our Crochet course. From foundational stitches to creating home accessories and fashion wearables, learn the art of crochet while prioritizing ergonomic practices. Perfect for beginners, this course is your gateway to the creative realm of crochet.

Search By Location

- Metal Courses in London

- Metal Courses in Birmingham

- Metal Courses in Glasgow

- Metal Courses in Liverpool

- Metal Courses in Bristol

- Metal Courses in Manchester

- Metal Courses in Sheffield

- Metal Courses in Leeds

- Metal Courses in Edinburgh

- Metal Courses in Leicester

- Metal Courses in Coventry

- Metal Courses in Bradford

- Metal Courses in Cardiff

- Metal Courses in Belfast

- Metal Courses in Nottingham