- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Photoshop Basic to Essentials Training Course One-to-One

By Real Animation Works

PHOTOSHOP ONE DAY COURSE ONE TO ONE LIFETIME EMAIL SUPPORT.

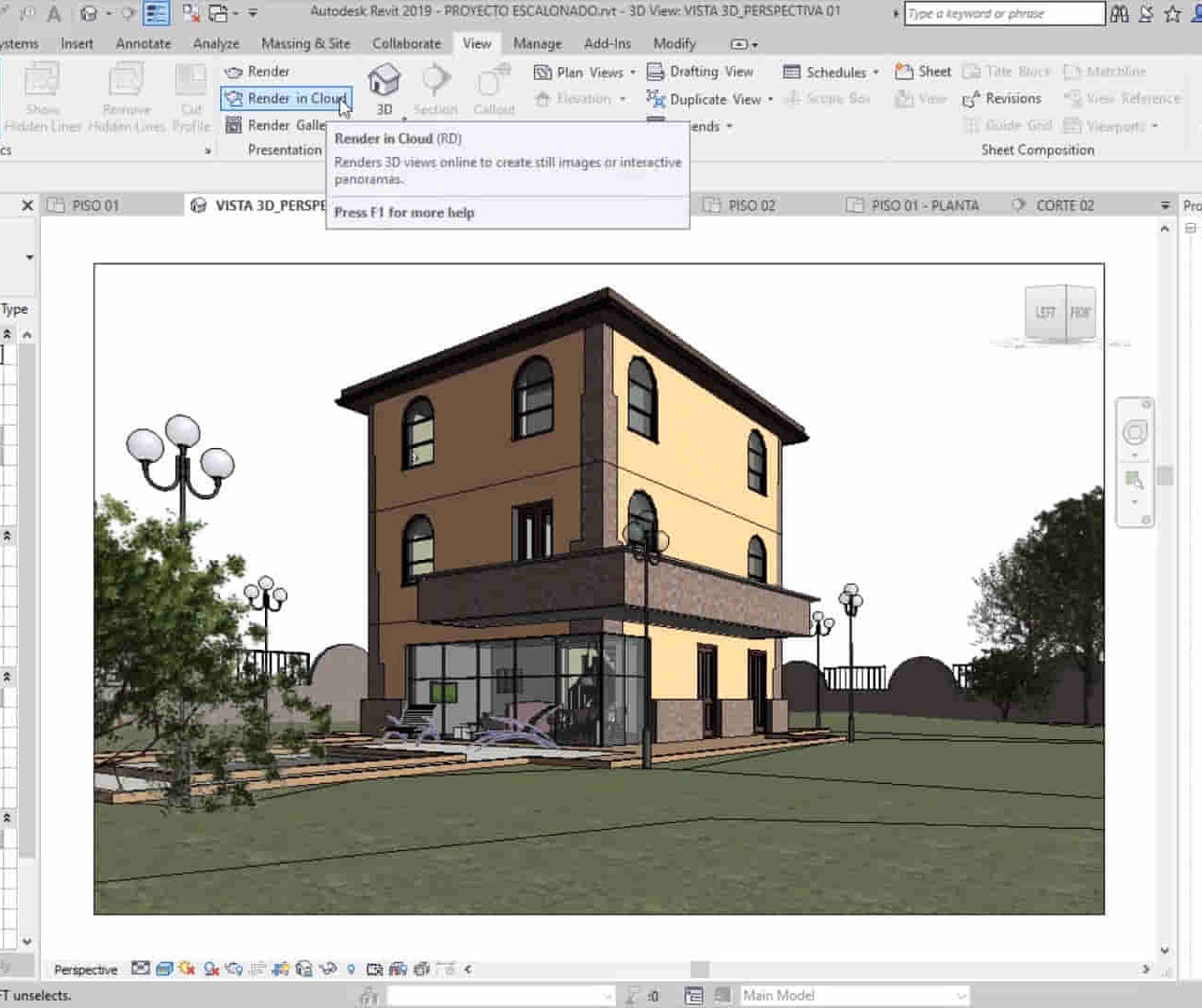

Revit Basic to Advanced Training Course

By ATL Autocad Training London

Why Book Revit Basic to Advanced Training Course? Learn BIM and Revit for engineers and architects, supporting 2-D and 3-D design for large-scale projects and combing with AutoCAD. Check our Website How to Book? 1-on-1 training tailored to your schedule. Book your sessions from Monday to Saturday between 9 am and 7 pm or call 02077202581 to book over the phone. Training Details: Duration: 16 hours Flexible scheduling, split across multiple days Method: 1-on-1 (In-person or Live Online) and Personalized attention Course Overview: I. Revit Fundamentals (1 hour) Understanding Revit's Purpose and Applications Navigating the Revit Interface and Essential Tools Mastering Navigation and Viewport Controls Creating and Managing Projects II. Project Setup (1 hour) Initiating a New Project Configuring Project Levels, Grids, and Site Information Defining Project Units for Precision III. Basic Modeling Techniques (2 hours) Building Walls, Doors, and Windows Designing Floors, Ceilings, Roofs, Stairs, and Railings IV. Advanced Modeling Skills (4 hours) Crafting Custom Parametric Families Utilizing Conceptual Modeling Tools Designing Complex Forms and Shapes Enhancing Models with Lighting and Materials Achieving Realism through 3D Rendering V. Views, Sheets, and Annotations (2 hours) Managing Views and Sheets Effectively Incorporating Schedules and Tags Crafting Detail Annotations for Construction Documents VI. Phasing, Worksharing, and Collaboration (2 hours) Understanding Phasing and Design Options Mastering Work Sharing and Collaboration Techniques VII. Project Collaboration and Management (1 hour) Establishing Work Sharing Environments Monitoring Worksets and User Activities Synchronizing Worksets for Seamless Collaboration VIII. Advanced Documentation Skills (2 hours) Creating Advanced Schedules and Legends Developing Construction Documents with Sheets and Title Blocks Customizing Schedules and Keynotes for Precision IX. Course Conclusion and Next Steps (1 hour) Reviewing Course Highlights Exploring Further Learning Resources and Tips Interactive Q&A Session and Feedback Opportunities Download Revit Master Revit Proficiency: Acquire advanced skills in Revit for 3D modeling, parametric design, and efficient project management. Craft Complex Architectural Designs: Create intricate building components, custom families, and detailed construction documents. Seamless Collaboration: Expertise in project collaboration, phasing, and work sharing, ensuring smooth teamwork and synchronization. Enhanced Visualization: Learn advanced rendering techniques for realistic 3D visualizations of architectural concepts. Customize Workflows: Adapt Revit tools, optimize workflows, and enhance efficiency in project execution. Career Opportunities: Architectural Designer: Create architectural