- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

131 Courses in Belfast

Environmental awareness and management (In-House)

By The In House Training Company

A flexible, modular-based, programme to heighten participants' awareness of ways in which their operations can affect the environment, the principles of environmental management and the practical steps they need to take as individuals and as an organisation to improve environmental performance. Depending on the course modules selected, this programme will give participants: Increased awareness of relevant environmental issues A greater understanding of, and commitment to, the organisation's environmental management programme Preparation for any responsibilities they may have under an Environmental Management System Further benefits according to options chosen 1 Environmental awareness Definition of 'the environment' Key environmental issuesGlobal warmingOzone depletionAcid rainAir qualityWater pollutionContaminated landLand take and green belt shrinkageResource usageHabitat destruction and species extinctions. Option: This module can be used to explain the key environmental issues related to the activities of your own organisation. Diagrams, photos, pictures, examples and statistics relevant to your own organisation are used where possible to illustrate the points being made. 2 Environmental legislation Key elements of environmental legislation affecting the activities of your organisation - including international, European and UK legislation. Legislation of particular relevance to your organisation - how it affects the operations of your organisation Option: Legislation can be dealt with according to which aspect of the environment it protects (eg, air, water, waste) or which part of your organisation's activities it affects Consequences of breaching legislation 3 Environmental management systems Overview of what an environmental management system isHow is an Environmental Management System (EMS) designed and put together?Key elements (emphasising Plan - Do - Check - Review cycle)The need to continually improve Pros and consReasons for having an EMSBenefits of an EMSConsequences of not managing the environmentCosts of installing an EMS Explanation of ISO 14001 and EMAS standards and guidance as applicable to the EMSs of your organisationOverview of your organisation's EMSHow it was set up / is being developed / operatesWho is responsible for itKey parts of system (eg, environmental policy, objectives and targets) identified and discussedEMS documentation - what and where it is. Workshop option: Brainstorm 'Pros and cons' with the participants, come up with all their ideas for good and bad things about EMS and demonstrate that the 'good' list is longer than the 'bad' 4 Environmental consequences Define what an environmental impact is and discuss how they are determined, with reference to the EMS Identify why we want to determine the environmental consequences of operations and activities; how they are used in the EMS for planning, and reducing the impact on the environment Establish key environmental consequences of construction and operational activities on the site; discuss significance ranking and the control measures in place in your organisation. Workshop option: In small groups, participants are asked to identify the impact on the environment of your organisation's activities or a part of their activities. They are then asked to rank these impacts in terms of their significance, using guidelines provided to help them be aware of the contributing factors (eg, frequency, severity). For a selected number of the impacts, the participants are asked to identify what control measures there are and which of these they play a part in. All stages can be discussed with trainers as a whole group at various stages during the workshop. 5 Protected species, nature conservation and invasive weeds Nature conservation, landscape and visual issues in the planning process - overview of key nature UK wildlife legislation, EIA, appropriate timing of surveys, Hedgerow regulations and landscape and visual impact issues Ecological issues - ecological legislation, significant species, hedgerows Archaeology in the development process - why archaeology is important, organisation in the UK, legislation and planning guidance Construction phase issues and consents - major environmental issues during construction, including water resources and land drainage consents, discharges to land or water, water abstraction, public rights of way, tree protection, waste management, Special waste, noise, good practice pollution control and Environmental Audits Identification and management of invasive weeds - including legal position regarding management 6 Chemicals and fuels handling and storage How health and safety management is closely linked to environmental management of materials Planning - what mechanisms