- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

173 Electric courses in Liverpool delivered Live Online

Our intensive 10, 15 or 20 day Total Air Conditioning and Refrigeration training courses have been structured to meet the ever increasing demands on industry to meet safety, environmental and legal requirements regarding installation, commissioning, service and maintenance of both refrigeration and air conditioning systems including the electrical aspects of installation dependent upon course selection. The first 10 days of the Total Air Conditioning and Refrigeration training course are mechanical only, the following 5 or 10 days are the electrical aspects, depending on which route you need to go down. The Total Air Conditioning and Refrigeration training courses are accredited with the City & Guilds 2079, BESA Pipework and Brazing – (commercial), along with an EAL Unit* – Maintenance of Refrigeration Systems from the EAL Certificate in Engineering Technology (QCF) qualification. (*Practical elements will be covered during the course with a Project booklet to be completed by the student with an element of self-study after the course completion for us to claim the Unit certification from EAL). Our Total Air Conditioning and Refrigeration training courses are designed to be as practical as they possibly can be, with workshop time taking more than 70% of the course. During the Total Air Conditioning and Refrigeration training course, you will, install, repair, fault find, adapt and commission on a variety of different equipment, because we believe the way to learn is to do it!! With ALL our courses we offer unbiased technical support and access to a wealth of knowledge and information upon completion. Once you’ve completed your course with Technique, you can be assured that our service doesn’t end there…

Our intensive 10, 15 or 20 day Total Air Conditioning and Refrigeration training courses have been structured to meet the ever increasing demands on industry to meet safety, environmental and legal requirements regarding installation, commissioning, service and maintenance of both refrigeration and air conditioning systems including the electrical aspects of installation dependent upon course selection. The first 10 days of the Total Air Conditioning and Refrigeration training course are mechanical only, the following 5 or 10 days are the electrical aspects, depending on which route you need to go down. The Total Air Conditioning and Refrigeration training courses are accredited with the City & Guilds 2079, BESA Pipework and Brazing – (commercial), along with an EAL Unit* – Maintenance of Refrigeration Systems from the EAL Certificate in Engineering Technology (QCF) qualification. (*Practical elements will be covered during the course with a Project booklet to be completed by the student with an element of self-study after the course completion for us to claim the Unit certification from EAL). Our Total Air Conditioning and Refrigeration training courses are designed to be as practical as they possibly can be, with workshop time taking more than 70% of the course. During the Total Air Conditioning and Refrigeration training course, you will, install, repair, fault find, adapt and commission on a variety of different equipment, because we believe the way to learn is to do it!! With ALL our courses we offer unbiased technical support and access to a wealth of knowledge and information upon completion. Once you’ve completed your course with Technique, you can be assured that our service doesn’t end there…

Alarm Installation Course

By Hi-Tech Training

The Alarm Installation Course is designed to teach participants how to install an intruder alarm system in domestic, commercial or industrial premises. The Alarm Installation Course simulates the practical installation of many different alarm control panels. The course is designed to equip students with the skills and expertise to competently install a wide variety of Alarm systems on the market.

Learn how to perform and read an ECG ... Nationally Recognised Qualification OCN Accredited - Level 3 (advanced level) CPD Accredited - The CPD Certification Service Introduces you to the fundamentals of setting up and operating an ECG machine Includes patient preparation Produce a valid (error free) ECG Learn and understand ECG traces Recognise recordings that require urgent attention Basic understanding of English language required OPEN TO ALL APPLICANTS VIRTUAL CLASSROOM OPTION INCLUDES COMPREHENSIVE PRACTISE@HOME ECG TRAINING KIT Final interpretation of all ECG recordings is the responsibility of a medical professional.

