- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

806 Health courses in Royston, South Yorkshire

Medication Awareness

By Prima Cura Training

Medication Awareness training is essential in the Health and Social Care Sector. This course aims to provide learners with the knowledge required to support the use of medication in Health and Social Care settings. It provides information on the different types, classifications and forms of medication, as well as providing guidance on safe storage and disposal.

H&S for FM (In-House)

By The In House Training Company

This workshop has been designed to help managers understand their responsibilities and what they need to do to ensure compliance with current workplace legislation - including the fire safety and CDM regulations. The day will cover the legal background - including an appreciation of how safety legislation has evolved and why; the logic behind recent developments and the implications for staff and employers; key areas of current legislation; roles and responsibilities in health and safety management, including monitoring contractors and suppliers effectively; implementing sound health and safety policies and procedures; getting staff on board, and implementing effective systems. Also, recognising potential risks and hazards and developing strategies to minimise their impact in the workplace. This course will give participants an understanding of: The broader context of the key areas of health and safety regulation which apply to your organisation Existing health and safety practice and guide them in how to shape and implement an effective health and safety policy What they should do and the procedures to support it Potential areas of risk in the workplace - and how to take action to minimise the threat to staff safety How sound health and safety processes can contribute to business performance 1 Understanding the workplace legislation Overview of health and safety and workplace legislation Compliance, the role of the facilities manager, and who is accountable? Breakout session to discuss where we are now and to highlight issues of concern Applying required policies and procedures Developing and implementation/review of the safety policy Communicating with users, clients and contractors Health and safety manual 'Selling' health and safety 2 Key legislation - a practical working guide Asbestos Regulations Construction (Design and Management) Regulations 2007 / 2015 Control of Substances Hazardous to Health (COSHH) Regulations Disability Discrimination Act (DDA) Display Screen Equipment (DSE) Regulations 1992 Electricity at Work Regulations 1989 Fire Precautions (Workplace ) Regulations 2006 Health and Safety (Consultation with Employees) Regulations 1996 Health and Safety (First Aid) Regulations 1981 Health and Safety at Work etc. Act 1974 Management of Health and Safety at Work Regulations 1992 Manual Handling Operations Regulations 1992 Portable Appliance Testing (PAT) Provision and Use of Work Equipment Regulations 1992 REACH - Registration, Evaluation, Authorisation and restriction of Chemicals Reporting of Injuries, Diseases, and Dangerous Occurrences Regulations (RIDDOR) 1995 Waste Electrical and Electronic Equipment (WEEE) Regulations 2006 Work Equipment Regulations 3 Controlling contractors Understanding the Regulations Selecting and assessing contractors Understanding and setting accountability Why a method statement? How to apply a permit to work system Safe systems of work Round-table discussion to bring out issues from participants' own experience 4 Risk assessment Understanding your hazards Identifying specialist areas How to undertake these assessments Implementation of sound systems and processes Syndicate exercise identifying where assessments are needed and carrying out assessments 5 Keeping the work environment safe Sick building syndrome and legionella Asbestos Waste management Pest control Provisions for first aid Accident reporting and investigation At-work driver safety Security 6 Fire safety Understanding the Regulatory Reform Fire Safety Order Fire certificates The fire risk assessment Testing fire-fighting equipment? Emergency procedures Workshop to examine the procedures for dealing with different types of emergencies 7 Ergonomics programme Ergonomics - important or irrelevant? Are you complying with HSE regulations? Furniture and equipment Display screen equipment assessments Homeworking - your concern or not? Syndicate exercise to review what to do when relocating or refurbishing an office 8 Inspecting and auditing Role of Health and Safety Executive Inspectors - 'be prepared' FM role Staff/trade union involvement Independent audits Records and reports Communicating the results 9 Action plan Participants to list actions they need to take after the course

Level 2 NVQ Diploma in Drilling Operations - Directional Drilling - Drill Rig Operator

By Dynamic Training and Assessments Ltd

Level 2 NVQ Diploma in Drilling Operations - Directional Drilling - Drill Rig Operator

Level 6 NVQ Diploma in Construction Site Management

By Dynamic Training and Assessments Ltd

Level 6 NVQ Diploma in Construction Site Management

NPORS Excavation Marshall - Banksperson (N027)

By Dynamic Training and Assessments Ltd

NPORS Excavation Marshall - Banksperson (N027)

NPORS Loading Shovel (N209)

