- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

2692 Maintenance courses in Leicester delivered Online

This industrial electrical maintenance course is designed to enable candidates who have a small amount of electrical knowledge to gain recognised qualifications and skills to enable them to enter an industrial environment and work as a industrial electrician. The industrial electrical maintenance course will include a large amount of practical, enabling the candidate to install, fault find, design and wiring up control panels, using a variety of different methods.

This industrial electrical maintenance course is designed to enable candidates who have a small amount of electrical knowledge to gain recognised qualifications and skills to enable them to enter an industrial environment and work as a industrial electrician. The industrial electrical maintenance course will include a large amount of practical, enabling the candidate to install, fault find, design and wiring up control panels, using a variety of different methods.

This is a full 4 day course covering the requirements of commercial fire alarm systems to BS 5839 Part 1 2017 Code of Practice for Design, Installation, Commissioning and Maintenance of Systems in Non-Domestic Premises. This is one of the few externally examined Level 3 courses available and is supported by the Fire Industry Association (FIA) and Independent Fire Engineering & Distributors Association (IFEDA). All successful delegates will receive a EAL Level 3 Award in the Requirements of Fire Detection and Fire Alarm Systems for Buildings BS 5839-1:2017

A five day Refrigeration Electrics Maintenance course aimed at anyone involved with refrigeration, air conditioning and heat pump electrical control systems. The Refrigeration Electrics Maintenance course covers the three elements which are common to most refrigeration and air conditioning systems, namely, protection, control and motors. For example, a typical air conditioning split system will have protection provided by the fuse in the fused connection unit, and further protection provided to the cable feeding the fused connection unit, probably by a circuit breaker, control provided by thermostat and time clock etc… and motor driven fans and compressor. During the Refrigeration Electrics Maintenance course emphasis is also placed upon the applicable wiring regulations to ensure the constructed system is compliant with BS7671:2018 The aim of the Refrigeration Electrics Maintenance course is to provide enough knowledge to allow maintenance and fault finding to be safely and effectively carried out. The Refrigeration Electrics Maintenance course comprises of: Essential Electrics Module City and Guilds 2382-22 Level 3 – 18th Edition Wiring Regulations Refrigeration Electrics Module The Refrigeration Electrics Maintenance course costs include examination entry fees.

We have an extensive range of PLC training courses available covering all PLC manufacturers and levels of expertise from the complete novice to the advanced. ALL of our training courses can be tailoured to your own requirements. ALL our courses will be based on the relevant software and hardware. We aim to make ALL our courses as practical as possible, leading to ‘real world’ skills and not just theoretical skills. No prior knowledge is required for this course as it starts from scratch and assumes no previous experience, you will reach the skilled level where you can look at becoming a programmer, get into engineering maintenance in an industrial environment, fault find or make amendments to programs, this is the course for you. The ‘Typical’ 5 day course usually covers 2 or 3 of the major manufacturers, Siemens S7, Allen Bradley and Mitsubishi (This can be amended to other manufacturers if you have a particular requirement). The course aims to be 90% practical, as we believe the easiest way to learn is to do it! Every student works on their own dedicated training rig and computer, enabling you to get the most from the course. A full set of course notes and a USB drive full of other manuals is provided at the end of the course. We can also cover a wide range of manufacturers including : Siemens Step 5 PLC Training (Using Step 5, Quadriga or Others) Allen Bradley PLC 3 & 5 Training (AB6200 Software) RSLogix 5 PLC Training SLC PLC Training (RSLogix 500) ControlLogix PLC Training (RS Logix5000) MicroLogix PLC Training (RSLogix 500) S7-200 PLC Training (Step 7 Micro) S7-300 PLC Training (Step 7 or TIA Portal) S7-400 PLC Training (Step 7 or TIA Portal) Kuhnke PLC Training (Kubes) Omron PLC Training (Syswin) Modicon PLC Training (ProWorx and Others) Mitsubishi PLC Training (Medoc, GX Developer, GPP & Others) Toshiba PLC Training GE Fanuc PLC Training GEM 80 PLC Training Telemecanique PLC Training Most other PLC manufacturer training undertaken. We also cover a wide range of SCADA Systems to enable engineers to modify and add to existing screens, fault find through systems, set up communications etc.

