- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

8986 Instructor courses

Doing online social work is a new form of contributing to social welfare in the digital age. This Online Social Work Course has been designed to educate you to contribute more dynamically and effectively teaching you essential guidelines and theories. It will teach you the framework of teamwork and casework procedure. Start learning Online Social Work Course that will give you enough knowledge and skills to build your dream career. About this course This Online Social Work Course helps to grow your skills faster through the power of relevant content and world-class tutors. In this industry-leading bite-sized course, you will learn up-to-date knowledge in the relevant field within a few hours and get certified immediately. The modules of this course are very easy to understand and all of the topics are split into different sections. You will easily grasp and use the knowledge gained from this course in your career and go one step ahead of your competitors. The course is designed to improve your employability and provide you with the tools you need to succeed. Enrol today and start learning your essential skills. Why choose this course Earn a digital Certificate upon successful completion. Accessible, informative modules taught by expert instructors Study in your own time, at your own pace, through your computer tablet or mobile device Get 24/7 help or advice from our email and live chat teams Get full tutor support on weekdays (Monday to Friday) Course Design The Online Social Work Course is delivered through our online learning platform, accessible through any internet-connected device. There are no formal deadlines or teaching schedules, meaning you are free to study the course at your own pace. You are taught through a combination of Video lessons Online study materials Who Is This Course For:â This Online Social Work Course is ideal for those who want to be skilled in this field or who wish to learn a new skill to build their dream career. If you want to gain extensive knowledge, potential experience, and be an expert in the related field then this is a great course for you to grow your career. Requirements This course is for anyone who would like to learn Online Social Work Course related skills to aid his/her career path. No formal entry prerequisites are required Certification Upon successful completion of the course, you will be able to obtain your course completion e-certificate free of cost. Print copy by post is also available at an additional cost of £9.99 and PDF Certificate at £4.99. Course Content Module 1: An Overview of Social Work Basics Module 2: Social Work Dimensions and Intervention Models I Module 3: The Role of a Social Worker and Guidelines for Social Worker Module 4: Social Working and Sociology Theories Module 5: Teamwork and Casework Procedure Course Content Social Work Basics Module 1: An Overview of Social Work Basics 00:14:00 Module 2: Social Work Dimensions and Intervention Models I 00:34:00 Module 3: The Role of a Social Worker and Guidelines for Social Worker 00:15:00 Module 4: Social Working and Sociology Theories 00:24:00 Module 5: Teamwork and Casework Procedure 00:22:00 Frequently Asked Questions Are there any prerequisites for taking the course? There are no specific prerequisites for this course, nor are there any formal entry requirements. All you need is an internet connection, a good understanding of English and a passion for learning for this course. Can I access the course at any time, or is there a set schedule? You have the flexibility to access the course at any time that suits your schedule. Our courses are self-paced, allowing you to study at your own pace and convenience. How long will I have access to the course? For this course, you will have access to the course materials for 1 year only. This means you can review the content as often as you like within the year, even after you've completed the course. However, if you buy Lifetime Access for the course, you will be able to access the course for a lifetime. Is there a certificate of completion provided after completing the course? Yes, upon successfully completing the course, you will receive a certificate of completion. This certificate can be a valuable addition to your professional portfolio and can be shared on your various social networks. Can I switch courses or get a refund if I'm not satisfied with the course? We want you to have a positive learning experience. If you're not satisfied with the course, you can request a course transfer or refund within 14 days of the initial purchase. How do I track my progress in the course? Our platform provides tracking tools and progress indicators for each course. You can monitor your progress, completed lessons, and assessments through your learner dashboard for the course. What if I have technical issues or difficulties with the course? If you encounter technical issues or content-related difficulties with the course, our support team is available to assist you. You can reach out to them for prompt resolution.

