- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

1204 Gas courses

Combustion Engineering for Coal Fired Power Plants

By EnergyEdge - Training for a Sustainable Energy Future

Gain valuable insights into combustion engineering for coal-fired power plants with EnergyEdge's in-depth classroom training course.

Carbon Capture and Storage (CCS): Project Risks & How to Manage Them

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Training (VILT) Governments, regulators and energy companies are pursuing CO2 storage technologies to meet their net-zero carbon commitments as well as targets set by the international Paris Agreement on climate change. For successfully executing Carbon Capture & Storage (CCS) projects, various technical, operational, economic and environmental risks and associated stakeholders need to be managed. In this 5 half-day Virtual Instructor Led Training (VILT) course, the methods for managing risk in CCS projects are addressed with a focus on CO2 injection and storage. The VILT course will also demonstrate how to assess storage capacity of a potential CO2 storage reservoir, model framing techniques, and well injectivity issues related to CO2 injection. The potential leak paths will be discussed such as reservoir seals, leakage along faults and aspects of well integrity. In the VILT course, the design of a monitoring programme will also be discussed. The VILT course will be supported by various case studies. This VILT course will cover the following modules: CCS projects in an international context Site selection and site characterization Storage capacity assessment Injectivity assessment Containment assessment Measurement, monitoring & verification Training Objectives On completion of this VILT course, participants will be able to: Uncover the functions and associated components required to capture, transport and store CO2 in subsurface aquifers and (depleted) hydrocarbon reservoirs Find a systematic and integrated approach to risk identification and assessment for CO2 storage projects (maturation) Appreciate the requirements (physics modelling) and uncertainties to assess the CO2 storage capacity of a selected site. Understand the challenges, data and methods to assess CO2 well injectivity and well integrity Identify the leakage pathways of a selected storage site, and understand the assessment methods and associated uncertainties Learn how to design a monitoring program Target Audience This VILT course is intended for all surface and subsurface engineers such as facility engineers, geologists, geophysicists, reservoir engineers, petrophysicists, production technologists/engineers, well engineers and geomechanical specialists. Also, (sub)surface team leads, project managers, business opportunity managers, decision executives, and technical risk assessment & assurance specialists will benefit from this VILT course as it provides a common framework and workflow to develop a CCS project. For each class, it is highly recommended that a mix of disciplines mentioned above are represented to facilitate discussions from different perspectives. Course Level Basic or Foundation Training Methods This VILT course is built around cases in which teams work to identify and assess CO2 storage site issues using a systematic thought approach in this course. In addition, exercises are used to practise the aspects of the CCS risk assessment process. The VILT course provides a venue for discussion and sharing of good practices as well as opportunities to practise multi-discipline co-operation and facilitation. Participants are encouraged to bring their own work issues and challenges and seek advice from the expert course leaders and other participants about all aspects of CCS. This VILT course will be delivered online in 5 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. Trainer Trainer 1: Your expert course leader has more than 36 years of experience in the oil & gas industry with Shell. He gained broad experience in petroleum engineering, with expertise in integrated production systems from subsurface, wells and surface. He has had assignments in Production Technology, R&D, Production Chemistry, Rock Mechanics and Reservoir Engineering cEOR, with a proven track record in technology screening, development and deployment, field development planning, conceptual well design and Production System Optimization (PSO) of gas and oil fields as well as preparing Well, Reservoir & Facility Management (WRFM) strategies and plans. He had also worked on assignments in NAM and did fieldwork in Oman, Gabon and Shell Nigeria. He is a skilled workshop facilitator. He discovered his passion for teaching following an assignment in Shell Learning. During his time in Shell, he developed and taught technical courses to Shell professionals via blended learning. Trainer 2: Your second expert course leader has over 30 years of experience identifying, assessing and mitigating technical risks with Shell. The main focal point of his experience is in subsurface and Geomechanical risks. He is the the founding father of various innovations in how we assess risks by tool development (for bore hole stability, 3D geomechanical field evaluations and probabilistic assessment). He also developed an eye for people motivation, change management and facilitation. He was also responsible for the Geomechanical competence framework, and associated virtual and classroom training programme in Shell for 10 years. Trainer 3: Your third expert course leader has more than 30 years of experience in Shell, focusing on research and development in drilling and offshore systems. His areas of expertise is in project management, finance, business planning, investment, development studies and economics models. In 2021, he worked on a project that looked into the economic evaluation of P18A field complex for CO2 storage. He has an MSc in Mechanical Engineering (M.E.) TU Delft Netherlands (Hons) and a baccalaureate from Erasmus University Rotterdam. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