are in place for planning materials use; legislation, guidance and policies which define how to manage materials Materials storage - what are the considerations for storing materials, covering:Labels: what are the different types and what do they tell us?Storage facilities: what are the requirements for safe storage of materials (eg, signs, secondary containment, access, segregation, lids/covers)Handling: safe handling for protecting the environment, organisational procedures, high risk situations (eg, decanting, deliveries), how to reduce the risks (eg, use of funnels, proper supervision, training)COSHH and MSDS: brief explanation of legislation and its role in environmental control of hazardous materials, how to use the information provided by COSHH assessments Option: These sessions can be illustrated with photographs/pictures and examples of good and bad storage and handling practices Workshop Options: Labelling Quiz - quick-fire quiz on what different labels tell us; Build a Storage Facility - participants are asked to consider all the environmental requirements for building a safe storage facility for their organisation 7 On-site control measures Overview of the legislation associated with nuisance issues on site and mitigating problems when they arise Examples of bad practice, including fuel storage tanks and mobile equipment - costs involved with prosecution of fuel spills, remediation costs, management costs, legal fees, bad PR coverage Identification and management of contaminated land and relevant legislation Workshop option: Participants are provided with a site plan containing information on site features, environmental conditions and indications of potential issues 8 Waste management Why worry about waste? - a look at how waste disposal can impact on the environment, illustrated by examples of waste-related incidents, statistics on waste production on national, industry-wide and organisational levels, landfill site space, etc Legislation - overview of the relevant legislation, what the main requirements of the regulations are, what penalties there are, and the associated documentation (waste transfer notes) Waste classification - a more in-depth look at how waste is classified under legislation according to hazardous properties, referring to Environment Agency guidance Handling and storage requirements - what are the requirements of the applicable waste legislation and how are they covered by organisational procedures? Examples of good and bad environmental practice associated with handling and storing waste. Workshop option: 'Brown bag' exercise - participants pass round a bag containing tags each with a different waste printed on. They are asked to pick out a tag and identify the classification and the handling, storage and disposal requirements for the waste they select Waste minimisation - overview of the waste minimisation 'ladder' and its different options (elimination, reduction, reuse and recycling), benefits of waste minimisation, examples of waste minimisation techniques Workshop option: Participants are asked to identify opportunities that actually exist within the organisation for minimising production of waste that are not currently being taken advantage of 9 Auditing Requirements for environmental auditing of operations Auditing the EMS Types of internal and external audits Requirements EMS standards (ISO 14001 and EMAS) Carrying out internal audits and being prepared for external audits Workshop options:Mock audit 'Brown Bag' - can be used either for trainers to test participants as if they were in an audit situation, or for the participants to test each other and practice their auditing technique. The bag contains tags each with a different topic printed on (eg, waste skips); participants pass the bag round and select a tag; they are then questioned by the trainer or another participant about that topic as if they were in an audit situation. If the participants are auditing each other, they will be provided with a set of guidelines to keep in mind during the workshop.Virtual auditing - a more practical workshop where participants review photographs of situations/activities relevant to the organisation's operations. They are asked to identify all the good and bad environmental practices that are occurring in the situations. 10 Incident response What should you do when an incident does happen? What should be in a spill kit? When should you call in the experts? When should you inform the Environment Agency or Environmental Health Officer? Workshop option: The participants are provided with some incident scenarios and asked to develop a response to the incident 11 Monitoring and reporting Environmental monitoring programmes and procedures Monitoring and reporting as control measures for environmental consequences Monitoring and environmental 'STOP' card systems - personal and behavioural monitoring and reporting

