- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Foundations in Palliative and End of Life Care

By M&K Update Ltd

This course provides the necessary knowledge and skills to facilitate development in palliative and end of life care.

Informed Consent in Clinical Practice

By M&K Update Ltd

This one-day course equips you to fully understand your role in the consenting process and matters that you need to take into consideration in order for the consent to be valid.

Manual Handling (In-House)

By The In House Training Company

Some 60% of injuries at work are caused by lifting heavy objects. This powerful, practical programme is designed to help stop any of your staff from becoming the next statistic. 1 Introduction and objectives 2 Overview of Health and Safety Legislation and HSE Injury Statistics Health and Safety at Work Act 1974 Management of Health and Safety at Work Regulations (MHSWR) 1992 MHSWR 1999 specific duties to risk assess Manual Handling Operations Regulations (MHOR) 1992 Breakdown of injury statistics and costs of poor manual handling 3 The musculoskeletal system explained Prevention and ill-health Ergonomics RSI The spine in detail 4 Risk assessment General principles The TILE method Employees' duties Workplace scenarios

Health & Safety Level 2

By Prima Cura Training

This Health & Safety in the Care Sector Course works alongside, and helps, learners understand Standard 13 of the Care Certificate. This Standard touches on the legislation, policies & responsibilities relating to Health & Safety in the care sector, as well as looking at accidents and sudden illnesses.

Introduction to Data Science

By futureCoders SE

Learn the basics of Data Science, combining a supported #CISCO Skills for All online course with practical learning and a project to help consolidate the learning.

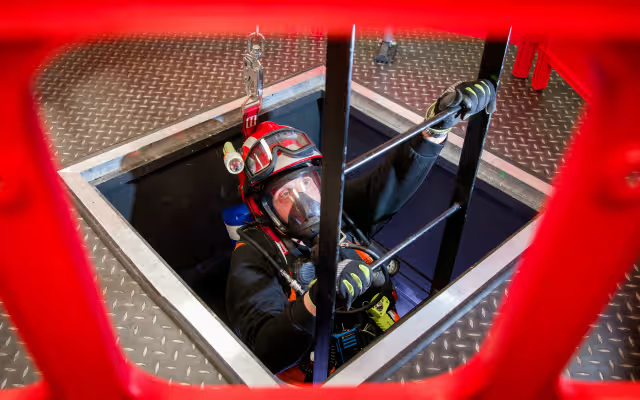

City & Guilds Level 3 Award in Control Entry and Arrangements for Confined Spaces (High Risk) - 6160-04

By Vp ESS Training

City & Guilds Level 3 Award in Control Entry and Arrangements for Confined Spaces (High Risk) - 6160-04 - This course is designed to provide delegates that need to enter medium and high risk confined spaces with an in-depth understanding of legislation, regulations and safe systems of work. This course includes recognising all risk levels of confined spaces. Book via our website @ https://www.vp-ess.com/training/confined-spaces/6160-04-level-3-award-in-control-entry-and-arrangements-for-confined-spaces-(high-risk)/ or via email at: esstrainingsales@vpplc.com or phone on: 0800 000 346

Health and Safety Representatives - Roles and Responsibilities (In-House)

By The In House Training Company

This practical course gives participants a brief overview of a range of legal aspects and also incorporates a topical perspective of health and safety matters in the workplace today. The programme will help elected staff safety representatives to grasp in more detail how to comply with the law in practice. 1 The legal framework Management of Health and Safety at Work Regulations (MHSWR) Safety Representatives and Safety Committees Regulations Representatives' functions H&S Consultation with Employees Regulation HSG 263 2 'The six pack' Management of Health and Safety at Work Regulations (MHSWR) Display Screen Equipment Regulation (DSE) Manual Handling Health, Safety and Welfare Provision and Use of Work Equipment Regulation Personal Protective Equipment Regulation 3 Accident reporting and procedures Reporting Injuries, Diseases and Dangerous Occurrences Regulation (RIDDOR) Accident investigation guidance

Seasonal hand-tied bouquet workshop - on request

By Wildside London

Get together with friends and family and learn the art of building a beautiful hand-tied bouquet of the best seasonal flowers. Mix a gorgeous selection of flowers, fillers and foliage using the 'spiralling' technique used by the pros to make your bouquet and gain lots of flower hacks, tips and tricks along the way. We finish by tying, wrapping and presenting and you'll leave with your floral creation to enjoy at home and the ability to do it all again.

CDM 2015 - in-depth (In-House)

By The In House Training Company

The learning objectives that we believe you require to be covered within the training include: A detailed understanding of the CDM 2015 Regulations and how they should work in practice An understanding of the key roles (Designer, Principal designer, contractor, principal contractor and client) under CDM 2015 What constitutes design and when you may be acting as a designer The requirements for notification Pre construction information, the construction phase plan and the H&S file An opportunity for delegates to ask questions and gain clarification on specific project requirements 1 Introduction Why manage health and safety? The costs of accidents Construction industry statistics Why CDM 2015? 2 Overview of health and safety law and liabilities Criminal and civil law Liability Enforcement and prosecution Compliance - how far do we go? Statutory duties 3 Health and safety law in construction - the current framework Framework of relevant legislationHealth and Safety at Work etc Act 1974Management of Health and Safety at Work Regulations 1999Construction (Design and Management) Regulations 2015Work at Height Regulations 2005 Who is responsible for the risks created by construction work? Shared workplaces/shared responsibilities Control of contractors - importance of contract law 4 CDM 2015 - the principles and current best practice Scope - what is construction? Application - when do the Regulations apply? The CDM management systemDutyholders (client, designer, principal designer, principal contractor, contractor)Documents (pre construction information, Notification, construction phase Plan, H&S File)Management process The 2015 HSE guidance / industry best practice Clarification of roles and responsibilities 5 Competence under CDM 2015 What is 'Competence'? The criteria to be used in construction Achieving continuous improvement 6 Part 4 Construction Health Safety and Welfare Overview of Part 4 Responsibilities Welfare arrangements 7 Risk assessment and the role of the designer Principles of risk assessment Loss prevention / hazard management What is a suitable risk assessment?Design v construction risk assessmentThe client is a designer?Whose risk is it? 8 Risk assessment exercise Understanding the principles of design risk assessment Identifying hazards under the control of clients and designers Quantifying the risk 9 Questions, discussion and review

This Skills for Care Endorsed & CPD accredited training has been designed for existing Social care Staff in line with CQC requirements. Delivered by experienced and professional tutors and trainers with over 25 years of combined experience.

Search By Location

- work Courses in London

- work Courses in Birmingham

- work Courses in Glasgow

- work Courses in Liverpool

- work Courses in Bristol

- work Courses in Manchester

- work Courses in Sheffield

- work Courses in Leeds

- work Courses in Edinburgh

- work Courses in Leicester

- work Courses in Coventry

- work Courses in Bradford

- work Courses in Cardiff

- work Courses in Belfast

- work Courses in Nottingham