Hybrid Vehicle Expert Training

By NextGen Learning

Hybrid Vehicle Expert Training Course Overview The Hybrid Vehicle Expert Training course provides an in-depth understanding of hybrid electric vehicles (HEVs), focusing on their design, operation, and technology. Learners will explore various types of hybrids, key components, and the degree of hybridisation, enhancing their technical knowledge for the automotive industry. This course equips participants with essential skills to analyse regenerative systems and other innovative features that improve fuel efficiency and reduce emissions. By the end of the course, learners will be confident in identifying different HEV architectures and understanding their functional principles, preparing them for roles in vehicle maintenance, engineering, and technical consultancy within the evolving green transport sector. Course Description This course offers comprehensive coverage of hybrid vehicle technology, beginning with an introduction to hybrid electric vehicles and their classifications. It delves into the degree of hybridisation, explaining how various systems operate to optimise energy use. Detailed study of HEV components provides insight into powertrains, batteries, and control systems. The course also covers regenerative braking and energy recovery technologies that enhance vehicle efficiency. Learners will gain analytical skills required to evaluate hybrid systems and keep pace with developments in sustainable automotive design. The structured learning experience combines theory and technical knowledge, suitable for those aiming to build expertise in green vehicle technologies and contribute to environmental sustainability within the automotive sector. Hybrid Vehicle Expert Training Curriculum: Module 01: Introduction Module 02: Types of Hybrid Electric Vehicles Module 03: Degree of Hybridisation Module 04: Components of HEVs Module 05: Regenerative Systems (See full curriculum) Who is this course for? Individuals seeking to develop expertise in hybrid vehicle technology. Professionals aiming to advance their careers in the automotive or green transport sectors. Beginners with an interest in sustainable automotive technologies. Technicians and engineers preparing for roles in vehicle systems analysis and maintenance. Career Path Hybrid Vehicle Technician Automotive Engineer specialising in green technologies Vehicle Systems Analyst Technical Consultant for sustainable transport solutions Research and Development Specialist in automotive innovation

Learn how to test portable electrical appliances with a qualification in Electrical Equipment Maintenance and Testing aimed at new starters to the testing of portable electrical equipment with minimal electrical knowledge. This qualification is aimed at those with responsibilities for the maintenance of electrical equipment and for those undertaking practical inspection and testing of electrical equipment. It allows those with the responsibility for the testing and inspection of electrical equipment to gain a qualification suitable to their job role. The qualification allows candidates to learn, develop and practise the skills required to inspect and test items of electrical equipment in line with the latest edition of the Code of Practice for In-Service Inspection and Testing of Electrical Equipment. Learners completing the qualification will have the ability to carry out mandatory responsibilities within the workplace depending on their prior electrical knowledge This level will suit you if you are looking to become involved in, the inspection and testing of electrical equipment. To successfully complete the qualification learners will have to sit an Evolve on-line test comprising of a 50 MCQ and a practical assignment. The practical consists of 3 tasks which are: Task 1 is inspect and test Class I equipment, Task 2 is inspect and test Class II equipment (this will be either unearthed metal or without unearthed metal or Class II FE – Learners will not need to do all 3 of these, they only need to do one type), Task 3 is completing the record forms

