- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

326 Courses in Birmingham

First Aid Basic Life Support and the safe use of an AED Level 2

By Passion4Training

This training course is delivered by Registered Trainers with many years of on-the-job experience and who can guide you through the theoretical and practical elements of this essential healthcare training course, and answer any questions that may arise during your training.

Being a Mentor using the SSSC National Induction resource

By Pamela Stein Early Years Leadership & Management Training

During this training you will learn skills how to: Be a successful Mentor Build a Professional relationship with your Mentee Use the questions in the SSSC National Induction resource safely. Conduct Mentor Meetings. Successfully monitor and evaluate the mentee's progress

Writing good Funding Applications

By SAVO CIC

This half day course is designed for voluntary and community organisations and those involved in community development who need to write funding applications and want to ensure that their bids are clear, focussed and meet the funders’ criteria.

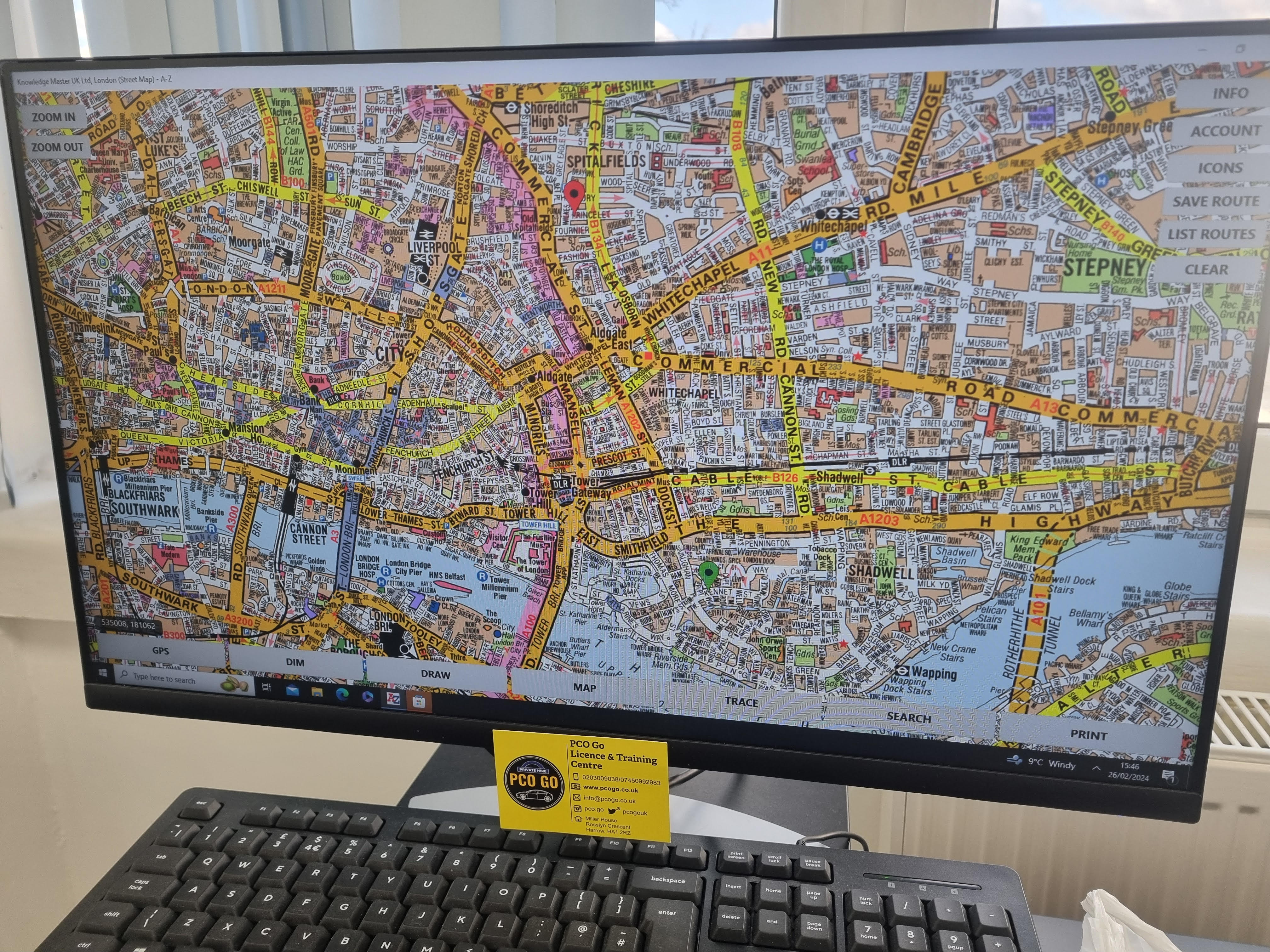

TOPOGRAPHICAL MAP ROUTE PLANNING TRAINING You will use the appropriate software to learn how to plan map routes. We will train you on the routes that you will most likely be tested on in your assessment. Most of our training is provided one to one, so as to give you our undivided attention and prepare you to the best of your ability, thereby giving you the best chance of passing this test. TOPOGRAPHICAL MOCK TEST We will provide you with topographical multiple choice questions mock test based on the actual test questions, to best prepare you. You will use the actual ’Master Atlas of Greater London’ which TfL uses in their test, to best prepare you to answers the multiple choice questions.

HACCP Trainer - RSPH HACCP Level 3 Training Course - Onsite - Nationwide

By Kitchen Tonic Training Company and Food Safety Consultants

HACCP Level 3 Training Courses

The QNUK Level 3 Award in Emergency First Aid at Work (RQF) is ideal for those employers that need to meet the minimum requirement of first aid regulations; typically those working in shops, offices and other low risk environments.