plans, 3D models, and construction documents. BIM Specialist: Develop detailed digital models in collaboration with architects and engineers. Construction Documenter: Prepare comprehensive construction documents, including plans and schedules. Project Manager: Oversee projects, ensuring timely completion and adherence to design specifications. Revit Specialist/Trainer: Provide Revit training and support services to individuals, firms, or educational institutions. Elevate Your Revit Skills with Our Advanced Training! Our Revit Basic to Advanced Training Course is tailored to enhance your expertise in Autodesk Revit. Delivered through in-person or live online sessions, this program covers advanced modeling, parametric families, collaboration tools, and project phasing. Course Benefits: Master Advanced Skills: Learn intricate 3D modeling, design complex building components, and implement advanced BIM workflows. Expert Instruction: Industry professionals guide you through advanced concepts via engaging demonstrations and hands-on exercises. Flexible Learning: Choose in-person or live online sessions with interactive instruction and personalized guidance. Lesson Recordings: Access class recordings for convenient review and practice, reinforcing your learning. Lifetime Support: Benefit from lifetime email support for ongoing guidance from our experienced instructors. Enhance your Revit proficiency, streamline design processes, and boost project efficiency. Whether you're an architect, engineer, or design professional, this course unlocks advanced Revit skills. Join our training for comprehensive learning and expert support! Individualized Training: Experience personalized attention and tailored guidance. Flexible Learning Hours: Select your preferred schedule for training sessions. Ongoing Support: Access complimentary online assistance even after course completion. Comprehensive Learning Materials: Receive detailed PDF resources for effective learning. Certificate of Attendance: Earn a certificate acknowledging your course completion. Affordable Pricing: Enjoy budget-friendly training rates. Software Setup Help: Get assistance with software configuration on your device. Referral Benefits: Receive discounts on future courses by referring a friend. Group Discounts: Avail special rates for group training sessions. Extended Availability: Access training sessions every day with extended operating hours. Customized Curriculum: Engage in tailored training designed to meet your specific requirements.

HV & MV Power System Design, Protection & Coordination - Virtual Instructor-Led Training (VILT)

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your expertise in HV/MV power system design and protection coordination with EnergyEdge's virtual instructor-led training. Join now!

Personalized AutoCAD Training for Interior Designers: Live Online and One-to-One

By Real Animation Works

Autocad face to face training customised and bespoke. In-person

AutoCAD and Photoshop Training Course 1-2-1

By Real Animation Works

Autocad face to face training customised and bespoke.

