- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

1169 Courses in Belfast

Process Control and Instrumentation

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This course will begin with a presentation of topics to familiarize Process and Instrumentation Engineers with procedures and practices involved in the choice of sensors related to the measurement of temperature, pressure, level and flow in relation to single-phase flows. It will provide guidance on the optimum commercially available devices through a detailed comparison of their relative merits. At the heart of this course is sensor calibration which is a crucial element for these topics. The course will also examine the various types of flow control valve, including Globe, Slide, Needle, Eccentric plug and Ball valves and their characteristics in industrial application, while focusing on the problems of Cavitation and Flashing and methods to minimise or eradicate these issues. With the use of examples, industry case studies and a wide range of videos, this course will also cover all aspects of proportional (P), derivative (D) and integral (I) control. In particular, it will address the advantages and disadvantages of PI and PID control. It will also describe Cascade, Feed forward, Split Range, Override and Ratio Control techniques. Training Objectives By attending this course, participants will acquire the following knowledge and skills: Apply an in-depth knowledge to the measurement of temperature, pressure, level and flow as well as to the fluid mechanics of pipe flows Assess the advantages and disadvantages of the major flowmeter types including the differential pressure, rotary positive displacement, rotary-inferential, electromagnetic, ultrasonic and Coriolis mass flowmeters to determine the optimum choice for a given application Make a considered judgement of the choice of fluid level measurement devices Understand the various types of flow calibration, metering systems and provers Carry out tank measurement and tank calibration methods and to calculate net sellable quantities Discuss valve characteristics & trim selection and illustrate the process of control valve sizing Explain the terms Open and Closed loop Define Process Variable, Measured Variable, Set Point and Error Define Direct and Reverse controller actions Explain the terms Process Lag, Measurement Lag, Transmission Lag, and Response Lag and their effect on controllability Explain ON/ OFF Control and the inherent disadvantages Explain Proportional Control, Offset, Gain and Proportional Band and the advantages and disadvantages of Proportional only control Explain the fundamentals and operation principles of Integral (I) Action and the disadvantages of proportional plus integral control Explain the fundamentals and operation principles of Derivative (D) Action in conjunction with P action Describe the operating principles of a PID Controller and explain the applications and advantages of PID control Describe Cascade, Forward, Split Range and Ratio Control operation principles Target Audience This course will benefit instrumentation, inspection, control, custody metering and process engineers and other technical staff. It is also suitable for piping engineers, pipelines engineers, mechanical engineers, operations engineers, maintenance engineers, plant/field supervisors and foremen and loss control coordinators. Trainer Your expert course leader is a Senior Mechanical & Instrumentation Engineer (UK, B. Sc., M.Eng., Ph D) with over 45 years of industrial experience in Process Control & Instrumentation, Pumps, Compressors, Turbines and Control Valve Technology. He is currently a Senior Independent Consultant to various petrochemical industries in the UK, USA, Oman, Kuwait and KSA where he provides consultancy services on both the application and operational constraints of process equipment in the oil & gas industries. During his early career, he held key positions in Rolls Royce (UK) where he was involved in the design of turbine blading for jet engines, subject to pre-specified distributions of pressure. During this period and since, he has also been closely involved in various aspects of Turbomachinery, Thermodynamics and Fluid Mechanics where he has become a recognised authority in these areas. Later, he joined the academic staff of University of Liverpool in the UK as a Professor in Mechanical Engineering Courses. A substantial part of his work has been concerned with detailed aspects of Flowmetering - both of single & multiphase flows. He has supervised doctoral research students in this area in collaboration with various European flowmeter manufacturers. He joined Haward Technology Middle East in 2002 and was later appointed as European Manager (a post which has since lapsed) and has delivered over 150 training courses in Flowmeasurement (single- and multi-phase), Control, Heat Exchangers, Pumps, Turbines, Compressors, Valve and Valve Selection as well as other topics throughout the UK, USA, Oman and Kuwait. During the last two years, he has delivered courses with other training companies operating in the Far and Middle East. He has published about 150 papers in various Engineering Journals and International Conferences and has contributed to textbooks on the topics listed above. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

The Principles of Asset Management - IAM Certificate in Asset Management - Virtual Instructor Led Certificate Training Course