NPORS Lift Supervisor Training The aim of the NPORS Lift Supervisor Training is to Provide candidates with underpinning knowledge to allow them to understand the role and responsibility of the Lift Supervisor. As a result of the Lift Supervisor Course, and following successful completion of the NPORS Crane Supervisor training candidates will be able to understand and follow safe systems of work for lifting operations. This Lift supervisor course is for 3 days and can be completed at your site or ours. It is important that all delegates have a good understanding of spoken and written English for NPORS Crane Supervisor Training. NPORS Lift Supervisor Experienced Test Book with Confidence at Vally Plant Training At Vally Plant Training, we guarantee unbeatable value with our Lift Supervisor Experienced Test Price Match Promise. When you choose us, you can book with confidence, knowing that we will not be beaten on price. If you find a lower price for the same NPORS Lift Supervisor Experienced Worker Test, we’ll match it—ensuring you receive top-quality training at the best possible rate. Click for our terms and conditions Your skills, our commitment—always at the best price. NPORS Lift Supervisor Experienced Worker Test is for operators who have received some form of Lift Supervisor Course in the past or alternatively has been working with Lifting equipment, like cranes, Excavators or Telehandlers for a number of years. If you are unsure if you qualify to go down the Lift Supervisor experienced test route please contact our team to discuss this in more detail. Discounts are available for multiple Lift Supervisor Course bookings There are two parts to the lift supervisor test, a theory section comprised of 25 questions and a practical session, however Lift Supervisor training revision notes will be sent once the test has been booked. It is important that all delegates have a good understanding of spoken and written English for NPORS Crane Supervisor Training Crane Supervisor Course Summary: Leading Safe and Efficient Lifting Operations Introduction Ever wonder who keeps construction sites and warehouses running smoothly and safely? That’s where lift supervisors come in. They’re the unsung heroes ensuring everything moves like clockwork. And when it comes to proving you’re the best in the biz, NPORS certification is your golden ticket. It’s not just a piece of paper; it’s your passport to climbing the career ladder. Choose our Lifting Supervisor Course Today. Why Choose Our NPORS Lift Supervisor Training? What makes our training stand out with our Lifting Supervisor Course? Imagine learning from folks who’ve been in the trenches, in training grounds that feel like the real deal, and schedules that bend to your life, not the other way around. We’re not about boring lectures; we’re about getting your hands dirty. Who Should Attend Lift Supervisor Training? Are you the go-to person when things need to get done? Whether you’re starting out or looking to step up, if you’re in the world of construction or logistics, this Lifting Supervisor Course is for you. It’s tailored for those who like to keep things moving, safely and efficiently. Course Objectives: 1. Understanding Regulatory Requirements: Familiarise participants with relevant regulations and industry standards governing crane operations, LOLER. Ensure compliance with legal requirements and best practices for safe lifting operations, BS7121. 2. Roles and Responsibilities of a Crane Lift Supervisor: Define the roles and responsibilities of a Lift supervisor within the context of lifting operations. Highlight the importance of effective communication, leadership, and decision-making skills. 3. Crane Safety Procedures: Provide an overview of crane safety procedures, including pre-operational checks, equipment inspection, and maintenance. Emphasize the importance of hazard identification, risk assessment, and mitigation strategies. 4. Lifting Plan Development: Guide participants in the understanding of the lifting plans tailored to specific lifting tasks and site conditions created by the Appointed Person(AP). Address factors such as load weight, size, shape, centre of gravity, and environmental considerations. 5. Site Safety and Hazard Awareness: Enhance participants’ awareness of potential hazards in the lifting environment, such as overhead power lines, unstable ground, and confined spaces. Implement effective measures to mitigate risks and ensure a safe working environment. 6. Communication and Coordination: Stress the importance of clear and effective communication between crane operators, riggers, signallers, and other personnel involved in lifting operations. Provide guidance on establishing communication protocols, using standardized hand signals, and conducting pre-lift briefings. 