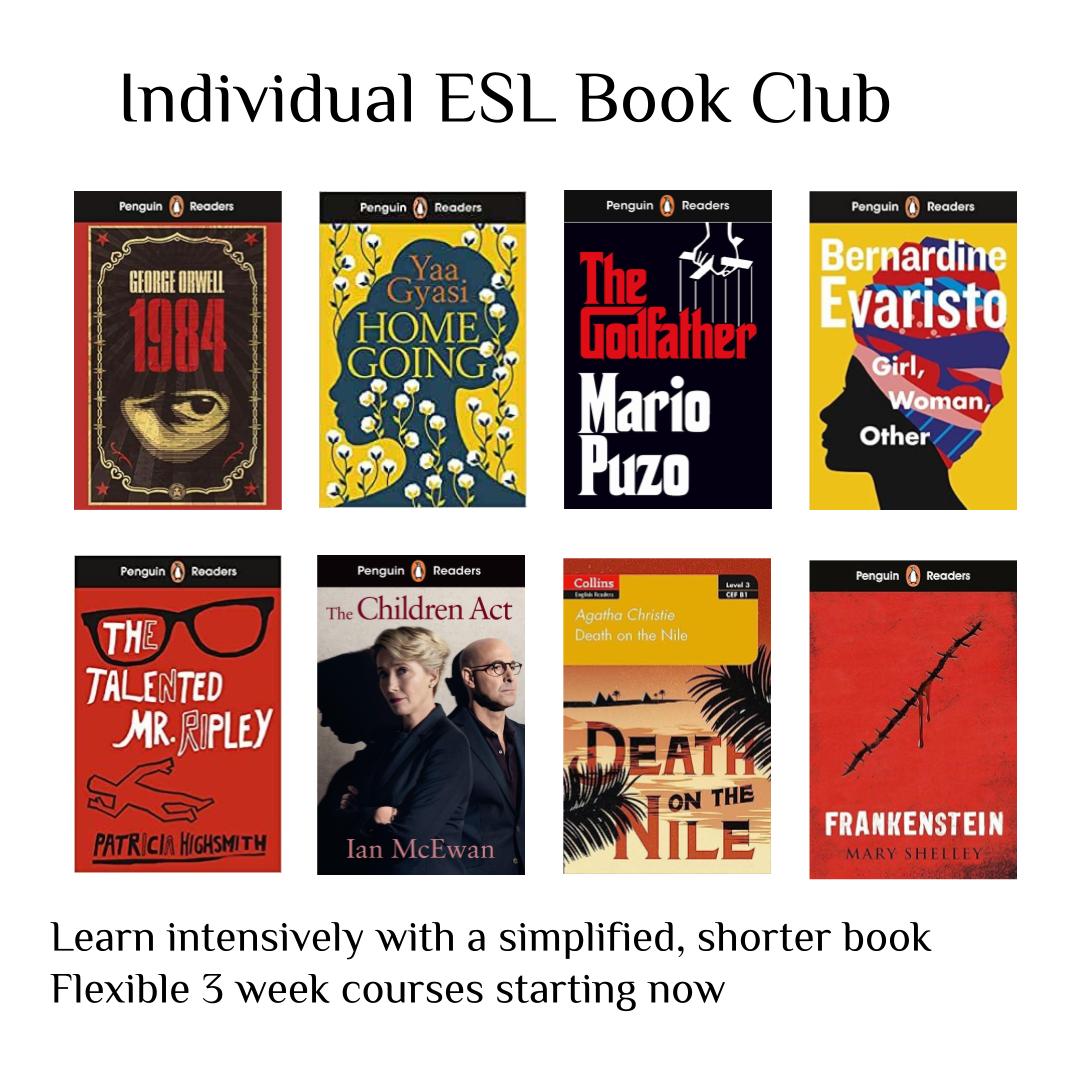

Build your confidence, fluency & accuracy with an individual ESL Book Club in English using a simplified, shortened and adapted novel. Highlights Join this individual ESL book club course to quickly improve your English confidence, fluency & accuracy 3 hours of live 1:1 English classes to help you develop your confidence in speaking in English Read a section of the book at home and then discuss what you have read Learn English 1:1 & be corrected by your private English teacher to remove errors and mistakes Build your confidence, skills and accuracy in this individual ESL book club in English course. Choose one of the books from the selection below. These books are shortened, simplified and adapted for learners of English as a foreign language. There are also language learning exercises and a short glossary of new words. Each week you read about 20-30 pages, write a summary of what you have read, and then discuss what you have read with your teacher Geoff. Personalised feedback improves your grammar, vocabulary and pronunciation. The Book Club book Individual ESL Book Clubs are flexible and can be taken on the following simplified and shortened "graded reader" books. Contact Geoff to agree a day and time, then enrol on the course. Intermediate (B1) Austen, Jane - Emma (Oxford Bookworms) Austen, Jane - Persuasion (Oxford Bookworms) Austen, Jane - Sense and Sensibility (Penguin Readers) Brontë, Emily - Wuthering Heights (Penguin Readers) Christie, Agatha - Death on the Nile (Collins English Readers) Christie, Agatha - The Body in the Library (Collins English Readers) Conan Doyle, Arthur - Sherlock Holmes: The Hound of the Baskervilles (Oxford Bookworms) Dickens, Charles - A Tale of Two Cities (Penguin Readers) Dickens, Charles - David Copperfield (Penguin Readers) Dickens, Charles - Great Expectations (Penguin Readers) Dickens, Charles - Oliver Twist (Penguin Readers) Hardy, Thomas - Far From The Madding Crowd (Penguin Readers) Hardy, Thomas - Tess of the D'Urbervilles (Penguin Readers) Hawkins, Paula - The Girl On The Train (Penguin Readers) Highsmith, Patricia - The Talented Mr Ripley (Penguin Readers) Joyce, James - Dubliners (Penguin Readers) Joyce, Rachel - The Unlikely Pilgrimage of Harold Fry (Penguin Readers) Le Carré, John - The Spy Who Came In From The Cold (Penguin Readers) Shelley, Mary - Frankenstein (Penguin Readers) Tóibín, Colm - Brooklyn (Penguin Readers) Upper-Intermediate (B2) Austen, Jane - Sense and Sensibility (Oxford Bookworms) Asimov, Isaac - I, Robot (Oxford Bookworms) Brontë, Emily - Wuthering Heights (Oxford Bookworms) Christie, Agatha - The ABC Murders (Collins English Readers) Christie, Agatha - Evil Under The Sun (Collins English Readers) Collins, Wilkie - The Woman in White (Penguin Readers) Dick, Philip K - Do Androids Dream of Electric Sheep? (Oxford Bookworms) Evaristo, Bernardine - Girl, Woman, Other (Penguin Readers) Fitzgerald, F. Scott - The Great Gatsby (Oxford Bookworms) Gyasi, Yaa - Homegoing (Penguin Readers) Hardy, Thomas - Far From The Madding Crowd (Oxford Bookworms) Kerouac, Jack - On the Road (Pearson English Readers) Mansfield, Katherine - The Garden Party (Oxford Bookworms) McEwan, Ian - The Children Act (Penguin Readers) Melville, Herman - Moby Dick (Penguin Readers) Orwell, George - 1984 (Penguin Readers) Puso, Mario - The Godfather (Penguin Readers) Smith, Zadie - White Teeth (Penguin Readers) Stevenson, RL - The Strange Case of Dr Jekyll and Mr Hyde (Pearson English Readers) Wharton, Edith - The Age of Innocence (Oxford Bookworms) Woolf, Virginia - Mrs Dalloway (Penguin Readers) Upper-Intermediate + (B2+) Austen, Jane - Pride and Prejudice (Oxford Bookworms) Brontë, Charlotte - Jane Eyre (Oxford Bookworms) Conan Doyle, Arthur - Sherlock Holmes: The Sign of Four (Oxford Bookworms) Flaubert, Gustave - Madame Bovary (Pearson English Readers) Gaskell, Elizabeth - North and South (Pearson English Readers) Garland, Alex- The Beach (Pearson English Readers) Hardy, Thomas - Tess of the D'Urbervilles (Oxford Bookworms) Tan, Amy - The Joy Luck Club (Oxford Bookworms) Geoff says: "This is a great way to start reading more in English, to build your confidence, to focus on your needs and language, and to make fast progress."