Be prepared for the upcoming Hiring Season by enhancing your professional skillsets with Apex Learning! Save Up To £5,206 and get Hard Copy + PDF Certificate + Transcript + Student ID Card as a Gift - Enrol Geotechnical Engineering Bundle Now Whether you are interested in a career specifically in geotechnics, or you are looking to brush up on recent methods, our courses in geotechnical engineering provide the detailed information necessary for success in the field. Even for those students interested in other engineering or related fields, like architecture, a detailed understanding of geotechnical topics will provide much-needed insight. After surveying thousands of learners just like you and considering their valuable feedback, this all-in-one Geotechnical Engineering bundle has been designed by industry experts. We prioritised what learners were looking for in a complete Geotechnical Engineering package and developed this in-demand Geotechnical Engineering course that will enhance your skills and prepare you for the competitive job market. Also, our Geotechnical Engineering experts are available for answering your queries and help you along your learning journey. Advanced audiovisual learning modules of these courses are broken down into little chunks so that you can learn at your own pace without being overwhelmed by too much material at once. This Geotechnical Engineering Bundle Consists of the following Premium courses: Course 01: Ultimate Geology Course Course 02: Land Management Course Course 03: Land Surveying Course 04: Oil and Gas Management Course 05: Architectural Studies Course 06: Town Planning Course 07: Diploma in Construction Management Course 08: Construction Industry Scheme (CIS) Course 09: Construction Cost Estimation Diploma Course 10: Agricultural Science Course 11: Diploma in Water Chemistry Course 12: Environmental Law Course 13: Environment Management Course 14: Environmental Health Benefits you'll get from choosing Apex Learning for this Geotechnical Engineering Course: Pay once and get lifetime access to 11 CPD courses Free e-Learning App for engaging reading materials & helpful assistance Certificates, student ID for the Geotechnical Engineering course included in a one-time fee Free up your time - don't waste time and money travelling for classes Accessible, informative modules of Geotechnical Engineering designed by expert instructors Learn about Geotechnical Engineering at your ease - anytime, from anywhere Study from your computer, tablet or mobile device CPD accredited courses - improve the chance of gaining professional skills How will I get my Certificate? After successfully completing the course you will be able to order your CPD Accredited Certificates (PDF + Hard Copy) as proof of your achievement. PDF Certificate: Free (For The Title Course) Hard Copy Certificate: Free (For The Title Course) Geotechnical Engineering Bundle Curriculum: Course 01: Ultimate Geology Course Course Promo Introduction Solar System Geologic Time Inside Earth Plate Tectonics Weathering Deserts & Winds Minerals Sedimentary Rocks Metamorphic Rocks Igneous Rock Deformation Volcanoes Mass Wasting Surface Water Course 02: Land Management Course Land Management: An Introduction Land Use and Land Use Planning Soil Management Course 03: Land Surveying Introduction to Land Surveying Land Surveying Basics Land Surveying Instrumentation Course 04: Oil and Gas Management Introduction to Oil and Gas Management Energy, Economics and Finance in Oil and Gas Oil and Gas Project Management Course 05: Architectural Studies Introduction to Architectural Studies Ancient Architecture Architectural Ideas and Movements Architectural Styles Course 06: Town Planning Introduction to Town Planning Process of Town Planning Residential Buildings and Neighbourhood Planning Course 07: Diploma in Construction Management Introduction to Construction Management Project Life Cycle and Success Cost Management Preliminary Site Investigation and Site Organisation Site Management Course 08: Construction Industry Scheme (CIS) Construction Industry Scheme (CIS) Coverage of the Scheme Contractors and Registration for the Scheme Course 09: Construction Cost Estimation Diploma Introduction to Construction Management Cost Estimation Role of Cost Estimator and New Aspects of Cost Estimation Elements and Factors influencing Cost Estimation Course 10: Agricultural Science Introduction to Agricultural Science Horticulture and The Nursery Production Plant Propagation Soil Science Course 11: Diploma in Water Chemistry Introduction to Water Chemistry Concepts of Basic Chemistry Alkalinity of Water Course 12: Environmental Law Legal System What is Environmental Law International Environment law Environmental Organisations National Environmental Legacy Act Course 13: Environment Management Environment and Ecology Environmental Issues Environmental Planning Course 14: Environmental Health Intro to Environmental Health Waste, Pollution and Pollutants Environment, Pollution, Climate Change and Health CPD 140 CPD hours / points Accredited by CPD Quality Standards Who is this course for? Anyone from any background can enrol in this Geotechnical Engineering bundle. Requirements Our Geotechnical Engineering course is fully compatible with PCs, Macs, laptops, tablets and Smartphone devices. Career path This Geotechnical Engineering Bundle includes a number of additional courses, which will enable you to pursue a successful career. Certificates Certificate of completion Digital certificate - Included You will get the PDF Certificate for the title course (Ultimate Geology Course) absolutely Free! Certificate of completion Hard copy certificate - Included You will get the Hard Copy certificate for the title course (Ultimate Geology Course) absolutely Free! Other Hard Copy certificates are available for £10 each. Please Note: The delivery charge inside the UK is £3.99, and the international students must pay a £9.99 shipping cost.