Discover the key role of a Property Coordinator in ensuring seamless real estate operations. Explore responsibilities such as property maintenance, tenant communication, and logistical coordination. Learn how a skilled Property Coordinator enhances property value and tenant satisfaction, making them an indispensable asset in the dynamic world of real estate management

Register on the Light Current Systems for Electrical Engineering today and build the experience, skills and knowledge you need to enhance your professional development and work towards your dream job. Study this course through online learning and take the first steps towards a long-term career. The course consists of a number of easy to digest, in-depth modules, designed to provide you with a detailed, expert level of knowledge. Learn through a mixture of instructional video lessons and online study materials. Receive online tutor support as you study the course, to ensure you are supported every step of the way. Get a digital certificate as a proof of your course completion. The Light Current Systems for Electrical Engineering is incredibly great value and allows you to study at your own pace. Access the course modules from any internet-enabled device, including computers, tablet, and smartphones. The course is designed to increase your employability and equip you with everything you need to be a success. Enrol on the now and start learning instantly! What You Get With The Light Current Systems for Electrical Engineering Receive an e-certificate upon successful completion of the course Get taught by experienced, professional instructors Study at a time and pace that suits your learning style Get instant feedback on assessments 24/7 help and advice via email or live chat Get full tutor support on weekdays (Monday to Friday) Course Design The course is delivered through our online learning platform, accessible through any internet-connected device. There are no formal deadlines or teaching schedules, meaning you are free to study the course at your own pace. You are taught through a combination of Video lessons Online study materials Certification Upon successful completion of the course, you will be able to obtain your course completion e-certificate. Print copy by post is also available at an additional cost of £9.99 and PDF Certificate at £4.99. Who Is This Course For: The course is ideal for those who already work in this sector or are an aspiring professional. This course is designed to enhance your expertise and boost your CV. Learn key skills and gain a professional qualification to prove your newly-acquired knowledge. Requirements: The online training is open to all students and has no formal entry requirements. To study the Light Current Systems for Electrical Engineering, all your need is a passion for learning, a good understanding of English, numeracy, and IT skills. You must also be over the age of 16. Course Content Light Current Systems for Electrical Engineering Light Current Fire Alarm System Module 1- Light Current Fire Alarm System Part 1 00:17:00 Module 2- Light Current Fire Alarm System Part 2 00:15:00 Module 3- Light Current Fire Alarm System Part 3 00:18:00 Module 4- Light Current Fire Alarm System Part 4 00:17:00 Module 5- Light Current Fire Alarm System Part 5 00:17:00 Module 6- Light Current Fire Alarm System Part 6 00:17:00 Light Current MATV and Telephone System Module 1- Light Current MATV System Part 1 00:14:00 Module 2- Light Current MATV System Part 2 00:17:00 Module 3- Light Current Telephone System 00:19:00 Light Current Data System Module 1- Light Current Data System Part 1 00:15:00 Module 2- Light Current Data System Part 2 00:20:00 Light Current CCTV System Module 1- Light Current CCTV System Part 1 00:14:00 Module 2- Light Current CCTV System Part 2 00:23:00 Light Current Sound System Module 1- Light Current Sound System Part 1 00:18:00 Module 2- Light Current Sound System Part 2 00:16:00 Order your Certificates & Transcripts Order your Certificates & Transcripts 00:00:00 Frequently Asked Questions Are there any prerequisites for taking the course? There are no specific prerequisites for this course, nor are there any formal entry requirements. All you need is an internet connection, a good understanding of English and a passion for learning for this course. Can I access the course at any time, or is there a set schedule? You have the flexibility to access the course at any time that suits your schedule. Our courses are self-paced, allowing you to study at your own pace and convenience. How long will I have access to the course? For this course, you will have access to the course materials for 1 year only. This means you can review the content as often as you like within the year, even after you've completed the course. However, if you buy Lifetime Access for the course, you will be able to access the course for a lifetime. Is there a certificate of completion provided after completing the course? Yes, upon successfully completing the course, you will receive a certificate of completion. This certificate can be a valuable addition to your professional portfolio and can be shared on your various social networks. Can I switch courses or get a refund if I'm not satisfied with the course? We want you to have a positive learning experience. If you're not satisfied with the course, you can request a course transfer or refund within 14 days of the initial purchase. How do I track my progress in the course? Our platform provides tracking tools and progress indicators for each course. You can monitor your progress, completed lessons, and assessments through your learner dashboard for the course. What if I have technical issues or difficulties with the course? If you encounter technical issues or content-related difficulties with the course, our support team is available to assist you. You can reach out to them for prompt resolution.