Commissioning of Combined Cycle Power Plants

By EnergyEdge - Training for a Sustainable Energy Future

About this Course This 5 full-day course provides a comprehensive understanding of all the commissioning procedures for combined cycle power plants. The Commissioning Management System (CMS) of combined cycle power plants is covered in detail in this course. This includes all the commissioning procedures and documents, purpose of commissioning, responsibilities, system description, organization, working parties, test teams, documentation, testing and commissioning schedules, test reports, safety, plant certification, and plant completion report. The course provides also a thorough understanding of all the commissioning requirements for gas turbines, steam turbines and auxiliaries, generator and auxiliaries, electrical equipment, switchgear equipment, switchgear and transformers. All the stages of the commissioning procedure are covered in-depth in this course. This includes preparation - planning various activities, pre-commissioning checks and tests, typical commissioning schedule, detailed tests and commissioning procedures and instructions for every component in a combined cycle power plant, instrumentation, trial run of the equipment, safety and precautions, commissioning of combined cycle power plant systems, safety rules clearance certificates, procedure for the control and handling of defects, commissioning reports, operational testing, first fire, generator synchronization, performance testing, heat rate testing, emission testing, contract testing, CO2 concentration tests, electrical full-load rejection test, duct burner testing, partial load stability test, and reliability test. This course is a MUST for anyone who is involved in the pre-commissioning or commissioning of any combined cycle power plant equipment because it provides detailed pre-commissioning checks and tests, and detailed tests and commissioning procedures and instructions for every component in a combined cycle power plant. In addition, the seminar provides an in-depth coverage of all preparation, planning activities, commissioning schedules, trial run of each combined cycle power plant equipment, safety and precautions, safety rules clearance certificates, procedures for handling defects, and commissioning reports. Training Objectives Pre-commissioning Checks and Tests, Detailed Tests and Commissioning Procedures and Instructions for Every Equipment in Combined Cycle Power Plants: Gain a thorough understanding of all pre-commissioning checks and tests, and all commissioning procedures and instructions for every equipment in combined cycle power plants Commissioning Management System (CMS) of Combined Cycle Power Plants: Discover the benefits of the CMS of combined cycle power plants including all commissioning procedures and documents, purpose of commissioning, responsibilities, system description, organization, working parties, test teams, documentation, testing and commissioning schedules, test reports, safety, plant certification, and plant completion report Commissioning Procedures and Instructions for Heat Recovery Steam Generators, Air Blow and Steam Blow of Steam and Gas Piping in Combined Cycle Power Plants: Learn about the commissioning procedures and instructions for heat recovery steam generators, chemical cleaning of heat recovery steam generators, air blow and gas blow of steam and gas piping in combined cycle power plants, safety valve setting and soot blowers Commissioning Procedures and Instructions for Gas Turbines and Steam Turbines: Gain a thorough understanding of all the commissioning procedures and instructions for gas and steam turbines and auxiliaries including acid cleaning of oil pipelines, lubrication and governing system (oil flushing and hydraulic testing), jacking oil system, governing system, regenerative system, barring gear, vacuum tightness test, first rolling of turbine and data logging Commissioning Procedures and Instructions for Generator and Auxiliaries: Discover all the commissioning procedures and instructions for generator and auxiliaries including generator, seal oil system, hydrogen gas system, stator water system, rolling and start-up of generators Commissioning Procedures and Instructions for Electrical Equipment: Learn about all the commissioning procedures and instructions for electrical equipment including switchyard equipment, switchgear, transformers and motors Operational Testing, Performance Testing, Heat Rate Testing, Emission Testing of Combine Cycle Power Plants: Gain a thorough understanding of operational testing, first fire, generator synchronization, performance testing, heat rate testing, emission testing, contract testing, CO2 concentration tests, electrical full-load rejection test, duct burner testing, partial load stability test, and reliability test of combined cycle power plants Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Training Methods The instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all the delegates gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Revit Courses Personalize Your Learning Schedule with On-Demand Options

By Real Animation Works

Personalized Revit Training: One-to-One Sessions with Pay-as-You-Go Flexibility

Search By Location

- Engineer Courses in London

- Engineer Courses in Birmingham

- Engineer Courses in Glasgow

- Engineer Courses in Liverpool

- Engineer Courses in Bristol

- Engineer Courses in Manchester

- Engineer Courses in Sheffield

- Engineer Courses in Leeds

- Engineer Courses in Edinburgh

- Engineer Courses in Leicester

- Engineer Courses in Coventry

- Engineer Courses in Bradford

- Engineer Courses in Cardiff

- Engineer Courses in Belfast

- Engineer Courses in Nottingham