Seismic Uncertainty Evaluation

By EnergyEdge - Training for a Sustainable Energy Future

About this training The Seismic Uncertainty Evaluation (SUE) course has evolved after a number of years of work experience in the sub-surface domain. A common question closely related to well planning is the quantification and qualification of depth uncertainty and robust estimation of the volumetric ranges, and this course addresses these topics. Training Objectives Upon completion of this course, participants will be able to: Define a structured approach toward seismic depth uncertainty analysis Construct data analytics on seismic products (well logs, velocities, and seismic) Classify advance vertical ray tomography on FWI models to assure a drill ready depth seismic, faults, surfaces, and logs Interpret probabilistic volumetric and automatic spill point control, amplitude conformance closures De-risk the depth uncertainty by providing drilling and completion with a risking score card Target Audience This course is intended for individuals who needs to understand the basic theory and procedures for assessment/ quantification/qualification of all drill-ready products (seismic, faults, horizons, etc.) Geologist Geophysicist Reservoir engineer Drilling engineer Course Level Intermediate Trainer Your expert course leader is a cross-functional Geoscientist and Published Author with 27 years of international experience working in Upstream Petroleum Exploration and Production for Oil and Gas Companies in Australia, India, Singapore, Saudi Arabia, and Oman. During his career he actively supported field development, static & dynamic reservoir modelling & well planning, 3D Seismic data acquisition with Schlumberger & SVUL, 3D seismic data processing with CGG & interpretation, Q.I. and field development with Woodside, Applied Geoscience, and Reliance. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Advanced Well Engineering