Grade 2 Ballet

By M & L School of Performing Arts

Every Wednesday at 16:15 – 17:30 Step into the captivating realm of the RAD Grade 2 ballet program at M&L School of Performing Arts, where the essential elements of ballet and character dance unfold within a curriculum that treasures the harmony of emotion and technique. This singular grade is a meticulously designed chapter in the ballet journey, offering young dancers the opportunity to revel in the dynamic blend of grace and strength that ballet commands. Nestled within a musical panorama that crosses centuries of dance heritage, our Grade 2 classes beckon students to dive deeper into the artistry of ballet and character dance. This grade serves as a pivotal moment, building upon the joy of movement discovered in earlier levels and encouraging a richer, more nuanced expression of ballet’s technical facets. Here, students are guided to explore their dance potential more fully, expressing themselves with renewed confidence and precision. Grade 2 in the RAD curriculum marks a delightful expansion in the breadth of character dance, presenting students with the chance to explore beyond the foundational steps and into a world rich with cultural diversity and expressive storytelling. The focus on character dance at this level enriches students’ understanding and appreciation of dance’s global tapestry, fostering a versatile approach to ballet that values both tradition and innovation. Why Choose RAD Grade 2 Ballet Lessons for Your Child? Holistic Physical Development: Focused on enhancing flexibility, strength, and coordination, Grade 2 ballet fine-tunes the physical attributes essential for dance. Boost in Self-Expression and Confidence: This grade empowers children to express complex emotions and stories through dance, nurturing a profound sense of self-confidence. Sharpened Discipline and Focus: The precise learning structure of Grade 2 ballet hones discipline, cultivates meticulous attention to detail, and strengthens concentration. Enriched Musical Appreciation: Grade 2 introduces students to an expanded array of musical styles, deepening their rhythmical understanding and appreciation for dance music’s diverse expressions. Joy and Fulfillment in Movement: Emphasizing the pleasure found in each step, leap, and turn, our curriculum encourages students to experience the genuine joy of dance. Social and Teamwork Skills: Ballet classes at this level offer a nurturing environment for developing friendships, learning about teamwork, and enhancing social skills through cooperative performances. Cultural Engagement and Awareness: Exploring character dances introduces students to a broader spectrum of the world’s dance heritage, enriching their cultural perspective and appreciation. Enhanced Coordination and Posture: Ballet at Grade 2 continues to improve overall body coordination and promotes the maintenance of good posture, contributing to a healthy and balanced lifestyle. Development of Important Life Skills: The discipline and perseverance learned through ballet are invaluable, teaching children time management and resilience in the face of challenges. Foundation for Future Learning: Laying a solid foundation for further ballet studies, Grade 2 enriches cognitive abilities and prepares students for the next steps in their dance education. Why M&L School of Performing Arts Is Uniquely Suited for Grade 2 Ballet: Choosing M&L School of Performing Arts for Grade 2 ballet means entering a world where passion for dance and music transforms into a tangible journey of growth and discovery. Inspired by our own experiences and fueled by a deep commitment to dance education, we offer a space where young dancers flourish under the guidance of RAD-certified instructors. Here, your child will not only advance in ballet but will also develop a deep-seated love for the arts, nurtured within a community that values creativity, discipline, and artistic integrity. Enroll your child in the RAD Grade 2 ballet program at M&L School of Performing Arts, and witness their transformation into a more confident, expressive, and technically proficient dancer. Join our family, where every class is a step toward cultivating passionate, skilled artists ready to embrace the vast world of dance. Book first lesson here: https://mandlschoolofperformingarts.com/book-first-lesson/

