- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

58 Design Engineer courses

Commissioning of Combined Cycle Power Plants

By EnergyEdge - Training for a Sustainable Energy Future

About this Course This 5 full-day course provides a comprehensive understanding of all the commissioning procedures for combined cycle power plants. The Commissioning Management System (CMS) of combined cycle power plants is covered in detail in this course. This includes all the commissioning procedures and documents, purpose of commissioning, responsibilities, system description, organization, working parties, test teams, documentation, testing and commissioning schedules, test reports, safety, plant certification, and plant completion report. The course provides also a thorough understanding of all the commissioning requirements for gas turbines, steam turbines and auxiliaries, generator and auxiliaries, electrical equipment, switchgear equipment, switchgear and transformers. All the stages of the commissioning procedure are covered in-depth in this course. This includes preparation - planning various activities, pre-commissioning checks and tests, typical commissioning schedule, detailed tests and commissioning procedures and instructions for every component in a combined cycle power plant, instrumentation, trial run of the equipment, safety and precautions, commissioning of combined cycle power plant systems, safety rules clearance certificates, procedure for the control and handling of defects, commissioning reports, operational testing, first fire, generator synchronization, performance testing, heat rate testing, emission testing, contract testing, CO2 concentration tests, electrical full-load rejection test, duct burner testing, partial load stability test, and reliability test. This course is a MUST for anyone who is involved in the pre-commissioning or commissioning of any combined cycle power plant equipment because it provides detailed pre-commissioning checks and tests, and detailed tests and commissioning procedures and instructions for every component in a combined cycle power plant. In addition, the seminar provides an in-depth coverage of all preparation, planning activities, commissioning schedules, trial run of each combined cycle power plant equipment, safety and precautions, safety rules clearance certificates, procedures for handling defects, and commissioning reports. Training Objectives Pre-commissioning Checks and Tests, Detailed Tests and Commissioning Procedures and Instructions for Every Equipment in Combined Cycle Power Plants: Gain a thorough understanding of all pre-commissioning checks and tests, and all commissioning procedures and instructions for every equipment in combined cycle power plants Commissioning Management System (CMS) of Combined Cycle Power Plants: Discover the benefits of the CMS of combined cycle power plants including all commissioning procedures and documents, purpose of commissioning, responsibilities, system description, organization, working parties, test teams, documentation, testing and commissioning schedules, test reports, safety, plant certification, and plant completion report Commissioning Procedures and Instructions for Heat Recovery Steam Generators, Air Blow and Steam Blow of Steam and Gas Piping in Combined Cycle Power Plants: Learn about the commissioning procedures and instructions for heat recovery steam generators, chemical cleaning of heat recovery steam generators, air blow and gas blow of steam and gas piping in combined cycle power plants, safety valve setting and soot blowers Commissioning Procedures and Instructions for Gas Turbines and Steam Turbines: Gain a thorough understanding of all the commissioning procedures and instructions for gas and steam turbines and auxiliaries including acid cleaning of oil pipelines, lubrication and governing system (oil flushing and hydraulic testing), jacking oil system, governing system, regenerative system, barring gear, vacuum tightness test, first rolling of turbine and data logging Commissioning Procedures and Instructions for Generator and Auxiliaries: Discover all the commissioning procedures and instructions for generator and auxiliaries including generator, seal oil system, hydrogen gas system, stator water system, rolling and start-up of generators Commissioning Procedures and Instructions for Electrical Equipment: Learn about all the commissioning procedures and instructions for electrical equipment including switchyard equipment, switchgear, transformers and motors Operational Testing, Performance Testing, Heat Rate Testing, Emission Testing of Combine Cycle Power Plants: Gain a thorough understanding of operational testing, first fire, generator synchronization, performance testing, heat rate testing, emission testing, contract testing, CO2 concentration tests, electrical full-load rejection test, duct burner testing, partial load stability test, and reliability test of combined cycle power plants Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Training Methods The instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all the delegates gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