By Dynamic Training and Assessments Ltd

NPORS Loading Shovel (N209)

NPORS Abrasive Wheels - Handheld Cut off Saw (N017)

By Dynamic Training and Assessments Ltd

Abrasive Wheels - Handheld Cut off Saw (N017)

Carbon Capture, Utilization & Storage (CCUS) Well Design & Monitoring

By EnergyEdge - Training for a Sustainable Energy Future

About this training course This 3-days training will provide a comprehensive review of integrity of wells exposed to carbon dioxide (CO2) in the context of Carbon Capture Utilization for enhanced oil recovery and Storage (CCUS). CO2 geological storage is a proven technology to reduce greenhouse gas emissions from sources such as coal power plants, cement kilns and steel mills. Wells are widely considered the most critical containment element, especially older wells that are not used to inject CO2 or monitor the plume evolution in the storage reservoir. The main reason for this perceived risk is the high corrosion rate of carbon steel when exposed to wet CO2, and the tendency of Portland cement to react with the gas. The training course advanced contents build on 15 years' experience in carbon storage, both in the development and deployment of technologies. First-hand, in-depth knowledge of the subject will allow us to debunk myths and focus on the real challenges of wells encountering CO2. Training Objectives After the completion of this training course, participants will be able to: Explain the CCUS market drivers Examine the behavior of CO2, on surface and in the reservoir Diagnose cement defects and design repairs Understand the limits of Portland cement Assess the benefits of different technologies and materials Realize why geology is a dominant factor in cement performance Critically choose the most appropriate monitoring techniques Classify aging processes of cement, steel, and rock when exposed to CO2 Assess the risk of existing wells if they encounter the CO2 plume Examine recent advances in real-time approaches to the production monitoring and lift management Target Audience This training course is suitable and will greatly benefit: All surface technical personnel such as process engineers & technologists Facility engineers, production engineers & technologists Drilling engineers and Well engineers Design engineers and Integrity engineers P&A engineers and Cementing engineers Geologists Senior management executives will benefit from this training as covers an overview of the technical and commercial details of CO2 capture technologies and risks involved. Course Level Intermediate Training Methods The training instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught in their own organization. Course Duration: 3 days in total (21 hours). Training Schedule 0830 - Registration 0900 - Start of training 1030 - Morning Break 1045 - Training recommences 1230 - Lunch Break 1330 - Training recommences 1515 - Evening break 1530 - Training recommences 1700 - End of Training The maximum number of participants allowed for this training course is 20. This course is also available through our Virtual Instructor Led Training (VILT) format. Trainer Your expert course leader is an engineer with a passion for well integrity and possesses 28 years of international experience in field operations, technology development and management in the oil & gas and carbon storage sectors. Since 2018 he is program chair of the Well Integrity Technical Section of the Society of Petroleum Engineers (SPE). He is also author or co-author of 31 technical papers, a book chapter on CO2 geological storage and 7 patent applications. He delivers training on well integrity, plug and abandonment, asset integrity, risk management and QHSE across the Eastern Hemisphere, and carries out active research on harnessing geological barriers, modeling leaks through cement, and quantifying methane emissions from oil & gas wells. He has extensive expertise in: Well integrity, cementing, corrosion, upstream oil & gas (drilling, completion), carbon capture and storage, mathematical modeling, risk management, reliability, HSSE (health/safety/security/environment), asset integrity, management systems, sustainable development, project management, portfolio management, training, and technology development and innovation. He has personally worked on CCS projects in Europe (France, Germany, Netherlands, Norway), Algeria, Japan and USA. Partial list of companies that have benefited from the trainer's expertise: Vermilion Energy Geostock Aker BP Shell Statoil ENI TNO Geogreen Wintershall Archer INA and many more Recent CCS consulting track record: Schlumberger Total Oxand TNO THREE60 Energy and others POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable

Risk Assessing

By Prima Cura Training

This course is designed to enable learners to increase their understanding of risk assessment and risk management in Health and Social Care settings.