Fire Safety Training - Level 3 CPD Certified

By Compliance Central

Are you looking to enhance your Fire Safety skills? If yes, then you have come to the right place. Our comprehensive course on Fire Safety will assist you in producing the best possible outcome by mastering the Fire Safety skills. The Fire Safety course is for those who want to be successful. In the Fire Safety course, you will learn the essential knowledge needed to become well versed in Fire Safety. Our Fire Safety course starts with the basics of Fire Safety and gradually progresses towards advanced topics. Therefore, each lesson of this Fire Safety course is intuitive and easy to understand. Why would you choose the Fire Safety course from Compliance Central: Lifetime access to Fire Safety course materials Full tutor support is available from Monday to Friday with the Fire Safety course Learn Fire Safety skills at your own pace from the comfort of your home Gain a complete understanding of Fire Safety course Accessible, informative Fire Safety learning modules designed by experts Get 24/7 help or advice from our email and live chat teams with the Fire Safety bundle Study Fire Safety in your own time through your computer, tablet or mobile device. A 100% learning satisfaction guarantee with your Fire Safety Course Fire Safety Curriculum Breakdown of the Fire Safety Course Module 01: Basics of Fire Safety Module 02: Regulations and Risk Assessment Module 03: Fire Safety Measures Module 04: Fire Safety routes and signs Module 05: Evacuation Strategies CPD 10 CPD hours / points Accredited by CPD Quality Standards Who is this course for? The Fire Safety course helps aspiring professionals who want to obtain the knowledge and familiarise themselves with the skillsets to pursue a career in Fire Safety. It is also great for professionals who are already working in Fire Safety and want to get promoted at work. Requirements To enrol in this Fire Safety course, all you need is a basic understanding of the English Language and an internet connection. Career path The Fire Safety course will enhance your knowledge and improve your confidence in exploring opportunities in various sectors related to Fire Safety. Certificates CPD Accredited PDF Certificate Digital certificate - Included CPD Accredited PDF Certificate CPD Accredited Hard Copy Certificate Hard copy certificate - £10.79 CPD Accredited Hard Copy Certificate Delivery Charge: Inside the UK: Free Outside of the UK: £9.99 each