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course Well engineers who are responsible for technically evaluating and authorizing programs for drilling or working over wells must have the required skills and competencies to safely design wells of varying nature. They also need to be able to confirm that well delivery and intervention programs generate intrinsic well control assurance. Such work programs must establish, verify, monitor and maintain suitable and sufficient barriers for the entire well lifecycle - from spud to abandonment. Well engineers must also be able to select a suitable drilling or workover rig, capable of safely performing the work within its operational envelope. This 3 full-day course aims to further develop and assess the knowledge required to work on and eventually, authorize a well delivery program as deemed fit for purpose. It also addresses elements of well control that must be embedded into well design, well work programming and equipment selection. This course is intended for participants who already have a sound understanding of the principles of the design and/or delivery of wells and with more than 3 years of relevant industry experience. Training Objectives By the end of this course, participants will be able to: Feel confident to design and plan drilling and workover activities while considering geological risks, formation pressures/strengths, and any integrity or well control concerns. Monitor wells operations and ensure that they can and will remain within the accepted design envelope. Assess risks and then apply mitigation or recovery methods in cases where design envelopes are threatened. Participants should be capable of assessing a drilling or workover program and then be able to answer the following key questions: Does the program delivery have a sound design and work plan that allows the well(s) to be drilled or worked over safely? Have we determined the appropriate kick tolerance for each open hole section and is it realistic for all drilling hazards that may be encountered? Have all drilling hazards been suitably assessed, and the associated risk mitigated to a level as low as reasonably practicable? Are there adequate, verifiable barriers in place throughout the operation and does everybody know their role and responsibility? And, as applicable, is the selected rig capable of implementing the work program? Target Audience This course is intended for personnel directly or indirectly involved in the preparation, review or authorization of drilling and workover programs. This includes: Well engineers and drilling supervisors who are responsible for planning and executing drilling and workover operations. Contractor well engineers, rig managers and other senior drilling staff. Senior well engineers and rig superintendents who are responsible for managing the delivery of a project or well. Technical authority holders who are responsible for licensing drilling and workover operations from a regulatory perspective. Assessment: A satisfactory command of critical knowledge and skills is assured by a 1+ hour closed book assessment. This assessment has a mix of multiple-choice questions (MCQs), calculations and answers that must be written up. The exam is taken electronically. Participants are provided with a suitable formula sheet. The pass mark for issuing a certificate is 70% and participants who are not successful will be issued with a certificate of attendance instead. Trainer Your expert course leader has over 45 years of experience in the Oil & Gas industry. During that time, he has worked exclusively in the well engineering domain. After being employed in 1974 by Shell, one of the major oil & gas producing operators, he worked as an apprentice on drilling rigs in the Netherlands. After a year, he was sent for his first international assignment to the Sultanate of Oman where he climbed up the career ladder from Assistant Driller, to Driller, to wellsite Petroleum Engineer and eventually on-site Drilling Supervisor, actively engaged in the drilling of development and exploration wells in almost every corner of this vast desert area. At that time, drilling techniques were fairly basic and safety was just a buzz word, but such a situation propels learning and the fruits of 'doing-the-basics' are still reaped today when standing in front of a class. After some seven years in the Middle East, a series of other international assignments followed in places like the United Kingdom, Indonesia, Turkey, Denmark, China, Malaysia, and Russia. Apart from on-site drilling supervisory jobs on various types of drilling rigs (such as helicopter rigs) and working environments (such as jungle and artic), he was also assigned to research, to projects and to the company's learning centre. In research, he was responsible for promoting directional drilling and surveying and advised on the first horizontal wells being drilled, in projects, he was responsible for a high pressure drilling campaign in Nigeria while in the learning centre, he looked after the development of new engineers joining the company after graduating from university. He was also involved in international well control certification and served as chairman for a period of three years. In the last years of his active career, he worked again in China as a staff development manager, a position he nurtured because he was able to pass on his knowledge to a vast number of new employees once again. After retiring in 2015, he has delivered well engineering related courses in Australia, Indonesia, Brunei, Malaysia, China, South Korea, Thailand, India, Dubai, Qatar, Kuwait, The Netherlands, and the United States. The training he provides includes well control to obtain certification in drilling and well intervention, extended reach drilling, high pressure-high temperature drilling, stuck pipe prevention and a number of other ad-hoc courses. He thoroughly enjoys training and is keen to continue taking classes as an instructor for some time to come. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Data Analytics Workflows for Artificial Lift, Production and Facility Engineers