AutoCAD Training Course for Electrical

By ATL Autocad Training London

Exclusive to AutoCAD subscribers, the AutoCAD Electrical toolset simplifies electrical system creation. Click here for more info: Website Our course provides a strong foundation in 2D electrical design, covering essential tools. Flexible one-on-one sessions from 9 a.m. to 7 p.m., Monday to Saturday. Call 02077202581 or book online. The 16-hour course offers flexibility, divide hours across days. Benefit from individualized attention and tailored content. Enroll for in-person or Zoom sessions to excel in AutoCAD Electrical. AutoCAD Electrical Course Content: Introduction to AutoCAD Electrical Software: Overview and features of AutoCAD Electrical Understanding the software interface and tools Project file structure and management Layout and Navigation: Navigating the AutoCAD Electrical workspace Creating new project files and using attribute editors Understanding WDD, WDX, and WDF project files Exploring the Project Manager interface and attribute editors Electrical Diagram Drawing: Numbering and titling wires in diagrams Labelling components Utilizing diagram symbol libraries Creating and editing Electrical Control Circuits (ECC) Component dialog box and Circuit Scale dialog box Introduction to Programmable Logic Controllers (PLCs) and Integrated Systems: PLC Symbols and Concepts Inserting Programmable Logic Controllers (PLCs) into diagrams Adding PLC Units to diagrams Working with PLC Input and Output points and circuits Understanding PLC-based classification Using the Spreadsheet to PLC Input and Output Points utility Custom and Bespoke Symbols: Creating custom symbols for Switches, Wires, Contactors, Motors, Transformers, etc. Specifying symbol conventions and standards Offline and online usage of AutoCAD Electrical databases Drawing for Terminals and Plans: Implementing Terminal symbols in diagrams Handling terminal plans and locations Working with compound level terminals and locations Utilizing the Component command for single and multiple components Managing Jumpers and wiring Modifying Terminal Strips and Dual In-Line Packages (DIP) Understanding DIN Rail, Electrical Enclosure, Circuit Breakers, and Electrical Equipment Generating PDFs and Reports: Exporting drawings to PDF format Organizing report templates Automating the generation of reports Creating Electrical Audit Reports This AutoCAD Electrical course provides comprehensive knowledge of the software, focusing on electrical diagram drawing, symbol creation, PLC integration, terminal planning, and report generation. Participants will gain the skills needed to efficiently design electrical systems using AutoCAD Electrical software. Upon completion, participants will proficiently use AutoCAD Electrical to create precise electrical diagrams, integrate PLCs, design custom symbols, plan terminals, and generate reports efficiently. They will possess the skills needed to confidently design electrical systems and enhance their expertise in electrical design and drawing. AutoCAD Electrical Training Course: Master precision in specialized electrical design skills. Optimize your design process with streamlined workflows. Ensure compliance with industry standards consistently. Boost productivity in electrical design tasks. Facilitate seamless collaboration with fellow professionals. Benefit from recorded lessons for convenient review. Enjoy continuous support with lifetime email assistance. Unleash the complete power of AutoCAD for your electrical design needs. Enroll today and craft precise, professional electrical drawings confidently. Select between in-person and live online sessions to suit your preference. Flexible Evening Sessions: Learn AutoCAD at your own pace with evening sessions designed for busy individuals. Boost your career opportunities in computer-aided design. Comprehensive Skill Development: Gain a strong foundation in AutoCAD's core features and advance to 3D modeling and rendering techniques, enhancing your design capabilities. Industry-Standard Knowledge: Become proficient in AutoCAD, a widely used CAD software in architecture, engineering, and construction fields, making you highly sought after by employers. Practical Application: Apply AutoCAD skills to real-world design scenarios, creating detailed plans for professional projects in architecture, engineering, and mechanical fields. Recorded Lessons for Review: Access lesson recordings to reinforce learning and review specific topics or techniques whenever needed. Lifetime Email Support: Enjoy ongoing support with lifetime email assistance, even after completing the course, for guidance and clarification.