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Certificate Training Course (VILT) Asset maintenance and equipment reliability teams play a significant role to ensure that there is no room for downtime and losses in production. They are often recognised for their contribution and ability to keep assets running productively in today's organisations. The Certificate in Asset Management Virtual Instructor Led Training (VILT) course will provide those involved in Asset Management with a full explanation of the key processes to manage assets across their lifecycle. This recognised VILT course has been designed to equip participants with practical skills to take back to work. This VILT course enables participants to ensure their organisation's assets are realising their full value in support of the organisation's objectives. Accredited by the Institute of Asset Management (IAM), this VILT course will prepare participants to sit for the IAM Asset Management Certificate qualification. The IAM exam is offered as an option for participants of this VILT course. Training Objectives By the end of this VILT course, participants will be able to: Understand the key principles, tools and terminology of Asset Management, and demonstrate how it will benefit your organisation Gain familiarity in the application of ISO 55000 in practice Access a range of models that will support the implementation of asset management in your organisation Assess your understanding of the current tools and concepts applied in Asset Management Capture new ideas and skills that will enhance performance and be better prepared for the Institute of Asset Management (IAM) Certificate Examination Target Audience This VILT course will benefit maintenance managers, operations managers, asset managers and reliability professionals, planners and functional specialists. It will also be useful for facilities engineers, supervisors/managers and structural engineers/supervisors/ and managers. IAM Qualifications Syllabi This document details the scope of the individual topics which comprise the examination modules, and how the exams are assessed. It is important that prospective candidates understand the scope of the modules to determine the preparation required. Download here IAM Qualifications Candidate Handbook This handbook provides more detailed information on registering as a candidate, learning resources, training courses, booking an exam, exam regulations and what happens after an exam - whether you are successful or unsuccessful. Download here Course Level Basic or Foundation Training Methods The VILT course will be delivered online in 5 half-day sessions comprising 4 hours per day, with 2 breaks of 15 minutes per day. Course Duration: 5 half-day sessions, 4 hours per session (20 hours in total) Other than world-class visuals and slides, this VILT course will include a high level of interaction between the facilitator and participants and group discussion among the participants themselves. There will be a number of exercises & quizzes to demonstrate key points and to give participants the chance to apply learning and appreciate key aspects of best practice. Participants will also have the chance to share examples from their own experience, discuss real problems they are facing and develop actions for improvement when they return to work. Examples of the exercises that are used in this VILT course are as follows: Exercises: Aligning Assets to Business Objectives, Planning for Contingencies, Understanding Function and Failure. Group exercises: Asset Management Decision Making, Incident Review & Operations Optimisation. The workshop content will be adjusted based on the discussions, interests and needs of the participants on the course. Trainer Your expert course leader is a is a highly experienced in maintenance and turnaround specialist. He is a Chartered Mechanical Engineer, having spent 19 years working for BP in engineering, maintenance and turnaround management roles. During this time, he worked on plants at all ages in the lifecycle, from construction, commissioning and operating new assets to maintaining aging assets and decommissioning. He has taken roles in Projects, Human Resources and Integrity Management which give real breadth to his approach. He also specialized in Continuous Improvement, gaining the award of International Petrochemical Coach of the year. He stays up to date with the latest industrial developments through his consulting support for major clients. He is also the Asset Management lead and a VILT specialist, having delivered over 70 days of VILT training in the last year. He has an engaging style and will bring his current industrial experience, proficiency of VILT techniques and diverse content, gathered from a comprehensive training portfolio, to deliver a distinctive training experience. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

OAL Level 3 Award in Epilepsy and Administration of Buccal Midazolam RQF

By Guardian Angels Training

Gain comprehensive knowledge and practical skills to manage epilepsy and administer buccal midazolam with the Level 3 Award in Epilepsy and Administration of Buccal Midazolam (RQF). Ideal for healthcare professionals and caregivers.