NPORS Crane / Lift Supervisor (N405)

By Dynamic Training and Assessments Ltd

NPORS Crane / Lift Supervisor (N405)

Natural Gas & LNG Sales Agreements

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your knowledge of natural gas and LNG sales agreements with EnergyEdge course. Enroll now to gain valuable industry knowledge and skills.

H&S for FM (In-House)

By The In House Training Company

This workshop has been designed to help managers understand their responsibilities and what they need to do to ensure compliance with current workplace legislation - including the fire safety and CDM regulations. The day will cover the legal background - including an appreciation of how safety legislation has evolved and why; the logic behind recent developments and the implications for staff and employers; key areas of current legislation; roles and responsibilities in health and safety management, including monitoring contractors and suppliers effectively; implementing sound health and safety policies and procedures; getting staff on board, and implementing effective systems. Also, recognising potential risks and hazards and developing strategies to minimise their impact in the workplace. This course will give participants an understanding of: The broader context of the key areas of health and safety regulation which apply to your organisation Existing health and safety practice and guide them in how to shape and implement an effective health and safety policy What they should do and the procedures to support it Potential areas of risk in the workplace - and how to take action to minimise the threat to staff safety How sound health and safety processes can contribute to business performance 1 Understanding the workplace legislation Overview of health and safety and workplace legislation Compliance, the role of the facilities manager, and who is accountable? Breakout session to discuss where we are now and to highlight issues of concern Applying required policies and procedures Developing and implementation/review of the safety policy Communicating with users, clients and contractors Health and safety manual 'Selling' health and safety 2 Key legislation - a practical working guide Asbestos Regulations Construction (Design and Management) Regulations 2007 / 2015 Control of Substances Hazardous to Health (COSHH) Regulations Disability Discrimination Act (DDA) Display Screen Equipment (DSE) Regulations 1992 Electricity at Work Regulations 1989 Fire Precautions (Workplace ) Regulations 2006 Health and Safety (Consultation with Employees) Regulations 1996 Health and Safety (First Aid) Regulations 1981 Health and Safety at Work etc. Act 1974 Management of Health and Safety at Work Regulations 1992 Manual Handling Operations Regulations 1992 Portable Appliance Testing (PAT) Provision and Use of Work Equipment Regulations 1992 REACH - Registration, Evaluation, Authorisation and restriction of Chemicals Reporting of Injuries, Diseases, and Dangerous Occurrences Regulations (RIDDOR) 1995 Waste Electrical and Electronic Equipment (WEEE) Regulations 2006 Work Equipment Regulations 3 Controlling contractors Understanding the Regulations Selecting and assessing contractors Understanding and setting accountability Why a method statement? How to apply a permit to work system Safe systems of work Round-table discussion to bring out issues from participants' own experience 4 Risk assessment Understanding your hazards Identifying specialist areas How to undertake these assessments Implementation of sound systems and processes Syndicate exercise identifying where assessments are needed and carrying out assessments 5 Keeping the work environment safe Sick building syndrome and legionella Asbestos Waste management Pest control Provisions for first aid Accident reporting and investigation At-work driver safety Security 6 Fire safety Understanding the Regulatory Reform Fire Safety Order Fire certificates The fire risk assessment Testing fire-fighting equipment? Emergency procedures Workshop to examine the procedures for dealing with different types of emergencies 7 Ergonomics programme Ergonomics - important or irrelevant? Are you complying with HSE regulations? Furniture and equipment Display screen equipment assessments Homeworking - your concern or not? Syndicate exercise to review what to do when relocating or refurbishing an office 8 Inspecting and auditing Role of Health and Safety Executive Inspectors - 'be prepared' FM role Staff/trade union involvement Independent audits Records and reports Communicating the results 9 Action plan Participants to list actions they need to take after the course

Offshore & Marine Supply Base Operations Management - For Servicing International E & P Fleet and Wind Farm Operations