We have an extensive range of PLC training courses available covering all PLC manufacturers and levels of expertise from the complete novice to the advanced. ALL of our training courses can be tailoured to your own requirements. ALL our courses will be based on the relevant software and hardware. We aim to make ALL our courses as practical as possible, leading to ‘real world’ skills and not just theoretical skills. No prior knowledge is required for this course as it starts from scratch and assumes no previous experience, you will reach the skilled level where you can look at becoming a programmer, get into engineering maintenance in an industrial environment, fault find or make amendments to programs, this is the course for you. The ‘Typical’ 10 day level 3 course usually covers 2 or 3 of the major manufacturers, Siemens S7, Allen Bradley and Mitsubishi (This can be amended to other manufacturers if you have a particular requirement). The course aims to be 90% practical, as we believe the easiest way to learn is to do it! Every student works on their own dedicated training rig and computer, enabling you to get the most from the course. A full set of course notes and a USB drive full of other manuals is provided at the end of the course. We can also cover a wide range of manufacturers including : Siemens Step 5 PLC Training (Using Step 5, Quadriga or Others) Allen Bradley PLC 3; 5 Training (AB6200 Software) RSLogix 5 PLC Training SLC PLC Training (RSLogix 500) ControlLogix PLC Training (RS Logix5000) MicroLogix PLC Training (RSLogix 500) S7-200 PLC Training (Step 7 Micro) S7-300 PLC Training (Step 7 or TIA Portal) S7-400 PLC Training (Step 7 or TIA Portal) Kuhnke PLC Training (Kubes) Omron PLC Training (Syswin) Modicon PLC Training (ProWorx and Others) Mitsubishi PLC Training (Medoc, GX Developer, GPP & Others) Toshiba PLC Training GE Fanuc PLC Training GEM 80 PLC Training Telemecanique PLC Training Most other PLC manufacturer training undertaken. We also cover a wide range of SCADA Systems to enable engineers to modify and add to existing screens, fault find through systems, set up communications etc.

Any person who requires the minimum legal requirement to work on air conditioning and refrigeration equipment including air conditioning and refrigeration engineers and technicians, all plant engineers, apprentices, personnel concerned with the recovery, charging or disposal of refrigerants and new comers into the industry. F Gas Regulations training courses are designed for both experienced air-conditioning and refrigeration engineers and also candidates who are looking to cross train and gain qualifications in the air conditioning / refrigeration sector. This F Gas regulations qualification is to meet the legal requirements of EC Regulation 842/2006 (commonly known as the F Gas Regulations). The Certification Schemes are designed for operatives who install, service and repair refrigeration, air-conditioning and heat pump systems, and require the following skills: Safe handling of refrigerant techniques Pipework and Jointing skills Recovery of Refrigerants (restricted to small systems only) Intrusive and non-intrusive leak and performance checking Category 1 covers all aspects of installation, commissioning, servicing, maintenance, recovery and leak checking on all refrigeration, air-conditioning and heat pump systems in accordance with the F-Gas Regulation EC842/2006, regardless of the weight of refrigerant in the system. F Gas regulations Course subjects are: Pressure test and discharge to BSEN378 Charge a blended refrigerant Evaluate system performance to ensure competence (using rule of thumb, temperature, refrigerant state and pressure) Leak test to EC1516/2007 Fabricate and fit brazed and mechanical joints Uphold F-Gas records and log books. Handle refrigerant safely and dispose of rightfully Pressure Regulation compliance All candidates will be able to ensure systems are tight, efficient in their use of energy and meet the F-Gas legal requirement.

