- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Report Writing 1 Day Training in Cardiff

By Mangates

Report Writing 1 Day Training in Cardiff

Delivered In-PersonIn-Person training program + more

£595 to £795

The Magic of Mentoring

By Mpi Learning - Professional Learning And Development Provider

In this course you will understand what mentoring is about, understand your roles in the process. Gain self-insight into your own interpersonal style and way of relating to others that may affect mentoring interactions.

Delivered in Loughborough or UK Wide or OnlineLoughborough or UK WideorOnlineFlexible Dates

£1,335

Human Resource Management 1 Day Training in Cardiff

By Mangates

Human Resource Management 1 Day Training in Cardiff

Delivered In-PersonIn-Person training program + more

£595 to £795

Human Resource Management 1 Day Training in St Davids

By Mangates

Human Resource Management 1 Day Training in St Davids

Delivered In-PersonIn-Person training program + more

£595 to £795

Human Resource Management 1 Day Training in Newport

By Mangates

Human Resource Management 1 Day Training in Newport

Delivered In-PersonIn-Person training program + more

£595 to £795

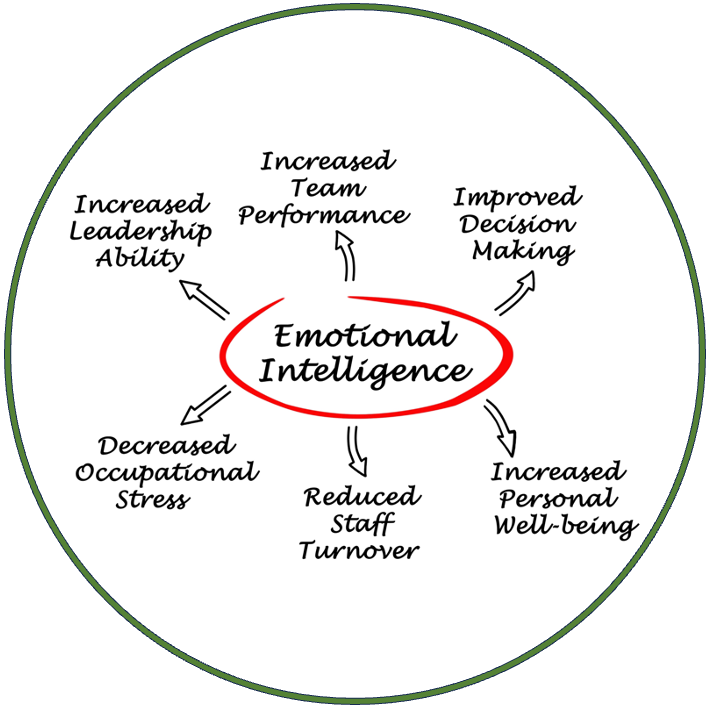

Developing Your Emotional Intelligence (EI) (£1450 total for the 2-day course for up to 15 participants)

By Buon Consultancy

Emotional Intelligence Training

Delivered In-Person in Edinburgh or UK WideEdinburgh or UK WideFlexible Dates

£1,450

Search By Location

- EQ Courses in London

- EQ Courses in Birmingham

- EQ Courses in Glasgow

- EQ Courses in Liverpool

- EQ Courses in Bristol

- EQ Courses in Manchester

- EQ Courses in Sheffield

- EQ Courses in Leeds

- EQ Courses in Edinburgh

- EQ Courses in Leicester

- EQ Courses in Coventry

- EQ Courses in Bradford

- EQ Courses in Cardiff

- EQ Courses in Belfast

- EQ Courses in Nottingham