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course The Oil & Gas E&P industry is evolving from deep sea exploration to renewable sources of energy through windfarms and solar fields offshore. In tandem, OSBs will need to evolve for sustainability and revival from stagnant traditional Supply Base Models. The changing role of OSBs is toward support services for decommissioning projects and LNG Floating Terminals. In addition, the new geographical regions of East and South Africa are coming up at a faster pace. All such operations are dependent upon a complex network of transport and supply in order to deliver the staff, materials, machinery, and crew provisions where and when needed. This 3 full-day course is curated to enhance the skills and competencies of passionate professionals to plan and organise resources, minimise turnaround time for the vessels engaged in support of Offshore E & P operations. Various hands-on exercises can equip the participants to implement viable and feasible approaches for safe and efficient management of OSBs in compliance with continuously evolving international best practices and Oil & Gas standards. This course is specially developed for investors, business owners, senior executives and professionals from the offshore & marine logistics industry, with the following objectives: To provide a firm understanding about the role of an Offshore & Marine Supply Base in support of Oil & Gas E & P fleet operations, in contrast with traditional merchant shipping logistics. To provide an in-depth knowledge about the range and diversity of services being offered by Offshore & Marine Supply Bases ('OSB') in the target regions. To equip with the knowledge and information required for taking investment decisions when venturing in Offshore E & P Sector. To introduce contemporary techniques and tools required to identify target customer segments while developing a new OSB or expanding operations of an existing OSB. To elaborate comparative management methodologies for OSB facilities and services management, based on deployment of ICT solutions so as to deliver value added services to the customers. To learn to identify methodologies for sales and distribution of services to the customers and non-paying users of the OSB. To identify relevant state legislation for licensing & governing an OSB, and enforce through contractual obligations, rights and responsibilities of the parties as clients of an OSB. To develop and implement Business Processes with built-in Performance Evaluation Metrics for achieving competitive advantage over the peers in the OSB segment. To develop and implement integrated OSB's Risk Management framework. This course can also be offered through Virtual Instructor Led Training (VILT) format. Training Objectives Upon completion of this course, the participants will be able to: Implement and comply with the QHSSSE regulations and national or Port Controls regime for safe handling of import & export cargo and movements of the vessels. Establish role and responsibilities of the Offshore Supply Base management team. Plan and organise resources so as to minimise turnaround time for the vessels engaged in support of Offshore E & P and Windfarms operations. Plan and organise OSB cranes, vehicles, MHE, spaces and relevant facilities for storage, movement, and custody transfer of various types of solid and liquid cargo, tools, shackles, bulk materials in open yards and ships' gears. Be aware of potential emergency situations and how to respond and coordinate with relevant internal and external agencies. Manage safety of personnel of sub-contractors, stevedores', tenants, and ship crew, when engaged in OSB operations. Differentiate between various ships, technical and functional characteristics, safety requirements and potential hazards of each operation. Build competency in developing and maintaining documentary evidence for traceability for all works executed during the specific period or operation. Develop techniques for performance monitoring and continuous improvements based on lessons learned from each operation at the Base as well as from reports about peers in the similar business. Target Audience This course is intended for: Operations Management personnel from existing OSBs, Ports, Logistics & Warehouses, Offshore Fields, E & P Infrastructure Support services providers. Professionals who are interested in OSB segment of the Offshore & Marine Oil & Gas Industry. Participants who have no prior knowledge about OSB Operations and are new to the Offshore Logistics And highly recommended for: Managers, Engineers, and Professionals assigned to lead new initiatives in Logistics Management of Offshore & Marine Segments of Oil & Gas Industry. Course Level Intermediate Trainer Principal Management Consultant Chartered Valuer and Appraiser (CVA) FACICA | FAMTAC | FAIADR | M.S.I.D | Member, AIEN LL.M. (IP Law), M. Sc. (Maritime Studies), M. Tech (Knowledge Engineering), MBA, First Class CoC (MCA, UK), B. E. (Elect) Your expert course leader during the last 47 year period, has worked and consulted in the industry verticals encompassing: Technology, Oil & Gas Exploration & Production, Petrochemical Process Plants and Power Plant Construction Projects, Logistics & Warehousing, Marine, Offshore, Oil & Gas Pipelines, Infrastructure Development Projects (Ports, Offshore Supply Bases, Oil & Gas Terminals and Airports etc), EPCIC Contracts, and Shipyards, in South East Asia, Africa, Middle East, Americas and Europe. He serves as the Principal Management Consultant with a management consultancy in Hong Kong and Singapore, specialising in the fields of corporate management consultancy, international contracts reviews and alternative dispute resolutions services. He undertakes special assignments for conducting audits and valuation of intangible properties involving proprietary processes for licensed production, and licensing of intellectual property rights (IP Rights) in patents, trademarks, and industrial designs. He is frequently engaged for assignments like due diligence, acquisitions, mergers, resolving various operational issues, technology transfer and agency services contracts reviews, cost controls, and enhancement of Supply Chain Management. He has been conferred the credentials of Chartered Valuer & Appraiser (CVA) by SAC and IVAS, in accordance with the international valuation standards setting body IVSC. His consulting experience includes Charterparty Management, Business Process Re-engineering, Diversifications, Corporate Development, Marketing, Complex Project Management, Feasibility Studies, Dispute Resolutions and Market Research. He has successfully assisted Marine and offshore E & P clients in managing contractual disputes arising from various international contracts for upgrading & conversion projects. He continues to be actively engaged in claims reviews, mediation, arbitration, litigation, and expert witness related assignments, arising from international contracts and Charterparty Agreements. He graduated with a Bachelor's degree in Electrical Engineering, MBA in General Management, Master of Technology in Knowledge Engineering, Master of Science in Maritime Studies, and LL.M. (IP Law). He also holds professional qualifications in Business Valuations and Appraisers for CVA, arbitration, law, and marine engineering, including the Chief Engineer's First-Class Certificate of Competency (MCA, UK). He is further qualified and accredited as Certified International Arbitrator, Chartered Arbitrator, Sports arbitrator under CAS Rules, WIPO Neutral, Australian Communications and Media Authority (ACMA) Bargaining Code Arbitrator, Accredited Adjudicator and Accredited Mediator (Malaysia). He is admitted to the international panels of arbitrators and neutrals with WIPO, Geneva; ACICA, AMTAC and ACMA, Australia; BVIAC (British Virgin Islands); JIAC (Jamaica); HKIAC Hong Kong; AIAC, Malaysia; AIADR, Malaysia; KCAB, Seoul, South Korea; ICA, Delhi, India; ICC (Singapore); SISV, Singapore; SCMA, Singapore; SCCA, Saudi Arabia; VIAC Vienna, Austria; Thailand Arbitration Centre (THAC), and Mediator with AIAC Malaysia, CMC, and SIMI Singapore. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