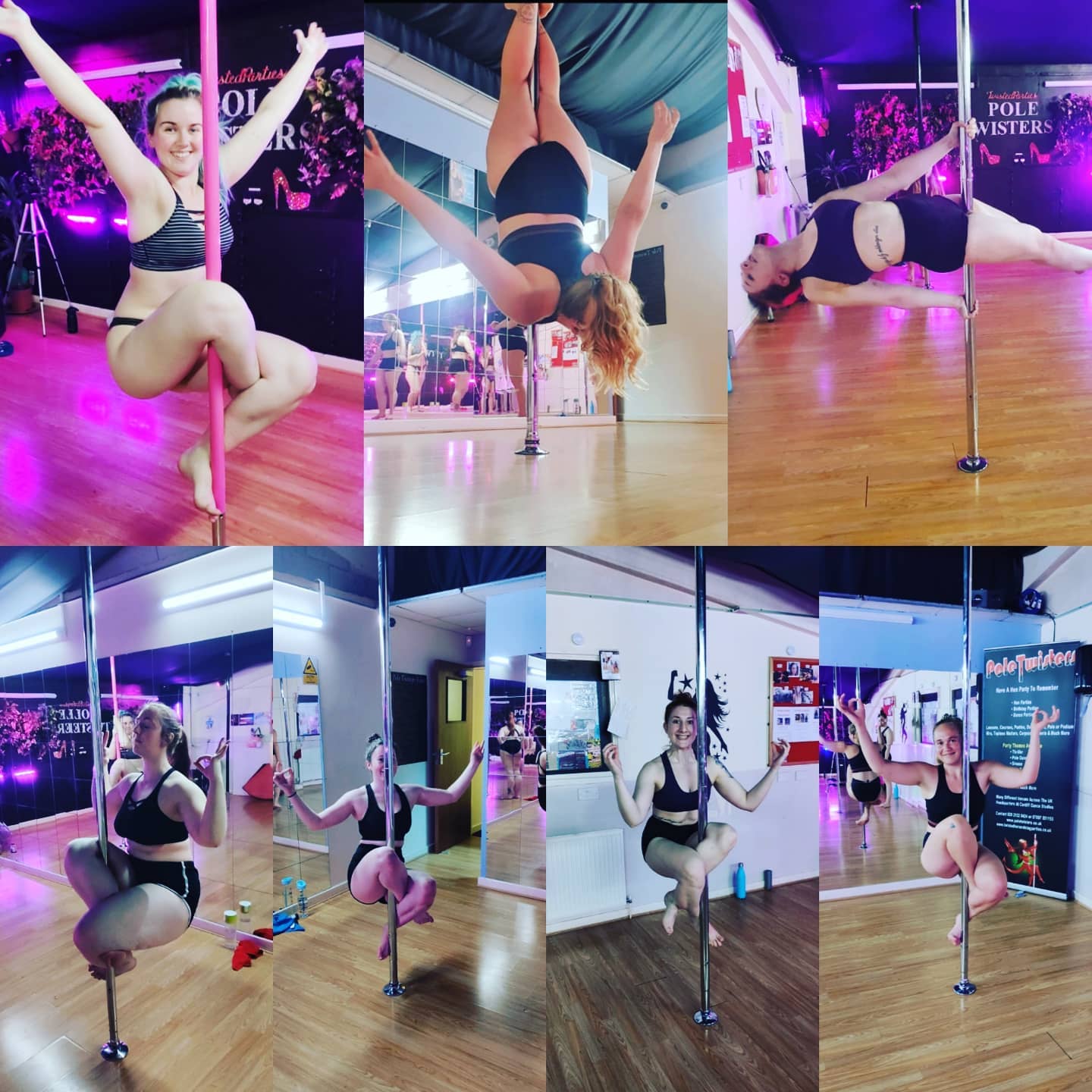

Pole jams run at the same time that another class is running at the other end of the studio. Class/course members receive priority over poles (due to paying a higher rate) so you may be required to share a pole with another jammer if we are busy, however most of the time you should have a pole to yourself.

Certificate in Fire Safety Training

By Compliance Central

Every year, there are major fires all across the world. As a result of such fires, people are killed or severely injured. Preventing fires from starting in the first place is the most effective approach to fire protection. The Certificate in Fire Safety Training Level 3 course is designed to provide individuals with the knowledge and skills they need to understand and implement fire safety measures in the workplace. The course covers a range of important topics, including legislation, measures of fire safety, and fire emergency evacuation procedures. Participants will learn about the different types of fires, how to identify and prevent hazards, and how to respond in the event of a fire emergency. Additionally, the course covers the latest fire safety legislation and best practices for fire safety in the workplace. So, without further ado, join our exclusive Certificate in Fire Safety Training Level 3 course and advance your career. By the end of this course, learners will be able to: Discover the essentials of fire safety. Identify the "Responsible Person" in the event of an emergency. Demonstrate knowledge of UK fire safety standards. Discover the escape route and the location of fire doors on their property. Identify and use extinguishers and other safety devices. Handle vulnerable employees. Make use of PEEP (Personal Emergency Evacuation Plan). Along with the Certificate in Fire Safety Training courses, you also get: Lifetime Access. Unlimited Retake Exam & Tutor Support. Easy Accessibility to the Course Materials- Anytime, Anywhere - From Any Smart Device (Laptop, Tablet, Smartphone Etc.) 100% Learning Satisfaction Guarantee. Fires have been a well-known calamity throughout history, with millions of people suffering the consequences, whether caused by natural or man-made causes. Throughout human history, fires have claimed human lives, wealth, and infrastructure. Fires inflict monetary losses as well as damage to critical infrastructure in both developed and developing countries. Furthermore, these incidences may have long-term psychological consequences for the victims. This course will educate you on what procedures must be followed and how to respond professionally in an emergency. Curriculum Module 01: Introduction Module 02: Legislation Module 03: Measures of Fire Safety Module 04: Fire Emergency Evacuation Procedures CPD 10 CPD hours / points Accredited by CPD Quality Standards Who is this course for? It is useful for learners who provide direct support as well as those who work and want to work in the following areas: Fire Safety Professionals Fireman Fire Service Corporate Office Employees Electrician Requirements To enrol in this Certificate in Fire Safety Training course, all you need is a basic understanding of the English Language and an internet connection. Career path Understanding Fire Safety will provide you with a competitive advantage and open the door to a variety of professional prospects. One can develop into: Fire safety engineer (Salary: £26,000 to £70,000) Health and safety adviser (Salary: £22,000 to £50,000) Firefighter (Salary: £24,191 to £32,244) Building site inspector (Salary: £21,000 to £50,000) Certificates Certificate of completion Digital certificate - Included Get a CPD accredited PDF certificate for Free. Certificate of completion Hard copy certificate - £9.99 Get a CPD Accredited Hardcopy Certificate For £9.99. After passing the assessment of this course, you can get a hardcopy certificate for just £9.99. The delivery charge for the hardcopy certificate inside the UK is £3.99 and international students need to pay £9.99 to get their hardcopy certificate.