7. Emergency Response and Crisis Management: Equip participants with the skills and knowledge to respond effectively to emergencies and crisis situations during lifting operations. Implement emergency procedures, evacuation protocols, and contingency plans to mitigate risks and ensure personnel safety. 8. Practical Exercises and Case Studies: Provide hands-on lift supervisor training opportunities for participants to apply theoretical knowledge in practical scenarios. Analyse real-life case studies to identify lessons learned, best practices, and areas for improvement in crane supervision. Learning Outcomes By the end, you’ll be a pro at keeping sites safe, managing lifts, and leading teams. You’ll walk away not just with knowledge, but with practical skills that meet and beat industry standards. It’s about making you the go to lift supervisor everyone wants on their team. Course Logistics Ready to jump in? We’ve got training spots across the UK, with dates and times that fit your life. Signing up is a breeze, and we’ll guide you through any paperwork or prerequisites. It’s all about making it easy for you to get started. Conclusion: A crane supervisor course aims to empower participants with the expertise and confidence to lead safe and efficient lifting operations on construction sites. By focusing on regulatory compliance, safety procedures, lifting plan development, hazard awareness, communication, and practical training, the course prepares crane supervisors to fulfil their roles effectively and ensure the well-being of all personnel involved in lifting activities. Investing in crane supervisor training is essential for promoting a culture of safety, minimising risks, and achieving excellence in crane operations management. Crane Supervisor Training Available 7 days a week to suit your business requirements. VPT have a team of friendly and approachable instructors, who importantly have a wealth of knowledge of lifting supervision and the construction industry We have our own training centre conveniently located close to the M5 junction 9, In Tewkesbury. With its own purpose-built practical training area to simulate an actual working environment for the supervisor course. Our Lift Supervisor training and test packages are priced to be competitive. Discounts are available for multiple bookings We can send a fully qualified NPORS supervisor Tester to your site nationwide, for instance to reduce the amount of time away from work More courses: Polish your abilities with our dedicated Lift Supervision Training, Slinger Signaller Training, Telehandler Training, Cat & Genny Training, Plant Loader Securer, Ride-On Road Roller, Abrasive Wheel Training, Lorry Loader Training and Scissor Lift Training sessions. Learn the safe and effective operation of these vital machines, crucial for construction and maintenance tasks. Elevate your skills and career prospects by enrolling in our comprehensive courses today. Frequently Asked Questions 1. What is Lift Supervisor Training? Lift Supervisor Training is a specialised course designed to equip individuals with the knowledge and skills required to supervise lifting operations safely and efficiently. This training typically covers topics such as planning lifts, managing lifting equipment, and ensuring compliance with safety regulations. 2. Who should attend The Lifting Supervisor Course? This training is ideal for individuals responsible for overseeing lifting operations on construction sites, in warehouses, or any environment where lifting equipment like cranes are used. It’s particularly beneficial for site supervisors, managers, and anyone involved in the planning and execution of lifting operations to attend the NPORS Lift supervisor Course. 3. What certifications are available through the Lift Supervisor Training? Participants can obtain several Lift Supervisor certifications, including: NPORS Traditional card: Valid for 5 years, widely accepted in various sectors. NPORS card with CSCS logo: Recognised by major building contractors, with an initial RED trained operator card that can be upgraded to a BLUE competent operator card after completing relevant Crane Supervisor NVQ. 4. Is a health and safety test required for the NPORS Crane Supervisor Red operator card with the CSCS logo? Yes, to qualify for this card, you must have completed the CSCS operatives health and safety test within the last two years. 5 . How long is the certification valid, and what is the renewal process? The NPORS Traditional card is valid for 5 years. The NPORS card with the CSCS logo’s RED trained operator card is valid for 2 years, after which it can be upgraded to a BLUE competent Crane Supervisor operator card upon completion of relevant NVQs. The renewal process typically involves undergoing a refresher course or assessment to ensure continued competence. For those looking for a “NPORS Crane Supervisor Training near me,” our widespread operations make it convenient for you to access Vally Plant Trainings top-quality training no matter where you are in the UK