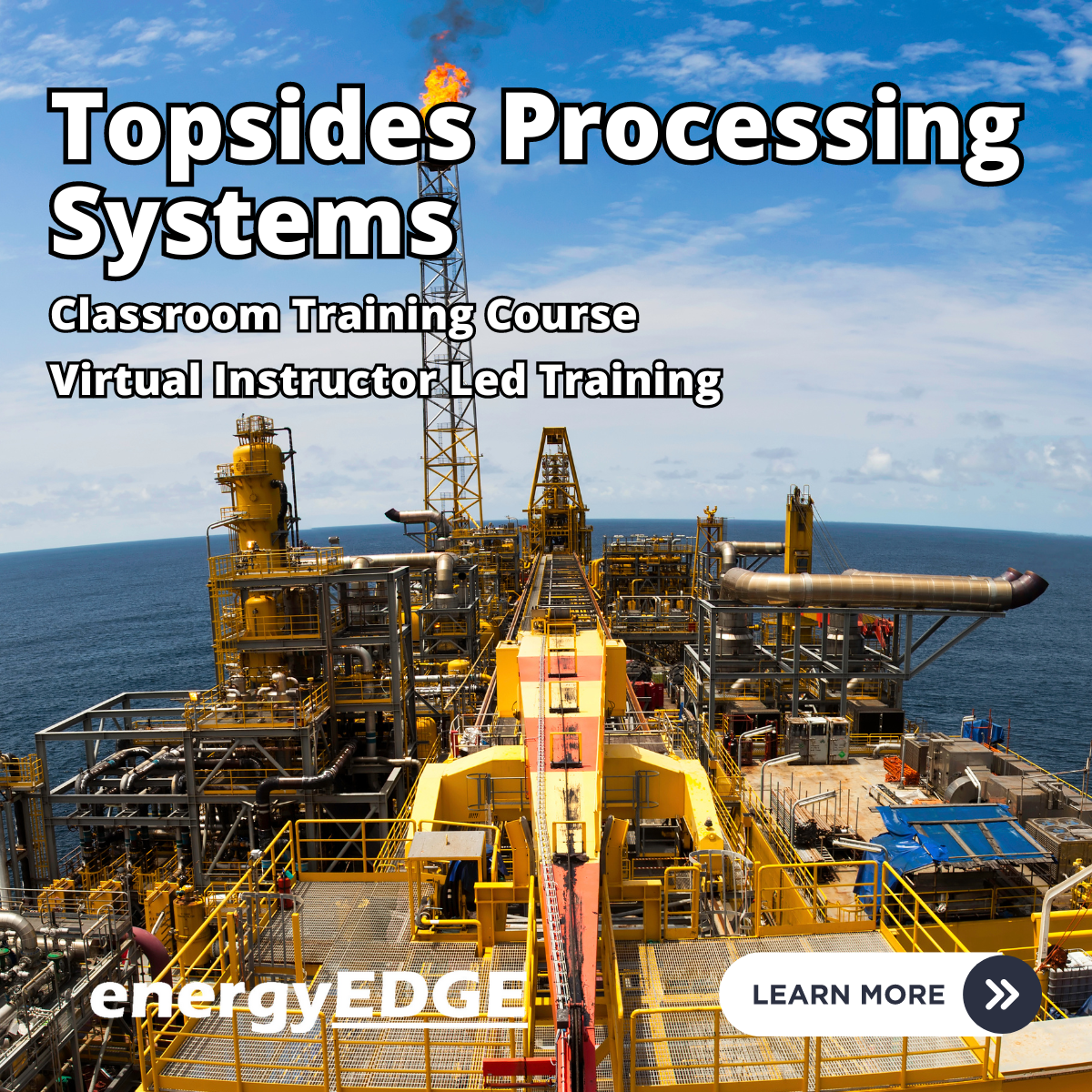

Topsides Processing Systems

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your knowledge with EnergyEdge's course on topsides processing systems. Enroll now to gain valuable skills and knowledge.