Day 1 Solenoids and actuators, principles of operation and maintenance State precautions that may be necessary when removing cores from energised AC solenoids Transformers, sizing, applications and uses Heaters, applications, uses and safety precautions to be observed Temperature controllers, various types, principles of operation and uses Thermal sensors, various types, principles of operation and uses. Day 2 Proximity devices, limit switches and proximity switches, various types, principles of operation and uses Practical workshop, gaining an understanding of typical connections of various proximity devices and the range of available supplies catered for, voltage levels and current type Development of a typical simple control system using push buttons, proximity devices, relays and indicator lamps. Day 3 Protection against overcurrent Protective devices, various types, suitability and uses Earthing, including principles of protection against indirect shock Undervoltage protection. Day 4 Cable and core termination techniques, including crimping and soldering Practical workshop terminating YY, SY, SWA and MICC cable Testing, basic principles of circuit protective conductor testing and insulation resistance testing, instruments used and expected values Practical workshop testing cables terminated previously and testing cables with faults on test rig. Day 5 Fault finding, safety precautions and principles Practical workshop on fault rigs Root cause analysis PPM and maximising uptime

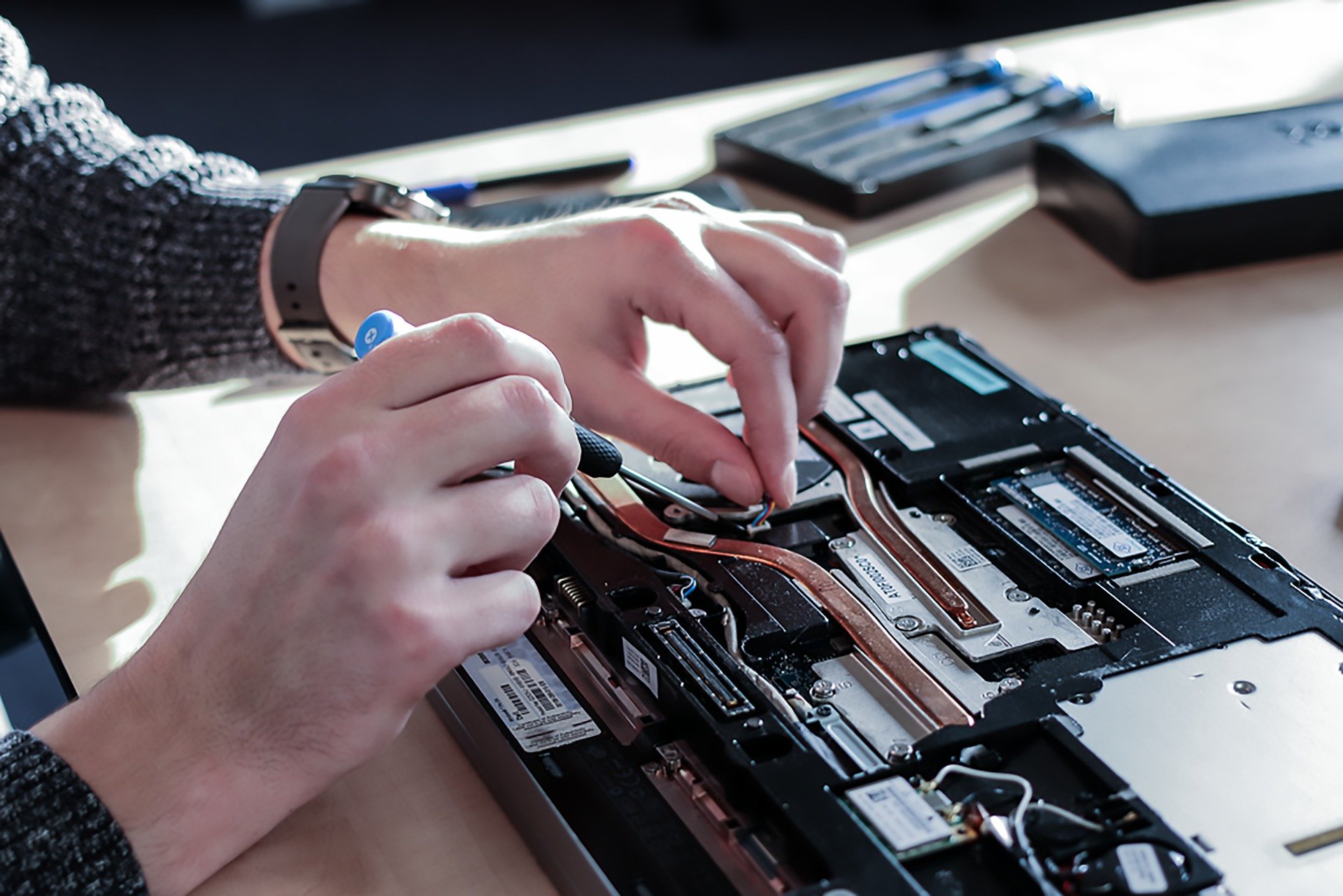

Computer Maintenance and Repair Course

By Hi-Tech Training

The Computer Maintenance & Repair Technician course aims to enable participants to diagnose and repair system level faults in computer-based systems at the foundation level.