By EnergyEdge - Training for a Sustainable Energy Future

About this training course Business Impact: The main aim is to provide insight and understanding of data analytics and machine learning principles through applications. Field data is used to explain data-analysis workflows. Using easy to follow solution scripts, the participants will assess and extract value from the data sets. Hands-on solution approach will give them confidence to try out applicable techniques on data from their field assets. Data analysis means cleaning, inspecting, transforming, and modeling data with the goal of discovering new, useful information and supporting decision-making. In this hands-on 2-day training course, the participants learn some data analysis and data science techniques and workflows applied to petroleum production (specifically artificial lift) while reviewing code and practicing. The focus is on developing data-driven models while keeping our feet closer to the underlying oil and gas production principles. Unique Features: Eight business use cases covering their business impact, code walkthroughs for most all and solution approach. Industry data sets for participants to practice on and take home. No software or complicated Python frameworks required. Training Objectives After the completion of this training course, participants will be able to: Understand digital oil field transformation and its impact on business Examine machine learning methods Review workflows and code implementations After completing the course, participants will have a set of tools and some pathways to model and analyze their data in the cloud, find trends, and develop data-driven models Target Audience This training course is suitable and will greatly benefit the following specific groups: Artificial lift, production and facilities engineers and students to enhance their knowledge base, increase technology awareness, and improve the facility with different data analysis techniques applied on large data sets Course Level Intermediate Advanced Training Methods The course discusses several business use-cases that are amenable to data-driven workflows. For each use case, the instructor will show the solution using a data analysis technique with Python code deployed in the Google cloud. Trainees will solve a problem and tweak their solution. Course Duration: 2 days in total (14 hours). Training Schedule 0830 - Registration 0900 - Start of training 1030 - Morning Break 1045 - Training recommences 1230 - Lunch Break 1330 - Training recommences 1515 - Evening break 1530 - Training recommences 1700 - End of Training The maximum number of participants allowed for this training course is 20. This course is also available through our Virtual Instructor Led Training (VILT) format. Prerequisites: Understanding of petroleum production concepts Knowledge of Python is not a must but preferred to get the full benefit. The training will use the Google Collaboratory environment available in Google-Cloud for hands-on exercises Trainees will need to bring a computer with a Google Chrome browser and a Google email account (available for free) Trainer Your expert course leader has over 35 years' work-experience in multiphase flow, artificial lift, real-time production optimization and software development/management. His current work is focused on a variety of use cases like failure prediction, virtual flow rate determination, wellhead integrity surveillance, corrosion, equipment maintenance, DTS/DAS interpretation. He has worked for national oil companies, majors, independents, and service providers globally. He has multiple patents and has delivered a multitude of industry presentations. Twice selected as an SPE distinguished lecturer, he also volunteers on SPE committees. He holds a Bachelor's and Master's in chemical engineering from the Gujarat University and IIT-Kanpur, India; and a Ph.D. in Petroleum Engineering from the University of Tulsa, USA. Highlighted Work Experience: At Weatherford, consulted with clients as well as directed teams on digital oilfield solutions including LOWIS - a solution that was underneath the production operations of Chevron and Occidental Petroleum across the globe. Worked with and consulted on equipment's like field controllers, VSDs, downhole permanent gauges, multiphase flow meters, fibre optics-based measurements. Shepherded an enterprise-class solution that is being deployed at a major oil and gas producer for production management including artificial lift optimization using real time data and deep-learning data analytics. Developed a workshop on digital oilfield approaches for production engineers. Patents: Principal inventor: 'Smarter Slug Flow Conditioning and Control' Co-inventor: 'Technique for Production Enhancement with Downhole Monitoring of Artificially Lifted Wells' Co-inventor: 'Wellbore real-time monitoring and analysis of fracture contribution' Worldwide Experience in Training / Seminar / Workshop Deliveries: Besides delivering several SPE webinars, ALRDC and SPE trainings globally, he has taught artificial lift at Texas Tech, Missouri S&T, Louisiana State, U of Southern California, and U of Houston. He has conducted seminars, bespoke trainings / workshops globally for practicing professionals: Companies: Basra Oil Company, ConocoPhillips, Chevron, EcoPetrol, Equinor, KOC, ONGC, LukOil, PDO, PDVSA, PEMEX, Petronas, Repsol, , Saudi Aramco, Shell, Sonatrech, QP, Tatneft, YPF, and others. Countries: USA, Algeria, Argentina, Bahrain, Brazil, Canada, China, Croatia, Congo, Ghana, India, Indonesia, Iraq, Kazakhstan, Kenya, Kuwait, Libya, Malaysia, Oman, Mexico, Norway, Qatar, Romania, Russia, Serbia, Saudi Arabia, S Korea, Tanzania, Thailand, Tunisia, Turkmenistan, UAE, Ukraine, Uzbekistan, Venezuela. Virtual training provided for PetroEdge, ALRDC, School of Mines, Repsol, UEP-Pakistan, and others since pandemic. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

