- Professional Development

- Medicine & Nursing

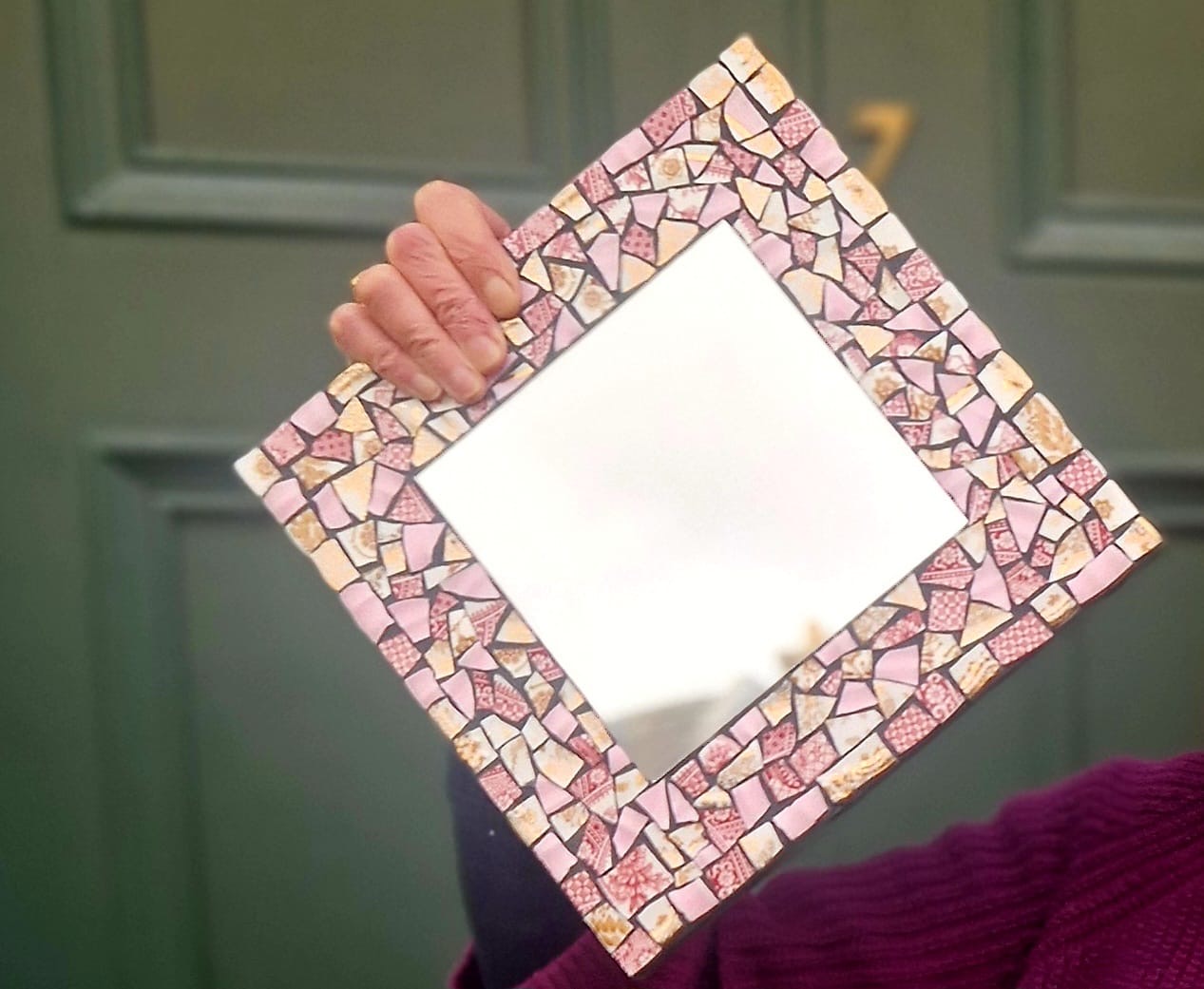

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Train-The-Trainer 1 Day Training in Edinburgh