Advanced Process Safety Engineering

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course Managing process hazards in the hydrocarbon and chemical processing industries is a critical function that requires relevant knowledge and skills due to the risks involved. The Advanced Process Safety Engineering course will discuss the interrelation of the various techniques of process safety for analysing, with a particular emphasis on engineering design aspects, as well as how to manage process hazards in a safe and effective way and how they can potentially be avoided. In this 3 full-day advanced level course, the expert course leader will provide participants with insights and examples from his career and experience to show how their learning should be applied in real-life situations. Feedback and questioning is highly encouraged. Reference material and reports can be provided to give more information on any particular topic of interest. Individual and group exercises, tutored exercises and video case studies will be provided throughout the course to underpin the key learning points. Training Objectives Upon completion of this course, participants will acquire in-depth knowledge of: Risk management and 'As Low as Reasonably Practicable' (ALARP) principles. Different aspects of process design that influence process safety. Approach to 'inherently safer' design. Defence in depth using 'layers of protection'. Process for ensuring the technical integrity of safety-critical equipment. Hazards associated with process materials. Range of hazard identification and consequence modelling techniques. Causes and mitigation of human error. Reliability and availability of safety-critical protection equipment. Role of engineered safety-critical equipment and systems. Target Audience This course is suitable for industry professionals who need to acquire a comprehensive understanding of process safety. This includes those who are required to make managerial decisions where process safety is a key consideration, those who are moving into process safety positions or those who wish to broaden their process safety knowledge within their existing discipline. It is particularly suited for anyone involved in the design, operation, modification or maintenance of a major hazard installation, and will demonstrate a substantial understanding of process safety for those engaged in Continuous Professional Development or aiming for Chartered Engineer status. This course will benefit professionals such as: Operations and maintenance supervisors Process, mechanical and chemical engineers and technicians Design engineers, project engineers and HSE managers Control, automation and instrumentation engineers Course Level Advanced Trainer Your expert course leader has 50 years' experience in chemical and process safety engineering. His early career included 20 years in design and project engineering with various fine chemical and pharmaceutical companies where he designed chemical processes, specified plant equipment and selected materials for highly corrosive and toxic processes, often where textbook data was not available. This was followed by 10 years in offshore oil and gas design projects where he was responsible for setting up a Technical Safety group to change design safety practices in the aftermath of the 1988 Piper Alpha disaster. In recent years, he has been called upon to conduct various offshore and onshore incident investigations. His career has given him experience in project engineering, project management, process design and operations, safety engineering and risk management. He is a Fellow of the UK Institution of Chemical Engineers. He served on the Scottish Branch committee, and was elected chairman for a two-year term in 1991. He has also been chairman of the Safety and Reliability Society - North of Scotland Branch. He has delivered training courses in Process Hazard Analysis (HAZOP and HAZID), Process Safety Management, Hazard Awareness, Risk Assessment, Root Cause Analysis, Failure Modes & Effect Analysis and has lectured on Reliability Analysis to the M.Sc. course in Process Safety and Loss Prevention at Sheffield University. In addition to delivering training courses, he currently facilitates HAZOP / HAZID / LOPA studies and undertakes expert witness roles advising lawyers engaged in contractual disputes, usually involving the design or construction of chemical plants or Oil & Gas production facilities, or criminal prosecutions. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Process Safety Management & Engineering Applications [IChemE Approved Training Course]

By EnergyEdge - Training for a Sustainable Energy Future

Gain expertise in process safety management engineering through EnergyEdge's course. Participate in our classroom training to enhance your skills and knowledge.

![Process Safety Management & Engineering Applications

[IChemE Approved Training Course]](https://cademy-images-io.b-cdn.net/61473516-39ac-4dcf-8c86-13410f3deb5f/71b244f5-0985-4ee5-928b-794f0ac07e61/original.png?width=3840)

Advanced Process Safety Engineering

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your knowledge in process safety engineering with EnergyEdge's advanced classroom training course. Register now to secure your spot!