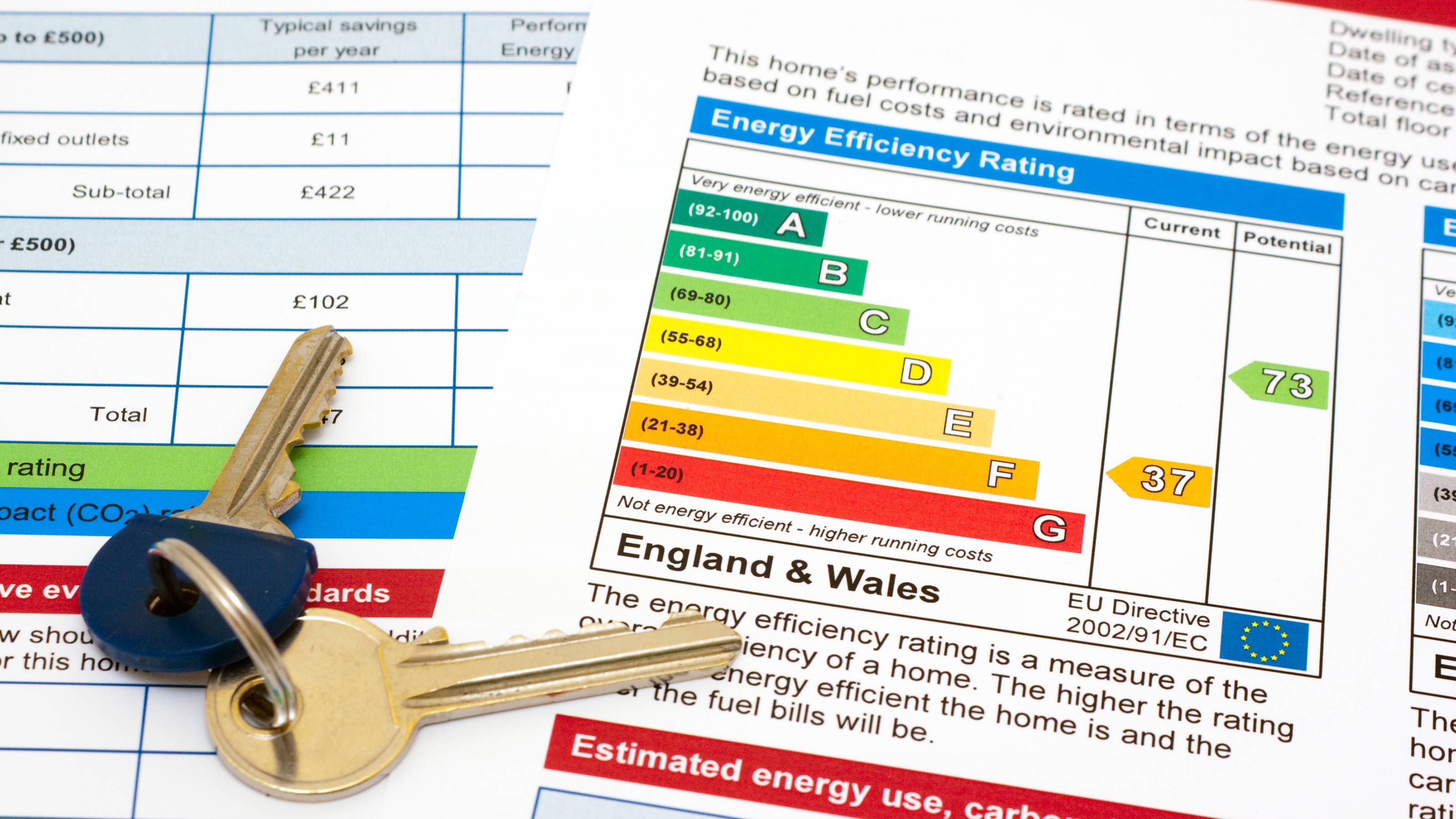

The Energy Efficiency (Part L) course empowers gas and oil-fired domestic heating and hot water system designers to comply with Part L of the Building Regulations. Who should attend? Heating engineers Design engineers Building services industry operatives Anyone looking to self-certify heating installations through Competent Persons Schemes (CPS) Course Objective: Develop the knowledge and skills to design heating systems that meet the energy efficiency standards outlined in Part L of the Building Regulations. Prerequisites (one required): ACS qualification OFTEC qualification Level 2 or 3 N/SVQ in plumbing (or equivalent) Level 2 or 3 N/SVQ in heating and ventilation (or equivalent) Level 2 or 3 N/SVQ in gas installation/maintenance (or equivalent) Level 2 or 3 N/SVQ in oil-fired technical services (or equivalent) Previous energy efficiency certificate What you'll gain: Understand the key requirements of Part L of the Building Regulations for domestic heating systems. Learn to design heating systems that achieve optimal energy efficiency. Master the skills needed to self-certify installations through CPS schemes. Benefits: Stay compliant: Ensure your heating system designs meet current regulations. Reduce energy consumption: Promote sustainable practices in the industry. Gain a competitive edge: Offer energy-efficient solutions to your clients. All participants must bring photo ID and a passport-sized photo for the course. Enrol today and become a leader in energy-efficient heating system design!