Scrum Product Owner Exam Prep: In-House Training

By IIL Europe Ltd

Scrum Product Owner Exam Prep: In-House Training This workshop prepares you for the Scrum.org PSPO™ I certification. A voucher for the exam and the access information you will need to take the exam will be provided to you via email after you have completed the course. NOTE: If you have participated in any of IIL's other Scrum workshops, you can bypass this program and focus on reading/studying the Scrum Guide and taking practice exams from Scrum.org The Product Owner is responsible for maximizing the value of the product and the work of the Development Team. The Product Owner must be knowledgeable, available, and empowered to make decisions quickly in order for an Agile project to be successful. The Product Owner's key accountability is the Product Backlog. Managing, maintaining, and evolving the Product Backlog involves: Establishing a clear vision that engages the Development Team and stakeholders Clearly expressing Product Backlog items Ordering the items in the Product Backlog to best achieve the vision and goals Ensuring that the Product Backlog is visible, transparent, and clear to all Working with the Development Team throughout the project to create a product that fits the customer's need What you will Learn You'll learn how to: Successfully prepare for the Scrum.org PSPO I exam Identify the characteristics of a successful Product Owner Create a powerful vision statement Apply techniques to understand your customers and the market Manage and engage stakeholders Write effective user stories with acceptance criteria Utilize techniques to visualize and prioritize the Product Backlog Participate in the 5 Scrum events as the Product Owner Understand the Product Owner's role in closing a Scrum project Getting Started Introductions Workshop orientation Exam prep preview Fundamentals Recap Agile Manifesto, values, and mindset Product Owner characteristics Good vs. great Product Owner Product Ownership Product ownership Project vision Understand your customers and market Personas Stakeholder management and engagement The Product Backlog User Stories and Acceptance Criteria Preparing User Stories for a Sprint The Product Backlog Visualizing the Product Backlog Product Backlog Prioritization Technical Debt Sprint Planning and Daily Standups Sprint Planning Planning Poker Team Engagement Daily Standups Sprint Review, Retrospectives, and Closing Sprint Reviews Key Agile Patterns Retrospectives Closing the Project

Skills Training for HCAs Working in GP Surgeries

By M&K Update Ltd

Understand the management of commonly presenting medical conditions and the significance of recording accurate diagnostic investigations.

Wireshark 101 training course description Wireshark is a free network protocol analyser. This hands-on course focuses on troubleshooting networks using the Wireshark protocol analyser. The course concentrates on the product and students will gain from the most from this course only if they already have a sound knowledge of the TCP/IP protocols What will you learn Download and install Wireshark. Capture and analyse packets with Wireshark. Configure capture and display filters. Customise Wireshark. Troubleshoot networks using Wireshark. Wireshark 101 training course details Who will benefit: Technical staff looking after networks. Prerequisites: TCP/IP Foundation for engineers Duration 2 days Wireshark 101 training course contents What is Wireshark? Protocol analysers, Wireshark features, versions, troubleshooting techniques with Wireshark. Installing Wireshark Downloading Wireshark, UNIX issues, Microsoft issues, the role of winpcap, promiscuous mode, installing Wireshark. Wireshark documentation and help. Hands on Downloading and installing Wireshark. Capturing traffic Starting and stopping basic packet captures, the packet list pane, packet details pane, packet bytes pane, interfaces, using Wireshark in a switched architecture. Hands on Capturing packets with Wireshark. Troubleshooting networks with Wireshark Common packet flows. Hands on Analysing a variety of problems with Wireshark. Capture filters Capture filter expressions, capture filter examples (host, port, network, protocol), primitives, combining primitives, payload matching. Hands on Configuring capture filters. Working with captured packets Live packet capture, saving to a file, capture file formats, reading capture files from other analysers, merging capture files, finding packets, going to a specific packet, display filters, display filter expressions. Hands on Saving captured data, configuring display filters. Analysis and statistics with Wireshark Enabling/disabling protocols, user specified decodes, following TCP streams, protocol statistics, conversation lists, endpoint lists, I/O graphs, protocol specific statistics. Hands on Using the analysis and statistics menus. Command line tools Tshark, capinfos, editcap, mergecap, text2pcap, idl2eth. Hands on Using tshark. Advanced issues 802.11 issues, management frames, monitor mode, packet reassembling, name resolution, customising Wireshark. Hands on Customising name resolution.