COSHH & RIDDOR

By Prima Cura Training

This course aims to provide a more in depth understanding of COSHH & RIDDOR.

COSHH & RIDDOR

By Prima Cura Training

This course is designed to provide delegates with awareness in the Control of Substances Hazardous to Health (COSHH) and how it may affect them, their colleagues, and their employer.

Production Sharing Contracts (PSC) & Related Agreements

By EnergyEdge - Training for a Sustainable Energy Future

Gain a deep understanding of Production Sharing Contracts (PSC) and related agreements through our expert-led course. Enroll now and excel in your field with EnergyEdge.

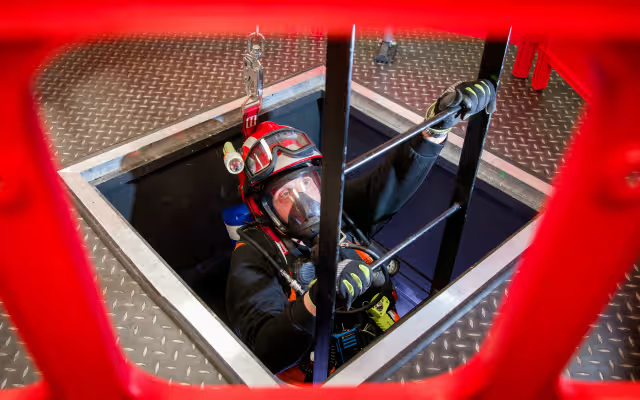

City & Guilds Level 3 Award in Control Entry and Arrangements for Confined Spaces (High Risk) - 6160-04

By Vp ESS Training

City & Guilds Level 3 Award in Control Entry and Arrangements for Confined Spaces (High Risk) - 6160-04 - This course is designed to provide delegates that need to enter medium and high risk confined spaces with an in-depth understanding of legislation, regulations and safe systems of work. This course includes recognising all risk levels of confined spaces. Book via our website @ https://www.vp-ess.com/training/confined-spaces/6160-04-level-3-award-in-control-entry-and-arrangements-for-confined-spaces-(high-risk)/ or via email at: esstrainingsales@vpplc.com or phone on: 0800 000 346

Search By Location

- Legislation Courses in London

- Legislation Courses in Birmingham

- Legislation Courses in Glasgow

- Legislation Courses in Liverpool

- Legislation Courses in Bristol

- Legislation Courses in Manchester

- Legislation Courses in Sheffield

- Legislation Courses in Leeds

- Legislation Courses in Edinburgh

- Legislation Courses in Leicester

- Legislation Courses in Coventry

- Legislation Courses in Bradford

- Legislation Courses in Cardiff

- Legislation Courses in Belfast

- Legislation Courses in Nottingham