Bike Maintenance / Motorcycle Maintenance

By Training Tale

Bike Maintenance / Motorcycle Maintenance Introducing: Bike Maintenance / Motorcycle Maintenance- Your Ultimate Guide to Keeping Your Ride Running Smoothly! Do you want to make a career in the Bike Maintenance / Motorcycle Maintenance field? This Bike Maintenance / Motorcycle Maintenance course aims to provide a better understanding of Bike Maintenance / Motorcycle Maintenance. Our extensive Bike Maintenance / Motorcycle Maintenance course covers all the latest topics to keep you better prepared for your Bike Maintenance / Motorcycle Maintenance profession. Our Bike Maintenance / Motorcycle Maintenance course is designed for those who want to learn how to maintain their bikes/motorcycles. You will learn essential skills, such as Engine Design & Basic Theory, Engine Cooling & Lubrication, Clutch, Suspension, Charging System, Troubleshooting and more. Our comprehensive Bike Maintenance / Motorcycle Maintenance course covers everything you need to know to keep your bike/motorcycle running smoothly and efficiently. Our format makes it easy and convenient to take the Bike Maintenance / Motorcycle Maintenance course at your own pace. You can access the Bike Maintenance / Motorcycle Maintenance course from anywhere and anytime, whether you are at home or on the go. Enrol now for a successful Bike Bike Maintenance / Motorcycle Maintenance career! Special Offers of this Bike Maintenance Course This Bike Maintenance Course includes a FREE PDF Certificate. Lifetime access to this Bike Maintenance: Bike Maintenance Course Instant access to this Bike Maintenance: Bike Maintenance Course Get FREE Tutor Support from Monday to Friday in this Bike Maintenance Course Courses you GET Course 01: Bike Maintenance / Motorcycle Maintenance Course 02: Car Mechanic Training Course 03: Bicycle Maintenance [ Note: Free PDF certificate as soon as completing the Bike Maintenance / Motorcycle Maintenance course] Bike Maintenance / Motorcycle Maintenance Industry Experts Designed this Bike Maintenance / Motorcycle Maintenance course into 15 detailed modules. Module 1: Engine Design & Basic Theory Module 2: Engine Cooling & Lubrication Module 3: Ignition Module 4: Intake, Fuel, & Exhaust Systems Module 5: Clutch Module 6: Transmission & Primary Drive Module 7: Final Drive Module 8: Suspension Module 9: Wheels & Tires Wheels Module 10: Brakes Module 11: Frame & Steering Module 12: Charging System & Battery Electrical Basics Module 13: Lights, Switches, & Instruments Module 14: Cleaning, Setting-Up, & Storage Module 15: Troubleshooting Assessment Method of Bike Maintenance / Bike Maintenance After completing each module of the Bike Maintenance / Motorcycle Maintenance Course, you will find automated MCQ quizzes. To unlock the next module, you need to complete the quiz task and get at least 60% marks. Certification of Bike Maintenance / Bike Maintenance After completing the MCQ/Assignment assessment for this Bike Maintenance / Motorcycle Maintenance course, you will be entitled to a Certificate of Completion from Training Tale. Who is this course for? Bike Maintenance / Motorcycle Maintenance This Bike Maintenance / Motorcycle Maintenance course is open to everyone. Requirements Bike Maintenance / Motorcycle Maintenance Students who intend to enrol in this Bike Maintenance course must meet the following requirements: Bike Maintenance: Good command of the English language Bike Maintenance: Must be vivacious and self-driven Bike Maintenance: Basic computer knowledge Bike Maintenance: A minimum of 16 years of age is required Career path Bike Maintenance / Motorcycle Maintenance Certificates Certificate of completion Digital certificate - Included