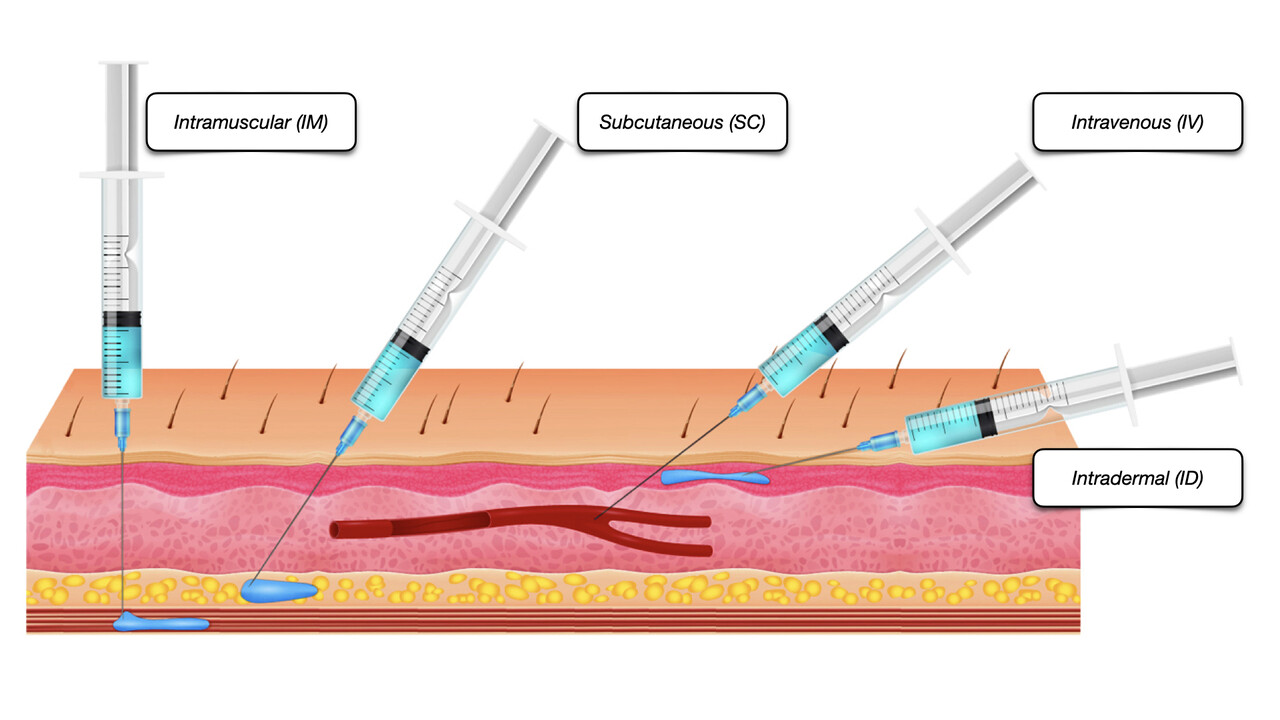

Intravenous Administration of Fluid and Medication

By Guardian Angels Training

Gain the knowledge and skills for safe and effective intravenous therapy with our "Intravenous Administration of Fluid and Medication" course. Ideal for healthcare professionals administering IV fluids and medications.

An Understanding of Injectable LHRH agonists

By Guardian Angels Training

Gain comprehensive knowledge on injectable LHRH agonists with our course. Learn about mechanisms, clinical applications, administration techniques, and more.