Plumber - Plumbing Training Diploma

By Compliance Central

Plumbers are the true superheroes of our daily lives, battling leaks, clogs, and mysterious drips. They possess the power to transform chaos into tranquillity, restoring harmony to our bathrooms and kitchens. So if you are interested in becoming a superhero in people's everyday lives, then enrol in this plumbing course and start your plumbing journey! The plumbing sector in the UK offers lucrative hourly wages and vast work opportunities, making it an attractive industry for job seekers. Skilled plumbers can command competitive hourly rates due to the high demand for their services. Hourly wages for plumbers in the UK range between £15 and £30 per hour, with potential for even higher rates based on experience and expertise. Additionally, the plumbing industry provides abundant work opportunities, ranging from residential and commercial projects to maintenance and emergency services. Embrace a career in plumbing and enjoy the benefits of flexible work, attractive compensation, and a thriving market for your skills. You will learn the plumbing skills: Learn the basics of plumbing for plumbers Acquire the fundamentals of adequate plumbing systems Get acquainted with plumbing tools and applications Know more about central heating systems Get an idea of how to control domestic hot and cold water Acquire thorough repairing methods and sanitation systems Increase your project Management for Plumbing Recognise the plumbing regulations in the UK Why would you choose the Plumbing course from Compliance Central: Lifetime access to Plumbing course materials Full tutor support is available from Monday to Friday with the Plumbing course Learn Plumbing skills at your own pace from the comfort of your home Gain a complete understanding of Plumbing course Accessible, informative Plumbing learning modules designed by experts Get 24/7 help or advice from our email and live chat teams with the Study Plumbing in your own time through your computer, tablet or mobile device A 100% learning satisfaction guarantee with your Plumbing course Curriculum Breakdown of the Course: Module 01: Basic Components of Plumbing Module 02: Principles of Effective Plumbing Systems Module 03: The Plumbing Tools Module 04: The Plumbing Process Module 05: Central Heating Systems Module 06: Domestic Cold Water System Module 07: Domestic Hot Water System - Part 1 Module 08: Domestic Hot Water System Part 2 Module 09: The Sanitation System and Repairs Module 10: Domestic Rainwater System Installation Module 11: Plumbing Projects: Case Study Module 12: UK Standards for Plumbing CPD 10 CPD hours / points Accredited by CPD Quality Standards Who is this course for? It is ideal for beginners who have yet to gain any plumbing experience. Anyone who wishes to learn the plumbing water supply should take this course. It is also intended for seasoned engineers or managers who want to improve their plumbing-related skills. Requirements To enrol in this course, all you need is a basic understanding of the English Language and an internet connection. Career path You can explore popular and in-demand careers associated with this course after completing it. Some job fields you can look into are: Domestic Plumbers Lead Pipefitter Maintenance Plumber Plumbing and Heating Engineer Gas Engineer Commercial Plumber In the UK, the salary for these positions is £32,000 - £35,000 per annum Certificates CPD Accerdited PDF Certificate Digital certificate - Included CDP Accerdited PDF Certificate for Free. CDP Accerdited Hardcopy Certificate Hard copy certificate - £9.99 Delivery Charge: Inside the UK: Free Outside the Uk: £9.99