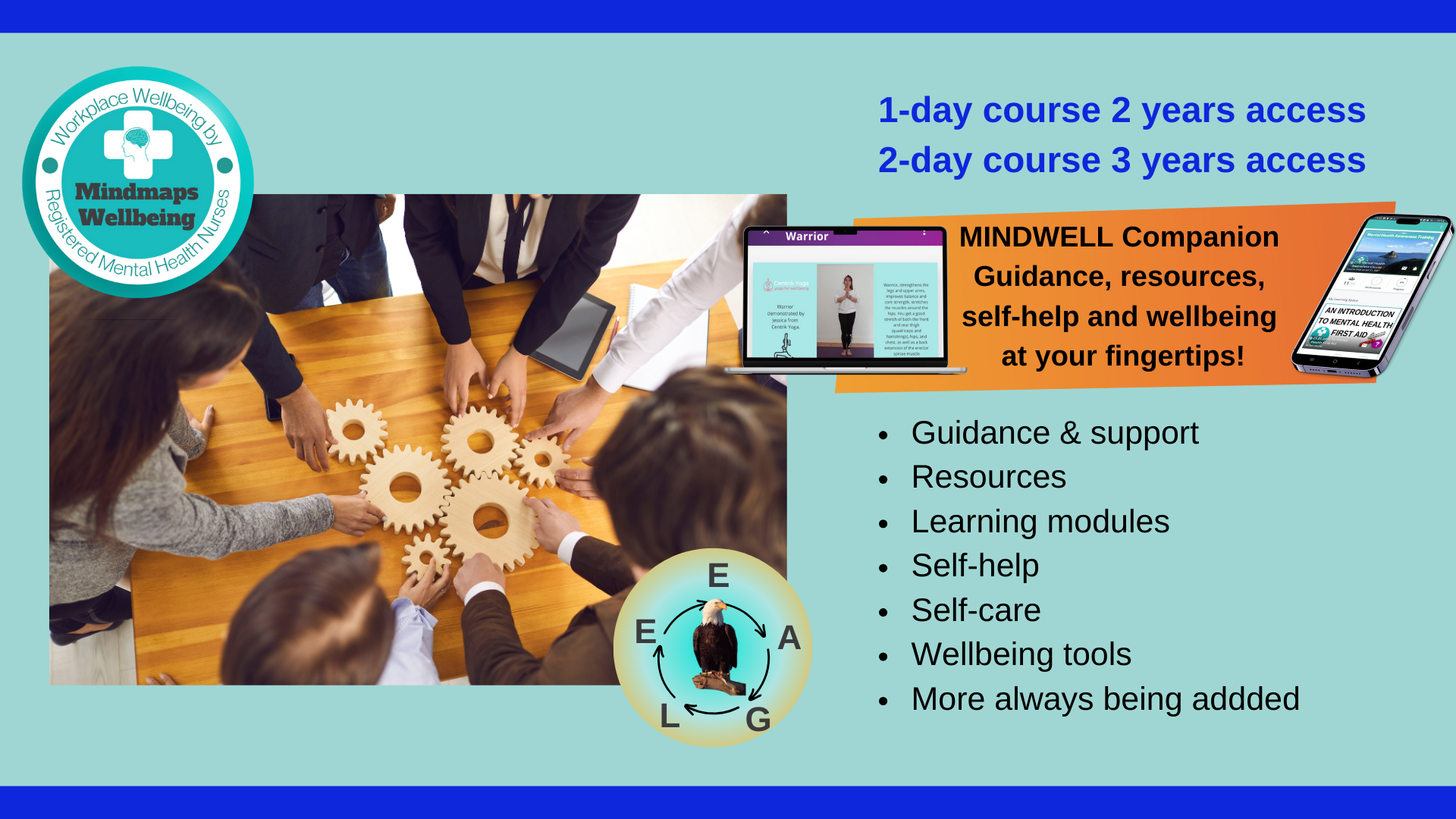

Workplace Wellbeing Skills for Leaders & Managers

By Mindmaps Wellbeing

Closed groups of 6 to 18 learners per session. Learn how to engage in meaningful conversations about workplace wellbeing with the supports designed to enhance your skills as an effective leader. Empowering leaders and managers to support mental wellbeing in the workplace. This comprehensive course is designed to equip learners with the necessary knowledge and skills to support themselves and their team’s wellbeing.

Search By Location

- Health Courses in London

- Health Courses in Birmingham

- Health Courses in Glasgow

- Health Courses in Liverpool

- Health Courses in Bristol

- Health Courses in Manchester

- Health Courses in Sheffield

- Health Courses in Leeds

- Health Courses in Edinburgh

- Health Courses in Leicester

- Health Courses in Coventry

- Health Courses in Bradford

- Health Courses in Cardiff

- Health Courses in Belfast

- Health Courses in Nottingham