Unravelling Minds: Demystifying dementia support Closed groups for up to 20 learners per workshop.

By Mindmaps Wellbeing

Empty Spaces, Expressionless Faces. Supporting colleagues in a hybrid workplace Dementia touches more than memory — it weaves into the lives, relationships, and wellbeing of everyone involved. This engaging 2 hour workshop dives into the types and prevalence of dementia, the daily realities for those affected, and how we can step up—individually, locally, and nationally. We’ll explore support, tackle tricky ethical questions, and break down stigma Workshop outline: Understand the types and symptoms of dementia Explore sources of support Reflect on ethical considerations Learn how to support others effectively Apply awareness in your workplace and communities Expect fresh insights, straight-talking discussions, and practical supports you can take back to your workplace. Plus, further signposting to keep your learning journey going. 2-hour workshop packages At Mindmaps Wellbeing, we know that every business is unique, and no team is the same. That’s why we’ve developed our range of short, specialist wellbeing and mental health themed workshops—a fully flexible approach to workplace training. With our selection of engaging and impactful 2-hour workshops, you can build a programme that truly meets your organisation’s needs. Whether you’re looking to manage stress, challenge stigma, or avoid burnout, you choose the sessions that suit your team best. Our training courses and workshop collection Book multiple workshops on the same day to save Why Mindmaps Wellbeing? Mindmaps Wellbeing is the trusted training provider for businesses looking to enhance workplace mental health and employee wellbeing. Our training is designed and delivered by registered Mental Health Nurses, ensuring credibility, expertise, and real-world application. Focus on culture change – Our training goes beyond theory transfer, aiming to embed lasting behavioural shifts that foster a positive, mentally healthy workplace Flexible delivery options – We offer in-person, online, and hybrid training solutions to fit your organisation’s needs Proven impact and measurable results – Our training leads to improved employee engagement, productivity, and retention Engaging and actionable – All our courses include interactive activities, case studies, and real-world applications for immediate impact

RSPH Level 2 Food Safety and Hygiene training Course

By Kitchen Tonic Training Company and Food Safety Consultants

Level 2 Food Safety and Hygiene in Catering Course

Search By Location

- questions Courses in London

- questions Courses in Birmingham

- questions Courses in Glasgow

- questions Courses in Liverpool

- questions Courses in Bristol

- questions Courses in Manchester

- questions Courses in Sheffield

- questions Courses in Leeds

- questions Courses in Edinburgh

- questions Courses in Leicester

- questions Courses in Coventry

- questions Courses in Bradford

- questions Courses in Cardiff

- questions Courses in Belfast

- questions Courses in Nottingham