Advanced Well Engineering

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course Well engineers who are responsible for technically evaluating and authorizing programs for drilling or working over wells must have the required skills and competencies to safely design wells of varying nature. They also need to be able to confirm that well delivery and intervention programs generate intrinsic well control assurance. Such work programs must establish, verify, monitor and maintain suitable and sufficient barriers for the entire well lifecycle - from spud to abandonment. Well engineers must also be able to select a suitable drilling or workover rig, capable of safely performing the work within its operational envelope. This 3 full-day course aims to further develop and assess the knowledge required to work on and eventually, authorize a well delivery program as deemed fit for purpose. It also addresses elements of well control that must be embedded into well design, well work programming and equipment selection. This course is intended for participants who already have a sound understanding of the principles of the design and/or delivery of wells and with more than 3 years of relevant industry experience. Training Objectives By the end of this course, participants will be able to: Feel confident to design and plan drilling and workover activities while considering geological risks, formation pressures/strengths, and any integrity or well control concerns. Monitor wells operations and ensure that they can and will remain within the accepted design envelope. Assess risks and then apply mitigation or recovery methods in cases where design envelopes are threatened. Participants should be capable of assessing a drilling or workover program and then be able to answer the following key questions: Does the program delivery have a sound design and work plan that allows the well(s) to be drilled or worked over safely? Have we determined the appropriate kick tolerance for each open hole section and is it realistic for all drilling hazards that may be encountered? Have all drilling hazards been suitably assessed, and the associated risk mitigated to a level as low as reasonably practicable? Are there adequate, verifiable barriers in place throughout the operation and does everybody know their role and responsibility? And, as applicable, is the selected rig capable of implementing the work program? Target Audience This course is intended for personnel directly or indirectly involved in the preparation, review or authorization of drilling and workover programs. This includes: Well engineers and drilling supervisors who are responsible for planning and executing drilling and workover operations. Contractor well engineers, rig managers and other senior drilling staff. Senior well engineers and rig superintendents who are responsible for managing the delivery of a project or well. Technical authority holders who are responsible for licensing drilling and workover operations from a regulatory perspective. Assessment: A satisfactory command of critical knowledge and skills is assured by a 1+ hour closed book assessment. This assessment has a mix of multiple-choice questions (MCQs), calculations and answers that must be written up. The exam is taken electronically. Participants are provided with a suitable formula sheet. The pass mark for issuing a certificate is 70% and participants who are not successful will be issued with a certificate of attendance instead. Trainer Your expert course leader has over 45 years of experience in the Oil & Gas industry. During that time, he has worked exclusively in the well engineering domain. After being employed in 1974 by Shell, one of the major oil & gas producing operators, he worked as an apprentice on drilling rigs in the Netherlands. After a year, he was sent for his first international assignment to the Sultanate of Oman where he climbed up the career ladder from Assistant Driller, to Driller, to wellsite Petroleum Engineer and eventually on-site Drilling Supervisor, actively engaged in the drilling of development and exploration wells in almost every corner of this vast desert area. At that time, drilling techniques were fairly basic and safety was just a buzz word, but such a situation propels learning and the fruits of 'doing-the-basics' are still reaped today when standing in front of a class. After some seven years in the Middle East, a series of other international assignments followed in places like the United Kingdom, Indonesia, Turkey, Denmark, China, Malaysia, and Russia. Apart from on-site drilling supervisory jobs on various types of drilling rigs (such as helicopter rigs) and working environments (such as jungle and artic), he was also assigned to research, to projects and to the company's learning centre. In research, he was responsible for promoting directional drilling and surveying and advised on the first horizontal wells being drilled, in projects, he was responsible for a high pressure drilling campaign in Nigeria while in the learning centre, he looked after the development of new engineers joining the company after graduating from university. He was also involved in international well control certification and served as chairman for a period of three years. In the last years of his active career, he worked again in China as a staff development manager, a position he nurtured because he was able to pass on his knowledge to a vast number of new employees once again. After retiring in 2015, he has delivered well engineering related courses in Australia, Indonesia, Brunei, Malaysia, China, South Korea, Thailand, India, Dubai, Qatar, Kuwait, The Netherlands, and the United States. The training he provides includes well control to obtain certification in drilling and well intervention, extended reach drilling, high pressure-high temperature drilling, stuck pipe prevention and a number of other ad-hoc courses. He thoroughly enjoys training and is keen to continue taking classes as an instructor for some time to come. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

NPORS Plant Supervisor Awareness (N034)

By Dynamic Training and Assessments Ltd

NPORS Plant Supervisor Awareness (N034)

Search By Location

- Management Courses in London

- Management Courses in Birmingham

- Management Courses in Glasgow

- Management Courses in Liverpool

- Management Courses in Bristol

- Management Courses in Manchester

- Management Courses in Sheffield

- Management Courses in Leeds

- Management Courses in Edinburgh

- Management Courses in Leicester

- Management Courses in Coventry

- Management Courses in Bradford

- Management Courses in Cardiff

- Management Courses in Belfast

- Management Courses in Nottingham