Firefighter and Fire Safety Level 3 Diploma

By EduXpress

Our comprehensive program is meticulously crafted to equip you with the essential skills and knowledge required to thrive in your chosen field. Developed by seasoned professionals with years of industry experience, this course is ideal for those seeking to kickstart their careers or enhance their existing skill set. Featuring an engaging audio-visual presentation and easily digestible modules, our program facilitates a self-paced learning experience. Our dedicated online support team is available on weekdays to provide assistance throughout your journey. Key Learning Outcomes: Grasp the fundamentals and their practical applications. Cultivate the necessary skills for success in your field. Apply newfound knowledge to real-world scenarios. Develop effective solutions for relevant topics. Elevate your employability and career prospects. Designed to give you a competitive edge in the job market, this course offers lifetime access to materials and the flexibility to learn at your own pace, from the comfort of your home. Why Choose Us? Learn at your own pace with 24/7 online access to course materials. Benefit from full tutor support available Monday through Friday. Acquire essential skills in the convenience of your home through informative video modules. Enjoy 24/7 assistance and advice via email and live chat. Study on your preferred device - computer, tablet, or mobile. Gain a thorough understanding of the course content. Improve professional skills and earning potential upon completion. Access lifetime course materials and expert guidance. Enjoy the convenience of online learning with flexible schedules. Why Enroll in This Course? Our program provides a comprehensive introduction to the subject matter, laying a solid foundation for further study. It empowers students to acquire knowledge and skills applicable to both their professional and personal lives. Assessment: The course incorporates quizzes to evaluate your understanding and retention of the material. These quizzes pinpoint areas for further practice, allowing you to review course materials as needed. Successfully passing the final quiz qualifies you for a certificate of achievement. Career Path: Our course is meticulously designed to equip you for success in your chosen field. Upon completion, you'll have the qualifications to pursue diverse career opportunities across various industries. Course Content Firefighter and Fire Safety Level 3 Diploma Module 1: Introduction to Firefighting Module 2: Fire Safety and Prevention Module 3: Personal Protective Equipment (PPE) and Apparel Module 4: Firefighting Tools and Equipment Module 5: Fire Dynamics and Behaviour Module 6: Search and Rescue Operations Module 7: Water Supply and Fire Hose Operations Module 8: Fire Control and Extinguishment Techniques Module 9: Specialised Firefighting Operations Module 10: Health, Safety, and Wellbeing of Firefighters

CTS FLEX Training (One to One) "FREE" 1 MONTH

By Cts Workout, Sl

CTS FLEX (one-on-one) training is designed to help you TRAINING and improve HEALTH with the CTS WORKOUT Training System anywhere. If you're ready to push your limits and see great results, sign up today! For 3 months you will have FREE ONLINE training with no obligation. Then if you want to continue, just let us know.