Well Test Analysis in Practice

By EnergyEdge - Training for a Sustainable Energy Future

About this training This 5-day training course enables participants to learn and understand the fundamental concepts of well test analysis. The methodology described in the course, which has become the standard of the industry, presents a systematic way of interpreting well tests in homogeneous and heterogeneous reservoirs, including fissured and multilayered systems. Recommendations for designing tests in such formations, examples, and problem-solving sessions for practical experience and immediate application are included in the course. Training Objectives Upon completion of this course, participants will be able to: Understand the well test analysis methodology Present the straight line, log-log pressure, derivative and deconvolution analysis methods Learn the most common reservoir behaviours and boundary effects Carry out the gas and multiphase analysis Target Audience The course is intended for individuals who involved with the design and interpretation of well tests. The following personnel will benefit from the knowledge shared in this course: Petroleum Production Engineers Production and Wellsite Geologist Geophysicist Reservoir Engineer Drilling Engineer Trainer Your expert course leader has taught numerous well test interpretation industry courses around the world and has been involved in many consulting projects. He is a member of the Society of Petroleum Engineers (SPE) since 1969, and he was elected a Distinguished Member in 2002 and an Honorary Member in 2009. He has chaired or organized many SPE Advanced Technology Workshops. He is a recognized expert in well test analysis and has published over one hundred technical papers and was responsible for many advances in well test interpretation, including: the use of Greens functions; wellbore storage and skin, fractured wells, and wells with double porosity behavior; the first major commercial computer-aided interpretation software; single-well and multi-well deconvolution; and a well test interpretation methodology which has become standard in the oil industry. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Thermal Power Plant Performance Testing

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your career prospects in thermal power plant performance testing with EnergyEdge's course. Enroll now and gain valuable insights!

Search By Location

- Gas Courses in London

- Gas Courses in Birmingham

- Gas Courses in Glasgow

- Gas Courses in Liverpool

- Gas Courses in Bristol

- Gas Courses in Manchester

- Gas Courses in Sheffield

- Gas Courses in Leeds

- Gas Courses in Edinburgh

- Gas Courses in Leicester

- Gas Courses in Coventry

- Gas Courses in Bradford

- Gas Courses in Cardiff

- Gas Courses in Belfast

- Gas Courses in Nottingham