- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

740 Manufacturing courses

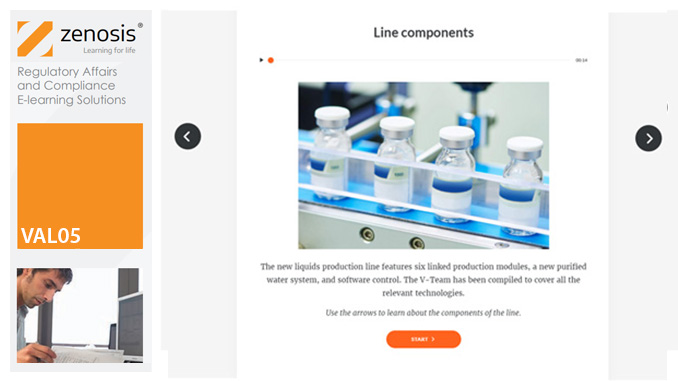

VAL05: Equipment Cleaning Validation

By Zenosis

Manufacturers of medicines and healthcare products must establish, validate and maintain an equipment cleaning programme. This is a regulatory requirement because validated cleaning procedures contribute to the assurance of product purity and safety. This module provides a comprehensive account of equipment cleaning validation requirements and procedures. It follows the work of a pharmaceutical company's validation team as they establish and validate the cleaning program for a new production line.

VAL04: Operational and Performance Qualification

By Zenosis

Having undergone Installation Qualification, before equipment can be used routinely in production, it needs to undergo Operational Qualification (OQ) and Performance Qualification (PQ). This module describes OQ and PQ requirements and procedures in the medicines and healthcare products industries. It follows the activities of a typical validation team as they carry out a project for a pharmaceutical company.

VAL03: Commissioning and Installation Qualification

By Zenosis

Before equipment can be used routinely in production, it must first be commissioned and, if necessary, undergo Installation Qualification (IQ). This module describes commissioning and IQ requirements and procedures in the medicines and healthcare products industries. It follows the activities of a typical validation team as they carry out a project for a pharmaceutical company.

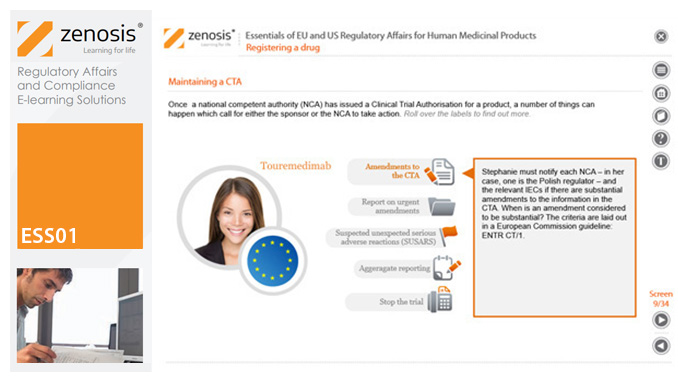

ESS01: Essentials of EU and US Regulatory Affairs for Human Medicinal Products

By Zenosis

This foundation-level module is the ideal introduction for new entrants to the field of pharmaceutical regulatory affairs and compliance. It describes the principal requirements that must be satisfied to gain and maintain approval to market medicinal products in the USA and Europe. The legal framework and the roles of major players in regulation are presented. The life-cycle of a drug is outlined. The various procedures available for assessment and approval of products are described and their requirements outlined. Obligations to be fulfilled after marketing approval are discussed.

SUB11: The Decentralised Procedure (DCP)

By Zenosis

This module describes the roles of the various players in the procedure, the sequence and duration of the stages involved, and the requirements on content, format and timing of submissions. It discusses the special issues that apply to generic products in the DCP.

SUB03: The Mutual Recognition Procedure (MRP)

By Zenosis

his module describes the roles of the various players in the procedure, the sequence and duration of the stages involved, and the requirements on content, format and timing of submissions. It discusses the special issues that apply to generic products in the MRP.

CT08: Clinical Trial Monitoring: Study Monitoring, Documentation and Closure

By Zenosis

The sponsor of a clinical trial must arrange for it to be monitored throughout its duration to ensure that the rights and wellbeing of subjects are protected, the trial data are accurate, complete and verified from source documents, and the conduct of the trial complies with the study protocol, Good Clinical Practice and regulatory requirements. In this module we describe how a Clinical Research Associate (CRA) monitors an ongoing trial to its conclusion.

Food safety combines a number of practices to reduce health hazards. These include premises hygiene, personal hygiene, risk control, pest control and waste management. This level 1 course is about minimising the level of potential hazards in a food manufacturing setting.

SAM04: Marketing of Prescription Drugs in the USA – Interactions with Healthcare Professionals

By Zenosis

The heaviest legal penalties imposed on drug companies concern interactions with healthcare professionals in the context of prescription drug marketing, notably for violations of the Anti-Kickback Statute and the False Claims Act. Monetary penalties have amounted to billions of dollars in some cases.

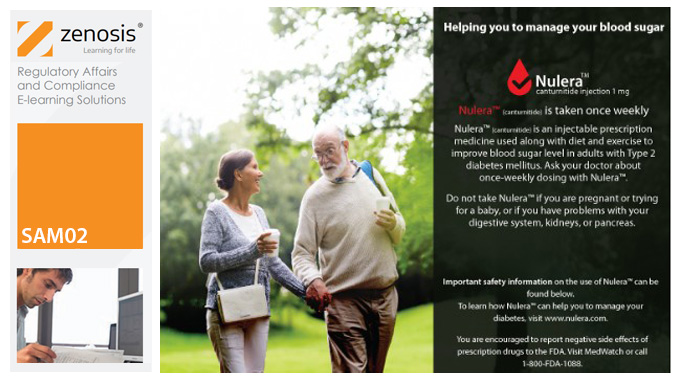

SAM02: Regulatory Requirements and Guidance on Advertising and Promotion of Prescription Drugs in the USA

By Zenosis

In this course we explain how to advertise and promote prescription drugs in various media, whether to healthcare professionals or consumers, in compliance with legal requirements and guidance from the FDA.

Search By Location

- Manufacturing Courses in London

- Manufacturing Courses in Birmingham

- Manufacturing Courses in Glasgow

- Manufacturing Courses in Liverpool

- Manufacturing Courses in Bristol

- Manufacturing Courses in Manchester

- Manufacturing Courses in Sheffield

- Manufacturing Courses in Leeds

- Manufacturing Courses in Edinburgh

- Manufacturing Courses in Leicester

- Manufacturing Courses in Coventry

- Manufacturing Courses in Bradford

- Manufacturing Courses in Cardiff

- Manufacturing Courses in Belfast

- Manufacturing Courses in Nottingham