Certificate in Fire Safety Training Course

By Compliance Central

Certificate in Fire Safety Training will assist you in producing the best possible outcome by mastering the skills. Those who want to succeed must enrol in the course Certificate in Fire Safety Training. By completing this course, you will acquire the skills required to become an expert in a comparable field. The basics of our Certificate in Fire Safety Training course are covered first, and then we move on to more advanced material. The lessons in this Certificate in Fire Safety Training course are therefore clear and easy to understand. Courses you'll get: Course 01: Certificate in Fire Safety Training Course 02: Fire Extinguisher Technician Course 03: Basic Life Support (CSTF): Anaphylaxis Course 04: Oxygen First Aid Training Course 05: CPR (Cardiopulmonary Resuscitation) Training Course 06: Health & Safety: First Aid Certificate in Fire Safety Training Course Basic Learning Outcomes: After completing this highly appreciated Certificate in Fire Safety Training course, you'll be a competent expert, besides- You can give assistance related to the Certificate in Fire Safety Training with complete knowledge and confidence. You'll be competent and proficient enough to explore Certificate in Fire Safety Training related job fields on your own. Furthermore, you can train up others and grow an efficient peer community in your locality and serve people. It will enhance your portfolio, you can use the certificate as proof of your efficiency to the employer. It will boost up your productivity, you can use the skill and credentials, and become more competent in your vocation with increased earning Key Highlights of Certificate in Fire Safety Training Course: CPD Accredited Course Unlimited Retake Exam & Tutor Support Easy Accessibility to the Course Materials 100% Learning Satisfaction Guarantee Lifetime Access & 24/7 Support Self-paced Course Modules Certificate in Fire Safety Training Module 01: Introduction to Fire Safety Module 02: Fire Safety Legislation Module 03: Measures of Fire Safety Module 04: Fire Emergency Evacuation Procedures Certification: CPD Accredited (CPD QS) Certificate Digital (PDF) & Hard Copy certificates are available CPD 60 CPD hours / points Accredited by CPD Quality Standards Who is this course for? Anyone from any background can enrol in this Certificate in Fire Safety Training course. This course particularly recommended for- Students Recent graduates Job Seekers Anyone interested in this topic People already working in the relevant fields and want to polish their knowledge and skill. Requirements Students seeking to enrol for Certificate in Fire Safety Training course should meet the following requirements; Basic knowledge of English Language Be age 16 years or above Basic Knowledge of Information & Communication Technologies for studying online or digital platforms. Stable Internet or Data connection in your learning devices. Career path After completing this course, you can explore trendy and in-demand jobs related to Certificate in Fire Safety Training. Fire Surveyor Fire Alarm Engineer Firefighter Fire Risk Assessor Fire Safety Consultant Fire Advisor Fire Engineer Fire Marshal Fire Stopper Certificates Certificate of completion Digital certificate - Included After successfully completing this course, you can get CPD accredited digital PDF certificate for free. Certificate of completion Hard copy certificate - £9.99 After successfully completing this course, you can get CPD accredited hardcopy certificate for free. The delivery charge of the hardcopy certificate inside the UK is £3.99 and international students need to pay £9.99 to get their hardcopy certificate.

Search By Location

- Instructor Courses in London

- Instructor Courses in Birmingham

- Instructor Courses in Glasgow

- Instructor Courses in Liverpool

- Instructor Courses in Bristol

- Instructor Courses in Manchester

- Instructor Courses in Sheffield

- Instructor Courses in Leeds

- Instructor Courses in Edinburgh

- Instructor Courses in Leicester

- Instructor Courses in Coventry

- Instructor Courses in Bradford

- Instructor Courses in Cardiff

- Instructor Courses in Belfast

- Instructor Courses in Nottingham