Process Safety Management & Engineering Applications

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This 5 full-day course covers all the main elements of IChemE's Process Safety Competency framework: culture, knowledge and competence, engineering and design, human factors, systems and procedures, and assurance. Participants will achieve at least the second level of competence 'Basic Application', which is defined as 'Performs fundamental and routine tasks. Requires occasional supervision. Increased functional expertise and ability. Works with others.' This course examines the interrelation of the various techniques of process safety for analysing and managing process hazards in the hydrocarbon and chemical processing industries. There is a particular emphasis on engineering design aspects with extensive participation in individual and group exercises, tutored exercises and video case studies throughout the course to underpin key learning points. The learning is consolidated in a comprehensive case study and requires collaboration between members of each syndicate. This course has been reviewed and approved by the Institution of Chemical Engineers. IChemE is the global professional membership organisation for chemical, biochemical and process engineers and other professionals involved in the chemical, process and bioprocess industries. Their knowledge of professional standards, close involvement with industry, education and regulators, and their expertise as a leading global training provider, means they are uniquely positioned to independently assess and approve training courses and professional development programmes across the world. Training Objectives By the end of this course, participants will be able to: Acquire the underpinning knowledge required to achieve process safety competency Gain a comprehensive understanding of process safety management Understand the concept of the safety life cycle of a process plant from conceptual design onwards including operation, maintenance and modification Understand the hazard scenarios associated with a process plant Understand how risks can be controlled by hardware and procedural measures Identify and analyse hazard causes and consequences Recognise when specialist analytical expertise is required Generate effective and appropriate measures to reduce risks Justify and communicate practical solutions to non-technical personnel Explain the rationale for process safety measures to decision makers Target Audience This course is suitable for process industry professionals who need to acquire a comprehensive understanding of process safety management, those moving into process safety positions or those who wish to broaden their process safety knowledge within their existing discipline. It is particularly suited for anyone involved in the design, operation, modification or maintenance of a major hazard installation. This includes: Supervisors, operators and maintainers in Oil & Gas, Petrochemical and Chemical industries, process, mechanical and chemical engineers and technicians Design engineers, project engineers and HSE managers Control, automation and instrumentation engineers It will also demonstrate a substantial understanding of process safety for those engaged in Continuous Professional Development or aiming for the Chartered Engineer status. Course Level Basic or Foundation Trainer Your expert course leader has 50 years' experience in chemical and process safety engineering. His early career included 20 years in design and project engineering with various fine chemical and pharmaceutical companies where he designed chemical processes, specified plant equipment and selected materials for highly corrosive and toxic processes, often where textbook data was not available. This was followed by 10 years in offshore oil and gas design projects where he was responsible for setting up a Technical Safety group to change design safety practices in the aftermath of the 1988 Piper Alpha disaster. In recent years, he has been called upon to conduct various offshore and onshore incident investigations. His career has given him experience in project engineering, project management, process design and operations, safety engineering and risk management. He is a Fellow of the UK Institution of Chemical Engineers. He served on the Scottish Branch committee, and was elected chairman for a two-year term in 1991. He has also been chairman of the Safety and Reliability Society - North of Scotland Branch. He has delivered training courses in Process Hazard Analysis (HAZOP and HAZID), Process Safety Management, Hazard Awareness, Risk Assessment, Root Cause Analysis, Failure Modes & Effect Analysis and has lectured on Reliability Analysis to the M.Sc. course in Process Safety and Loss Prevention at Sheffield University. In addition to delivering training courses, he currently facilitates HAZOP / HAZID / LOPA studies and undertakes expert witness roles advising lawyers engaged in contractual disputes, usually involving the design or construction of chemical plants or Oil & Gas production facilities, or criminal prosecutions. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Search By Location

- Design Engineer Courses in London

- Design Engineer Courses in Birmingham

- Design Engineer Courses in Glasgow

- Design Engineer Courses in Liverpool

- Design Engineer Courses in Bristol

- Design Engineer Courses in Manchester

- Design Engineer Courses in Sheffield

- Design Engineer Courses in Leeds

- Design Engineer Courses in Edinburgh

- Design Engineer Courses in Leicester

- Design Engineer Courses in Coventry

- Design Engineer Courses in Bradford

- Design Engineer Courses in Cardiff

- Design Engineer Courses in Belfast

- Design Engineer Courses in Nottingham