Fire Alarm Foundation Course

By Hi-Tech Training

The Fire Alarm Foundation course is designed to give participants a practical knowledge of the operation and installation of Fire Alarm Systems at a foundation level. During this practical and theory-based course students will gain the skills and knowledge to install and wire up a Fire Alarm Control Panel to typical auxiliary equipment such as Break Glass Units, Smoke Detectors, Heat Detectors, Bells, and Sirens.

QA Level 2 Award In Health And Safety In The Workplace (RQF) Health and Safety Training Courses QA Level 2 Award In Health And Safety In The Workplace (RQF) Course Contents: Roles and responsibilities of employers and employees Health and safety laws Risk assessments and risk control hierarchy Identifying and controlling risks from common workplace hazards, including: Slips, Trips and Falls Manual Handling Fire Working from Height Electricity Hazardous Substances Workplace conditions Ergonomics Equipment Noise and vibration Transport and vehicles Violence Smoking, alcohol and drugs Stress Procedures for responding to accidents and incidents Recording incidents, accidents and ill health Benefits of this course: In 2023/24, 1.7 million people suffered from a work-related illness 600,000 sustained a non-fatal injury 138 People lost their lives 776,000 Workers suffered from work-related stress, depression or anxiety The estimated cost of injuries and ill health last year was £21.6 billion 33.7 million working days, or 140,417 working years, were lost due to work-related illnesses and injuries It is an employer's duty to protect the health, safety and welfare of their employees and other people who might be affected by their business. This includes providing sufficient information, instruction and training of employees, so they can work in a way that does not put themselves or others at risk This QA Level 2 Award in Health and Safety in the Workplace (RQF) course helps employees gain an understanding of health and safety issues and their own role within that Accredited, Ofqual regulated qualification: This Health and Safety Training Course is a nationally recognised, Ofqual regulated qualification accredited by Qualsafe Awards. This means that you can be rest assured that your Health and Safety Certificate fulfils the legal requirements and is an excellent way to make sure you and your employees are trained in Health and Safety. The Ofqual Register number for this course is 603/2687/6