By Mangates

Train-The-Trainer 1 Day Training in Edinburgh

Train-The-Trainer 1 Day Training in Dunfermline

By Mangates

Train-The-Trainer 1 Day Training in Dunfermline

Train-The-Trainer 1 Day Training in Livingston

By Mangates

Train-The-Trainer 1 Day Training in Livingston

Recruitment Skills 1 Day Workshop in Edinburgh

By Mangates

Recruitment Skills 1 Day Workshop in Edinburgh

Recruitment Skills 1 Day Workshop in Dunfermline

By Mangates

Recruitment Skills 1 Day Workshop in Dunfermline

Recruitment Skills 1 Day Workshop in Livingston

By Mangates

Recruitment Skills 1 Day Workshop in Livingston

Ever ever wished someone would just swoop right on in, sprinkle some magic on your photos or maybe just tell you exactly what to do and how to do it? On this half day, exclusive, in-person workshop, personal brand photographer Susan Heaton Photography will do just that! And it comes complete with an invaluable aftercare support package. Susan has been photographing small businesses in and around Edinburgh for 20 years! I love what I do! I have a wonderful network of business owners and I love sharing my tips and tricks to help them take their own photos - either to tide them over between brand shoots or to help them until they have the budget to get a professional in!” On the Stand Out Shots workshop you’ll learn how to use your phone using very little else (except perhaps a tripod) to take stand-out, professional-looking photos for your business, for social media, blog posts, profile images, website, marketing material and more. Susan will share tips, tricks and secrets she has gathered from 20 years of photographing small businesses in Edinburgh, to help you to take photos that stand out, and you will have invaluable post workshop access to a WhatsApp group for support with implementing what you have learnt. You will: learn how to make the most of the settings on your phone and what they all mean develop skills that will last a lifetime find out how to find the best light available get tips on how to arrange and style your photos practice top posing tips and find the ones that work best for you gain confidence and get rid of the awkward! network and connect with fellow workshoppers If you're self-employed and need some shots of you in action, or run a product-based business, this is the perfect workshop for you and will help you attract customers. But this workshop is not just for business owners, it's for anyone wanting to improve the way they take photos with their phone. What's included: half day workshop fuelled by light refreshments from local suppliers full after-care package so that you can always go back to Susan with questions in-person workshop is only available at The Arienas Collective Earth conscious credentials We are mindful of the effect we have on the environment, and do our best to minimise our impact. Your workshop correspondence and notes are sent to you electronically. Favourite feedback We love to hear what you think about our workshops. Here's a favourite review for Stand Out Shots: If you are wondering whether this course is for you, then it definitely is! I knew I had a great phone but absolutely zero knowledge of its capability or even how to use it! Susan's delivery is friendly, calm, patient and insightful and her experience is invaluable. Just learning the basics of my phone, and more about photo composition, lighting and editing tips has already paid dividends for my marketing posts. More information The Arienas Collective workshops, courses and events are run from a welcoming and supportive environment within a Georgian mews home in Edinburgh’s City Centre New Town. We invite you to join us, leave any day-to-day worries behind and immerse yourself in being creative. Spaces on our workshops and courses are limited so that our creative team of artists and makers can offer you the hands-on help and support you need to make the most of your time with us. Our taster and introductory workshops focus on teaching creative skills and methods you can continue practising at home, using affordable materials and equipment. Where more expensive equipment is required we will mention this in the workshop description. All the equipment and materials you need are included in the price, unless stated otherwise. Light refreshments from local suppliers are provided. On full day workshops you are welcome to bring your own lunch to eat inside or out. There is also a wide range of independent sit-in or takeaway delis, cafés, and restaurants, plus a range of supermarkets all within a 5-10 minute walk. Accessibility The workshop space is on the first-floor of our Georgian mews home and unfortunately we do not have lift access. Blue badge holders can park outside our front door on the single yellow line by arrangement. Allergies The workshop space is in our open plan living space and is not nut free. Please let us know about any skin or food allergies before booking. We offer a dairy-free milk and gluten free snack alternative. Minimum number no refund policy To ensure we can always pay our creatives a fair fee, we require a minimum number of bookings for each workshop and for this reason bookings are non-refundable. Should we have to cancel due to low numbers, we will offer you the option to swap to an alternative date or workshop, or to request a refund. We do our very best to avoid cancellations. Since we often get late bookings, we keep our workshops on sale for as long as possible. We realise that some of you travel from afar, so if you book a space and have not yet received an email confirming your workshop is going ahead and need to make plans for your trip, please get in touch before booking any travel or accommodation so we can update you on booking numbers. Or check in before booking. Private workshop bookings Most of our workshops are also available to book for: private get-togethers with family and friends; themed wedding and birthday celebrations; corporate team building and well-being purposes; and in-store retail events for your customers. If you’d like to know more please Email Lynn. Age restrictions Our workshops are planned with adults in mind. Many are suitable for teenagers, but some may require under 16s to be accompanied for insurance purposes. Please check with us before booking.

Search By Location

- Materials Courses in London

- Materials Courses in Birmingham

- Materials Courses in Glasgow

- Materials Courses in Liverpool

- Materials Courses in Bristol

- Materials Courses in Manchester

- Materials Courses in Sheffield

- Materials Courses in Leeds

- Materials Courses in Edinburgh

- Materials Courses in Leicester

- Materials Courses in Coventry

- Materials Courses in Bradford

- Materials Courses in Cardiff

- Materials Courses in Belfast

- Materials Courses in Nottingham